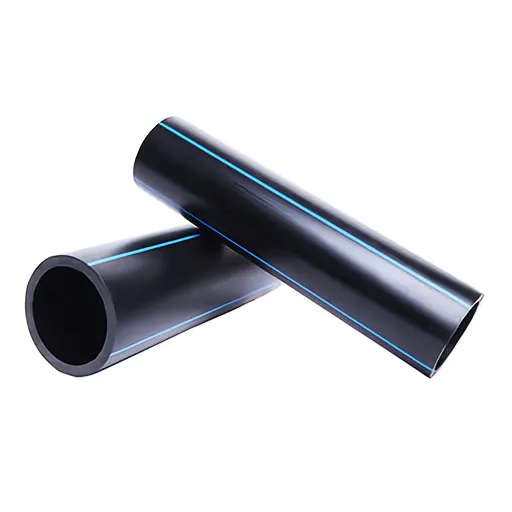

HDPE pipes have revolutionized water supply systems by offering a durable, efficient, and environmentally sustainable option for water transportation. With exceptional longevity, corrosion resistance, and high-pressure tolerance, HDPE pipes have become the preferred solution for both residential and industrial water supply applications.

Introduction to HDPE Pipes

What is HDPE?

High-Density Polyethylene (HDPE) is a thermoplastic polymer produced through the polymerization of ethylene using petroleum derivatives as feedstock. Its exceptional strength-to-density ratio makes HDPE both lightweight and incredibly durable, leading to widespread adoption across various industrial and commercial applications.

Key Properties of HDPE:

- Superior impact resistance – Withstands physical stress without cracking

- Chemical resistance – Immune to corrosion from water, chemicals, and soil conditions

- Environmental stress-crack resistance – Maintains integrity under demanding conditions

- Temperature tolerance – Performs reliably from -220°F to 180°F

- Environmental sustainability – Fully recyclable with lower energy manufacturing requirements

Characteristics of HDPE

HDPE encompasses a comprehensive range of properties that establish it as a material of choice across multiple industries. Beyond its high strength-to-density ratio, HDPE demonstrates excellent resistance to environmental stress cracking and chemical attack, ensuring long-term reliability in harsh conditions.

A crucial characteristic of HDPE is its thermal stability and UV resistance. Many HDPE products are formulated with UV inhibitors to prevent degradation during prolonged sunlight exposure, making them ideal for outdoor applications, including underground piping and agricultural systems.

Types of HDPE Pipes

| Pipe Type | Primary Applications | Key Features |

|---|---|---|

| Corrugated Pipes | Drainage and stormwater management | Enhanced strength through corrugations, suitable for underground installations |

| Solid Wall HDPE Pipes | Water distribution, gas transmission, sewage systems | High tensile strength, flexibility, and chemical resistance for high-pressure environments |

| Perforated HDPE Pipes | Subsurface drainage, groundwater treatment | Strategic perforations allow water entry while preventing soil infiltration |

Benefits of Using HDPE Water Supply Pipes

Lightweight and Durable Design

HDPE water supply pipes deliver an unmatched combination of lightweight construction and exceptional durability. This unique blend offers significant advantages:

- Reduced Transportation Costs – Lighter weight means lower shipping expenses for large infrastructure projects

- Faster Installation – Easier handling reduces manual labor requirements and project timelines

- Maintained Structural Integrity – Despite being lightweight, pipes resist physical stress and environmental challenges

- Extended Service Life – Properly maintained HDPE systems can operate for over 50 years

Resistance to Corrosion and Chemicals

Unlike traditional materials such as metal or concrete, HDPE is inherently non-corrosive. This characteristic, combined with its chemical impermeability, enables HDPE pipes to maintain structural integrity even in aggressive soil conditions, varying pH levels, or saline water environments.

Chemical Resistance Benefits:

- Resists common solvents, oxidizers, acids, and bases

- No galvanic or electrolytic corrosion issues

- Enhanced with UV stabilizers and antioxidants

- Maintains performance properties for decades

Flexibility and High-Pressure Suitability

HDPE’s exceptional flexibility allows it to accommodate dynamic loads and resist ground movement without cracking or breaking. This quality is particularly valuable in earthquake-prone areas or regions with unstable soil conditions where rigid piping systems would fail under stress.

HDPE pipes demonstrate remarkable capability in high-pressure applications, typically withstanding substantial internal pressures while maintaining their lightweight advantage over steel or PVC alternatives.

