As construction methods advanced, High-Density Polyethylene pipes began to be favored because of their qualities of durability, flexibility, and resistance to corrosion. Yet, one profound limitation professionals face is deciding on the bonding technique that will hold the pipes together most effectively. While the nature of the HDPE surface is that it is non-porous and resistant to chemical action, it renders the traditionally used adhesives useless. This leaves many wondering: Is there really any glue that will work? This guide thoroughly explores the world of HDPE pipe adhesives and gluing methods-so their workings, types of glues, and the gluing methodology itself. Be it a DIY project or an industrial setup, this article equips you with the know-how to glue high-density polyethylene pipes in a manner that guarantees carrying strength.

Introduction to HDPE Pipe Glue

What is HDPE Pipe Glue?

HDPE pipe glue is a potent adhesive that is able to chemically fix HDPE (high-density polyethylene), a thermoplastic that may be used in piping systems due to its hardness, flexibility, and chemical resistance. Unlike in the case of common glues, HDPE pipe glue is formulated to overcome the difficulties of bonding HDPE hemmed in by its nonporous and low surface energy nature, which otherwise renders glues useless.

The best HDPE adhesives involve the highest level of chemical bonding, including reactive polyolefin-based formulations or epoxy systems with simultaneous surface preparation. Such glues might include the initial steps of priming or mechanical abrasion of the surface so as to enhance adsorption, thereby improving the durability of the bond and the strength properties. The proper selection of the glue depends on pipe diameter, environment, and application.

In a successful application, it is imperative to follow the manufacturer’s guidelines closely. This typically entails surface cleaning, application of primer if necessary, and allowing adequate curing time to ensure a strong bond. An HDPE pipe glue is used within both industrial and domestic piping projects to offer reliable solutions in the creation of permanent and leak-proof joints under harsh conditions.

Importance of HDPE Glue in Various Industries

High-density polyethylene (HDPE) glue serves as an indispensable support structure across industries owing to its ability to form strong bonds that are waterproof and resistant to chemicals. In the construction industry, HDPE glue is used extensively to join piping systems meant for water distribution, drainage, and gas transportation. Given its strong adhesive property, this glue ensures that the pipes withstand high pressures and remain intact in varying environmental conditions.

Another major area of utilization for HDPE glue is in agriculture, mainly irrigation systems. HDPE glue is used to form strong joints in pipes for water supply so that the water pipelines can survive in hard terrains or places with variable temperatures. This reliability ensures that agricultural operations are not held up while awaiting pipe repairs.

One other vital application of HDPE glue is in industrial fields, including chemical processing and wastewater management. In resisting a variety of chemicals, its bonds stay secure during the transportation of hazardous substances. That property diminishes leakage possibilities, thus enhancing the safety of operations, and henceforth making HDPE glue an important component for other industries all faint with piping solutions that need to be genuine and durable.

Overview of High-Density Polyethylene

One of the types of thermoplastics is High-Density Polyethylene (HDPE); it possesses the highest strength-to-density ratio, and so it is very tough and versatile in nature. It is prepared by polymerizing ethylene into long chains of hydrocarbon molecules, which constitute a dense and structured lattice. This arrangement espouses very specific characteristics: very good impact resistance, chemical inertness, slow moisture absorption rate, etc., which are needed in many industrial and consumer applications.

Among HDPE’s more notable features is resistance against chemicals and environmental stress cracking. It withstands variations of acids and bases, as well as many organic solvents. Hence, this polymer becomes one of the finest materials for multiple uses, such as chemical storage tanks, piping systems, and containers for hazardous substances. In the presence of stabilizers, HDPE resists UV rays well, which makes it suitable for geomembranes, agricultural equipment, and playground structures.

HDPE is functional while being environmentally favorable since it can be recycled to minimize waste during production. Secondary plastics are produced from recycling, including piping, decking, and furniture; thus, sustainability is being promoted. Additionally, the light weight of HDPE means that far less energy is required for transportation; hence, industries interested in cost and environmental factors consider it an attractive option. It is these factors that have kept the demand for HDPE high everywhere.

