Pipe systems are the heart of industrial operations, ranging from water distribution to oil and gas transport and industrial manufacturing processes. Through exact engineering and careful selection of materials, pipe systems assure reliability, efficiency, and longevity, and thus form an essential backbone of modern infrastructure. This guide illustrates key factors of pipe system construction and applications, giving readers a brief but comprehensive overview of how pipe systems operate and are built, and the vital role they play in various industries. For those working in any engineering domain, construction, or facility management, this guide would be an insightful reservoir of basics and recent innovations in the field of pipe systems.

Applications of Pipe Systems

Pipe Systems in Plumbing

Plumbing systems include pipes that ensure water, waste, and fluids flow throughout residential, commercial, and industrial constructions. Usually, clean water distribution for drinking and sanitary purposes and wastewater disposal involve these pipes, fittings, and valves. Common materials in use are PVC (polyvinyl chloride), copper, and PEX (cross-linked polyethylene), chosen according to durability, cost, and performance of the system at hand.

It is important to design plumbing pipe systems well and execute their installation properly to maintain their function and longevity. The pipe design is based on calculations that consider diameter, pressure rating, and flow requirement so as to hinder any leaks, pressure losses, or contamination; in other words, pipes that carry drinking water should not be connected to wastewater systems.

Such plumbing innovations are claimed to improve the efficiency and sustainability of pipe system installations. For instance, smart systems can detect leaks upon occurrence and alert the user in real time, limiting water wastage and cost. Furthermore, plumbing systems play a greater role in water conservation with the use of greener materials and low-flow fixtures. In all respects, these systems still remain indispensable for the high standards of hygiene, comfort, and resource management demanded in modern-day built environments.

Pipe Systems in Construction Projects

Pipe systems play a vital role in construction; they convey water, sewage, gases, and other fluids essential for infrastructure. The design and installation of these systems ensure that operations are carried out safely and efficiently while conforming to local building codes. The commonly used pipe materials include PVC, copper, steel, and polyethylene, with each material being chosen for a particular application depending on factors such as the material’s strength in service, flexibility, or corrosive resistance. The correct selection of pipe material automatically facilitates the smooth and efficient performance of the entire system for a long time.

Key Consideration: During construction, pipe systems have to be coalesced into the structure by forethought to serve both structural and functional requirements. Pipe systems must be routed and placed in such a way that allows access for maintenance without obstructing other building systems like electrical wiring or HVAC ducts.

Coordination among architects, engineers, and plumbing professionals is conducted well in advance to ensure integration and avoid conflicts during construction.

Innovation for pipe systems has further enhanced their working capability in construction projects. Existing technologies embrace the pre-insulated pipes and smart monitoring systems that ascertain energy efficiency and provide real-time alerts for leaks or pressure drop issues. All these advances have renewed pipe system reliability and have helped make buildings sustainable by reducing the wastage of resources and ensuring operational efficiency in the long run. To sum up, pipe systems are and shall forever remain integral in operational efficiency and aligning with the functional requirements of contemporary construction projects.

Pipe Systems in Agriculture and Manufacturing

The pipeline system offers critical support for the transportation of liquids, gases, solids, and other substances in both agriculture and industry. In agriculture, these systems are mainly for irrigation; in other words, water is supplied to crops in the right quantities. The modern drip irrigation possibilities depend on pipes that are strong and corrosion-resistant, made out of polyvinyl chloride (PVC) or polyethylene; such materials allow for hardly any water leakage and precise water delivery. This kind of efficiency with water management leads to reduced wastage and increased crop yield; thus, it is imperative from a sustainability point of view.

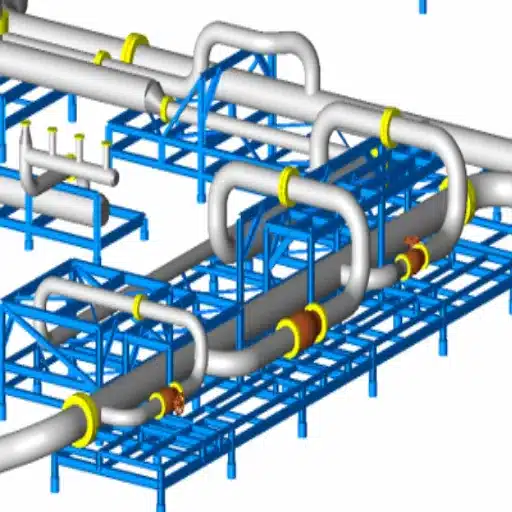

In manufacturing, pipe systems are hung onto an industrial plant basically for the transport of raw materials, chemical substances, and by-products. This might be anything from conveying steam to power plants or supplying cooling agents to take care of temperatures in production-related processes. Systems that are made of stainless steel and heat-resistant materials are frequently installed to guarantee that such systems survive and can withstand extreme conditions. Besides, pipe systems in such an industrial process integrate advanced monitoring systems that provide real-time data on flow rates and help the anomaly detection to prevent downtime and enhance efficiencies.

