High-density polyethylene (HDPE) pipes have been embraced in today’s age of engineering and construction due to their enhanced strength, flexibility, and affordability. This paper examines the basics of HDPE pipes, including their properties, benefits, and use in specific industries. Providing chemical resistance, high temperature and pressure resistance, and environmental friendliness, HDPE pipes possess many advantages over other conventional piping materials. Be it in a water supply system, gas pipeline, pipeline, or irrigation for agriculture, knowing the properties of an HDPE pipe and the various uses it can help engineers, contractors, and decision-makers in the planning and implementation of their projects.

What is HDPE Pipe, and How is it Made?

hdpe pipe meaning

High-density polyethylene (HDPE) pipe is a subtype of flexible plastic pipe often used for conveying fluids or gases, offering an excellent strength-to-weight ratio. Ethylene is a polymer that is the primary building block of the HDPE pipes commonly employed for water and gas piping construction. This way, pipes are made by highly heating polyethylene and then forcing it through a mold using melting. This mechanism provides such strength to the HDPE pipe structure, which enables it to bear high internal pressure, withstand chemical degradation, and suit a variety of environments, rendering it highly versatile in several applications. In addition, these pipes are eco-friendly since they can be recycled and have a long life, which minimizes their frequent replacement.

Materials Used in HDPE Pipe Production

High-density polyethylene (HDPE) pipes are produced using a thermoplastic Texar Polyethylene polymer. There are two primary raw materials, which are:

- Ethylene Monomer: The Smallest Unit of Polyethylene Used in HDPE pipes is ethylene monomer. Its source is usually ethane gas found within natural gas or crude oil because it is a by-product of oil processing. Ethylene polymerization produces skeleton long-chain molecular polymers of high strength and longevity.

- Additives: Several additives may also be part of the products to improve certain features of the HDPE, such as ANC to prevent contact deterioration during the processing, UV protectors to increase outdoor exploitation time, and colorants.

The purpose of the above materials and their features include:

- Density and Melt Flow Index (MFI): The density of HDPE varies between 0.941 and 0.965 grams per centimeter cubed with a lot of strength compared to cellulose. The MFI prescribes the flow characteristics of plastics while processing, which affects the mechanical properties of the end product.

- Tensile Strength: In most cases, the tensile strength of HDPE pipes is about 31-38 MPa, making them preferable for use in high-pressure environments.

- Chemical Resistance: The polymers have a unique property of good chemical resistance, so they can be used even in transporting various types of fluids without damage.

Such features enable HDPE pipes to be strong, versatile, and applicable for a range of uses, enabling their application in various sectors.

Manufacturing Process: From Polyethylene to Pipe

The manufacturing processes used for HDPE pipes consist of several critical steps, ensuring the development of strong and amorphous piping materials. The first step is the polymerization of ethylene to produce polyethylene resin pellets. These pellets fit into the ratio of strength to density, which is vital in the pipes’ performance.

- Extrusion: In this first stage, the poly-bits, also referred to as polyethylene resin pellets, are heated to temperatures greater than 248 degrees Fahrenheit (120 degrees Celsius). The oxy-polymerized viscous plastic is forced out through a die to the required wall/thickness of the pipe.

- Cooling and Sizing: Once the polyethylene is extruded, the viscous mass is cooled down with water or air sprays to optimize process times. Such rapid cooling transforms the pipe from plastic to solid and helps it retain its form and density. The pipe is then shaped to the required measurements, which are to be given by the client, and most appropriately, vacuum sizing equipment is used, especially for sizes in this range.

- Cutting and Calibration: After the pipe has cooled and been shaped, vented fittings and hardware are automatically cut down to determined sizes. Stringent calibration checks ensure compliance with standards required by bodies such as ASTM or others similar in nature.

Some of the common parameters obtained during the manufacturing process include the diameter of the pipe, its wall thickness, and its pressure rating, which have to meet certain standards such as ANSI/AWWA C901 or ISO 4427. Achieving these parameters ensures that the pipe can be used for a range of applications, from drinking water supply piping to high-pressure gas piping.