Key Uses and Advantages of HDPE Pipe Glue

Applications for Professionals

HDPE pipe adhesives constitute a glue that strongly binds in professional applications where the bond must be strong and reliable to join HDPE piping systems. Below is a list of five key applications where HDPE pipe glue is commonly employed:

- Municipal Water Supply Systems: HDPE pipe glue ensures a perfectly sealed joint in the water distribution network. It has its bonding strength of up to 250 PSI water pressure, which, therefore, guarantees long-term efficiency for water grids in urban and rural areas.

- Irrigation Systems in Agriculture: Agricultural practitioners use HDPE pipe glue to stiffen joints in irrigation networks. It stands resistance against UV degradation and longer chemical attacks, which include fertilizers and pesticides, thereby guaranteeing the durability of the system in adverse environmental conditions.

- The transport of industrial chemicals: HDPE pipe glue has its application in industries that require the transportation of corrosive or reactive chemicals. Hence, the few that remain–resist acid and alkali attacks as well as any solvent-one are identified as essential applications requiring being watertight for HDPE pipe glue.

- Wastewater Management Installation: In wastewater plants, connections are sealed by HDPE pipe glue in piping systems used for the transport of gray water and sludge. It is capable of functioning under variable temperatures and pressure changes, while also assuring greater safety and efficacy.

- Gas Transmission Pipelines: The joint bonding brought about by HDPE pipe glue for gas transmission piping very securely binds gas transmission pipelines, making leaks very scarce indeed, thereby meeting stringent safety standards.

These applications depict just how versatile and dependable HDPE pipe glue is when paramount are performance and safety standards in the professional arena.

Benefits for DIY Enthusiasts

Piping glue of HDPE serves as an industrial lure, whereas it presents more gains in favor of the DIY fraternity. Its versatile nature, simple application, and suitability for a host of home projects provide the onus of advantage in its favor. The following list presents the five important benefits:

- Strong and Reliable Bonds: The portend of HDPE pipe glue to forge strong connections amongst pipes and fittings makes utmost sense in home projects that will last long. The durability of the glue implies there is no need to worry about joints failing.

- Ease of Application: Applying the glue is a very straightforward process, needing no special tools or expertise. DIYers will work with materials quickly and effectively, with precise and consistent results, no matter their skill. Research shows that under 24 hours is accepted for maximum curing time, which greatly shortens project duration.

- Compatible with Multiple Materials: An HDPE pipe glue is very versatile, as it bonds not only HDPE but a wide variety of thermoplastics such as PVC and CPVC. This opens the possibilities for builders and DIY enthusiasts to use the glue in myriad household repairs and construction applications.

- Budget-Friendly: Compared to alternative binding methods, HDPE pipe glue acts as a cheap method. It gives results similar to those of experts without any need for expensive equipment, thus being a plus for any homeowner on a tight budget.

- Environmental Resistance: It creates a bond resistant to water, temperature variations, and chemical attacks. Hence, it can be great for outdoor or plumbing-related DIY projects that require resistance to harsh conditions.

With these abilities taking the top place for consideration, a DIY enthusiast can be able to do a whole lot in the capacity of repairing and modifying his or her house while staying safe and cost-wise.

Comparison with PVC Glue

HDPE glue is endowed with superior durability, chemical resistance, and flexibility, whereas PVC glue enjoys the ease of its use with cost-effectiveness and underwater application being its two other qualities.

| Aspect | HDPE Glue | PVC Glue |

|---|---|---|

| Strength | High | Moderate |

| Resistance | Excellent | Moderate |

| Flexibility | High | Low |

| Usability | Moderate | High |

| Expense | Higher | Lower |

| Submersion | Not Applicable | Applicable |

| Bonding | Heat Fusion | Solvent Cement |

| Sealing | Leak-Free | Possible |

| Purpose | Industrial | Residential |

| Longevity | 50-100 Years | 50-70 Years |

Step-by-Step Guide to Applying HDPE Pipe Glue

Preparation of Surfaces

Making sure the surface is well-prepared is foremost for a strong and durable bond when bonding HDPE pipes. The procedure, first of all, includes good cleaning to ensure no dirt or grease, or contaminants float on the surface of the pipe or fitting. Use a clear, lint-free cloth soaked in pure isopropyl alcohol-great for removing any dirt as it evaporates quickly-so the surface remains truly clean and dry after us.

