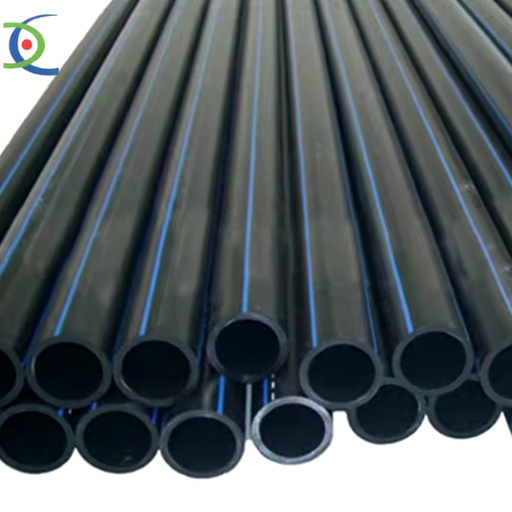

The demand for high-density polyethylene (HDPE) pipes has increased tremendously across industries as a result of the durability, versatility, and affordability of the material. This blog seeks to educate the audience on the subject of HDPE pipes, beginning with illuminating what this abbreviation stands for and how the pipes can be made useful across various industries. Some of the unique attributes that make HDPE pipes an optimal choice for the construction of water systems, gas distribution systems, and other similar structures will also be discussed. Strategies will also be formulated for the last paragraph, which explains why HDPE pipes are used more than the other used materials and how the design characteristics of the pipes influence the system designs, making them efficient and ecologically friendly.

What is the full form of HDPE?

Various types of polymers are extensively used in a variety of applications. For instance, as an industry expert, I will inform you that the full form of HDPE is “high-density polyethylene.” This material is a thermoplastic polymer and is known for its high strength-to-density ratio. It is made from petroleum, and due to its robust properties, it is widely employed in the making of plastic bottles, corrosion-resistant piping, and plastic lumber. It is important to add that one of the dominant characteristics of this material is its toughness, which ensures excellent performance when utilized for multiple construction and industrial activities. Clearly, HDPE is resistant to many chemical solvents and other factors; it is also highly green and cost-effective, hence preferred in different industries.

Defining HDPE and its significance

High-density polyethylene (HDPE) is very energetic, and with a high strength-to-density ratio, it is a thermoplastic that can be employed in several industries. It is important as it provides effective means for various applications including, but not limited to, water and gas pipelines due to its corrosion resistance and high impact strength. Its resistance to many chemicals, coupled with its durability, has made it one of the most indispensable materials in cost and environmentally-friendly construction. Such properties go a long way in explaining its popularity over conventional piping materials, which is essential for optimum system designs.

Common misconceptions about the full form

but it simply stands for High-Density Polyethylene. There is a myth that all polyethylene materials, including HDPE, are the same and can perform the same functions, which is definitely not true. A combination of high strength and high density characterizes the exceptional characteristics of SAP HDPE and determines the boundaries of its scope of use. In addition, although it is a plastic, it is often said that HDPE is not ecologically sound; however, it is highly recyclable and helps further sustainable development efforts. If we can eliminate these misconceptions, we will see the true potential and value of this material.

Difference between HDPE and other types of pipes

I recognize that when making decisions about pipe selection, it is important to differentiate between HDPE pipes and other types of pipes so that you can best suit your projects. In contrast to PVC, copper, and steel, HDPE pipes have certain characteristics that set them apart.

- Flexibility: Being flexible in nature, HDPE pipes are not as rigid as PVC or steel, thus making it easier to install them in uneven land and reducing the number of fittings and joints needed.

- Durability: The HDPE pipes are not sensitive or do not corrode when exposed to various types of chemicals. However, even though metal pipes rust away, HDPE material remains sturdy and is thus applicable in many harsh environments.

- Weight: Given that HDPE is lighter than copper or steel, this allows the weight to be handled more easily while reducing logistic costs.

