Piping materials are a critical consideration in a wide range of industries, from construction and infrastructure to water management and chemical transport. Among the most commonly debated materials are High-Density Polyethylene (HDPE) and Polyvinyl Chloride (PVC) pipes, each offering distinct characteristics and advantages. Selecting the right material for your application requires a thorough understanding of its performance, durability, cost, and environmental impact. This article dives deep into a detailed comparison of HDPE and PVC pipes, providing you with the technical insights needed to make an informed decision. Whether you’re a project manager, an engineer, or simply curious about the science behind these materials, this guide will clarify the key differences and help you determine which pipe type is best suited for your specific needs.

Durability of HDPE and PVC Pipes

Structural Differences Between HDPE and PVC

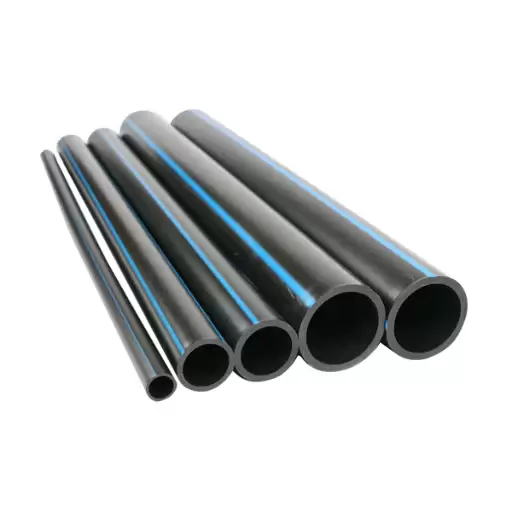

The mechanical properties of HDPE (High-Density Polyethylene) and PVC (Polyvinyl Chloride) pipes vary significantly and enhance or limit their performance for certain applications. HDPE pipes are flexible and resilient, allowing them to bear dynamic loads and environmental changes, such as movements in soil or temperature variations. Applying this much-needed degree of flexibility with very strong joint systems allows HDPE pipes to be installed underground or in places where the greatest degree of flexibility would be required.

PVC pipes, meanwhile, are characterized by rigidity and strength. They resist all types of external impacts and hold themselves perfectly under static load conditions, thus finding application above the ground, where conditions for stability exist. The main disadvantage of PVC pipes is the rigidity that they bear: that is, unlike HDPE pipes, they cannot tolerate heavy or sudden external stresses or ground movements.

Both materials provide excellent resistance to corrosion and chemical attack, certainly a key feature for long-term durability. However, being highly flexible, HDPE is more advantageous in environments that have seismic activities or that experience frequent variations in stress. PVC, with its higher tensile strength, can perform well under steady circumstances provided that rigidity means something to its reliability. Your choice of material should also consider environmental conditions, pipe lay methods used, and levels of expected stress so as to yield good performance.

Pressure Resistance and Temperature Tolerance

Pressure resistance and temperature tolerance stand high when the materials of pipes are to be selected, as they affect the system sharply, in terms of performance and life, under different conditions of operation.

HDPE pipes have an extraordinary strength-to-pressure resistance, due to their fabric, structure, and resistance to dynamic pressure variations. It is built to work efficiently in a temperature range from below freezing at -40°F on high to a warm 140°F. High temperature lowers the pressure rating of HDPE pipes, and this is imperative to consider at the design level of the system.

First, HDPE pipes offer a tight retention of pressure resistance up to about 140°F standard temperature; however, this may erode faster for PVC than HDPE when temperature extremes are present. PVC is very effective in uniform temperature environments but less so in conditions of thermal cycling. Hence, considering the temperature and pressure expected to swell should be given proper attention if a PVC pipe is being considered for long-term reliability in a system.

In general, the decision for either HDPE or PVC should respond to your application’s pressure and temperature conditions. The dynamic situations where pressure and temperature change favor HDPE, while PVC would do well in controlled environments with steady pressure.

Flexibility and Impact Resistance

In the flexibility comparison, HDPE ranks quite higher than PVC, owing to its greater ductility and resilience. HDPE, being extremely flexible, can bend without breaking-a huge plus in systems subject to shifting terrains or dynamic loads. The great advantage offered when witnessing deformation and retaining the original shape is implied to describe the capabilities of a product to fulfill its needs, for example, when buried pipelines or any layout exists in ground areas susceptible to seismic activity.

Whereas rigidity is much higher in PVC, due to which it is not able to withstand deformation under load and tends to crack or even powder depending upon the extent of impact being imparted on it, especially at a low-temperature range. PVC might withstand static stress and does so remarkably; however, the inelasticity feature will lessen its ability to resist sudden shocks, rendering it less appropriate in scenarios where impact resistance is a pre-requisite. Whereas, PVC would be the more economical and dependable material in the absence of impact-promoting external forces.

