When working on a PVC pipe project, ensuring accurate measurements is critical for a successful outcome. Whether you’re constructing a plumbing system, building a greenhouse frame, or tackling a DIY craft, understanding how to measure the diameter of PVC pipe correctly can save you time, money, and frustration. This article provides a detailed, step-by-step guide on how to measure PVC pipe diameter effectively, debunking common misconceptions and equipping you with the knowledge needed to choose the right pipe for your project. By the end, you’ll be confident in your ability to handle pipe measurements like a professional.

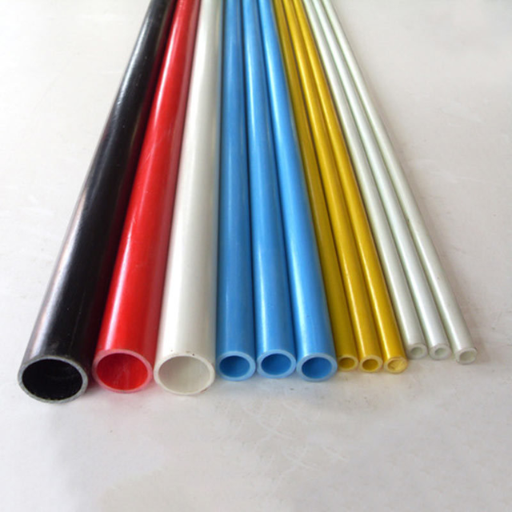

Understanding PVC Pipes and Their Sizes

Image source:https://b2b.baidu.com/

PVC Pipe Sizes and Dimensions

Normally, a PVC pipe size will be standardized and classified according to nominal size, which stands for the approximate inside diameter of the pipe, but its true dimensions, such as its outside diameter and wall thickness, change with its schedule or pressure rating. Hence, while PVC pipes of Schedule 40 and Schedule 80 have the same outside diameters for the same nominal sizes, they differ in wall thicknesses and inside diameters accordingly.

The important dimension for fittings is the outside diameter. These dimensions remain constant for fittings of the same nominal diameter across schedule numbers. For example, nominal 1-inch Schedule 40 PVC and nominal 1-inch Schedule 80 PVC both have outside diameters of 1.315 inches. The difference is in wall thickness; Schedule 80 has thicker walls, and hence, the inside diameter is reduced. Thus, it is necessary to be aware of both the nominal size and the schedule of a PVC pipe for fittings to properly interconnect.

To determine the actual size of the PVC pipes, first, always select from a standard PVC pipe sizing chart. Upon using this information to select a PVC pipe, you will secure a proper fit and good working conditions for the pipe in terms of pressure or flow rate of the application.

Types of PVC Pipes

PVC pipes are categorized into a few types based on their properties, applications, and manufacturing process. Some of the most common types of PVC pipe with their particular characteristics and uses include:

- Schedule 40 PVC Pipes: Schedule 40 PVC pipes are widely used due to their versatility and relatively low price. They have a relatively thin wall compared to other schedules and are suitable for low-pressure applications such as irrigation, drainage, and residential plumbing. These pipes are very lightweight, easy to handle, and most fittings used in plumbing are compatible with these pipes.

- Schedule 80 PVC Pipes: Schedule 80 PVC pipes have walls thicker than Schedule 40 PVC pipes and therefore enjoy even higher pressure ratings and durability. They are mostly used in industrial and commercial areas where the pipe is subjected to much stress and higher pressures. The gray color distinguishes them from the white Schedule 40 pipes.

- CPVC Pipes: Lining up with Chlorinated Polyvinyl Chloride, CPVC pipes stand for heat-resistant applications. They are therefore higher temperature resistant as compared to usual PVC and hence generally are used for carrying hot water in residential and industrial systems. CPVC is also used for chemical handling applications because it is chemically resistant.

- PVC DWV Pipes: PVC Drain, Waste, and Vent (DWV) pipes are made for use under non-pressurized working conditions. Such pipes find use in sewage, venting, and drainage. These are lightweight yet are not intended to withstand internal pressure; they give priority instead to gravity-based internal flow.

Knowing the types of PVC pipes out there and considering the right function will enable you to make the right selection suited specifically to the requirements of your project. Always consider industry standards and product specifications to help identify the right type of pipe for your desired application.

Importance of Accurate Measurements

Accurate measurements are crucial to the planning and execution of any construction or plumbing operation. Flawed measurements will rarely allow all components to fit perfectly; therefore, instead of rectifying, buyers or plumbers end up damaging the construction with errors, costing them their systems. In slight variances in dimension while setting PVC pipes, possible conflagrations can be improper connections; it can be something-crippling leaks, or the whole structure may on its a standstill. The customer needs to make sure that a perfectly accurate measurement is carried out to avoid the above scenarios that damage functionality.