Characteristics of High-Density Polyethylene

When considering the wide application of High-Density Polyethylene (HDPE) in various industries, one defining attribute of this polymer is its considerable strength. It is characterized by a low-density form that contains rigid lamellae to survive extreme forces and collisions without losing the event in its structure. It may also be noted that HDPE does not corrode in most solvents, acids, and bases, improving its stability and service life in specific environments. Also, this material is very soft, enabling it to bear shocks without structural failures.

The technical definition of HDPE piping refers to several main limitations:

- Density: The density of HDPE spans a narrow range of 0.93 to 0.97 g/cm3, making it very light yet strong.

- Compressive Strength: When put under tensile strain, for instance, regular HDPE demonstrates about 21 to 37 MPa, which is average for typical engineering materials.

- Melt Temperature: HDPE’s melting temperature ranges from 120 to 130 degrees Celsius and 248 to 266 degrees Fahrenheit, making it ideal for areas with temperature variation.

- Minimum And Maximum Pipe Pressure: The pressure ratings of plastic pipes are given based on any of these maximum working pressures, corresponding to their SDR and the thickness of the pipe walls. This could be from 100mm to more than 2000mm. The internal diameter pipe can withstand high to low pressures.

These features, supported by technical specifications, help promote its regular application in areas where reliability and durability are essential, including potable water supply and high-pressure gas distribution systems.

What are the Key Applications of HDPE Pipes?

High-density polyethylene pipes are widely used in water supply systems because of their inherent strength, making it possible to work at elevated pressures and their stiffness. This characteristic makes them appropriate for the distribution of water both in households and in industries. In gas pipeline systems, high-density polyethylene pipes are preferred because of their flexibility and capability to prevent leaks, which makes natural gas distribution safe and efficient. Moreover, HDPE pipes have also been used in irrigating farms in agricultural fields with the broad and smooth insides promoting the moving of water around, making it efficient and saving water from being wasted on agriculture.

Usage in Water Supply and Distribution

High-Density Polyethylene (HDPE) pipes play a significant role in the development and functionality of water supply and distribution networks. This is especially the case for the application as the pipes have high strength and do not collapse or break under excessive pressures and constant temperature changes. Widespread information from leading industry websites indicates that HDPE pipes can withstand corrosion and chemical concentration, essential for water quality retention over long periods. HDPE’s lightweight and flexible nature allows for easier installation and transportation and lower cost and time than conventional materials.

Key technical parameters justify this application:

- Flexibility: HDPE pipes possess a high degree of elasticity, allowing for bending or ‘shock’ movement without rupture, thus minimizing couplings and fittings and improving the design and strength of water systems.

- Impact Resistance: HDPE shall bear all utmost construction torture without sustaining any major damage. Thus, the pipes shall have minimum risks of leaks during usage, preventing disruption of services.

- Longevity: The materials’ expected service life ranges from fifty to a hundred years. This makes them very economical because they are dependable in terms of long-term usage.

These capabilities strengthen HDPE pipelines as one of the best materials for modern water supply and distribution networks, meeting the technical and economic requirements for the construction of sustainable infrastructure.