Impact resistance further highlights the qualities of HDPE in exacting environments. HDPE is highly resistant to mechanical impact, so it can retain its integrity while subjected to heavy loads and sudden impacts. It is this property that gives HDPE systems in harsh environments a longer life. Where long-life installations and the ability to withstand physical stress are priority considerations, HDPE shall be the material of choice, whereas PVC is better in applications under controlled and predictable situations.

Cost-Effectiveness of HDPE vs PVC

Initial Costs and Long-Term Savings

The economic perspective of HDPE and PVC requires the evaluation of initial costs along with its implications on long-term maintenance and operational efficiency. PVC usually scores lower on initial costs for procurement and installation due to being lightweight and easy to get hold of. This quality makes it favorable in short-term projects or wherever expenses are of greater priority.

However, whereas relatively much more expensive materials and installations are required for HDPE, long-term savings can be generated. Its very high durability and ability to withstand environmental stresses minimally contribute to maintenance along the way. Hence, with HDPE, the prolonged resistance against corrosion and degradation by chemicals caused by aging reduces the replacement and repair requirements, multiplied many times. For example, research and field applications stand to show that HDPE systems normally can remain functional for well over 50 years when conditions are optimum, thereby lessening the cost-per-year use.

Depending on the environmental conditions involved in the application, the cost-effectiveness of these materials tends to vary. HDPE works perfectly in environments where variable load, thermal expansion, or harsh chemicals are involved. On the other hand, PVC sometimes appears attractive under predictable, controlled conditions, but HDPE will generally be the better choice when adaptability and life-span are considered, hence justifying the higher initial cost.

Maintenance and Repair Costs

Maintenance and repair costs considerations between HDPE and PVC mainly revolve around the frequency and complexity of actions required. Being resistant to cracking and able to resist pressure surges, HDPE requires less often than PVC. To put it in simple terms, HDPE can better withstand cyclic loading without material fatigue and the occurrence of stress-induced fractures that would ordinarily be more common in PVC under similar circumstances.

Repair also leans towards allowing HDPE in a multitude of cases. Fusion welding technology allows seamless repairs and connections to HDPE piping networks, thus presenting fewer leakage points and being able to claim system integrity. Repairs for PVC may require the use of additional fittings or adhesives that will raise the price of materials or possibly extend downtime. Besides, HDPE further resists environmental influences like UV radiation and chemical interactions, hence prolonging uninterrupted working hours under industrial or municipal uses, making it worthy of its reputation of low maintenance costs throughout its working life.

Such cost drawbacks are currently turning into an asset, which will keep HDPE an evermore favored choice in applications wherein maintenance and systems’ reliability are considered prime performance criteria.

Life Expectancy of HDPE and PVC Pipes

The longevity in service of pipes of HDPE and PVC is a crucial factor influencing their choice for particular applications. HDPE pipes are supposed to have a service life of more than 50-100 years in an ideal setting due to their resistance to chemical degradation, extremely low susceptibility to environmental stress cracking, and flexibility in absorbing ground movements. This long life is supported by corrosion resistance, making it very efficient to work for water distribution, gas pipeline, and sewerage systems.

Likewise, PVC pipes are known to be durable, usually lasting between 50 and 70 years in typical environments. Their rigid polymer structure offers greater pressure-handling abilities, and they are resistant to scaling; they find all of their applications in irrigation and drainage systems. In somewhat extreme temperature conditions, PVC pipes may indeed exhibit somewhat decreased life prospects, especially where prolonged UV exposure or freeze-thaw cycles are present, thus troubling their functional life.

Both materials provide long-term reliability, contingent upon proper selection for their required use and installation. Maintenance, alongside the knowledge of environmental conditions, is key to raising the stake toward their expected longevity upper limits. Also, with the improvement of material engineering and production processes, the structure and longevity of pipeline solutions are further enhanced, bringing the utmost efficiency into a modern infrastructural apportionment.

Environmental Impact of HDPE and PVC Pipes

Recyclability of HDPE and PVC

Balancing high-pressure PVC pipe sales and warranties, and the environmental impact of measures corrected would be on recycling. The ability to recycle materials becomes a factor for sustainability considerations in industrial, construction, or infrastructural applications. HDPE is generally considered one of the most recyclable plastic materials, possessing a polymeric constitution simple enough to allow for secondary processing, consisting of being remelted and reformed, with practically negligible diminution of its property characteristics. After shredding, washing, and melting, recycled HDPE can be applied in a variety of products such as pipes, containers, and building materials, thus reducing demand for virgin materials.

