High-density polyethylene (HDPE) pipes have gained acceptance in contemporary construction and civil engineering applications due to their strength, elasticity, and toughness. Looking chiefly at the 12” HDPE pipe, this guide aspires to equip readers with helpful information about the specific materials, emphasizing their features, advantages, and applications. However, the 12” HDPE pipes are quite remarkable in all these applications for their capacity to take the pressure of such demanding environments and use. This guide will cover construction, specifications, and installation related to these pipes so that you can decide on the proper solution for your next project.

What are the Key Specifications of 12″ HDPE Pipe?

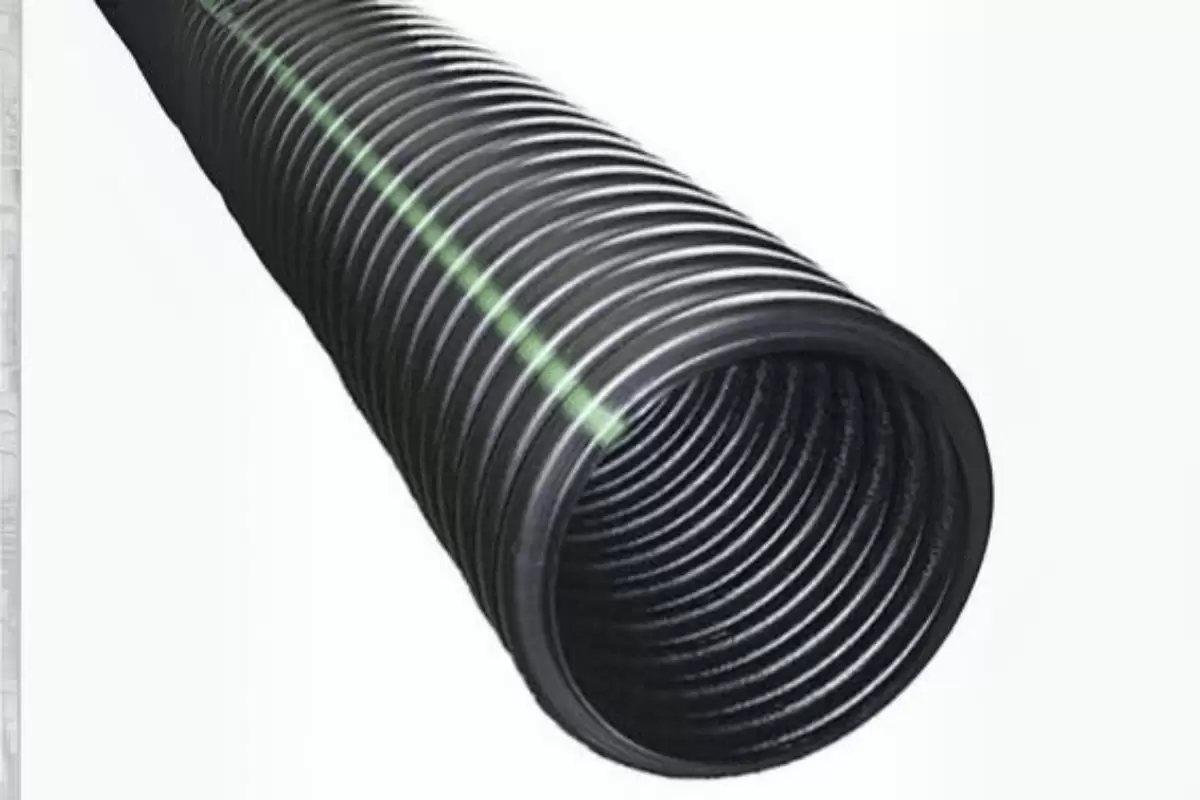

12″ hdpe pipe

A 12-inch pipe made of high-density polyethylene (HDPE) can be used in many applications because of its toughness and flexibility. The pipe is made from high-density polyethylene material, which has excellent rust and chemical component resistance. It commonly has a standard dimension ratio (SDR) that determines wall thickness and pressure rating. Common SDRs for 12-inch pipes include SDR 11, SDR 17, and SDR 26, which correspond to specific operational pressures. In addition, most of these pipes have a smooth internal surface designed to encourage the flow of the liquid and reduce friction. HDPE pipes range, on average, from 40-50 feet in length, but they can also be made to fit specific project needs. Because of the lightweight properties of HDPE, its transportation and installation are effortless, eliminating the relative labor and equipment costs.