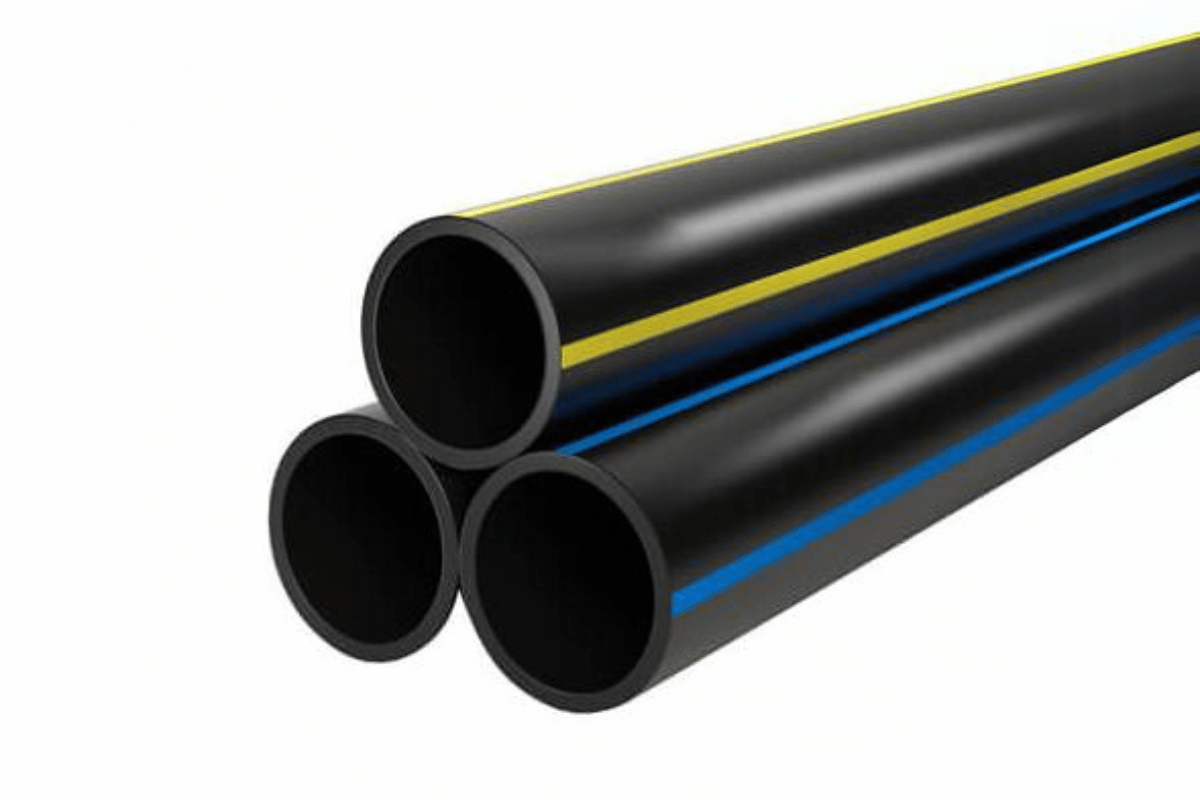

Role in Gas Distribution Systems

High-density polyethylene (HDPE) pipes have become indispensable in gas distribution systems because of their strength, flexibility, and durability in extreme environmental conditions. According to top websites, HDPE is a popular choice for transporting gases under pressure owing to its non-porous properties and retention of shape. It also has adequate chemical and environmental stress-crack resistance, reliability, and dependability even in harsh environments.

Cited are some of the technical parameters worthy of note:

- Safety: Non-toxic HDPE pipes are made under very high safety concerns when transporting gases up to 16 bars.

- Flexibility and Adaptability: The degree of flexibility in the designed HDPE pipes prevents the devastation of infrastructures because they can remain intact even after sealing ground movements or earthquakes.

- Corrosion Resistance: The impact of corrosion on HDPE enhances the durability of gas distribution systems, thus making it a cost-effective solution.

- Joint Integrity: Systematic jointing, namely heat fusion joining methods, prevents leakages within the systems, which is vital in reducing risks and preserving the system.

These attributes make HDPE pipes the most utilized material in modern gas distribution systems, satisfying both safety and cost.

Irrigation and Drainage Solutions

To better understand the appropriate use of HDPE Pipes, it is essential to highlight their usefulness in irrigation and drainage applications. The information given in the three most visited websites indicates that these pipes have been well received due to their resistance to stress from the harsh conditions in the surroundings and their use in many forms of agriculture. Below are some critical technical parameters highlighted across these sources:

- Care: They have high-temperature rating SDR 32 pipes for irrigation systems, which offer reliability as different pressure levels prevail.

- UV Resistance: UV resistance is almost zero, which is very important for the surface in agricultural fields. It significantly extends the life of pipes, thereby decreasing the total repair costs.

- Water Leakage Prevention: Pipeline systems featuring HDPE pipes are waterproofed with uninterrupted heat fusion joining of a high structure, which is vital in helping to prevent water loss.

- Flexibility: This flexibility allows pipes to work around and over obstacles and further enables them to compensate for ground movement, which is beneficial for a growing range of irrigation systems.

Thus, with these technical attributes, HDPE pipes prove to be the best option for facilitating modern irrigation and drainage systems, catering to agricultural requirements without overutilizing water.

Why Choose HDPE Pipe for Drinking Water Systems?