- Fusion Welding: HDPE pipes can be fused welded together, creating a system without any leakages. However, this process is starkly different from that of metal pipes, where ones requiring soldering or threading are time and labour-consuming.

- Longevity: So long as the conditions allow for it, HDPE pipes have an expected service time of many over 50 years and thus, beat out many plumbing materials and their life expectancy.

This point speaks to the reason why HDPE is usually preferred construction material choice in most infrastructure projects. Adopting such benefits helps create wider lasting, economical and environmentally efficient pipeline systems, which in the end contributes positively to the efforts required for maintenance and the entire life of the project.

What are the properties of HDPE?

HDPE, or high-density polyethylene, is a type of plastic that is quite versatile and has a thick set of characteristics that make it ideal for a number of uses. We can delve into its important characteristics:

- Strength and Flexibility: High-density polyethylene has a remarkable strength-to-density ratio. It is lightweight but strong and flexible, withstanding toughness. Its flexibility allows it to bend and absorb stress without rupturing, which is extremely useful during installations and stress-prone zones.

- Chemical Resistance: One of the most distinguishing factors of HDPE that captures one’s attention is its resistance to many chemical compounds. This attribute permits it to be used for chemical transportation as it will neither decompose nor react with chemicals it is exposed to.

- Corrosion Resistance: HDPE pipes do not rust or corrode like metal pipes do when exposed to moisture or most atmospheric gases. Thus, it becomes applicable in situations where there are chances for pipes to be installed and exposed to corrosive mediums.

- Durability:One of the most striking features of HDPE is the tensile strength that it possesses allowing it to withstand many environmental factors without suffering the phenomena of degradation. Its impact resistant and can withstand tremendous temperature fluctuations ultimately causing its lifespan to be evolved compared to other materials.

- Non-Toxic and Safe: HDPE is mostly employed in the foods and drinking water industry owing to the fact that it does not leech any toxins into them. Its non-toxic nature helps it to be suitable for various industries and complies with safety regulations.

- Ease of Installation: HDPE is lightweight and can be produced in long coils making joints and fittings less necessary. A result the installation is cheaper in labor and joints maintenance cost. This solves the issue.

Tri chemical and regenerative matching is also called HDPE. Even these properties explain why it is perceived as a very versatile material across the projects hence the material continues to be regarded as economically and environmentally friendly alternative material for all types of development work on a long term basis.

Key Characteristics of High-Density Polyethylene

- Chemical Resistance:Because of its ability to endure a broad range of chemicals, HDPE has a very diverse area of application like chemical tanks, pipelines, and containers. This particular trait is beneficial in industries where contact with chemical substances is sometimes unavoidable.

- Corrosion Resistance: Unlike metals, even after constant exposure to moisture and atmospheric gases, HDPE is impervious to rusting or corrosion. This attribute is very important for environmental conditions that would otherwise be hostile to other materials, for which it proves effective across diversified industries.

- High Durability: The robustness of HDPE enables it to sustain high impacts and extreme climatic conditions without being dented or corroded. Being durable in the long run leads to a lower replacement cost and less disruption during its lifetime.

- Non-Toxicity: Due to the non leaching properties of HDPE it is widely employed in food packaging as well as in systems for drinking water, since it will not leach harmful substances into the food or water it holds.

- Ease of Installation: Due to their light weight and availability in long coils, installation of HDPE is faster. HDPE also lowers labor costs and the chances of leaks or weak spots by decreasing the amount of soldering and welding required.

These traits not only emphasize the multifunctionality of HDPE but also depict its applicability across the spectrum in domains where security, dependability, and economy are of utmost importance.

How HDPE compares to metal pipes

For instance, comparing HDPE to metallic pipes, which I have used on several occasions, shows HDPE has quite an edge over metallic pipelines. First of all, with regard to the weight, it’s a common fact that pipes manufactured from HDPE are quite heavy. Due to this low weight, transportation and installation are simplified, thus lowering the cost of labor and machinery. Concerning the resistance against corrosion, unlike some metals that corrode in aggressive environments, polyethylene hasn’t been found to corrode; thus, its life is increased substantially as there are no barriers or restraints needed to maintain it regularly.