In contrast, PVC is a kind of product whose recyclability is perhaps more complicated, owing to the stabilizers, plasticizers, or other additives employed in its formulation to enhance the performance characteristics. Nevertheless, PVC has been the subject of recent technological advances targeted toward rendering its recycling efficient through either mechanical or chemical recycling procedures. PVC flooring, window frames, and new pipe systems are just some applications for recycled PVC, emphasizing the importance of PVC in extended product life. However, for PVC recycling to take place, special facilities must be established for collection and processing, and this depends on PVC materials characterization.

In my view, the promotion of recycling systems for HDPE/PVC pipes involves a multifaceted effort in improving and strengthening the waste management systems as well as creating awareness among the layman and industry alike on sorting, disposal, and recycling issues. While HDPE furnishes a somewhat easier route to sustainability, overcoming hindrances in PVC recycling will ensure that both materials can be ported to achieving a sustainable development goal. With better recycling technologies at hand and initiatives from manufacturers, regulatory authorities, and consumers, we surely can greatly lessen any desired environmental handprint from these materials while maintaining the functional and economic advantages they offer.

Environmental Concerns and Sustainability

Environmental problems arising today about a material like PVC are due to its synthetic nature, near-non-biodegradability, and ability to release harmful substances during manufacture, transshipment, application, and/or disposal. PVC poses challenges to waste management as it contains additives such as plasticizers and stabilizers, some of which may leach gradually into the environment. Studies reveal that they are among the major contaminants when it comes to microplastic pollution across aquatic ecosystems, due to improper disposal of PVC waste.

With the advances in recycling technologies in recent years, newer methods such as feedstock recycling and chemical recycling are being introduced that break PVC down into its constituent compounds. That is to say, the ill-impacted plight in waste formation gets ameliorated while valuable substances are being recovered for reuse. To cite, chemical depolymerization might provide high-purity monomers that may be recycled into the production circuit, thus lessening the demand for virgin raw materials. However, scale-up and cost-efficiency remain obstacles to widespread implementation.

Along with this, sustainability programs include the manufacture of bio-based alternatives and PVC-free materials and work on the spectrum from packaging to medical applications. Sustainable certification programs and more stringent regulatory frameworks have played a critical part in encouraging industries to focus on greener alternatives and to enhance lifecycle assessments. Such implications mesh well with global endeavors to reduce carbon emissions, promote circular economies, and lessen the environmental footprint attributed to synthetic polymers.

Applications of HDPE and PVC Pipes

Common Uses in Plumbing

HDPE and PVC pipes find significant applications in plumbing because of their characteristics of strength, cost-effectiveness, and versatility. HDPE pipes are specifically referred to for their flexibility and anticorrosive nature, making them the best choice when it comes to underground water distribution and irrigation. An excellent strength-to-density ratio allows the pipes to resist pressure to a great extent, thereby minimizing leakage and system failure.

PVC pipes are widely used for residential and commercial plumbing. Being lightweight and easy to install, they show resistance to chemical degradation, which is very important for sewage and wastewater systems. Recent improvements in materials have now made PVC pipes exhibit better thermal performance and durability; hence, they can be used for the supply and drainage of fresh water.

Having an implication of these means that HDPE pipes can be considered to give operational performance for over 50 years. In contrast, PVC may give about forty years to one hundred years of performance under suitable environmental conditions. Recycling and, conversely, low impact on the environment during production tie operationally cementing both materials into modern plumbing solutions, addressing issues of performance and sustainability.

Applications in Agriculture

The utilization of HDPE and PVC pipes has indeed given a new identity to irrigation and water management operations, ensuring efficiency and sustainable use of resources. The following are five leading applications of these materials in agriculture:

- Irrigation Systems: These are used for various types of irrigation systems, such as drip and sprinklers. Their lightweight feature and chemical-resistant nature enable water to be carried straight to the crops, thereby reducing water wastage by nearly 50% compared with the traditional methods used.

- Drainage Systems Come Next: These pipes are installed in drainage fields that avoid waterlogging on agricultural lands. A large number of studies conclude that if drainage is well set up, crop yield increases by around 20% on average in water-sensitive environments.

- Fertilizer Distribution: Fertilizer injection systems often utilize PVC and HDPE pipes as they can transport liquid fertilizers without corrosion. This makes the even distribution of nutrients possible and gives a breed an increase in productivity of up to 30%.

- Greenhouse Water Systems: PVC pipes, being durable at high temperatures, and HDPE pipes, being flexible, are suitable for greenhouse irrigation infrastructure. Thus, under controlled environments, water is consistently delivered while maximizing water-use efficiency.