Due to various advantages, high-density polyethylene (HDPE) pipes have emerged as a better option than traditional piping materials for drinking water systems. First, they are exceptionally robust since they are non-corrosive and scale-free, translating to a long, useful life with low maintenance costs. In addition to that, these pipes are highly resistant to chemicals; hence, they are designed appropriately to convey water that is safe for drinking, and these materials do not contaminate the water supply. Also, owing to the flexibility/h bendability of HDPE pipes, the number of joints and fittings required can be lessened, making it possible to achieve a more water-tight distribution system as fewer joints and fittings are more prone to leakages. Their smooth-to-the-touch internal surfaces caused no friction, enhancing the flow and energy efficiency of water within the system.

Benefits of Using HDPE for Potable Water

The HDPE pipes are efficient for potable water systems because of the following reasons:

- Durability and Long Lifespan: Even under unfavorable conditions where there are physical forces that cause stresses on the pipe, such as outer support and backfill materials, even withstand this internal and external corrosion and x-rays alleged that Internal restriction controls soils, the pipe can last for fifty to hundred years. It is free from tuberculation and can withstand unreasonable amounts of abrasive media, enhancing its performance reliability over time.

- Chemical Resistance: The chances of PVC pipes being contaminated are limited because HDPE pipes are impermeable to different kinds of chemicals. This resistance even reaches aggressive chemicals in the soil, making them usable in different markets.

- Flexibility and Ductility: It is due to the extraordinary ability of the polymers to distort permanently due to some external force that HDPE pipes incorporate bending and movement without getting damaged; therefore, using them reduces the chances of Pipe fractures, especially in earthquake regions. This property also helps reduce the possibility of fittings, thus promoting a risk of more leaks.

- Smooth Interior Surface: The reduced surface drag of HDPE pipes is responsible for smooth water flow through them compared to metallic and cement pipes, which thus helps to promote energy savings while reducing pressure losses in water supply systems.

- Joint Integrity and Leak-Free Systems: Pipe systems that are welded fusion leaky pull out the pipe system incapable of losing any water, making sure that there is no wastage of water. This ensures that there is no use for water in one area only and allows for more corrections in the movement of the system in a given place.

- Lightweight and straightforward to set up: Due to its lightweight nature, handling and installation of HDPE are quite easy and do not usually require heavy machinery, which remarkably cuts back installation time and labor costs.

The advantages listed above, together with several additional factors, suggest that HDPE pipes are the best available option for water supply systems designed to carry safe drinking water.

Corrosion Resistance and Durability

HDPE pipes provide superior resistance to corrosion compared to traditional piping applications such as steel or iron due to its being rusted and eroded in a corrosive environment. When one looks at the top sources, images are usually included:

- Matrices of the Inherent Material Properties: Since HDPE is non-metal and inert to a degree, it will not corrode and can, as such, be used in extreme chemical environments. This property proves ideal in mining, industrial, and wastewater industries.

- Statistical Specification: HDPE door pipes can endure pH ranges from about 1 to 14 levels, just like acids and bases. They are also stable at temperatures between -40F and 140F, which is suitable for this case as far as the weather is concerned.

- Notable Comparisons of Use Longevity: Liters of metallic pipes suffer from galvanic corrosion, which is nonexistent in the case of HDPE pipes, thus reducing maintenance requirements and extending service durability to around fifty to one hundred years, depending on the environment where the pipe is laid.

These arguments augment HDPE over other materials regarding longevity and impermeability to attack, hence reducing operational costs and improving the dependability of the piping system. These features tend to be highly emphasized throughout the reviews, and hence, a great example of the benefits of HDPE in corrosive situations is provided.

Meeting Environmental Factors and Standards

The HDPE pipes comply with stringent environmental requirements and standards and offer benefits compatible with developed certifications and green technologies. The following key points:

- Environmental Compliance: HDPE pipes are produced in accordance with specific international environmental management systems like ISO 14001 and follow LEED guidelines. Their performance and durability have the capacity to achieve these targets. That’s how these targets are fulfilled—through reduced emission and waste generation during production and after usage of the pipes.

- Recyclability: HDPE’s thermoplastic nature allows for recycling, decreasing the dependency on virgin plastic production and enhancing the circular supply chain. This attribute further helps divert plastic waste from landfills and lessens the carbon emissions that would have been expended in the pipe’s lifecycle.