Incorrect measurements might also have material wastage and project cost inflation attached. Pipes or components ordered in the wrong size would cause delays until replacements are procured. On the other hand, besides causing delays, the wasting of extra material is simply an unnecessary cost to the environment. Focusing on accuracy surely keeps the projects within budget and on time, so the professionals working on the projects can never be subjected to reworks or adjustments.

Accurate measurements are attained through the successful application of institutionalized industrial methodology, developed and applied through the specified conclusion of accepted measuring tools. Further, it is paramount for measuring instruments, sensor gauges, or tape measures subjected to regular inspections to retain their reliability. Over and above that, upon the occurrence of drastic circumstances, one should readily reaffirm measurements and involve experts where applicable, hence doing away with possible error-making. The applications of these practices make sure that construction or plumbing works uphold their integrity and reduce the risk of liability, thereby adding great value in the long run.

Measuring Techniques for PVC Pipe Diameter

Using a Tape Measure

Using a tape measure for measurement is a simple but effective method that works in most situations. To get accurate measurements, first, identify whether you plan on measuring the outer diameter (OD) or inner diameter (ID) of the pipe. It is a very important distinction to make since generally, ID measurements will be more important for determining flow capacity, and OD measurements will be more likely to go into larger classification systems.

To measure the outer diameter, simply measure the circumference of the pipe using the tape measure and record the total measurement. Thereafter, compute the diameter using the formula diameter = circumference ÷ π (about 3.1416). Ensure that the tape measure is held tightly around and is straight on the pipe so as not to cause any deviations in measurement.

To get accurate readings of the inner diameter, the pipe must be sectioned in such a way that the inner surface is accessible and the tape measure can be placed straight across the center of the circular opening from one side to the opposite side. Lastly, record the measurement at the widest point.

These provisioned steps allow for ease and accuracy, provided that the pipe surface is clean and without distortions that may affect accuracy. The cross-referencing of these results with the standard size charts for PVC classification will further examine the accuracy of your final measurements. Minimize errors and maximize measurement accuracy by combining these methods with procedural checks and calibration tools.

Measuring Outside Diameter (OD)

Measuring the outside diameter (OD) of a cylindrical object, like a PVC pipe, calls for precision and good measuring tools to obtain correct measurement outcomes. Pick a good instrument, such as a caliper, a micrometer, or an OD tape measure for cylindrical objects. Keep the measuring instrument at a right angle to the pipe’s central axis; otherwise, an inaccurate reading may be noted.

For precision measurement, ensure that the pipe is free of any dirt, residue, or irregularities that may affect the measuring operation. Take OD measurements at different points along the length of the pipe to allow for variations in shape, and average them if differences are discovered. Whenever possible, compare those measurements against the relevant standards or manufacturer specifications to confirm their conformity to the expected classification or size.

However, measurements using electronic displays are better, minimizing human error and offering absolute readings. It is very important to calibrate any measuring tool periodically to maintain accuracy from use to use. All these practices are good for the reliable collection of data in any industrial or technical operation.

Distinguishing Between Internal and External Diameters

The distinction between internal and external diameters is far more important for engineering, manufacturing, and quality assurance activities. Internal diameter or ID usually means the measurement across the hollow of a cylindrical or tubular object. External diameter or OD is the measurement across the outermost circumscribing surface of the same object. Both measurements are very important for the proper fit of components to be accurately assembled.

Some precision tools, such as bore gauges or inside jaws of calipers, are used in measuring the internal diameter. For external diameters, calipers, micrometers, and other external measuring devices are used. These measurements must adhere to set tolerances established at the design phase to achieve the purpose of maintaining assembly requirements. Laser measurement systems or coordinate measuring machines (CMM) are some advanced measuring techniques used for top-grade industries since they provide microscale accuracy and reduction of manual intervention errors.

An understanding of application-dependent uses of internal and external diameter data is essential. For instance, in fluid dynamics, internal diameter calculations influence flow rates and pressure losses. External diameter measurements matter when one needs to consider material strength under stress or external load conditions. Staying abreast of measurement standards and making sure appropriate technologies are applied is what ensures operation from dimensional accuracy to functional accuracy.

Common PVC Pipe Schedules

Schedule 40 PVC Pipe

Schedule 40 PVC pipes are among the most used piping systems in residential, commercial, and industrial works due to the balance of strength, affordability, vis-a-vis versatility. They are designed with a wall thickness that is standardized to strict industry codes to foster dependability under varying pressure conditions. For example, a 1-inch Schedule 40 PVC pipe normally carries a wall thickness of 0.133 inches and a pressure rating of 450 PSI, depending on temperature and fluid transported.