- Aquaculture and Fish Farming: HDPE pipes serve to carry water in aquaculture setups. Their high-pressure tolerance and chemical resistance ensure safe and durable clean water delivery for fishponds and other aquatic farming needs.

Hence, in integrating HDPE and PVC pipes in such departments, agricultural activities will benefit by leaps and bounds in efficiency, productivity, and conservation of the environment.

Industrial Applications of HDPE and PVC

HDPE (High-Density Polyethylene) and PVC (Polyvinyl Chloride) pipes have greatly contributed toward a vast number of industries due to their superior physical and chemical features. They are preferred between industries because of their strength, corrosion resistance, and inexpensive maintenance. Below is a list of five key applications under which HDPE and PVC are widely applied:

- Chemical Processing: HDPE and PVC pipes carry aggressive chemicals in industrial plants because they are resistant to a wide range of chemicals, including acids, alkalis, and solvents. To illustrate, PVC pipes handle temperatures up to 140°F and are resistant to hydrochloric acid, whereas HDPE is often chosen for sodium hydroxide transport due to its superior heat and corrosion resistance.

- Oil and Gas Sector: In these materials are transportation is means through crude oil, natural gas, and other petroleum derivatives. The plastic pipe is flexible to a certain degree with resistance to high pressure, and is used in onshore and offshore pipelines, whereas PVC pipes mostly find application in low-pressure regimes such as vent lines.

- Wastewater Management: PVC and HDPE pipes are paramount in building durable sewerage and wastewater pipelines for treatment. Their non-corrosive nature enables them to withstand the aggressive attacks of wastewater and sludge over long periods. Especially in the case of HDPE, they are preferred for trenchless rehabilitation procedures, including pipe bursting and slip lining.

- Mining Operations: Both HDPE and PVC pipes are utilized in mining operations, transporting slurry, water, and compressed air. HDPE’s impact resistance contributes to effective material handling in harsh conditions, while the lightweight nature of PVC facilitates transport. For example, HDPE pipes can withstand extreme levels of pressure and rough terrains, ensuring service life.

- Power and Telecommunications: HDPE conduits find their primary use in housing and protecting power and fiber optic cables. To have an infrastructure that remains reliable, it is very important to withstand harsh environmental conditions while protecting these sensitive wires from being physically damaged. PVC pipes are also placed for smaller cable management systems in power distribution networks.

Sustaining various functions from HDPE and PVC from applications testifies to the wide range of industrial processes. Their presence enables the streamlining of operations, reducing maintenance costs, and increasing system longevity.

Choosing the Right Pipe for Your Needs

When to Choose HDPE

When HDPE pipes are named for best durability and flexibility against weather conditions, these pipes can withstand heavy weight and pressure without cracking, owing to the high tensile strength of HDPE. Such pipes can consequently be used for water transmission, gas distribution, and industrial piping systems. Thanks to their chemical inertness, such piping systems resist being from corrosive chemicals like acid and alkaline solutions, thus maintaining efficacy against corrosive environments in the long run.

Severe temperature fluctuations or seismic activities pose risks for materials susceptible to wear and tear, and HDPE piping does well under such conditions. Its inherent resilience can absorb stresses developed during ground movements, and this, in turn, lowers maintenance and repair costs in such places. One other major advantage of HDPE pipes lies in each section being joined by electrofusion or butt fusion, eliminating any possible leakage and securing a watertight system.

From an environmental standpoint, HDPE is recyclable and boasts a low carbon footprint in comparison to most materials. It is a blessing indeed for sustainable infrastructure-focused projects. HDPE serves as a versatile and inexpensive solution for urban water, agricultural irrigation, or industrial process systems.

When to Choose PVC

PVC is a thermoplastic resin that has found wide application because of the combination of durability, economy, and simplicity of installation. PVC fits best in environments in which resistance to corrosion and chemical exposure is needed, like wastewater treatment and chemical processing pipelines. Unlike HDPE, PVC is highly regarded for its tensile stress because it is generally used in the high-pressure domain, also in the municipal water distribution system.

When considered thermally, PVC is functional in temperature ranges between 32°F and 140°F. Therefore, it would not have been selected for high-temperature or very low-temperature environments, which could have been chosen in case of an option. But, since it possesses rigidity and reflex structural integrity, it can be equipped with relatively thin walls to allow maximum flow without compromising stability. The material is also chosen due to its flame-retardant property by industries with fire safety-related implementation.

Economically, PVC is cheaper upfront, especially if the projects are of a shorter term, or installations with lower environmental demands. Engineers and designers concerned about cost efficiency while also considering a given performance under certain environmental criteria would consider PVC an option.