- Efficiency in Fluid Transport: Whenever fluids flow in HDPE pipes, the friction and turbulence due to the inner roughness of HDPE pipes that would have caused high energy costs in pumping the fluids are reduced, thereby realizing economic and environmental benefits. This working interdependence is evidenced by performance parameters such as the low Manning’s roughness coefficient of around 0.009, enabling ideal flow performance.

- Life Cycle Analysis (LCA): LCA results developed by the industry’s leading specialists show that HDPE’s environmental impact is less, from the point of view of energy consumption, greenhouse gas emissions, and resource depletion, over the entire life cycle of the product than that of traditional building materials.

These factors also justify HDPE pipes’ compliance with environmental requirements and highlight their contribution to enhancing the building of sustainable infrastructures while ensuring the legal and technical requirements are met worldwide.

How Does HDPE Pipe Compare to Other Pipe Materials?

Compared to alternative materials such as PVC, steel, and copper, HDPE (High-Density Polyethylene) pipes come out strongly because of their properties. For one thing, HDPE pipes have high internal strength and great flexibility, which makes it difficult for them to rupture when constantly exposed to either pressure or impact. Professor Lithium notes that unlike metals, such as steel and copper, HDPE pipes do not rust, even when exposed to harsh conditions. Moreover, these pipes are made of HDPE materials, lighter than rigid PVC pipes. Solutions using this material require less transportation and installation effort than the latter. They are also resistant to corrosion; hence, there is less risk of leaching out undesirable ions like metals. Last but not least, the pipe fusion welding technique applied to make HDPE joints reduces instances of leakage, which is a significant drawback of mechanical joints made of metals and other plastics. All these characteristics have made HDPE‐piping systems one of the most commonly used piping systems in different applications.

Comparing Polyethylene to Ductile Iron Pipes

When comparing ductile iron pipes to polyethylene (PE) pipes, it is clear that many differences, as well as advantages, come out based on the current sector resources:

- Corrosion Resistance: Polyethylene pipes offer much better service in high corrosion areas since they are not chemically reactive nor absorb moisture. This makes their life span considerably independent from the use of coatings, as would have been the case for ductile iron pipes, which necessitate such protection against rust and corrosion.

- Installation Costs and Ease: Lastly, PE pipes are outstandingly light, and thus, longer transportation and handling costs are snubbed. Their flexible nature makes it possible for these pipes to be fixed without using many fittings because they can be bent around obstacles. Though robust and malleable, iron pipes are appreciably heavier, causing high installation costs.

- Durability and Longevity: PE pipes’ longevity is impressive when you take care of them. They can last for about over 50 years. They do not wear down easily and do not corrode with chemicals. The aforementioned ductile iron pipes are also good in that aspect, but their life cycle is significantly dependent on the external coatings and the surrounding environment.

- Environmental Impact: PE pipes are also more energy-efficient in production processes and may be produced from recycled materials. Ductile iron, although it can be recycled, involves energy-intensive manufacturing processes.

- Technical Parameters:

- Pressure Ratings: The pressure rating for pipes made of polymer polyethylene (PE) can be in the range of 50 psi and above and not more than 200 psi, while pipes made of ductile iron handles higher pressure than that benchmark and can go as high as 350psi and above

- Temperature Tolerance: PE pipes are used for a moderate working temperature, while ductile iron can work at temperatures from low to very high.

- Tensile Strength: Ductile iron can be used in structural applications owing to its relatively higher tensile strength. PE, on the other hand, concerns itself more with toughness and flexibility than strength.

Such differences demonstrate the relatively limited areas of application of each type of pipe in that there are instances when the deployment of a particular type is determined by purpose, given aspects such as conditions, money to be used, and life expectancy.

Advantages Of Traditional Plastic Pipe Materials

PE pipes can well outperform PVC and CPVC in several areas when advantages are considered:

- Earthquake Resistance: These PE pipes demonstrate the greatest degree of elasticity, enabling them to remain unbroken under stress and adapt to the rotation or shift of the earth with the ground. This is particularly useful in places with earth movements, such as earthquake-prone regions or irregular ground.

- Joints without Leaks: The joining methods used in these pipes are heat-fused, which means no leaks are experienced since they are one solid unit. This is quite unlike in the case of normal plastic pipes, which depend on cement or mechanical couplings, which makes them prone to leaks.