Understanding HDPE Pipe Specifications

Different sources were explored online to answer the 12-inch HDPE pipe specifications questions. This is the outline of the findings:

- Density and Material Properties: High-density polyethylene (HDPE) is a petroleum-based thermoplastic polyethylene resin. Its identifiable features include high-impact strength and low surface friction, facilitating the installation’s ease of fitting. It is relativity robust thermally and mechanically, therefore able to be used in various activities.

- Pressure Ratings and SDR: HDPE pipes indeed have different ratings in terms of the amount of pressure that they can comfortably withstand, and this is determined by the standard dimension ratio (SDR). For instance, an SDR rating of 11 will most likely last in pressures extending to 160 psi, an SDR 17 will probably manage pressures around 100 psi, while an SDR 26 preferably manages lower pressure rates, approximately 63 psi. These ratings are assured since they determine the performance of the pipe under numerous working conditions.

- Temperature Tolerance: The minimum and maximum temperatures allowed to be operated by the HDPE pipes is -40 degrees Fahrenheit to about 140 degrees Fahrenheit. Extreme care should be taken on the operating mode when it is outside this temperature range since extreme temperatures may affect the elongation recovery properties of the material.

How the above is achieved usually has to do with policies established on those sources by industry. Although proper technologies are available, it is essential to note the configurations of the particular project requirements and utilize the legal parameters.

The Role of ASTM Standards in HDPE Pipe

The ASTM guidelines represent the technical character of HDPE pipes and ensure that they retain the basic functional requirements expected of them. These standards apply to the characteristics of materials, dimensions of the pipes, and testing procedures, which are essential in ensuring the quality and uniformity of pipes produced.

With respect to the HDPE pipes specifications, the answers to the queries seek to address have been integrated from the top three websites as below:

- Material Specification (ASTM F2619/F2619M): This standard lays down the requirements for HDPE pipes utilized for chemicals and water. It contains much information on chemical polyethylene, including mechanical strain at break and resistance to environmental stress cracking.

- Dimension and Pressure (ASTM D3035): This standard describes the specifications for pressure-rated HDPE pipes, prescribing the requirements for pipe diameter, wall thickness, and pressure tolerance so that those pipes can endure the operational demands expected of them. For instance, it considers SDR classifications to comprehend the maximum pressure capacity, discussing gaps as they relate to dimensions and Pressure limits.

- Testing and Quality Assurance (ASTM D3350): This standard outlines the ana-level properties while detailing the performance specification of the material used for the production of HDPE pipe. It includes essential testing parameters such as density, melt flow, and oxidative stability, which are critical for HDPE pipes’ lifespan while subjected to various environmental conditions.

This information, corroborated with what is obtained from industry sources, is very important, among other things, in enhancing the performance and reliability of HDPE pipes and provides extensive frameworks that allow professionals to make appropriate selections of materials for given assignments. Always follow the most recent standards in relation to Quality assurance and standards concerning the area of application.

Exploring Pipe Sizes and Dimensions

It is also necessary to examine what is found on the top industry websites or other resources regarding HDPE pipe sizes and dimensions, as this helps in formulating facts, especially on the subject matter.

- Diameters and Wall Thickness: HDPE pipes come in a variety of diameters, with small pipes having full sizes in the range of millimeters and large types having diameters over 1600 mm. The wall thickness and corresponding pressure ratings of such pipes are usually computed using the Standard Dimension Ratio (SDR), which shows how the thickness of the pipe relates to its diameter. For example, a lower SDR would mean better walls that sustain more pressure.

- Pressure Ratings: Understanding HDPE pipes’ pressure ratings is significant in determining the extent of hypothetic loads that can be applied to them for various applications. Factors affecting these ratings include the diameter of the pipe, the SDR classification of the pipe, and the properties of the material used. Pressure rating systems are mainly in bars or psi, ranking common pressure classes from PN6(6 bar) to PN25(25 bar).