I have also seen that in installation works, because of the versatility of the cross-linking of HDPE, it accommodates bends and corners, thereby eliminating the requirement for most of the fittings and joints and welding that metal pipes require. This quality helps to reduce manufacturing costs and trouble spots, which tend to be high with other materials. Again, the inner surface of the HDPE pipes has smoother surfaces, which enable a constant flow rate of various fluid mediums, thereby cutting down friction loss, which is often seen in other metal elbow pipes.

When it comes to safety, HDPE stands out in that it is chemically neutral and does not migrate undesired substances into drinking water or food, which is especially important for sensitive applications. Even though metal pipes excel in areas like high tensile strength and heat resistance, it is often HDPE that gets selected for applications requiring a long service life, cost-effectiveness, and environmental stability. The various data that I have studied over time complement such conclusions and indeed confirm the fact that HDPE is becoming widely used in many industries.

Understanding corrosion resistance in HDPE

What is more remarkable in the understanding of corrosion resistance in HDPE is its self-chemical stability. The features characteristic of metals, namely the electro-chemical reactions that form the basis of corrosion mechanisms, are absent in HDPE. Thanks to its non-polar structure and high-density polyethylene composition, it can remain inert in various chemical environments and hence, provide excellent corrosion resistance without additional coatings or treatments. Such resistance does not only extend the lifetime of HDPE pipes, but enables the pipes to retain their structural integrity at conditions likely to deteriorate metal counterparts. As such, HDPE has become the preferred material in industries where piping systems that are strong and resistant to corrosion are sought.

What are the advantages of using HDPE pipes?

Broadly speaking, it is very well known that HDPE pipes have many advantages. They have excellent corrosion resistance, good flexibility, and long service life. Economically, their lightweight property lowers the costs associated with freight installation and construction, while their sturdy nature makes for low maintenance in the future. Moreover, HDPE pipes have good chemical resistance and very high impermeability, which assist in preventing contamination during transport and ensure that the substances in those containers presented maintain their purity. In addition, their smooth interior helps to lessen friction losses which improves flow rates and the overall energy efficiency of water distribution systems. All these attributes combine to make HDPE pipes a perfect solution to modern piping requirements in terms of strength, cost, and reliability.

Durability and longevity of HDPE

Regarding the performance of HDPE pipes, I have been in this industry long enough to understand the attributes of durability and lifespan associated with these pipes. From the experience gained over the years, I have witnessed the effects of erosion and the environmental stress cracking on the lifespan of the pipes, most of which, if not all, are over 50 years under normal operating conditions. The ability of the material to stand bending reduces the number of failures on joints made and also allows pipe movement due to the shift of soils which leads to the protection of pipes from breaking. Such reliability over time makes it necessary to replace the pipes less frequently, hence saving money for the business and the municipality. A large part of the cost, which is primarily determined by other variables, relates to the length of the pipelines. HDPE pipes are something that I wouldn’t dread installing for various reasons, such as substituting without rigid self-restraint while also satisfying performance and flow requirements, as well as the resistance pressure, even with compromised quality in some applications.

Cost-effectiveness of HDPE pipe systems

Gauging the cost-effectiveness of HDPE pipe systems, it would be sensible to take into consideration a number of key features that explain why these pipes remain economical:

- Initial Material Cost: Even though the initial cost of HDPE pipes compared to some other materials is higher, savings can be realized due to their increased durability and low maintenance requirements.

- Maintenance and Repair Costs:High density polyethylene pipe systems are abrasion-resistant, can withstand effects of the environment and have a long lifespan which makes them easier to maintain and repair. Most interruption and costs that would have otherwise occurred with constant pipe rehabilitation are significantly reduced.

- Energy Efficiency: With low friction created by the smooth interior surface of HDPE pipes, there is an increased flow which enhances Efficiency. The implication is that there will be no need for vigorous work for pumps and other equipment, thus energy costs and operational costs are reduced.