Practical Considerations for Pipe Selection

There are several factors to consider in making a choice for pipes in any engineering, industrial, or construction task. These are essential for assuring optimal performance and cost efficiency. One major consideration is the incompatibility of materials. For example, a material’s chemical resistance would need to align with the nature of the fluids or gases being transported. PVC, for example, being highly resistant to acids, alkalis, and salts, is used for applications in chemical processing; on the other hand, stainless steel could be used for applications involving high pressure or extreme temperatures.

The strength ratings or external loads that the pipe must carry also present another concern. The pipe strength and flexibility should be adequate for the demands laid upon the system, especially when pipes are buried or pressurized. The engineers must provide the pressure ratings of the pipes (in PSI or bars) and be able to withstand external influences like soil movement or seismic annealing.

There is, of course, the environmental element. Temperature change, UV exposure, and corrosion hazards are factors in the aging and functioning of a pipe system. UV-resistant plastics or coated metals can give durability to outdoor installations.

Thus, long-term economic and installation factors are always paramount. Ductile iron or RCP, while more expensive initially than PVC, may offer better service lives for very large-diameter water mains or applications requiring high structural performance. Thus, life cycle cost analysis is very important in determining the overall worth of a pipe system during operation.

References

Frequently Asked Questions (FAQ)

Q: What are the main differences between HDPE and PVC pipes?

A: The differences between HDPE and PVC pipes primarily lie in their material properties. HDPE, or high-density polyethylene, offers greater flexibility and resistance to impact, whereas PVC, or polyvinyl chloride, is known for its rigidity and stiffness. Additionally, HDPE pipes can handle higher pressure ratings and provide better chemical resistance, making them suitable for a wider range of piping applications.

Q: Which type of pipe is more cost-effective for drainage systems?

A: When comparing HDPE vs PVC pipe for drainage systems, HDPE is often considered more cost-effective due to its long service life and lower installation costs. The flexibility of HDPE allows for trenchless installation methods, reducing labor and excavation expenses compared to rigid PVC pipes.

Q: Can HDPE pipes be used for potable water supply?

A: Yes, HDPE pipes are an excellent choice for potable water supply due to their high chemical resistance and durability. They are made from high-density polyethylene, which does not leach harmful substances, ensuring that the water remains safe for consumption.

Q: How are HDPE and PVC pipes joined?

A: HDPE and PVC pipes are typically joined using different methods. HDPE pipes are commonly connected using heat fusion, which creates a strong, seamless joint. In contrast, PVC pipes are usually joined with solvent cement or mechanical fittings, which may not provide the same level of strength as heat-fused connections.

Q: What are the strengths and weaknesses of HDPE and PVC pipes?

A: The strengths of HDPE pipes include their flexibility, resistance to corrosion, and ability to withstand higher pressures. Conversely, their weaknesses may involve a higher upfront cost and less rigidity compared to PVC. PVC pipes, while cost-effective and easy to install, are more prone to cracking under stress and have a lower failure rating compared to HDPE.

Q: In which specific applications is PVC pipe preferred over HDPE?

A: PVC pipe is often preferred in applications that require rigidity and stability, such as in some municipal drainage systems and plumbing installations. Its stiffness makes it a better choice for vertical applications where support is needed. However, for applications requiring flexibility and resistance to environmental factors, HDPE is usually favored.

Q: What is the role of the Plastic Pipe Institute in the HDPE and PVC pipe industry?

A: The Plastic Pipe Institute plays a crucial role in the pipe industry by promoting the use of plastic pipes, including HDPE and PVC. They provide resources, guidelines, and standards for the installation and use of these materials, ensuring safety and efficiency in piping applications.

Q: What are the benefits of using HDPE pipes in gas distribution?

A: HDPE pipes offer significant benefits in gas distribution, including exceptional strength and flexibility, which allow them to withstand ground movement. Additionally, their resistance to corrosion and chemicals ensures a long service life, making them a reliable choice for transporting natural gas.

Q: How does the cost of HDPE compare to PVC?

A: The initial cost of HDPE pipes may be higher than that of PVC pipes; however, when factoring in the long-term durability and reduced maintenance costs, HDPE can offer significant cost savings over time. Its ability to handle higher pressures and resist environmental factors contributes to its cost-effectiveness in many applications.

Q: What is the typical lifespan of HDPE and PVC pipes?

A: HDPE pipes typically have a service life of over 50 years under proper installation and maintenance conditions, while PVC pipes generally last around 25 to 40 years. The longevity of both types of pipes makes them suitable choices for various piping applications, depending on specific project requirements.