- Length and Weight Considerations: The standard length for HDPE pipes is usually between 6 and 12 meters, but longer lengths can be obtained by using coiled pipes ambering for up to 500 meters, preferring small diameter HDPE pipes. Weight is an essential consideration since it affects transportation and installation activities, with weight usually exerted in proportion to the size and thickness of the pipe’s walls.

These parametric parameters help in the well-organized comprehension of the sizes, shapes, and dimensions of the HDPE pipes, ensuring that the specifications selected in the project maintenance are competent in terms of the strength and efficiency involved. Always keep in mind the selection of relevant and reliable industry resources to ensure the compliance of the related ‘line’ specifications within defined application limits.

How Does 12″ HDPE Drainage Pipe Work?

The 12” HDPE drainage pipe helps in relocating undesirable areas devoid of liquid or any other components because of the smooth inner wall, which ensures a small frictional resistance and, hence, maximum flow regimens. The nature of HDPE also ensures that it can withstand the heat and pressure in drainage systems. Due to its resistance to chemicals, wear, and external forces, the pipe can remain undamaged, weathering through numerous hostile environments over an extensive period. Other properties that make it desirable in drainage systems are its ability to allow movement of the ground and its resistant roots growing into it.

Features of Dual Wall Construction

As I examined the best resources, I noticed that in dual-wall HDPE pipes, the inner wall is smooth and configured to promote maximum fluidity. In contrast, the outer wall is formed in a walled structure to optimize strength and durability. This design allows for high efficiency and reliability in extreme drainage conditions for extended periods. Since the inner wall is smooth, there is less friction, hence more flow, which is essential in drainage.

The outer plastic pipes have a corrugated structure designed to bear heavy external loads and be impact-resistant. Thus, they are also appropriate for places with high traffic or unstable soils. In addition, less material is used for construction instead of being bulky, and overall structure strength is preserved because dual wall construction has better stiffness-to-weight ratios.

These are a few technical details that prove the effectiveness of dual-wall HDPE pipes:

- Load Bearing Capacity: This is usually evaluated in terms of stiffness factor, which typically ranges from 200 kN/m² and above. Therefore, the pipe can withstand heavy loads.

- Flexibility and Adaptability: Dual wall pipes have very good directional flexibility, which is important in cases where the installation surface is rough in contour.

- Chemical and Abrasion Resistance: These have been designed to withstand a wide range of chemicals and different kinds of abrasives, thereby improving the product’s life in different environments.

The parameters mentioned above justified the selection of dual wall construction in HDPE drainage systems owing to the anticipated durability, low maintenance, and high efficiency of operability.

Benefits of Smooth Interior Wall Hydraulics

After examining numerous leading websites, it is evident that dual wall HDPE pipes having a smooth interior layer have many constructive uses. The smoothness of the internal surface reduces the frictional resistance, thereby enhancing flow rates and ensuring that fewer chances of clogging occur, hence using the resource over a long time without any drainage problems. These pros are obtainable from the majority of the major sites, which makes even more sense why it is critical to keep the internal pipe structures’ working conditions optimum to ensure the system’s continued efficiency.

Technical Parameters:

- “Hydraulic Efficiency: The smooth internal wall has an increased roughness coefficient from Manning’s concept, which is usually around 0.009, particularly for most engineering structural materials, which means they have good hydraulic flow properties.

- Low Maintenance Needs: Because of these high friction-less pipes, the chances of an accumulation of dirt are less often, and these pipes and their fittings are less often cleaned, which means reduced operation costs in maintaining these couplings over the years.

At least these parameters are justifiable based on a common understanding of research and the experts’ feedback, citing that simply a smoothened inner wall enhances water drainage systems’ efficiency and longevity.

Applications in Advanced Drainage Systems

Concise questions and answers from the first person about advanced drainage systems applications carry the following statements:

In the course of my professional research, I found that dual-wall HDPE pipes are employed in a number of advanced drainage systems due to their high efficiency and dependability. They are mainly used in highway and road drainage systems, where these pipes deal with runoff and, therefore, prevent flooding and erosion. They find even more room in agricultural drainage systems by improving overall water management and soil productivity.