Sustainability Impact: Both areas continue to evolve in this regard with respect to pipe materials and technologies for improving efficiency and reducing maintenance costs. Sensor technology combined with intelligent pipe systems paves the way for predictive maintenance and automated controls.

This, on one hand, improves production, and on the other hand, promotes sustainability by rationalizing resource requirements and minimizing environmental impact. Also, therefore, pipe systems remain an unprecedented factor of advancement for both the agriculture and manufacturing industries.

Installation Processes for Pipe Systems

Step-by-Step Installation Guide

- Pre-Installation Area Assessment: Conduct a full inspection of the site for installation suitability. Check for soil stability, environmental conditions, and accessibility to determine the best place for the pipe. This actually lowers the risk that may be faced in the future during operations and the translation of the project efficiently.

- Material Inspection and Preparation: Check all pipes, fittings, and other associated components for manufacturing defects or damage during transit. Clean and prepare surfaces so that no cross-contamination occurs and to make certain that components are fit for the intended system pressure-temperature requirements.

- Trenching: Excavate trenches in accordance with the pre-established layout, maintaining specified depths and slopes, and adhering to regulatory codes. Provide support to trench walls where required in situations with unstable soils.

- Laying of Pipes and Alignment: Lay pipes sequentially from the lowest elevation point for optimum flow. Use laser or GPS alignment to ensure high precision, with the least amount of deviation that will interfere with the efficiency or strength of the system.

- Jointing and Sealing: Joint according to the manufacturer’s instructions; ensure proper alignment, apply consistent torque, and use approved sealants, gaskets, or welding techniques to produce leak-proof joints suitable for the operating pressure and flow environment.

- Pressure Test and Inspection: Carry out pressure tests-hydrostatic or pneumatic the system to verify leak, deformation, or pressure drop occurrences. Upon observing any faults during the test, corrective measures shall be taken to uphold the requirements of safety and performance standards.

- Backfilling and Stabilization: Backfill trenches in layers using suitable fill materials, compacting each layer to ensure soil stability and pipe positioning. Sharp or abrasive fill materials should especially be avoided to protect the pipe surfaces during backfilling.

- Final Verification and Documentation of the System: Carry out a full system inspection; verify operational parameters such as flow rate, pressure hold, and integration with the control system. Keep a record of all installation-related information, test results, and certifications for future reference and enforcement.

Important Note: These elaborate, stepwise instructions assure the service life and functionality of the pipeline system, minimize maintenance, and in the process make the system more efficient in its actual operation.

Safety Considerations During Installation

Safety during the installation of pipeline systems matters a lot because any occurrence of mishaps and hazards, along with operational interruptions and, in some cases, damage to the environment, can be in the offing. Begin by carrying out a site risk assessment where dangers would be identified example, exposure to hazardous substances, high pressure, or ground instability. All involved personnel must be adequately trained in equipment handling, in emergency response, and in the use of local codes with respect to safety, such as the OSHA (Occupational Safety and Health Association) standards.

Critical Safety Requirements: All tools, machinery, and materials must be inspected before use to determine if they are suitable and fit for the purpose. In confined spaces, special precautions shall be taken to avoid accidents relating to oxygen deficiency, toxic gases, and restricted means of egress.

Increasing safety in the workplace includes making sure workers wear their PPE, which includes hard hats, gloves, protective glasses, and safety harnesses.

Environmental elements are monitored toward the last phase of the installation; weather is the primary factor to be considered because unfavorable weather conditions may affect the fortunes of worker safety or cause equipment to become unstable. Monitoring systems with advanced control, along with smooth communication during installation, will provide better safety and operational effectiveness. Following all the above-stated safety measures will minimize the chances of accidents and promote a safe and smooth installation.