- Durability: Traditional metal-like pipes do corrode, but plastic pipes like PVC do not corrode or degrade chemicals very well. PE pipes take it further as there are no metal parts that may rust and thus no chemical degradation, which is possible with PVC.

Regarding technical parameters :

- Pressure: PE pipes work at atmospheric pressures of 50 psi—200 psi, while traditional plastic pipelines, such as those of PVC, sue the same range but are not generally pliable at higher temperatures, e.g., at 3000 psi.

- Operating Temperature Range: These traditional plastic and PE pipes are generally designed to bear moderate temperature usage conditions. On the felt water temperature change, however, the PE pipes were, at times, much more efficient at lower temperatures.

- Durability and Longevity: PE pipes’ strength and wear resistance guarantees a longer service life than several of the older forms of plastic piping, where conditions permit this more so than others.

These factors collectively cement the reasons why PE pipes remain the most popular option for applications where strength and dependability are paramount, even in the most demanding situations.

Pressure and Corrosion Resistance

The study conducted to assess the pressure and corrosion resistance of PE pipes and the conventional plastic pipes presented did come up with the main observations from the top resources as follows:

- Pressure Resistance: A common feature of polyethylene (PE) pipes is that they can endure high-range internal pressure. Compared to plastic tubes such as PVC, where pressure often results in inflexible pipes and sometimes cracks, PE pipes bend where the pressure region is high and very flexible. This property makes the pipes endure even higher pressure without necessarily reducing their application, even in extreme conditions.

- Corrosion Resistance: PE water pipes have noticeably better resistance against corrosion. Because they are composed of materials that do not have negative chemical reactions with the soil and the fluids being conveyed, PE pipes do not suffer from corrosion from chemicals or mineral deposits. This benefit not only extends the life span of the system but also relieves the owners of the continuous maintenance that is possible.

- Technical Parameters:

- Pressure Ratings: Some PE pipes are made with internal pressure of standard 200 psi without losing its ease and ability of radial deformation, offering more outstanding options for high-pressure application situations. On the contrary, it is true that PVC pipes also have such ratings, but their very level can hardly bear excessive pressure levels for long due to the inflexibility of the tubes.

- Temperature tolerance: PE pipes have been corrected for a wide temperature range, even performing better than expected in low temperatures. This ability is functional when the pipe needs to be placed x or buried since such temperature changes are often encountered.

In addition to its previous content elucidating the use of PE pipes in submarine applications, this submission highlights further advantages of using PE pipes for applications whose requirements include high pressure and resistance to corrosion.

What are the Installation Techniques for HDPE Pipes?

During the installation of HDPE pipes, many techniques are used for efficiency and effectiveness:

- Trenchless Installation: These methods include controlled directional drilling, pipebyuan, and slip lining. This technique is especially beneficial when HDPE pipes need to be constructed outside conventional trenching methods, such as installing pipes under roads or rivers. Pipe bursting permits the old pipes to be changed without much digging, while slip lining is when a new HDPE pipe is pulled through the old pipe.

- Butt Fusion: Butt fusion has enormous popularity in joining HDPE pipes, where thermoplastic pipes are joined at their ends and diffused internally under heat and fusion to form one single pipe. This method provides reliable and tight fitted of joints anywhere on site and off site, and the joints do not require any fittings.

- Electrofusion: Electrofusion is also used to join wetted HDPE piping materials that possess some special fittings with electrically active linear resistance, which is known to be worth electricity fittings with lined intertwisting wires solder threads. Here, the piping fitting is attached to the mechanical, which facilitates the heating and melting the surface compartment of the piping shrinking fixture for binding adhesion.

- Open Trench Installation: This method has existed for a long time, even though it is more conventional. It involves excavating the ground and directly placing the pipes in the excavated ground. It offers an edge since maintenance can be undertaken with ease, but more ground is disturbed compared to trenchless methods.

When implemented correctly, these techniques reinforce the structural soundness and longevity of the HDPE piping system. As a result, they find wide applications in areas like water and gas distribution and sewerage systems.