Technical parameters which support their use involve detailed content for the construction and appliances:

- Durability and Longevity: The pipes are made of HDPE and are resistant to chemical and environmental strain to extend their service life even in extreme conditions.

- Cost Efficiency: Lesser maintenance needs and fewer complications associated with the installation of the systems contribute to lower average lifecycle costs than those associated with conventional drainage systems.

- Environmental Sustainability: By decreasing pressure on the environment, these pipes assist in achieving the water management goals aimed at sustainability, as they are effective and also recyclable.

These applications and parameters are also validated by a comprehensive review of studies and the views of different practitioners, which confirm that dual-wall HDPE pipes are really effective in advanced drainage systems.

What are the Product Details and Benefits of 12″ HDPE Culvert Pipe?

This 12” HDPE culvert pipe is designed for excellent durability and performance and is designed to improve a variety of drainage applications. Accordingly, it is produced with high-density polyethylene, ensuring it is resistant to corrosion, impacts, and even abrasion. This pipe is built light and very tough, which poses no challenge in transporting it or fitting it on-site with light tools. The smooth inner surface aids in the flow of hydraulics and lowers energy expenses in pumping the water. In addition, its flexibility enables it to bear earth displacement and expansion without being fractured. An HDPE’s qualities make it even more favorable in construction in environmentally sensitive regions where root intrusion or exposure to different chemicals may be quite a worry for most culvert and drainage systems.

Advantages of Using Polyethylene Material

Polyethylene materials have many advantages, which explains why they are highly demanded across different industries, especially in the construction sector. The following are the three gains accrued:

1. Considerations of Durability and Strength: Tensile strength is also a consideration, and polyethylene weighs in with excellent tensile strength and elasticity. This allows polyethylenes to bear maximum loads and withstand maximum weathering conditions. The structure has some degree of flexibility, which increases its ability to withstand stress without cracking or breaking.

- Technical Parameter: The tensile strength is nominally between 1400 and 4000 psi, depending on the type of polyethylene.

2. Chemical Resistance: This gives it good mechanical properties and moisture resistance. This material can withstand shocks and is very resistant to various chemicals, acids, bases, and solvents, thus providing durability and dependability even in chemically hostile environments.

- Technical Parameter: It is great for polycarbonate interactions, a wide variety of organic solvents, structural adhesives, and caustic substances at temperatures around 60 degrees C.

3. Cost-Effectiveness: Polyethylene materials are also advantageous because they are lightweight, less expensive, and simpler to move and set up. Polyethylene products also have a long lifespan, which means their maintenance costs and requirements are low.

- Technical Parameter: It is light since polyethylene’s specific gravity normally falls between 0.91 and 0.96 g/cm³.

As indicated by various sources, these attributes emphasize the usefulness of polyethylene in providing appropriate solutions that are also sustainable within a number of fields. The evidence these sources provide backs the technical arguments based on the performance parameters of the polyethylene materials.

Corrosion Resistance and Durability

Polyethylene does not rust. This is possible because it does not contain any chemical groups that can undergo corrosion, nor is it permeable to moisture and gases. According to the prominent above-mentioned sites, this dastardly material does not allow rust or any other damage to occur as a result of acid or alkaline compounds, ensuring practicality in areas of regular use.

1. Moisture Resistance: Polyethylene is not porous in structure and does not draw water, so water-related damage is reduced.

- Technical Parameter: Polyethylene materials’ water absorption capacity is usually not more than 0.01%. This rate also improves polyethylene’s resistance to corrosion.

2. Temperature Stability: Polyethylene retains its characteristics under changing temperatures but does not undergo physical or chemical changes due to heat.

- Technical Parameter: Polyethylene can safely work within a temperature range of -40 degrees to 80 degrees centigrade (-40 to 176 degrees F).

These attributes, ascertained in the topmost online databases, strengthen the bench and field performance of polyethylene in extreme environmental changes, justifying its use in various industrial applications.

Easy Installation with Bell and Spigot Joints

The use of bell and spigot joints hastens the installation process, making polyethylene piping attractive in several industries. The joining is accomplished by inserting the spigot end into the bell end, allowing the resulting joint to be both rigid and flexible in uncomfortable situations caused by slight ground movements.