Tools and Resources Needed

Before a project can even be considered successfully executed, it should have all sorts of specialized tools and resources designed specifically to meet the particular requirements of said project. Such crucial tools customarily range from whatever can guarantee correct alignment, for instance, some kind of very precise measure, whether it be laser levels, theodolites, or total stations. Next in importance is the availability of hand tools throughout the duration, from torque wrenches to pliers, screwdrivers, etc., along with power tools that prepare you to undertake harder installations, from drills to lifts.

Digital Systems

Building Information Modelling (BIM) and Computer-Aided Design (CAD) spell relief in planning and implementation. They provide extremely accurate visualization and detailed schematics to reduce the chance of errors. Resource management platforms would be required for tracking equipment usage, allocation of manpower, and time-frame adherence.

Safety Equipment

Harnesses, hard hats, gloves, and fall arrest systems should be set in place to decrease the number of injuries and meet compliance with the industry standards. And even with safety, with precise alternatives such as drones fitted with HD cameras that can be used for surveying or inspecting hard-to-reach areas.

Knowledge of manuals for operation, maintenance, and codes is of equal importance to inform decision-making processes and abide by industry expectations. Ultimately, these technologies are combined with transparent project-tracking systems to achieve maximum performance with minimum inefficiency.

Maintenance and Best Practices

Regular Inspections and Preventive Measures

Having regular inspections and preventative maintenance is important to maintain the proper operation and, in turn, prolong the useful life of the equipment and systems. Establishing an inspection protocol is a must, including checklists specific to each equipment. Such checklists should include criteria for assessing the equipment’s performance, allowable limits of wear, and conditions that merit further investigations or repairs.

Advanced Techniques: Using predictive analytics, machine learning algorithms, and real-time monitoring systems could greatly increase the chances of discovering a possible failure. Vibration analysis, for instance, and thermal imaging are methods usually employed to detect the beginning stages of mechanical or electrical technician failures.

And, once the machines are installed, maintenance shall be executed following the manufacturer’s recommendation; otherwise, voiding the warranty and a reduction in operational performance might happen.

Since organizations are small-time operations, practically every time unplanned downtime crops up, repair costs and other problems increase while critical assets lose their useful life. The firm should maintain an up-to-date documentation record of the findings and inspection reports, and maintenance operations to appropriately chart trends and prove compliance with regulations.

Corrosion Management Techniques

Effective corrosion management passes through a multiplicity of mechanisms aimed at prevention, tracking, and application of new materials. One common method of gild protection involves protective coatings and linings comprising epoxy, polyurethane, or zinc-based materials to block moisture and oxygen from making contact with the metal surface. Applying cathodic protection system methods brings protection from corrosion, with the impedance current method and the sacrificial anode method being some of the most popular.

Environmental Control

Dehumidification, temperature control, and ventilation act together to minimize the exposure of materials to corrosion agents such as humidity, salts, and pollutants.

Chemical Inhibitors

Corrosion inhibitors may be applied, which are chemicals that interfere with the reaction mechanism and slow down the degradation of metals in the industrial environment.

Advanced Materials

Development of corrosion-resistant alloys, such as stainless steels and nickel-based superalloys, assures employment in the most aggressive of environments.

Advanced analytical techniques allow for the early detection of corrosion and accurate material integrity monitoring: ultrasonic testing, radiography, magnetic picking, etc. The inversion of corrosion management has come about through the aid of machine learning algorithms, with predictive analytics allowing companies to foretell probable failures from historical data and current conditions.

Integrated corrosion management not only helps earn the service life of the assets but also helps demonstrate conformity to industry standards such as ISO 12944 and NACE SP0169 so that operations are safe and cost-effective.

Identifying Common Issues: Leaks and Blockages

Leaks and blockages are two of the most common problems encountered in fluid transport and containment systems. Leaks may be due to defects in the materials, poor installation, or slow deterioration by environmental factors such as corrosion, thermal stress, or mechanical fatigue. Of serious nature are leaks because they may lead to environmental hazards, safety hazards, and economic issues, owing to downtime and wastage of valuable resources.

Blockage Causes: Clogging is mainly caused by the accumulation of debris, sedimentation, or corrosion products within pipelines or conduits. These blockages considerably obstruct flow rates, increase system pressure, and, in extreme cases, can bring the operation to a halt.