One then examines the surfaces for any deformation, cracks, or irregularities that might weaken the bond. Area can be lightly abraded with fine-grit sandpaper, as this is good for increasing the roughness of the adhesive surfaces that improve the performance of the adherent with respect to excessive sanding; HDPE could get easily deformed due to over-abrasive sanding.

Once cleaned and prepared, ensure that they are also free of oil and moisture until the free apply adherence procedure begins. During free temperature-on or application of adhesives, the set free condition will make for the very best bond for tough joints in HDPE systems.

Instructions for Use

Surface Preparation

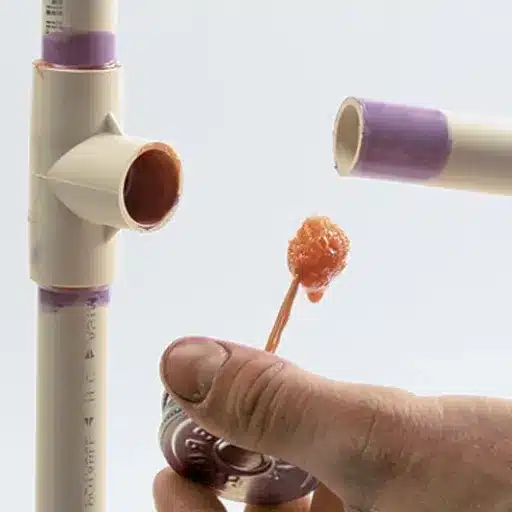

Start by thoroughly cleaning the HDPE surfaces with a degreasing agent to ensure all contaminants, such as oil, grease, or dirt, are removed. Once clean, any bonding surface should be lightly sanded with a fine-grit sandpaper, e.g., 180-220 grit, to improve mechanical bonding. Pressure should not be high during sanding to avoid deformation of the HDPE material. After sanding is complete, the surfaces should be wiped down with a clean, lint-free cloth dipped in isopropyl alcohol to remove any residue. Keep the surfaces in a dust-free environment to dry.

Selecting the Adhesive

Select a high-performance adhesive suitable for bonding HDPE. Epoxies or polyurethane reactive (PUR) hot melts work very well due to their strong chemical bonding ability. Check the manufacturers’ specifications for their particular application needs, such as load-bearing capacity, chemical resistance, or environmental durability.

Adhesive Application

Apply the adhesive according to the thickness indicated by the manufacturer, normally as a single layer. If a two-component adhesive is utilized, make sure it is mixed properly to achieve the best bond strength. In the event that a heat-activated adhesive is used, preheat the HDPE surfaces with a calibrated heat gun, usually within 120°F-160°F, to heighten adhesion. Be careful not to heat excessively, as HDPE has quite a low melting point in comparison with other polymers.

Aligning and Clamping

Ensure that surfaces are aligned carefully for proper fit and bonding. After applying the adhesive, firmly press the surfaces together and hold them in place using clamps or mechanical fasteners for the entire curing period. Pressure should be applied evenly across the joint to avoid the occurrence of weak spots. During this time, do not disturb the assembly.

Curing

Follow the adhesive curing time as stated in the technical datasheet-e.g., a few hours or 24 hours, or more, depending on the environment, such as land temperature and humidity. Always keep monitoring the temperature during the curing process when curing using heat-activated adhesives.

Inspection and Testing

After full curing, examine the bonded joint; there must be a check of its uniformity and strength. Stress, peel tests, or any relevant test will ensure the bond performance requirements. If the bond is not satisfactorily established, the adhesive may need to be reapplied or the joint reinforced by welding or mechanical fasteners.

Following these steps in detail will guarantee the greatest possible effectiveness of HDPE bonding procedures, reliability, and long service life in industrial installations down to household repairs.

Curing Times and Conditions

The curing process of HDPE (High-Density Polyethylene) adhesives is an essential factor to keep in mind; otherwise, poor performance and durability are bound to result. Curing time is determined, within a range of factors, by the adhesive type, the thickness of application, and the ambient temperature or level of humidity. Typically, the general epoxy adhesives’ initial cure takes from 24-48 hours to be completely cured at room temperature, while some adhesives are fully cured in 6-12 hours with additional heat application.

