Key Takeaway: HDPE pipes offer unparalleled advantages in water main applications through superior corrosion resistance, exceptional flexibility, and long-term cost-effectiveness, making them the preferred choice for modern water distribution systems worldwide.

Ensuring an uninterrupted and consistent supply of water is a critical concern for any modern infrastructure project. The choice of piping material becomes paramount in achieving this goal. High-Density Polyethylene (HDPE) pipes have emerged as the superior solution for water mains, offering unmatched utility, flexibility, and corrosion resistance compared to traditional materials.

This comprehensive guide explores the technical aspects and benefits of HDPE pipe systems, explaining why they have gained preference among engineers and utility companies globally. Whether you’re a civil engineer, utility manager, or infrastructure developer, understanding HDPE capabilities is essential for designing efficient and sustainable water distribution frameworks.

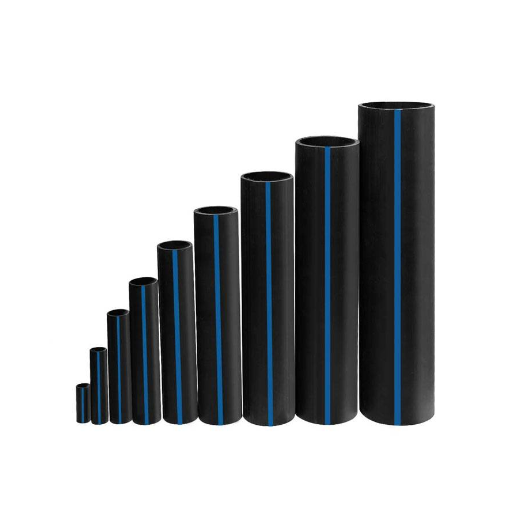

Advantages of HDPE Water Pipes

Corrosion Resistance

HDPE water pipes offer exceptional corrosion resistance, which stands as one of their greatest advantages. Unlike metal piping systems that rust and corrode when exposed to moisture, HDPE pipes are manufactured from non-metallic polymer materials that remain unaffected by:

- Water exposure: Continuous contact with water doesn’t degrade the material

- Chemical interactions: Resistant to various chemicals found in soil and water

- Environmental conditions: Suitable for diverse climatic and soil conditions

- Coastal environments: Excellent performance in salt-rich atmospheres

Performance Impact: This corrosion resistance extends the service life of HDPE pipes far beyond traditional materials like steel or ductile iron, eliminating frequent maintenance, costly repairs, and premature replacements.

Flexibility and Strength

HDPE pipes provide an optimal combination of flexibility and strength, offering numerous installation and performance benefits:

- Adaptability: Flexible enough to bend without breaking during installation

- Reduced fittings: Fewer connections needed, reducing labor and costs

- High tensile strength: Resists deformation from internal and external pressures

- Impact resistance: Exceptional durability during transportation and installation

- Environmental resilience: Withstands temperature extremes and soil movements

Cost-Effectiveness and Longevity

HDPE pipes represent a lasting, economically advantageous solution for modern infrastructure projects:

| Cost Factor | HDPE Advantage | Benefit |

|---|---|---|

| Installation | Lightweight and easy to handle | Lower labor costs and faster implementation |

| Maintenance | Corrosion and chemical resistant | Minimal ongoing maintenance requirements |

| Lifespan | 50+ years of service life | Reduced replacement frequency |

| Repairs | Flexible, damage-resistant | Lower probability of ground movement damage |

Applications of Large Diameter HDPE Pipe

Municipal Water Supply

HDPE pipes excel in municipal water supply systems due to their comprehensive advantages:

- Safety for potable water: Non-toxic material suitable for drinking water

- Leak reduction: Seamless construction minimizes water loss

- Pressure handling: Capable of managing high-pressure applications

- Seismic resistance: Flexible design withstands ground movements

- Trenchless compatibility: Suitable for modern installation techniques

Water Loss Statistics: Research shows conventional pipes can contribute losses of up to 30% in older distribution networks. HDPE pipes significantly reduce this risk through superior joint integrity and corrosion resistance.