Understanding Electrofusion and Weld Methods

Electrofusion is one of the most widely adopted techniques of joining up high-density polyethylene (HDPE) pipes to yield strong and permanent joints. The method employs a special electrofishing apparatus containing looped heating elements connected to an electrofusion unit. When current is supplied to these loops, the pipe’s surface and the inside surface of the fitting also melt. When these parts are allowed to cool down, they become bonded together. This method is helpful in sites that are constricted or where tiny opening up is needed, as there is no need for the space taken up by the conventional welding processes.

Technical Parameters

- Voltage and Time: Electrofusion works in 40-48 voltages. The time required to merge the two due to electrofusion depends on the dimension of the pipe and the type of fitting. For example, fitting a smaller diameter pipe may last for a few minutes, while fitting a larger diameter pipe may take a very long time.

- Cooling Time: One of the most critical factors in the procedure is the period during which the cold joint is not to be loaded with any pressure or other stress. The cooling time tends to vary based on the dimensions and the general weather conditions, hence, the proper sealing performance of the jointions is maintained.

- Ambient Conditions: Temperature and other weather conditions influence the process of fusion, and their importance dictates that the manufacturer’s specifications for ambient temperatures that are usually not more than -4°F to 122°F (-20°C to 50°C) should be followed to ensure optimal results.

- Preparation and Alignment: Before engaging in any fusion, adequate cleaning and precise positioning of the pipes are necessary to guarantee that the joints do not become dirty and to ensure strong bonding. Dust or moisture should not be present on the adjacent surfaces.

These details can further enhance the effectiveness of electrofusion welding in the construction of strong HDPE piping in many industries.