- Longevity: Typical life expectancy of more than half a century under normal operating conditions does not recommend HDPE pipes to be replaced frequently as such infrastructure planning is able to gain cost benefits in the long run.

When taking into consideration all these factors, it is apparent that the savings accrued from the cost of installation, maintenance and operational efficiency off-sets the depreciation of HDPE pipe systems so that their claim as an economical production technique for pipe materials stands correct.

Environmental benefits of HDPE as a plastic material

- Recyclability: A great deal of recycling of HDPE aids in the concept of circular economy and helps to reduce the amount of plastic waste. In fact, studies suggest that about thirty percent of HDPE products are made of recycled materials, hence reducing further the need to manufacture more plastics, which in turn preserves the raw materials.

- Reduced Carbon Footprint: In comparison to various other forms of plastics, manufacturing of HDPE is not power-hungry. For instance, the use of HDPE pipes in construction has been proven to slash carbon emissions by nearly 40% when measured against concrete or metal alternatives. When it comes to GHG emissions, HDPE is, therefore, the better option.

- Non-Toxicity: Most commonly used plastics contain BPA, phthalates, and other toxic compounds, which, in the long run, would be quite damaging to the environment. In this regard, HDPE has a potential advantage as it does not pose a risk of leaching toxins into materials such as water used within water supply systems. This leads to water and soil biodiversity and other forms of life being less threatened due to less release of toxic compounds into the ecosystems and habitats.

- Durability and Longevity: Long life span of HDPE products reduces the number of replacements needed and therefore the resources needed to manufacture and the waste created thereafter. Reports indicate that under certain conditions, HDPE can last more than century, therefore increasing the time between replacement and minimizing waste produced.

- Low Environmental Impact during Use: HDPE pipes are smooth on the inner surface which requires less energy to move fluids through them, thereby increasing the efficiency of systems that use these pipes. Consequently, it has a lesser total life cycle environmental impact as compared to more conventional piping systems which are more energy consuming due to friction and other losses.

These advantages under the environment further advocate HDPE to be a reasonable option in the selection of a plastic material, in relation to mitigating the adverse consequences of utilizing plastics and disposing of them.

What are the applications of HDPE?

There’s no doubt that High-Density Polyethylene (HDPE) can be widely used in the low-density plastic industry. In my opinion, as an industry expert, let me walk you through some of the major areas where HDPE is used:

- Water Supply Systems: Waterborne polyethylene (HDPE) is easily of non-toxic nature and thus can be used for safe water transfer with its resilient nature resisting corrosion and leaching harsh materials, hence making great potable water pipes.

- Agriculture:Rice and sugarcane farmers utilize plastics for constructing irrigation pipes and also for farms with an emphasis on HDPE due to its flexibility and strength that aids in combating severe environmental conditions for better management and protection of crops.

- Industrial Piping: Because PE plastic pipes have high resistance to chemicals, they are a good fit in complete industrial and chemical processes due to their very high durability in the long run, enabling them to endure a vast range of fluids without decaying and easy maintenance.

- Packaging Materials: HDPE is utilized widely for the production of several products that require packaging which include; bottles, containers, and plastic bags due to its lightweight, good moisture barrier, and ease to recycle it reducing the adverse effects on the environment.

- Geomembranes: They are mostly used in landfill liners, pond liners, and mining operations and integration of geosynthetic polymer barrier on HDPE geomembranes enables it to achieve its purpose of preventing the leaching or contamination of hazardous materials into the environment.

These applications emphasize the reason for the multilayering popularity of HDPE across a variety of industry sectors. Its environmental advantages as well as parametric characteristics make it an essential material in contemporary manufacturing.

Use of HDPE pipes in drinking water systems

Several important characteristics have made HDPE pipes one of the most preferred materials for water distribution systems, particularly for drinking water supply. First, this material is extremely strong and highly resistant to oxidation meaning that it will remain rust free even when submerged in water continuously. This ensures its longevity as the pipes have long time life with little or no need for maintenance.