The Schedule 40 PVC is made from polyvinyl chloride, which confers significant advantages such as chemical resistance, corrosion resistance, and low thermal conductivity. The lightweight and easy-to-install nature of the pipe allows it to be joined by a standard solvent weld or threaded connection, making it advantageous for plumbing, irrigation, drainage, and light-industrial fluid transportation.

The Schedule 40 PVC pipes exhibit temperature-dependent behavior, which in turn determines their performance. While such PVC pipes would be rated for pressure well under any typical cold-water system, their average maximum working temperature will be limited to 140°F (60°C). Beyond this, the relatively high temperature severely weakens the structure and rigidity of the material, and consequently, results in system failure.

To obtain maximum performance from Schedule 40 PVC while complying with the specified standards in ASTM International concerning installation and maintenance, one should combine the technical information on specification with good practice. These attributes make it a reliable choice for a wide range of applications in modern infrastructure.

Schedule 80 PVC Pipe

Schedule 80 PVC is intended for applications that require higher pressure ratings and higher durability in comparison to Schedule 40. Made of polyvinyl chloride (PVC), this type of pipe has a thicker wall construction that increases its capability to sustain higher internal pressures. For example, a 1-inch diameter Schedule 80 PVC pipe is rated to handle pressures up to approximately 630 psi at 73°F (23°C), as compared with the Schedule 40, whose pressure rating is only about 450 psi under similar conditions.

Increased wall thickness also means higher resistance to mechanical forces, thereby making Schedule 80 PVC best suited for industries including chemical processing and high-pressure water distribution systems. Besides, it has phenomenal chemical resistance capable of repelling a broad spectrum of acids and bases as well and salts, thereby increasing its utility for corrosiveness.

Nevertheless, with PVC piping, temperature remains paramount. Operational pressure ratings for Schedule 80 PVC reduce as the temperature increases above 73°F (23°C). For instance, at temperatures close to 140°F (60°C), this pipe typically retains about 22% of its rated pressure at room temperature. Hence, all suitable considerations must be given for temperature de-rating in the system design to avert any possible risk of failure in high-temperature applications.

Schedule 80 PVC is manufactured per strict standards, such as being from ASTM International, particularly ASTM D1785 for dimensions and ASTM D2467 for threaded fittings, to assure interchangeability and reliability across applications. Due to its versatility and compliance with industry standards, it is the go-to selection for any engineer or contractor requiring durable piping in demanding environments.

Understanding Schedule 120 PVC

Schedule 120 PVC represents the zenith of high-pressure PVC piping, being manufactured with a much thicker wall thickness than its Schedule 40 and Schedule 80 counterparts. The extra wall thickness of Schedule 120 pipes permits them to withstand higher internal pressures, making them suitable for very demanding applications such as industrial fluid transfer, compressed air systems, and some chemical handling. Schedule 120 PVC profiles, under very strict specifications for dimension and material quality, including ASTM D1785, are tested for performance under high stress.

Some of the major characteristics that distinguish Schedule 120 PVC include its pressure ratings, which are often much higher than other PVC schedules, because of its reinforced and sturdy nature. Hence, it is being increasingly used in all kinds of systems where pipes must work under high pressure, without compromise. However, this also means it can stand chemical resistance, thermal conductivity, and installations traditionally offered by PVC while weathering constant stress from this nature.

For the pressure withstanding capability offered by the wall thickness, the internal diameter of such pipes is grossly reduced as compared to lower schedules, thereby affecting the flow rate. Hence, it becomes imperative for system engineers and designers to strike a fine balance between pressure-related functional requirements and flow-related characteristics during the design phase. A well-designed Schedule 120 PVC system can offer professionals a safe and efficient working environment even in the most demanding conditions.

Working with PVC Fittings

Choosing the Right PVC Fitting

Choosing an appropriate PVC fitting for use in a project involves considering several critical factors relating to performance and compatibility. First is the type of application, which guides one to know the fitting’s pressure rating, temperature handling, and general durability requirements. For example, a fitting used in a high-pressure system must be rated to withstand such stresses; however, for low-pressure or even non-pressurized applications, more flexibility in material selection and cost considerations occurs. One must comprehend the operational demands of such a project to decide accordingly.