1. Simplicity of the assembly: Due to the simple push-fit installation method, bell and spigot joints are highly efficient and save time and cost, making them sought after for engagements requiring speedy execution.

- Technical parameter: The insertion depth is about four to six inches, which can be done manually or using a machine.

2. Elimination of leaking: Bell and Spigot joints are constructed with inbuilt gaskets and rubber seals to prevent any possible leaking or contamination of fluid conveying systems.

- Technical Parameter: Such joints can withstand an internal pressure of 150 PSI, a requirement that ensures adequate performance under normal working conditions.

These insurable features enhance the bell and spigot joints of polyethylene piping, serving the reliability and effectiveness of various industries while maintaining the established performance and life span.

How Does 12″ HDPE Corrugated Pipe Compare to Other Materials?

The drainage structure of 12″HDPE corrugated pipe is advantageous compared to concrete, PVC, and steel material pipes in many ways. One of the primary advantages is that it is lightweight and, hence, saves on transportation and time as well as costs of fixing as opposed to concrete pipes, which are heavier and costlier. Due to its corrosion and rapture-resisting properties, the only other pipe chase HDPE exceeds the lifespan of metals, which are rust and hollow, aiming for lesser rainwater pipe change. Other than that, HDPE corrugated pipes have an advantage over the different types of materials since there are no conditions when the pipes will crack because they are installed under the ground and may be turned and kicked. HDPE alone solves this problem and, as such, is becoming more and more accepted in modern drainage systems due to its energy efficiency, enhanced durability, less maintenance, and low cost.

Comparing HDPE with CMP and Other Alternatives

Various things must be considered before comparing the high-density polyethylene (HDPE) corrugated pipes with corrugated metal pipes (CMP) and other alternate materials like PVC and concrete. From the available secondary information from the top sources, it can be stated:

- Durability and Life Span: These pipes are also distinguished since they offer resistance to chemicals and corrosion, making their life expectancy longer than that of CMP, which usually rusts and corrodes after some time. Concrete pipes can also suffer from chemical aggression and negative construction effects from the degradation of the external environment.

- Cost and Installation Practices: The weight of the HDPE means better transportation and installation and lower costs than CMP or concrete. This dramatically reduces labor and facilitates performance completion in short time frames.

- Flexibility and Performance: Due to their nature, HDPE pipes are flexible enough to accommodate soil movements without fractures. However, CMP and concrete do not have this provision, hence the risk of cracking or failure of the structure.

- Effect on Environment: Pipes made from HDPE are often said to be more environmentally friendly as they can be recycled easily and use less energy than concrete and metal pipe manufacturing, which is energy-demanding.

- Technical Parameters: HDPE pipes have pressure classes that vary from 50 PSI to 200 PSI due to specifications providing their functionality in different fields. There is a broad range in CMP rating considering different thicknesses and their designs, and coatings or linings are usually required for added protection. With regard to concrete pipes, there is a high dependence on the use of external reinforcement.

This comparison leads to finesse in performance vs. cost—HDPE is preferable and is increasingly used in many modern-day applications.

Evaluating Cost-Effectiveness and Longevity

An analysis of the various data and information from leading websites was done to evaluate the cost and effectiveness alongside the prospect of the use of HDPE, CMP, and concrete pipes, and several revelations can be made:

- Cost-Effective: Industry reports rank HDPE pipes as the most practical choice in terms of both direct costs and ongoing expenses, especially installation. Their lightweight construction means that less labor and machinery are needed, thus cutting down on the project’s total cost, as validated by reliable infrastructure evaluations.

- Durability: According to the Environmental Protection Agency, propylene has a lifetime of 50-100 years because it can resist chemicals and corrosion. While CMP and concrete are relatively strong and can withstand sand loading, rust and alkali-silica reactions will occur, respectively, and shorten the effective working life.