Secondly, and most importantly, HDPE pipes are free of any harmful substances, which prevents any chances of pollution in the water supply. They do not leach any harmful chemicals into the water, making them a safe option for potable water supply.

Moreover, High-density polyethylene pipes are very flexible which makes it possible for the pipes to change their shape according to the soil texture without breaking or cracking off. This flexibility also helps to cope with the sudden increase in the amount of water compressed inside the pipe, which reduces the chances of pipes bursting.

Next, instead of gluing, HDPE pipes are made joint free by the heat fusion process making the joint as resistible as the pipe and this makes the supply leak proof. This guarantees a reliable water supply system which eliminates wastage.

Last but not the least, high density polyethylene is cheaper to transport and install, being lighter than many older materials. This economic benefit is good for large projects in the field of drinking water supply.

All these qualities together explain the reason why HDPE pipes are utilized in potable water systems – safety first and a cap on cost and maintenance.

Applications in Gas Pipelines

HDPE pipes are also extensively utilized in gas pipeline networks due to their strong characteristics. Below are the reasons they are widely utilized:

- Corrosion Resistance: HDPE can flex which helps it break ground motions and shocks which is necessary for the pipeline construction. Such flexibility and strength show its usefulness in areas having earthquakes or when the soil itself is weak.

- Flexibility and Strength: The flexibility of HDPE allows it to withstand ground movements and vibrations without breaking, which is crucial in maintaining pipeline integrity. This resilience is particularly beneficial in earthquake-prone areas or regions with unstable soils.

- Leak-Free Joints: With respect to heat fusion jointing, there are no gaps or welded areas that may leak with HDPE pipes. This is particularly useful for gas pipelines as the chances of gas leakage are easy to control, thereby resulting in safety and effectiveness.

- Lightweight Nature: Metal pipes are heavier than steel pipes, making them more expensive to transport and install. This is particularly important in remote or difficult areas where transportation may be an important aspect of project costs.

- Economic Advantage: The combination of durability, reduction in maintenance, and easy installation mean that using HDPE materials in gas projects is deemed economically viable in the end.

It explains quite succinctly as to why the usage of these pipes, with respect to gas pipeline applications, is economical and efficient and hence HDPE lifting pipes are a preferred option.

Industrial applications of high-density polyethylene

In my professional capacity, I have had the opportunity to see the many industrial uses of high-density polyethylene (HDPE.). To begin with, its anti-corrosive nature makes it very valuable in chemical processing plants where pipes and containers come in contact with harsh chemicals. Also, HDPE is quite elastic and strong, making it suitable for manufacturing processes that require movements of various types. This material is also very important in the construction field as its use in welding ensures that plumbing and irrigation systems are completely watertight. On top of this, because HDPE is light, it helps to both lower shipping expenses and ease its use while being installed in large civil engineering projects. To summarise, HDPE is definitely an invaluable asset for any sector that is looking for a combination of strength and ease of use.

How do you differentiate between HDPE and other types of pipes?

To identify HDPE pipes, a few important features need to be examined. First, consider the flexibility of the material, as HDPE pipes possess the ability to flex, unlike the more brittle PVC or steel. Next, consider the density or weight; HDPE is less dense than metals and some plastics, making transportation and installation relatively cheaper. Durability is another issue since HDPE is often much more resistant to rusting and chemical corrosion than other materials. In addition, the methods of joining HDPE, such as heat fusion, allow for strong and leakproof joints, which are better than those joints used for pipes made from other materials. Finally, throughout the course of the analysis, HDPE pipes have been reported to have the ability to withstand extreme environmental conditions, such as heat or earthquakes, far greater than other pipe types. Due to these differences, HDPE has proven to be useful in many applications.