Irrigation Systems

Modern irrigation systems have been transformed by HDPE piping technology:

- Agricultural applications: Ideal for drip irrigation and sprinkler systems

- Temperature tolerance: Wide operational range from -40°F to 140°F

- Smart integration: Compatible with IoT solutions and smart controls

- Water conservation: Prevents evaporation and water waste

- Terrain adaptability: Suitable for rough or uneven landscapes

Industrial Use

HDPE finds extensive application across various industrial sectors:

- Chemical processing: Resistant to aggressive chemicals

- Mining operations: Durable in harsh environmental conditions

- Oil and gas: Suitable for high-pressure applications

- Waste management: Used in geomembrane liners and containment systems

- Industry 4.0: Compatible with automation and sensor technologies

Installation Techniques for HDPE Water Pipes

Preparation and Planning

Successful HDPE pipe installation begins with thorough preparation:

- Site survey: Assess soil type, topography, and potential obstacles

- Material inspection: Verify pipe specifications and compatibility

- Risk assessment: Identify potential challenges and preventive measures

- Resource coordination: Align all stakeholders and personnel

- Site preparation: Clear pathways and prepare trenching areas

Steps for Proper Installation

- 1Site Assessment and Planning: Conduct a thorough site assessment, understanding soil conditions, load requirements, and environmental factors while ensuring all necessary permits are in place.

- 2Excavation and Trench Preparation: Excavate trenches to prescribed depths and widths according to local and manufacturer criteria, ensuring uniform contours and proper grading.

- 3Placement of Bedding Material: Place properly graded bedding material (sand or crushed stone) to provide uniform support and prevent concentrated pressure on pipes.

- 4Pipe Handling and Assembly: Use careful lifting and handling techniques to avoid surface damage. Apply heat fusion technology for jointing with strict adherence to manufacturer instructions.

- 5Alignment and Support: Ensure proper pipe alignment within specified tolerances using temporary bracing where necessary during backfilling operations.

- 6Backfilling and Compaction: Perform systematic backfilling using approved materials with adequate compaction of each layer to maintain structural integrity.

- 7Testing and Inspection: Subject the pipeline to pressure testing according to industry standards to ensure integrity and identify any potential issues.

- 8Final Restoration and Documentation: Restore site to original condition and prepare comprehensive installation records for future reference.

Common Mistakes to Avoid

| Common Mistake | Consequence | Prevention |

|---|---|---|

| Improper trench preparation | System failure, pipe damage | Follow depth/width specifications, use proper bedding |

| Faulty fusion methods | Weak joints, leaks | Use calibrated equipment, follow temperature protocols |

| Omitting pressure testing | Unknown system weaknesses | Conduct thorough pressure testing per standards |

| Ignoring thermal expansion | Joint stress, deformation | Allow for thermal movement in design |

| Poor handling/storage | Structural damage, UV degradation | Follow the manufacturer’s storage guidelines |

Maintenance of HDPE Water Systems

Routine Inspection Tips

Regular inspections are essential for maintaining system efficiency and longevity:

- Visual inspection: Check for discoloration, deformation, or surface damage

- Leak detection: Monitor pressure changes and water consumption patterns

- Pressure testing: Conduct scheduled tests to assess structural integrity

- Environmental assessment: Evaluate external factors affecting system performance

- Documentation: Maintain detailed records for trend analysis

- Support verification: Ensure proper alignment and support structures

Repairing HDPE Pipe Fittings

Effective repair procedures restore system integrity:

- Isolation: Secure the affected section and stop water flow

- Assessment: Evaluate damage extent and repair requirements

- Minor repairs: Use specialized tools for surface damage

- Major repairs: Apply fusion welding for cracks and punctures

- Alternative methods: Use mechanical fittings when fusion isn’t practical

- Testing: Conduct pressure tests to verify repair effectiveness

Extending the Lifespan of Your Water System

Maximize system longevity through proactive measures:

- Preventative maintenance: Regular inspections and timely repairs

- System flushing: Periodic cleaning to prevent sediment accumulation

- Smart monitoring: Use technology for early problem detection

- Quality materials: Invest in superior HDPE piping systems

- Staff training: Ensure proper maintenance procedures

Comparing HDPE with Other Pipe Materials

HDPE vs. PVC Pipe

| Aspect | HDPE | PVC |

|---|---|---|

| Flexibility Level | High | Low |

| Strength | High | Moderate |

| Sunlight Tolerance | Yes | No |

| Temperature Suitability | -40°F to 140°F | -10°F to 140°F |

| Connection Type | Heat Fusion | Cement/Gasket |

| Initial Expense | Higher | Lower |

| Service Life | 100+ years | 50-100 years |

| Resistance to Chemicals | High | Moderate |

| Pressure Capacity | High | Moderate |

| Eco-Friendliness | High | Limited |

When to Choose PE Pipe

Polyethylene (PE) pipe is the optimal choice when:

- Durability matters: Long-term performance is paramount

- Chemical resistance needed: Exposure to aggressive substances

- Temperature extremes exist: A Wide operational temperature range is required

- Difficult terrain: Installation in challenging landscapes

- High-pressure applications: Superior pressure containment needed

- Environmental concerns: Sustainability and recyclability are important

Frequently Asked Questions (FAQ)

A: An HDPE pipe water main refers to large diameter pipes made of high-density polyethylene used for potable water distribution in water supply systems. HDPE pipes are highly resistant to corrosion, making them ideal for water main applications.

A: HDPE pipes offer flexibility, corrosion resistance, low maintenance requirements, and easy installation. They can withstand adverse environmental conditions, making them a long-term solution for water utilities.

A: HDPE pipes are more durable and flexible than PVC pipes. While PVC is widely used for various plumbing applications, HDPE excels in large diameter water mains due to superior corrosion and chemical resistance.

A: HDPE pipes utilize various fittings and joints, including welded and mechanical fittings. Heat fusion welding of HDPE pipes ensures reliable, leak-proof connections essential for maintaining water quality in pipelines.

A: Yes, HDPE pipes can be used in hot water applications provided the specifications meet temperature requirements. HDPE pipes have good thermal conductivity and can perform well in high-temperature environments.

A: HDPE pipe water mains typically have a service life exceeding 50 years, depending on installation conditions and maintenance. Their longevity in water distribution systems comes from resistance to corrosion and chemical attack.

A: Yes, HDPE pipes are suitable for drinking water supply as they’re made from high-density polyethylene, a non-toxic material safe for potable water applications. They maintain water quality and prevent contamination.

A: HDPE pipes are generally easier and faster to install than traditional metal pipes. They’re lightweight, flexible, and can be installed using directional drilling, limiting soil disturbance and reducing installation time.

A: HDPE pipes are preferred due to excellent durability, flexibility, and corrosion resistance. Additional benefits include cost-effectiveness and ease of installation, making them appealing for various water supply and distribution applications.

References and Further Reading

- Developed Pipe Bursting Specifications Using High-Density Polyethylene (HDPE) – Bowling Green State University ScholarWorks

- Experimental Investigation of the Behavior of Steel Reinforced HDPE Pipes – University of Texas at Arlington Repository

- Long-Term Performance of Corrugated HDPE Pipes with Recycled Materials – OhioLINK Electronic Theses and Dissertations Center

- Material Behavior in Sewer Systems: HDPE and Other Materials – Academia.edu

- Final Closure Plan for Surface Impoundments Using HDPE Liners – Office of Scientific and Technical Information (OSTI)