Heat curing certainly reduces cure times when applicable. Temperatures within a specific range, generally stipulated by the manufacturer, set the polymerization speed. For example, curing at 140°F (60°C) would cut the cure time to 50% or less. There is also a need to keep constant environmental conditions. Variation of moisture or temperature can greatly influence the bonding strength of the adhesive.

It is even more meaningful to have proper ventilation during the curing procedure if adhesives are being used that release volatile compounds. In addition, adherence to the manufacturer’s curing condition specifications, along with conducting periodic tests for bond integrity, ensures that the adhesive will acquire its designated mechanical and chemical properties.

Expert Tips for Best Results

Techniques for Achieving Strong Bonds

The key to achieving a strong adhesive bond is detailing preparation, application, and curing procedures. First, surface preparation is fundamental: clean the bonding surfaces thoroughly of contaminants such as dust, grease, or oxidation so that maximum adhesion is achieved. Mechanically roughening the surfaces with sandpaper or a similar abrasive technique could assist in exposing more bonding surface area, thereby significantly increasing strength.

For the next step, basic adhesion guidelines suggest the uniform application of the adhesive. The adhesive must be applied evenly to form consistent bond lines, avoiding air pockets and gaps. When required, an automated dispensing system can also serve as an excellent means of controlling the volume and placement of the adhesive.

Lastly, curing under the right set of environmental conditions, such as temperature, humidity, and pressure, cannot be downplayed. Those associated with deviation from the specified optimum conditions, as asserted by the adhesive manufacturer, would most likely cause incomplete polymerization that ultimately affects bond strength. For example, a thermosetting adhesive might have to be cured at an elevated temperature to allow for the utmost chemical cross-linking. Ensuring temperature uniformity through the curing process is also essential in large applications.

With very critical assemblies available for bonding, NDT methods such as ultrasonic or shear testing shall allow performance assurance of the joints such that their long-term durability is theoretically guaranteed under operational stresses. In combination with these advanced test methods, a quality control procedure of adhesive bonding assures strict adherence to industry specifications.

Ensuring Durability and Reliability

I strive to secure complete durability and reliability of adhesive bonds by applying the most rigorous of quality control criteria and extensive testing procedures. Long-term performance will never be achieved unless meticulous attention is paid to surface preparation, as this guarantees an ideal adhesive affixing environment that efficiently blocks failure from contaminants or substandard surface conditions. The next step calls for thoroughly met specifications for curing, ensuring that the adhesive develops into a uniform area possessing the advertised mechanical properties and strength with sufficient stability.

More NDT methods will be implemented in the monitors that use ultrasonic waves to confirm bond integrity under non-influencing factors on the assembled structure. This gives me access to any voids, irregularities, or other latent defects that may hinder the joint’s performance under operational stresses. By considering and analyzing the critical parameters of adhesion and cohesion, I am then able to predict possible problems and, so far, eliminate factors that would otherwise hamper the longevity of the structure from contesting environmental and mechanical demands.

I also rely on testing that simulates stresses and that meets industry standard conditions for adhesion testing. Such tests observe the behavior of adhesives at variations of temperature, pressure, and fatigue. On the basis of these data and through a constant evaluation of the process, I am confident enough to affirm that theoretically, the durability and reliability of adhesive joints are constitutionally guaranteed upon applications on sites of the highest demand.

Understanding Pressure Ratings

Pressure ratings are among the critical parameters defining the operational limits of components and systems under specific conditions. These ratings specify the maximum pressure a certain material, joint, or system can sustain before failing. Pressure ratings are assigned by subjecting the components to rigorous test conditions following an industry standard, such as ASME B31.3 for piping systems or ISO 19879 for components of fluid power and hydraulics. These tests subject the materials to conditions exceeding those expected in actual load, thereby providing a safety margin under normal operation.

Material strength, temperature, and the nature of fluid or gas being transported go a long way in influencing pressure ratings. On the other hand, typical metallic items are subject to hydrostatic and pneumatic testing to check their ability against deformation due to very high pressure. Other than that, temperature also affects them being elevated as it weakens their strength as time goes by, thus calling for derating for any application in continuous high-temperature exposure.