Key features distinguishing HDPE from PVC

I have been in the pipe trade for so long, and so it is common for me to be asked about the distinctions between HDPE and PVC pipes. Therefore, Here is a simple description of the features that differentiate HDPE from PVC:

- Flexibility: It is important to note that HDPE pipes possess greater flexibility in comparison to PVC. Given this property, they will be able to bend and accommodate various installations without incurring any damages which is very critical in places where shifting of ground is likely to occur.

- Durability and Resistance: Environmental and chemical stresses would not affect HDPE as it is highly resistant to them. Unlike some materials, it does not undergo corrosion, thus, increasing its durability and making it suitable for extreme conditions.

- Weight: Since most HDPE pipes are lighter than PVC, their transportation and handling are less cumbersome. This factor helps in reducing the cost of transportation and also makes the installation process quicker and easier.

- Joining Methods: The manner in which these pipes are interconnected is yet another notable difference. HDPE, which is generally joined by means of heat fusion, provides a smoother and more secure joint than PVC, which commonly has joints that are more likely to leak.

- Temperature Tolerance: The ability of HDPE to remain structurally sound within wider temperatures indicates that it can be used in areas where there are changes in temperatures.

It is then obvious why HDPE is frequently applied in construction projects where strength and cost reduction are critical requirements.

Understanding the difference between HDPE and PE pipes

I must explain that HDPE is actually a form of PE better known as polyethylene. This particular section will highlight the differences that HDPE has from the other forms of PE, enabling you to appreciate the different roles and advantages they provide:

- Density: The molecules of very high density characterize high-density polyethylene. Such structural units give HDPE greater strength and preservation than even the other sorts of polyethylene with lower densities.

- Strength and Rigidity: Because of the dense molecular structure, high density polyethylene is greater and more rigid than other forms of PE. Therefore, it is very well suited for use in water and gas distribution pipes, as well as other applications that require strong materials.

- Chemical Resistance: HDPE can stand up to a multitude of chemicals, making it effective when transporting dangerous materials without noticeable degradation. Although this trait is found in other types of PE materials, the higher the density of a type of PE the more effective this trait is, for instance with HDPE.

- Applications: HDPE, because of its strength and rigidity, is ideal for piping systems. However, where flexibility is of utmost importance, such as in films and packaging, other lower density polyethylene variants may be needed.

Taking into account these parameters, HDPE could be differentiated from other PE materials and it explains why such types of this material are ideal for applications where higher strength and resistance to chemicals is required.

Identifying HDPE in the Plastics Industryplastics industry

In order to identify and classify HDPE products within the plastic family, various parameters of differentiation can be evaluated:

- Molecular Structure:

- Linear Structure: Since HDPE’s molecular structure is more linear, this leads to tighter chain packing, which, in turn, results in greater density and greater strength.

- Crystallinity: High crystallinity (70 to 80% range) normally present in HDPE also adds to its stiffness and better structural strength.

- Material Properties:

- Density Measurements: The range of density for high density polyethylene (hdpe) generally falls between 0.941 g/cm³ and 0.965 g/cm³ which helps in distinguishing it from other low density polyethylene variants.

- Tensile Strength: HDPE is characterized by good tensile strength, with a 31 MPa usually being the minimum value, which is also an important contributor of its strength under stress.

- Thermal Characteristics:

- Melting Point: The most distinct characteristic of high-density polyethylene (HDPE) is its high melting point, which usually falls within the range of 120 to 135 degrees Celsius. This factor makes the material optimal for use in applications where high temperature is required.

- Thermal Expansion: Due to its comparably lower value of the coefficient of thermal expansion, HDPE is also regarded as a material that performs adequately in environments that experience temperature variations.

- Chemical Indicators:

- Resistance Testing: HDPE is subjected to chemical resistance tests, and it is proven to stand in against acids, alcohols, and bases. This is of utmost importance in terms of safety for chemical handling devices.

- Identification Codes:

- Recycling Code: Categorized with the resin identification code “2”, HDPE is listed in the hierarchical structure of plastics, making its appropriate sorting and recycling easier within waste management systems.