PVC pipe type and size come next. Sizing is very crucial; even the slightest variation means less integrity of the system and can cause leaking or inefficient operation. I make sure the dimensions of the fitting, including the inner diameter and type of connection (i.e., slip, threaded, solvent weld), are compatible with the pipes being considered. Then I look at the joint type: must the connection provide a mechanical fix or chemical bond? Doing the job right in fitting selection prevents potential connectivity problems and ensures system integrity for the long haul.

Many environmental factors and conditions may have an impact on how the fitting is expected to cope. Factors such as UV exposure, chemical resistance, and temperature fluctuation help in selecting fittings of suitable materials. Fittings with enhanced UV stabilization or chemical resistance would be preferred in outdoor or chemically exposed systems. By an attack on the criteria of applications, pipe compatibility, and environment, I am confident when selecting PVC fittings that will satisfy a project’s functional and safety requirements. This structured methodology ensures the accuracy and reliability of the entire system.

How Wall Thickness Affects Pipe Size

Wall thickness plays a significant role in the overall performance, suitability, and longevity of pipe systems. Within the industry, it is measured under the schedules or grades of a pipe, such as Schedule 40 or Schedule 80 pipe. Wall thickness dimensions affect the inner diameter of pipes so that the inner diameter is dependent upon and varies with the thickness of the wall. With an increase in wall thickness, the pipe’s fluid or gas flowing capacity diminishes as viewed from the flow rate of fluids at a certain flow rate. This particular relationship needs to be calculated with the utmost attention, especially during the design of high-pressure systems or situations demanding specific flow velocities.

From their perspective, the mechanical design considers that thicker walls give better mechanical strength and, therefore, should be adopted in places subjected to high internal or external pressure. In contrast, a thin-walled pipe would best serve, albeit lightweight and cheap, for low-pressure systems where weight saving becomes an alternative. The engineer uses wall thickness as a variable alongside others such as material properties, installation conditions, and regulatory codes to arrive at a secure operating condition within design parameters.

Understanding this interlinking of wall thickness and pipe size is needed to optimize flow efficiency while adhering to safety stipulations and until operational costs are as low as possible.

Fitting PVC Pipes for Your Project

PVC pipes are carefully chosen and installed according to the system requirements and compatibility of the materials. They are designed and manufactured to fit diverse applications, including potable water systems, chemical transport, etc. Specifics of pipe dimension, pressure ratings, and fitting selection depend on the application considered. Begin by making exact measurements of the pipe sections to be joined. A layout ensuring fewer joints will reduce the risk of leakage.

For installation, pipe ends and fittings should be clean and free of dust. Ensure that a PVC primer and cement suitable for PVC are applied correctly to weld the joints. The curing time of the adhesive must conform to the manufacturer’s recommendations to ensure bonding strength. Consideration must be given to thermal expansion in hot ambient temperatures, as PVC will expand or shrink considerably. Any expansion joints or expansion loops must be properly spaced to ensure the stability of the system.

Further regulations and codes, such as those developed by ASTM International, will guide your selection of materials and installation procedures to ensure that the system satisfies both safety and efficiency criteria under the specified operating conditions. In a detailed approach to fitting PVC pipes, you get to build a hard-wearing solution that serves the technical requirements of your project.

Tips and Tricks for Accurate Measurements

Tips for Measuring Different Pipe Sizes

Pipe sizes must be accurately measured to synergize with piping and plumbing installations towards being efficient and fully functional systems. The difference between nominal pipe size (NPS) and external measurements, such as outside diameter (OD), must be understood when deciding upon purchases of different pipe sizes. For example, when dealing with PVC or metal pipes, the nominal size is very often not the actual size but rather an approximate designation. Always rely upon a precision caliper or measuring tape with clearly marked metric and imperial scales to record measurements. This is to ensure no deviation from the standard given or approved tolerance.

Measuring smaller pipe sizes under the diameter of two inches should be done with the help of a caliper to acquire accurate OD measurements. Besides, those small pipe sections might have male or female threaded ends that would also need to be measured for pitch and compatibility with fittings. For larger sizes of pipes, flexible steel measuring tapes should be preferred, especially those that have graduations marked for diameter-to-circumference conversion. Additionally, measurement instruments should always undergo calibration after a period of working life or if evidence of wear appears; environmental conditions are also of concern, especially when rusting or thermal expansion can influence measurements.

In the case of non-cylindrical or irregular types of pipe, such as those with flanges or those that change in thickness in some segments, consult the manufacturer’s references or specifications to validate the dimensions. A combination of accurate measurements attained from a dependable set of tools and a sturdy comprehension of industry standards guarantees hereto smooth integration of the pipes into the greater systems, thus minimizing the danger associated with improper sizing and fitment.