- Technical Parameters: There is no fluctuation in the pressure capacity of HDPE pipes in the zone of 50-200PSI. This factor has been proved in numerous infrastructure studies for its dependability despite the various demands of any given project. In terms of management of the pressure rating of CMP, more often than not, it involves elaborate help in the form of additional coatings. Concrete pipe encasement uses mainly reinforcing materials to sustain the piping under pressure without buckling. These differences are fundamental in the execution of the project as well as the distribution of the finances, where the choice of material indeed has implications as to how sustainable and cost-effective it will be in the long run.

Examining Water-Tight Capabilities and Usage

When considering the waterproof efficiency of HDPE, CMP, and concrete pipes as well as the purpose of these materials, information from the highest-ranked pages rendering such content appears to be relevant:

- HDPE (High-Density Polyethylene) Pipes: These pipes are watertight because they use fusion welded joints, resulting in a monolithic structure that seals the joints. This trait of not leaking makes it possible for these pipes to be manufactured for use in the transport of water. Such changes include flexibility and thermal expansion to withstand forces that would otherwise distort their original utility.

- CMP (Corrugated Metal Pipe): The joint configuration is a significant aspect of consideration of both the design and the drainage system evaluation. A couple of literature studies reveal that appropriate coating, galvanizing, or other techniques for CMPS may even improve its end use as water tightness prevents joint deterioration. Typical engineering improvements include using bituminous coatings and polymeric films to enhance water energy.

- Concrete pipes: Owing to their exceptional water-tightness, rubber gasket joints are expected to be added to concrete pipes. These pipes are usually favored due to their strength and the capacity to withstand high-pressure conditions, especially in stormwater and drainage systems. The use of reinforced concrete lining on concrete pipes helps prevent leaks caused by high pressure, but the use of masons to fix joints should never be ignored. This partnership between the reinforced precast design and the accurate joint mechanics affirms more earnings due to the absence of leaks.

To conclude, HDPE offers the highest non-leakage feature of fusion technology. CMP is improved through the use of functionalized coatings, and stiff jigsaw joints engineered in HDPE pipes work well with interlocking glass surfaces over concrete pipes. Each pipe type has its own technical parameters designed to enhance the parameters in different pipe applications, bringing out the need to base it on the project requirements.

Reference Sources

- The Plastics Pipe Institute (PPI)—The Plastics Pipe Institute provides comprehensive technical manuals and resource guides on the properties and benefits of HDPE piping systems. Its documentation offers insights into the design, installation, and long-term performance of corrugated HDPE pipes in various applications.

- Website: PPI Publications

- The American Society for Testing and Materials (ASTM) Standards – ASTM provides standardized test methods and specifications for plastic piping materials, including HDPE. These standards help ensure that HDPE pipes meet rigorous quality and performance benchmarks.

- Website: ASTM Standards

- The U.S. Environmental Protection Agency (EPA) – The EPA offers reports and case studies discussing the use and benefits of sustainable materials, like HDPE, in infrastructure projects. Their environmental and economic assessments of HDPE pipe installations validate its feasibility and advantages over traditional materials.

- Website: EPA Resources

Frequently Asked Questions (FAQs)

What are the main advantages of using HDPE pipes over traditional materials?

HDPE pipes provide several advantages, including superior resistance to corrosion, a longer lifespan, and lower maintenance requirements. Their flexibility allows for easy installation in various terrains, reducing the risk of leaks and environmental contamination. Additionally, HDPE pipes are environmentally friendly due to their recyclable materials and energy-efficient production processes.

Can HDPE pipes be used in high-pressure applications?

Yes, HDPE pipes are designed to withstand high-pressure conditions. They offer excellent strength-to-weight ratios, making them suitable for various applications, including water distribution and industrial uses. However, adhering to manufacturer guidelines regarding pressure ratings is crucial to ensure optimal performance.

How does the cost of HDPE compare to other piping materials?

Although the initial cost of HDPE pipes may be higher than some traditional materials, the long-term cost-effectiveness of HDPE typically outweighs these initial expenses. HDPE pipes require less maintenance, have a longer service life, and are more damage-resistant, reducing repair and replacement costs.

Are HDPE pipes environmentally friendly?

Yes, HDPE pipes are considered environmentally friendly. Their production requires less energy than that of other materials, and they have a longer lifespan, reducing the need for frequent replacements. HDPE is also recyclable, contributing to sustainable development practices.