Having a clear grasp of these ratings is paramount for any engineer and technician to avoid system failures, maintain safety, and optimize performance. Thanks to today only pressure ascertainments with advanced simulation data, modern-day engineering appliances have ensured better reliability and long life for pressure-dependent systems.

Common Mistakes to Avoid

⚠️ Issues Leading to Leaks

Leaks in pressure-dependent systems often arise from both material degradation and improper installation or operation. Most leakage in piping occurs because the materials fatigue from cyclic loading or are degraded locally by corrosive environments. The ability of seals and gaskets to retain a seal is diminished over time due to thermal expansion and contraction, mechanical stresses that occur repeatedly, or interactions with chemicals. Inadequate torque upon assembly can cause a sealing element either to be insufficiently compressed or to be over-compressed, thereby compromising sealing integrity.

At the design level, stress points poorly accounted for in tolerances or incompatible materials pollute the system, while operation under certain conditions just leads to failure. An example exists where fabrication and design of pipelines and joints do not account for pressure surges and thermal cycling, causing microfissures. Likewise, violating the stipulation of Maximum Allowable Operating Pressure (MAOP) or an inadequate maintenance schedule set by an operator makes things worse in this regard.

Should they desire to diminish these sets of risks, material testing must be stringent, installation procedures must be given absolute attention, and preventive maintenance programs should be highly considered. Moreover, the system can be safeguarded further by first installing online real-time monitoring systems and then applying advanced predictive analytics that provide very timely information on warning signs toward sudden failures, thus enabling enhancement of system service life and safety during operation.

⚠️ Improper Bonding Techniques

Improper bonding methods are among the major factors causing problems that affect the structural integrity and cause system collapse in various industries. With bonding, materials are joined using adhesives, welding, or mechanical fasteners. It creates a single structure or system. When bonding is employed without following the technical guidelines, weak joints develop, uneven stress distribution occurs on joints and structures, and impeding resistance to factors such as environmental temperature variation, corrosion, or vibrations compromises the solution.

The common mistakes vis-à-vis bonding methods include failures in surface preparation, choice of bonding agents, and curing times. In the first instance, contaminants can interfere with the bonding process when surfaces are not cleaned or prepared properly, whereas an inappropriate adhesive can cause premature ageing under the environmental or mechanical stresses imposed by its actual use. Lastly, insufficient pressure during application or deviations in curing conditions (temperature, humidity, etc.) will diminish bond strength, eventually causing the material to fail.

Solutions targeting these compatibility issues and others keep recent technological advancements in bonding and adhesives in focus. Stress distribution within bonded assemblies is modeled computationally to predict joint performance with greater detail. Furthermore, the implementation of industrial standards (such as ASTM and ISO) guarantees the adherence of bonding methods to strict reliability and safety requirements. Ongoing research into nanomaterial-enhanced adhesives and self-healing bonding agents promises to be the next generation of enhancements to bonded systems’ durability and adaptability.

⚠️ Using Incompatible Sealants

The use of incompatible sealants in bonded assemblies has been found to present a multitude of issues relating to beautiful integrity, performance, and ultimate durability of these systems. Chemical incompatibility amongst sealant and substrate materials often leads to unwanted chemical reactions, such as bonds being degraded, the substrates being corroded, or voids being formed inside the sealant layer. These chemical reactions negatively affect the mechanical performance of the bonds and thus do not allow them the full capacity to resist the loads imposed upon them and the environmental stresses that include temperature changes, moisture, and UV radiation. For example, silicone-based sealants may not be suitable for some polycarbonate substrates due to stress cracking or failure of the sealants on a long-term basis.

Another major issue results from sealants not being able to adhere to their substrates upon setting because of mismatches in surface energy. Sealants developed for high-energy surfaces will exhibit poor adhesion to low-energy surfaces such as polyethylene or polypropylene; thus, this mismatch will translate into a less cohesive joint, therefore, risking leaks, structural instability, and decreased performance on applications in the aerospace, marine, or automotive industries. Additionally, choosing the wrong sealants could interfere with the curing process, either by obstructing curing or promoting over-curing, which results in irregular bonding and reduced mechanical strength of the joint. Research has confirmed the fact that the lack of compatibility testing before sealant application brings about the necessity of maintenance or sometimes even premature failure of the bonded system.