Zone zone diagnostics tools, such as ultrasonic testing and internal inspection devices like pigging systems or fiber-optic technologies, become paramount to mitigating these issues.

A data-driven approach based on real-time monitoring, together with the use of predictive maintenance algorithms, will allow for a proactive detection and resolution of leaks and blockages. The integration of modern technologies such as IoT sensors and machine-learning algorithms will bestow industries with the power to keep operational efficiency intact, reduce risks, and comply with ever-stringent regulatory regimes.

Advancements in Pipe System Technology

Smart Monitoring Systems

Smart monitoring systems are one of the most critical advances in pipeline technology to date, for they allow precise acquisition and analysis of data on demand. IoT-enabled sensors are embedded within the pipeline infrastructure by smart monitoring systems to monitor variables such as pressure, flow rate, and temperature continuously. Such systems would detect any anomaly so early that major disruptions caused by leaks or blockages could be avoided.

Meanwhile, the collected data are subject to analysis using machine learning algorithms that allow them to develop a predictive maintenance approach. For instance, sensor reading patterns can be intertwined with historical data to predict system failure before it actually occurs. Certain industries, such as energy distribution and water management, are critical enough that any downtime results in heavy financial terms and environmental consequences, making this capability very valuable.

Cloud Integration Benefits: The fusion of analytics tools and cloud-based platforms enriches the features of a smart monitoring system. Cloud computing system collects the sensor data raised from numerous operational sites so that they can be overseen and deliberated centrally.

Such a system can therefore be relied upon for conducting automatic routine inspections and presenting thorough diagnostic reports, and it can, thus, enhance operational efficiency and reduce maintenance costs. In other words, smart monitoring systems are among the facilitators made for modern-day resilient pipeline networks.

Eco-Friendly Materials for Pipe Systems

The use of eco-friendly materials in pipe systems is one of the strategic solutions that reduces the impact on the environment while remaining durable and efficient. HDPE or high-density polyethylene and PEX or cross-linked polyethylene are materials that are gaining more preference because they can be recycled, are non-toxic, and, most importantly, resist corrosion, thus increasing the life cycles of the systems and reducing waste. HDPE, for example, possesses superior chemical resistance and uses less energy to produce when compared to traditional materials such as steel or concrete.

| Material Type | Key Benefits | Environmental Impact |

|---|---|---|

| HDPE | Superior chemical resistance, energy-efficient production | Fully recyclable, reduced carbon footprint |

| PEX | Non-toxic, corrosion-resistant, extended lifecycle | Reduces waste generation, sustainable production |

| Bio-based Composites | Natural fiber reinforcement, renewable resins | Reduces non-renewable resource depletion |

Besides, bio-based composites, made from natural fibers or renewable resins, are now emerging as a sustainable alternative for piping applications. These materials reduce the depletion of non-renewable resources and are generally associated with a lesser negative environmental effect in terms of greenhouse gases emitted through their lifecycle. Another engineering advance saw the development of thermoplastics reinforced with recycled content, thus having the dual advantage of performance and a reduced carbon footprint.

Other green alternatives for coatings include epoxy resins with low VOC (volatile organic compounds) levels. This can enhance pipeline safety and longevity by offsetting yellowing and leakage while reducing maintenance excursions. Adoption of these advanced materials will therefore support the global objective of sustainability while also assisting in meeting regulatory standards for environmental compliance in pipeline infrastructure.

Innovations Enhancing Durability and Sustainability

Innovations relate to studies in the material realm and engineering that could benefit industries in durability and sustainability. For instance, the introduction of composite coatings and advanced polymers has altered the conventional standards of conventional infrastructure. These materials provide resistance to environmental factors such as corrosion, moisture intrusion, and UV radiation. Assets like pipelines, bridges, and industrial machinery thus acquire much longer service life than they would need to be repaired with the consumption of resources.

Self-Healing Technology: Another key development involves self-healing materials. These are capable of healing by themselves microscopic cracks or damages in the very early stages so that structural weaknesses do not set in and finish with catastrophic failures.

Industries, upon incorporation of these materials into existing systems, can save on maintenance costs and reduce waste resulting from premature component replacements. In short, I view this as a breakthrough because it meets the need for resilience and environmental stewardship at the same time.