Through the evaluation of these parameters, industries will be able to guarantee the proper use and product recovery of the material which in turn makes further more its significance as a fundamental element in the contemporary era manufacturing and building industry.

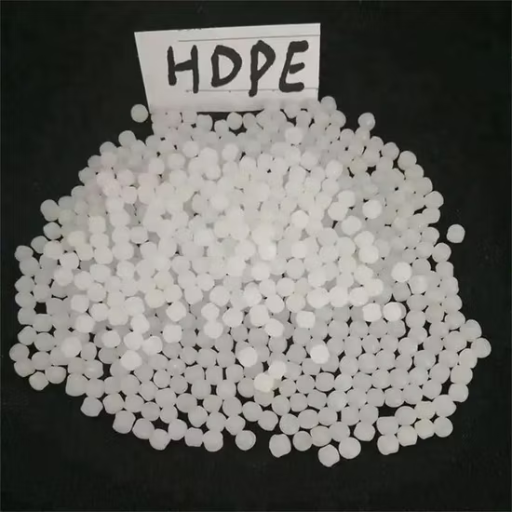

How is HDPE manufactured?

HDPE is produced as a result of polymerization of ethylene using catalysts like metallocene and Ziegler-Natta. This process is done in reactors involving high temperatures and high pressure. By emulsifying concentrated ethylene gas, which is made up of long hydrocarbon chains, HDPE comes into conception whose structure is linear and high in density. Finally, the polymerized material is cooled and pelleted for processing and subsequent uses. The techniques provide uniformity, high purity, and the typical properties of HDPE, making it suitable for many industrial requirements.

The role of raw materials in HDPE production

Being an expert in the field, it’s important to comprehend where the input materials for the production of HDPE originate. The following analysis has condensed the entire process and highlighted some critical aspects:

- Ethylene: The emphasis is on ethylene , a raw material in HDPE production. Ethylene, which is a natural gas or derived from petroleum through a process known as cracking. It is the fundamental component in HDPE, as its molecules are linked together in units to form long molecular structures that endow the material with strength and wide end uses.

- Catalysts: In the course of polymerization, Ziegler-Natta or metallocene polymerization catalysts act as critical metal catalysts. They assist the joining of ethylene’s molecules into the polymer chain but do not partake in the reaction. Thus, it accelerates the process and also helps in modifying the properties such as molecular weight and density.

- Additives: There are a number of additives that are applicable as a blend with HDPE in order to improve varied performance aspects. For instance, additives like antioxidants could be used to make the materials more heat resistant, ultraviolet stabilizers could be used for shielding it from sunlight and colorants used to beautify the exterior.

These raw materials are crucial in the customization of HDPE for applications ranging from pipes to packing. Manufacturers can tailor the HDPE by modifying these materials and parameters to accommodate the industry requirements.

Understanding the molecular structure of HDPE

The comprehension of HDPE’s unique properties and usage can only be focused if the molecular structure of the polymer is comprehended. High-Density Polyethylene, or HDPE, has a simple chain-like linear structure. This property ensures a high strength-to-density ratio to be useful, making HDPE stronger and highly impermeable than its lower-density version. Here is a detailed summary of the major structural parameters of the molecular structure and their consequences:

- Chain Length (Degree of Polymerization):

- Details: The reason behind the increase of physical properties of HDPE is due its molecular length. The longer the chains are, the greater the mechanical strength and the impact resistance.

- Data:The type of HDPE has a degree of polymerization of more than 10, 000 and might go up to 100, 000 repeating units.

- Density:

- Details: In HDPE’s case a higher degree of density is the consequence of close packed polymer chain due to a lower level of branching present within the chains.

- Data: HDPE has a density range of approximately 0.93 to 0.97 g/cm³.

- Crystallinity:

- Details: The level of crystallinity in HDPE facilitates its strength as well as enhances its thermal properties. The presence of crystalline areas lends this material rigidity and impact strength.

- Data: The crystalline structure of HDPE can be between 70% and 95%.