Common Challenges and Solutions

Many challenges generally appear while working with pipes and tubes, most of which can be prevented by precise working methods and adhering to industry standards.

- Dimensional Variability in Manufacturing: Because of production tolerances, pipes may not all conform exactly to their nominal size. This dimensional variability has posed loose-fitting or tight-fitting conditions on applications that result in leakage or structural formation. Solution: Rely on standards, including ANSI or ASTM specifications, for tolerable acceptance of size variation, and use metrology instruments for measurement on lines, such as a laser-based measuring instrument, to check for compatibility before installation.

- Material Compatibility: Different applications require different types of properties of a material regarding tensile strength, corrosion resistance, or heat tolerance. If wrongly selected, this generic selection would further lead to premature failures like cracking, rusting, or deformation under load. Solution: Employ detailed specification sheets to select materials based on environmental and operating conditions. For harsh environments, stainless steels or alloys such as Hastelloy are more often specified for their durability.

- Corrosion and Oxidation: Piping systems exposed to aggressive environments are those found in chemical plants, a marine environment being an example of these, with accelerated corrosion, thereby decreasing service lives and structural integrity. Solution: Corrosion-resistant coatings shall be imparted or use materials designed for such environment; e.g., galvanized steel or plastic composites. Scheduled maintenance and inspections will reduce wear in the long run!

- Improper Installation Practices: Errors occurring during installation, like misaligned joints or insufficient sealing, are some of the causes of operational inefficiencies. Solution: Provide training for technicians in the standard installation procedures and employ a series of quality assurance activities, such as pressure testing all joints before full integration of the system.

With ever-evolving technologies in manufacturing and testing procedures and strict observance of international codes, these challenges can be minimized, paving the way for piping systems with better safety and efficiency.

References

Frequently Asked Questions (FAQ)

Q: What is the best way to measure PVC pipe diameter?

A: To measure PVC pipe diameter, you can use a tape measure to determine the outer diameter (OD) of the pipe. For more accuracy, especially in plumbing projects, it’s important to measure the pipe on the side and ensure it’s straight.

Q: How do I determine the size of the PVC pipe for my plumbing project?

A: To determine the right size of PVC pipe, measure the outer diameter of the pipe and refer to the PVC pipe dimensions chart. This will help you understand the nominal pipe size and select the appropriate PVC pipe for your specific application.

Q: What is the difference between the inner diameter and outer diameter of a PVC pipe?

A: The inner diameter (ID) refers to the space inside the pipe where fluid flows, while the outer diameter (OD) is the total width of the pipe, including the thickness of the walls. Understanding these measurements is crucial when selecting fittings and connectors.

Q: Can I use schedule 40 PVC pipe for water supply?

A: Yes, schedule 40 PVC pipe is commonly used for water supply systems and is suitable for residential plumbing. It has a pressure rating that makes it appropriate for various applications, including drainage systems and sink drains.

Q: How do I measure the inside diameter of a PVC pipe?

A: To measure the inside diameter of a PVC pipe, you can use a caliper or a tape measure to find the distance across the interior of the pipe. This measurement is essential when selecting fittings that will fit inside the PVC.

Q: What sizes of PVC pipe are available for drainage systems?

A: PVC pipes come in various sizes, including 1 inch, 2 inches, and 3 inches, among others. The sizes can vary based on the application, such as residential plumbing or water lines used for drainage.

Q: How do I select the right fittings for my PVC pipe?

A: When selecting fittings for your PVC pipe, ensure that the fittings provide a snug fit for your project. Measure the outer diameter of the pipe to match it with the appropriate PVC pipe fittings, considering the thickness of the pipe walls.

Q: What are the differences between schedule 40 and schedule 80 PVC pipes?

A: Schedule 40 and Schedule 80 PVC pipes differ primarily in wall thickness and pressure ratings. Schedule 80 pipes have thicker walls and higher pressure ratings, making them suitable for more demanding applications, whereas Schedule 40 is commonly used for standard plumbing and drainage.

Q: Is there a specific method for measuring the thickness of the pipe walls?

A: Yes, you can measure the thickness of the pipe walls by measuring the outer diameter and subtracting the inner diameter, then dividing the result by 2. This will give you the thickness of each wall, which is important for understanding the pipe’s capacity to handle pressure.

Q: What should I know about PVC pipe sizes and dimensions before starting a project?

A: Understanding PVC pipe sizes and dimensions is crucial before starting a plumbing project. Make sure to know the nominal system sizes, the outer and inner diameters, and the thickness of the pipe walls to ensure all components fit together properly and meet your project’s requirements.