In addition to this, new materials are aided further by digital innovations. The employed IoT (Internet of Things)-based sensors and real-time monitoring systems track precise wear-and-tear conditions into some form of critical infrastructure. Hence, this serves predictive maintenance in time while avoiding unnecessary maintenance and saving resources. Hence, the confluence of advanced materials, self-healing, and intelligent monitoring systems should be considered as the core for durability and sustainability in engineering practices today.

Case Studies and Real-World Examples

Successful Pipe System Implementations

Polyethylene Municipal Systems

The adoption of polyethylene piping systems in municipal water distribution networks. The polyethylene pipe is also very durable, being resistant to corrosion and capable of withstanding ground movements due to its flexibility. Several cities around the world have recorded a huge reduction in water loss through leakage after replacing older infrastructure with PE systems. The pipes also have longer lifecycle advantages, with their service life ranging from 50-100 years, thereby cutting down the replacement cost in the long run.

Smart Pipeline Monitoring

The adoption of smart monitoring systems for pipelines represents yet another intriguing case. Sensor-laden pipelines, together with sophisticated data analytics, have changed the means by which companies trace anomalies, whether pressure drops, corrosion, or possible breaches. Real-time monitoring for temperature and strain changes in the pipeline using fiber optic sensors has by far elevated response time to any impending failures. This smart approach serves to foster operational efficiencies while also mitigating environmental hazards due to spillage.

Ductile Iron Urban Systems

The use of ductile iron pipes in urban sewerage portrays the vital equilibrium between strength and sustainability. Ductile iron is a mixture of strength and recyclability. It is capable of withstanding heavy loads and high internal pressures. Cities that have invested in the upgrading of ductile iron systems have, however, noted a sharp enhancement in the sewage handling capacity of the systems, thereby reducing blockage occurrences and overflows.

Key Takeaway: These case studies bring out the advanced materials and intelligent solutions applied in piping systems that answer challenges of the 21st-century infrastructure and provide a base for future sustainability. By choosing suitable materials and integrating technology-based monitoring systems, industries and municipal bodies improve not only operational efficiency but also environmental stewardship.

Industry Trends Impacting Pipe Systems

The pipe systems industry is witnessing a dynamic change in its functioning due to advances in technology, changes in laws, and an ever-increasingly tight sustainability focus. One such significant trend is the use of smart piping technology incorporating IoT-enabled sensors for monitoring pressure, flow rate, and temperature. These systems are for enabling predictive maintenance and thus avoiding failures and causing downtime.

- 🔧 Smart Technology Integration: IoT-enabled sensors for real-time monitoring of pressure, flow rate, and temperature

- 🌱 Sustainable Materials: Increasing demand for corrosion-resistant, lightweight materials such as PVC, HDPE, and PEX

- 📋 Regulatory Compliance: Laws on water quality and safety are driving infrastructure upgrades

- 🏙️ Urbanization Impact: Focus on scalable solutions for high-demand water supply and wastewater management

The second trend is the ever-increasing consideration for sustainable materials. Of late, the demand for corrosion-resistant, light-weight materials such as PVC, HDPE, and PEX has risen. These materials demand minimal environmental intervention in their presence. The scope of further reduction in the carbon footprint of piping systems can be achieved through innovations in bioplastics and composite materials.

Furthermore, laws on water quality and safety, e.g., lead-free materials standards, are incentivizing operators to upgrade old infrastructure. Already, these sets of regulations do encourage investments in pipe-integrated advanced treatment systems that ensure compliance and improve public health outcomes.

Urbanization and infrastructure modernization also have their influence on the design and sizing of pipe systems. Developers are giving attention to scalable solutions capable of handling high demand from water supply and efficient wastewater management, integrating data analytics on resource utilization and infrastructure planning. These trends together somewhat change the pipe systems industry landscape, giving it the potential for innovation-driven growth and stronger performance.

Expert Insights and Future Outlook

The pipe systems industry is undergoing a pivotal transformation driven by advancements in materials science, automation, and IoT integration. Pipe networks of the future are envisioned by experts to increasingly make use of smart sensors that measure flow rates, pressure, or suspected leakage in real time. The deployment of these technologies leads to not only operational efficiency but also infrastructure durability through predictive maintenance.

Sustainability is given further importance in the choice of materials, with developers focusing on those that are recyclable and resistant to corrosion, such as HDPE and PEX. Regulatory frameworks on water conservation and carbon footprint reduction are pushing towards implementing energy-efficient manufacturing processes, as well.