In an attempt to avoid the afore-described incompatibilities, very stringent testing of materials’ compatibility is called for, along with subsequent adherence to the available industry standards. One can think of DSC and FTIR analyses as examples of methods for the investigation of thermal and chemical behavior of the interacting sealant and substrate material. Manufacturers should team up with material scientists, aiming to develop tailor-made sealant formulations that diminish the incompatibility risks. As a parallel effort, engineers and technicians should be thoroughly trained to assess compatibility and perform applications correctly, thereby further ensuring the reliability of bonded assemblies in every respect. Through the combined attacking of incompatibilities from scientific and procedural fronts, the industrial world stands to significantly raise bonded systems’ durability and safety.

Frequently Asked Questions (FAQ)

Q: What is the HDPE pipe glue, and how does it operate?

A: HDPE pipe glue is a high-strength adhesive developed specifically for the bonding of high-density polyethylene pipes. This glue creates a chemical bond at the surface of the HDPE, thus ensuring that the connection can withstand high pressure and wear.

Q: What are the physical properties of HDPE pipe glue?

A: The physical properties of HDPE pipe glue include high tensile strength, flexibility, and resistance to chemical effects. It, thus, makes it an extremely good choice for industrial applications, sewage systems, and drainage systems, where durability is essential.

Q: How do I choose the best HDPE pipe glue for my project?

A: You should consider the application, materials, and the environment when selecting the best HDPE pipe glue. Look for high-strength bonding adhesives, especially if you are bonding materials such as PVC pipe to HDPE.

Q: Is HDPE pipe glue suitable for PVC pipe?

A: Yes, HDPE pipe glue is compatible with PVC pipe theoretically, but you must select one that specifically states its ability to bond different materials. High-strength glue should be used to give the best adhesion between the HDPE and PVC surfaces.

Q: What type of connection should be followed when using HDPE pipe glue?

A: With HDPE pipe glue, the typical connection method is thorough cleaning of the surfaces, applying glue on both surfaces of the pipe evenly, and allowing enough curing time before subjecting the pipe to pressure. Always check and follow guidelines on the product itself for best practice.

Q: How does electrofusion welding differ from HDPE pipe glue?

A: Electrofusion welding melts and fuses HDPE pipes, forming a strong bond; however, despite its ability to produce effective joints, HDPE pipe adhesive has the advantage of being simpler to apply and is best suited for repairs or smaller projects where welding is impractical.

Q: How long does it take HDPE pipe glue to cure?

A: It takes different brands different curing times, and an adequate period should be allowed to fully cure to maximum strength. Usually, full bonding can depend on environmental conditions and the glue type, and may take from 24 hours to several days.

Q: Is HDPE pipe glue resistant to chemicals?

A: Yes, many HDPE pipe glues are resistant to many chemicals and are, therefore, good candidates for industrial applications and sewage systems. However, the user must double-check through the product descriptions for the chemical resistance requirements.

Q: Can I use super glue as an alternative to HDPE pipe glue?

A: Although super glue can hold fast, it is not recommended as a substitute for HDPE pipe glue in high-strength bonding applications. HDPE pipe glue is meant to withstand high-pressure systems and will provide a bond that is far tougher than that offered by common superglue.

Q: What are the advantages offered by two-part epoxy-based HDPE pipe glues?

A: Two-part epoxy-based HDPE pipe glue offers a stronger bond and improved resistance to wear and tear when compared to single-part adhesives. It performs well when bonding HDPE in substantially high-pressure and industrial-grade applications to offer a long-lasting connection under difficult conditions.

References

- Adhesive patch development for polyethylene gas pipe

The study at Oregon State University looks into adhesives for polyethylene gas pipes, including HDPE. - Testing and repairing of polyethylene natural gas distribution pipe

The study focuses on the repair and bonding of HDPE gas pipe. - Long-term performance of corrugated HDPE pipes produced using post-consumer recycled materials under constant deflection

This Ohio University study deals with the performance and material properties of HDPE pipes. - Adhesive performance of 3-layer PE pipe coatings

This ScienceDirect article analyzes adhesives used for polyethylene pipe coatings and their performance.