Applications of HDPE Pipes

Municipal Water Systems

HDPE pipes have gained widespread adoption in municipal water systems due to their durability, chemical resistance, and cost-effectiveness. The heat-fusion joining process creates superior network integrity compared to traditional jointed systems, significantly reducing leakage points.

Performance Impact: Some municipalities have experienced up to 30% reduction in leakage-related water losses after implementing HDPE pipes in their distribution networks.

Industrial Uses

HDPE pipes serve numerous industrial applications due to their versatility and reliability:

- Chemical Processing – Transfer of corrosive chemicals and industrial fluids

- Mining Operations – Transportation of tailings and abrasive materials

- Power Generation – Cooling water and discharge pipelines in power plants

- Oil and Gas – Distribution systems requiring high-pressure resistance

Potable Water Transportation

HDPE pipes excel in potable water distribution due to their non-toxic properties and compliance with major health and safety standards. Their corrosion resistance and minimal biological buildup characteristics ensure safe water transport over extended distances.

| Performance Metric | HDPE Pipes | Traditional Systems |

|---|---|---|

| Leak Rate | As low as 0.5% | 5-15% typical |

| Service Life | 50+ years | 20-40 years |

| Maintenance Requirements | Minimal | Regular/Frequent |

Installation Techniques for HDPE Pipes

Fusion Welding Methods

Fusion welding represents a critical technique for ensuring structural integrity and operational efficiency in HDPE pipe systems. Two primary methods dominate the industry:

Butt Fusion Welding

- Aligns two pipe ends using a specialized heating plate

- Controlled temperature, pressure, and alignment ensure optimal results

- Ideal for larger diameter pipes and straight runs

- Cost-effective solution for robust joining

Electrofusion Welding

- Utilizes specialized fittings with embedded electrical heating elements

- Provides precision for tight locations and repair applications

- Suitable for angular connections and different diameter pipes

- Offers unmatched flexibility and strength

Trenchless Installation Technologies

Trenchless technologies represent a significant advancement in modern pipeline engineering, enabling underground utility system installation with minimal surface disruption.

| Technology | Application | Key Advantages |

|---|---|---|

| Horizontal Directional Drilling (HDD) | Pipeline installation under existing structures | High accuracy, suitable for various terrain conditions |

| Pipe Jacking | Dense urban area installations | Minimal disruption, precise placement |

| Microtunneling | Simultaneous excavation and pipe installation | Automated process, excellent for challenging conditions |

| CIPP Lining | Pipeline rehabilitation | Restores structural integrity without excavation |

Environmental Impact: HDD methods can reduce greenhouse gas emissions by up to 70% compared to traditional open-cut methods, while reducing project completion time by an average of 30%.

Best Practices for Installation

Successful HDPE pipe installation requires adherence to established best practices:

- Comprehensive Site Analysis – Conduct detailed soil condition assessments and utility mapping

- Equipment Selection – Choose appropriate installation methods based on project specifications

- Technology Integration – Utilize real-time tracking systems and ground-penetrating radar

- Continuous Monitoring – Implement torque and pressure monitoring during installation

- Quality Assurance – Perform post-installation inspections using CCTV or laser profiling

Environmental Impact of HDPE Pipes

Reducing Water Leakage

HDPE pipes significantly contribute to water conservation through their superior leak-resistance properties. Heat-fusion joints create seamless connections that eliminate common failure points found in traditional piping systems.

Water Conservation Impact: Water distribution systems utilizing HDPE pipes have demonstrated up to 30% reduction in water loss compared to older infrastructure systems.

Recyclability and Eco-Friendly Production

HDPE pipe systems demonstrate exceptional environmental responsibility through their recyclability and efficient production processes:

- Full Recyclability – End-of-life pipes can be completely recycled through advanced processing methods

- Energy Efficiency – Manufacturing requires significantly less energy compared to alternative piping materials

- Reduced Carbon Footprint – Lightweight design minimizes transportation emissions

- Circular Economy Support – Recycled HDPE maintains strength comparable to virgin materials

Frequently Asked Questions (FAQ)

References

- Case studies on HDPE pipe applications in municipal and industrial projects across North America – Published by ASCE

- Non-target screening study of high-density polyethylene pipes in drinking water distribution systems – ScienceDirect

- Investigation on hot melting temperature field simulation of HDPE water supply pipeline applications – ScienceDirect

Conclusion: HDPE pipes represent the future of water supply infrastructure, combining exceptional durability, environmental sustainability, and cost-effectiveness. Their superior performance characteristics and innovative installation methods make them the optimal choice for modern water management systems.