Growth Opportunities: Emerging markets represent major opportunities for growth-especially in countries undergoing rapid urbanization and industrialization. The need for novel pipe solutions is expected to be driven by investments in improvements in water distribution and wastewater management systems across the Asia-Pacific and Sub-Saharan Africa.

The integration of AI and machine learning in planning and infrastructure is expected to streamline resource allocation and network optimization. In addition to cost savings, these improvements contribute to building resilience when addressing climate change issues, such as flooding or drought. Industry players see cross-sector cooperation, where engineering, data science, and environmental management converge, as establishing an environment that would be critical to walk through the era of modernization.

References

-

Noise Sources and Transmission in Piping Systems

Published by ASME (American Society of Mechanical Engineers), this paper discusses noise sources, transmission paths, and modeling procedures in fluid-filled pipe systems. -

Fluid-Structure Interaction in Liquid-Filled Pipe Systems: A Review

This review explores fluid-structure interaction (FSI) in pipe systems, including practical excitation sources and system dynamics. -

Survey Report on Structural Design of Piping Systems and Components

A report from OSTI (Office of Scientific and Technical Information) focusing on codes and standards for nuclear plant piping systems. -

Corrosion of Pipelines in Urban Water Systems

Published in ScienceDirect, this paper analyzes the current research status and future trends in urban water pipeline corrosion. -

Pipes Conveying Fluid: A Model Dynamical Problem

This paper reviews the dynamics of fluid-conveying pipes and provides an authoritative discussion on the system’s continuous dynamics. - Click here to read more.

Frequently Asked Questions (FAQ)

Q: What do we call pipe systems?

A: The pipe systems are pipe networks that transport fluids, gases, or slurries from one place to another. These systems are very much needed for many purposes, including the supply of drinking water, drainage, and industrial processes. The design of such systems has to take into account aspects of safety and efficiency.

Q: What materials are commonly used in pipe systems?

A: Normally, steel piping, thermoplastic materials, and other corrosion-resistant materials are used in pipe systems. Steel pipes are much preferred in industrial applications for resistance, whereas, for the sprinkler system, thermoplastic materials are desirable as they are lightweight and flexible. Temperature change occurs in the presence of temperature fluctuations. This phenomenon can affect the integrity of the system, thus necessitating the installation of expansion joints or some other engineering solutions to accommodate changes in length and prevent damage.

Q: Why is corrosion a concern in pipe systems?

A: Corrosion can drastically reduce the lifespan and effectiveness of pipe systems. Corrosion happens when pipes come in contact with moisture and chemicals, whereby the deterioration slowly progresses. Usage of corrosion-proof materials with timely maintenance can help curb this issue beforehand to ensure functionality in the long run.

Q: What role do pipe systems play in sprinkler systems?

A: Pipe systems serve as a conduit for the water that gets dispersed in the affected areas of fire protection by sprinkler systems. The design and construction of the pipe systems must at least ensure that the pressure and flow are adequate enough to extinguish a fire, considering the industry-best standards of safety and reliability.

Q: How is a pipe system constructed in relation to schools and corporate buildings?

A: Pipe systems for schools and corporate facilities are constructed worldwide through careful planning processes and community registration. Engineers have to consider certain requirements of the facility, such as empty water or water for cleansing and safe drainage systems, to be able to design a safe and efficient pipe system that sustains the environmental demands.

Q: How are regional aspects important in pipe systems?

A: And hence, regional aspects intervene in the pipe system designs decided upon or materials chosen based on their environmental conditions, regulations, and availability of resources. Thus, engineers have to understand these regional considerations to put across an effective and sustainable solution pertinent to local needs.

Q: How is safety provided for pipe system installations by the companies?

A: Companies ensure the safety of their pipe systems through comprehensive planning, traditional inspections, and the scrupulous application of technical standards. Leveraging state-of-the-art technologies and materials, they minimize environmental risks from leakages, failures, and any hazards that could arise.

Q: What are the advantages of steel pipe in industrial applications?

A: Steel pipe imparts high strength, durability, and high-pressure resistivity in industrial applications. The power to resist high pressure makes it possible to create a really corrupt environment for several industries that may be trusted to offer reliable solutions for fluid and gas conveying.

Ready to Implement Advanced Pipe Systems?

This comprehensive guide provides the foundation you need to understand, design, and maintain modern pipe systems that meet today’s demanding infrastructure requirements.