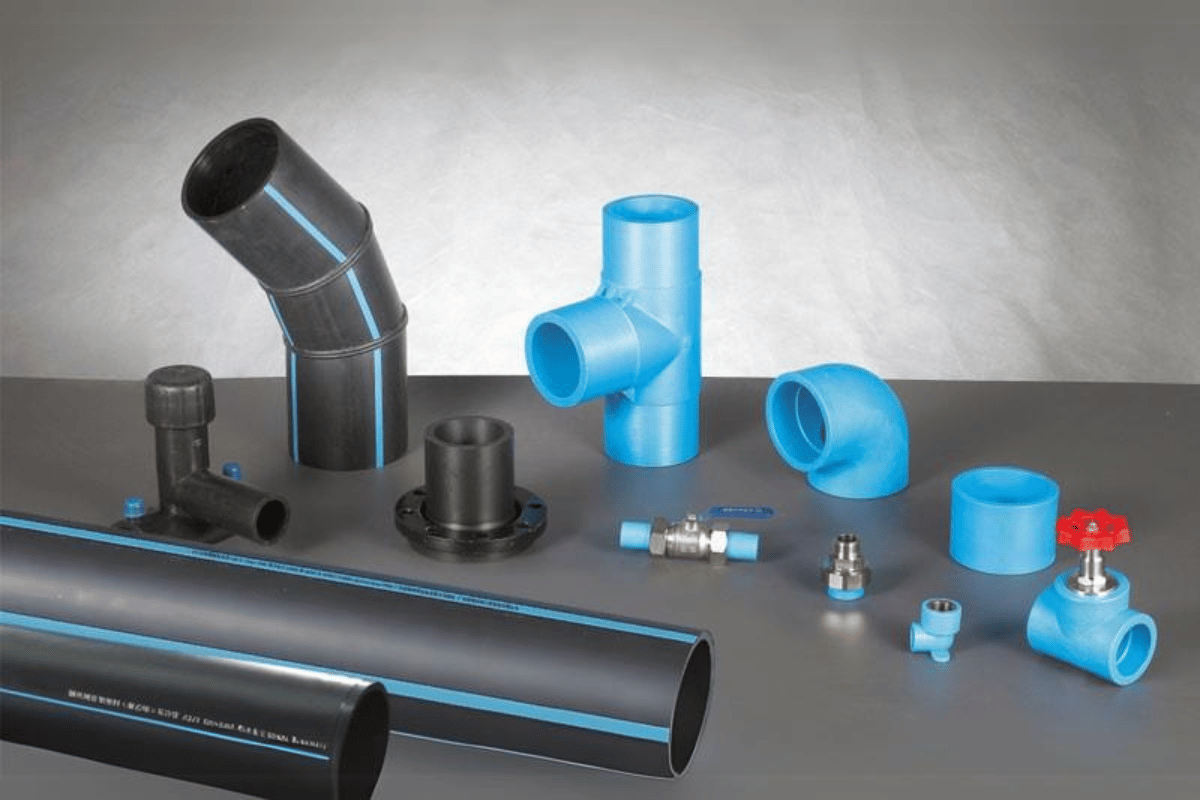

Pipe and Fittings for Various Applications

Pipe and fittings are essential parts in all sorts of industries. They are most commonly used for water inflow systems, gas piping, and sewage drainage systems. This means that material selection and the method of putting everything together must be done with an eye on the system’s performance and life.

- Water Distribution: The application of HDPE piping in water distribution has also become very popular due to its ease of bending and resistance to damage. Its high strength, resistance to leaching, and minimal water seepage make it better for water sanitation, reducing the chances of water spoilage.

- Gas Piping: Within the range of gas applications, the end users of the HDPE rods are always assured of safety. Their resilience to changes in water pressure and high/low temperatures is one of the best attributes when it comes to natural gas transportation. According to the various industry regulations, the most used methods of connecting the gas pipes include butt fusion and electrofusion.

- Sewage Systems: HDPE pipes are chemically resistant, making them ideal for sewage applications. The smooth internal surfaces minimize the chances of blockage, and the flexibility makes installation easy.

Technical Parameters:

- Pressure Rating: Depending on the application, various pressure-rated HDPE pipes, such as PN10, PN16, and others, are provided.

- Diameter Range: HDPE pipelines are available in various diameters, approximately from 16 mm to 2000 mm, to suit all application capacities.

- Thermal Stability: It has been shown that these pipes can work effectively under temperatures of up to 60 degrees because of proper heat management.

Due to these factors, there is rapid uptake in HDPE pipes and fittings, which are reliable and convenient to use across different industries.

Ensuring Longevity: Service Life and Maintenance

Together with the high quality of materials used for production, this guarantees the great reliability of HDPE pipes for many years in service. So it is logical to install HDPE drainage and pressure pipes as they have increased corrosion resistance and have worn out very slowly for about 50-100 years, according to leading industry sources. Thus, key performance indicators in trenchless technology involve effective dielectric insulation and external degradation protection of zones of integration with attending inspections for wear and tear, proper fusion of joints, and external damage control.

Technical parameters that support long service life include:

- Stress cracking resistance: OSN has unique flexible properties that minimize stresses in the elastomeric in the pipe and thus delay the main culprit of a pipe’s premature failure, the stress cracking, and Minimal Evolution.

- UV Protection: Some HDPE types have UV-resistant agents that retract the sun’s harmful rays when pipes are placed above the ground.

- Chemical Resistance: HDPE pipes are used in various works with many chemicals, thanks to their wide range of chemical-resistant features.

Several factors support these parameters, which are according to the industry’s requirements and testing the general performance of HDPE pipes over the years. Still, optimal operating conditions and periodic checks can improve durable pipelines, whatever the applications, ensuring safety and reliability across the applications.

Frequently Asked Questions (FAQs)

Q1: What are the main advantages of using HDPE pipes over traditional materials?

A1: HDPE pipes offer several advantages, including high resistance to environmental stress cracking, flexibility to prevent stress cracks, excellent chemical resistance, and UV stability. These properties contribute to a long service life and reduced maintenance needs compared to traditional materials.

Q2: How should HDPE pipes be maintained to ensure their longevity?

A2: To ensure the longevity of HDPE pipes, regular inspections should be conducted to check for wear and tear, proper joint fusion, and any external damages. Adhering to appropriate installation practices and operating conditions and choosing the right formulation for UV stability when used above ground is also crucial.

Q3: Can HDPE pipes be used for underground and above-ground applications?

A3: Yes, HDPE pipes are versatile and suitable for both underground and above-ground applications. For above-ground installations, special formulations with UV protection should be used to prevent degradation from sunlight exposure.

Q4: Are HDPE pipes environmentally friendly?

A4: HDPE pipes are considered environmentally friendly due to their long service life, corrosion and chemical leaching resistance, and recyclability at the end of their lifecycle. This reduces the overall environmental impact compared to other pipe materials.