- Molecular Weight Distribution:

- Details: The unique properties are similar due to the narrow molecular weight distribution, whereas it broadens the scope of processability when the distribution of the weight fraction is of a larger degree.

- Data: Weight-average molecular weight (Mw)has a variability range of (200,000 ≤ Mw ≤ 500,000 g/mol), while the average molecular weight (Mn) can significantly differ, thus determining the qualities of the product.

Custom characteristics such as toughness, flexibility and chemical resistance of HDPE can be adjusted by manufacturers and researchers working with the material as long as they concentrate on the molecular parameters.

Manufacturing process of high-density polyethylene pipe

As an industry expert, I can explain how HDPE pipes are manufactured and detail important factors related to its production and quality control.

- Raw Material Selection: The procedure begins with the selection of a resin with an elongated HDPE. The selection is very important since degree of polymerization, density and even the crystallinity of the resin specify the tensile strength, durability, and flexibility of the pipe made from the resin.

- Extrusion: Then, the selected HDPE resin is heated and turned into an extrusion machine. The purpose of extrusion is to manufacture pipe of long continuous segments by melting the material and then pushing it through a die. Here, molecular weight distribution is critical as a narrow distribution minimizes the thickness of the pipe made and also minimizes internal stress resistance in the pipes.

- Cooling and Sizing: The hot pipe is then allowed to cool to freeze the shape of the pipe. Cooling is very important for high crystallization which would ensure a good thermal and mechanical system for the pipe. Sizing is meant to ensure that the pipe has the prescribed diameter and wall thickness requirements.

- Cutting and Coiling: After cooling and targeting the correct size, the pipe is cut into different lengths as necessary. Coiling could be done in the case of smaller diameters of pipes, to increase the efficiency of transportation. This stage ensures the pipe’s structural stability and durability over time.

- Quality Control and Testing: B Distribution would only take place after all HDPE pipes have been subjected to exhaustive tests for all physical and chemical properties. Controlling for parameters like density and crystallinity would assist in validating the environmental performance of the pipes.

The steps and parameters discussed above ensure that the HDPE pipe produced, is suitable for different purposes with good impact strength and chemical resistance.

Reference

- What is the HDPE pipe? – This source provides a comprehensive overview of HDPE pipes and their applications.

- What is High-Density Polyethylene? (HDPE) – This guide offers detailed information about HDPE, including its properties and uses.

- Five Things You Need to Know About HDPE Pipe – This article discusses key aspects of HDPE pipes and their market relevance.

Frequently Asked Questions (FAQs)

Q: What is the full form of HDPE?

A: The full form of HDPE is High-Density Polyethylene.

Q: What are the common sizes available for HDPE pipes?

A: HDPE pipes are commonly available in various sizes, including 6-inch and 12-inch diameters, to suit different applications.

Q: What is the typical psi rating for HDPE pipes?

A: HDPE pipes typically have pressure ratings that can go up to 160 psi and are available in various pressure classes based on the specific application.

Q: How can I place an order for HDPE products online?

A: You can place an order for HDPE products by creating an account on our website, selecting the desired size and quantity, and following the checkout process.

Q: Is there a shipping charge for HDPE pipe orders?

A: Shipping charges for HDPE pipe orders vary based on the delivery location and the size of the order. You can check the shipping details on the billing page during checkout.

Q: Can I track my HDPE pipe order after it has been shipped?

A: Yes, once your order is shipped, you will receive a tracking link via email to monitor its status.

Q: What payment methods do you accept for HDPE products?

A: We accept various payment methods, including credit cards, PayPal, and bank transfers. You can choose the preferred payment method during the checkout process.

Q: How do I update my shipping address for an order?

A: To update your shipping address, please log into your account, navigate to the account settings, and edit your shipping information before placing a new order.

Q: Are there any related products to HDPE pipes available?

A: Yes, we offer several related products, such as fittings, valves, and accessories that complement HDPE pipes for various applications.