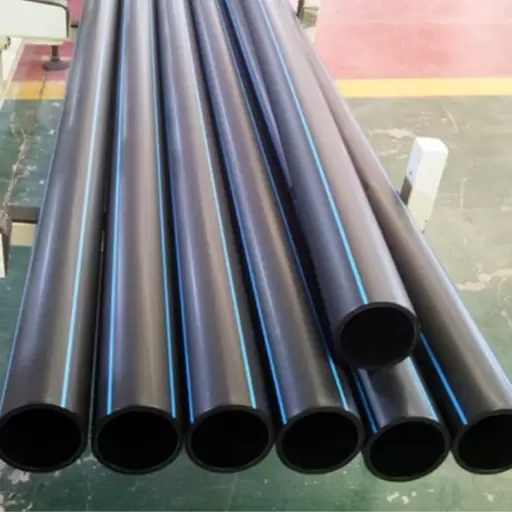

HDPE Pipe

Home » HDPE Pipe

High-density polyethylene (HDPE) pipes have revolutionized the modern piping industry due to their superior properties and versatility. These pipes are known for their high strength, durability, and flexibility, making them ideal for various applications, including water supply, gas distribution, sewage systems, and industrial processes.

HDPE Pipe for Sale

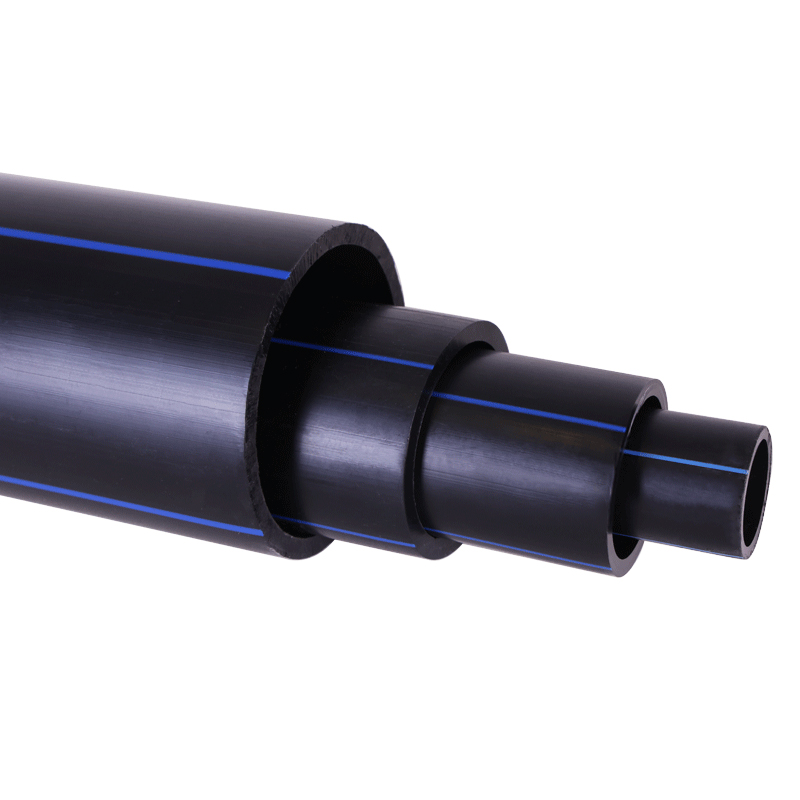

HDPE Pipe for Water Supply

High-density polyethylene (HDPE) water supply pipes are designed for durability, flexibility, and resistance to environmental stressors, making them ideal for a wide range of fluid conveyance applications.

- Urban and Rural Water Supply

- Industrial Applications

- Agricultural Irrigation

- Sewage and Drainage

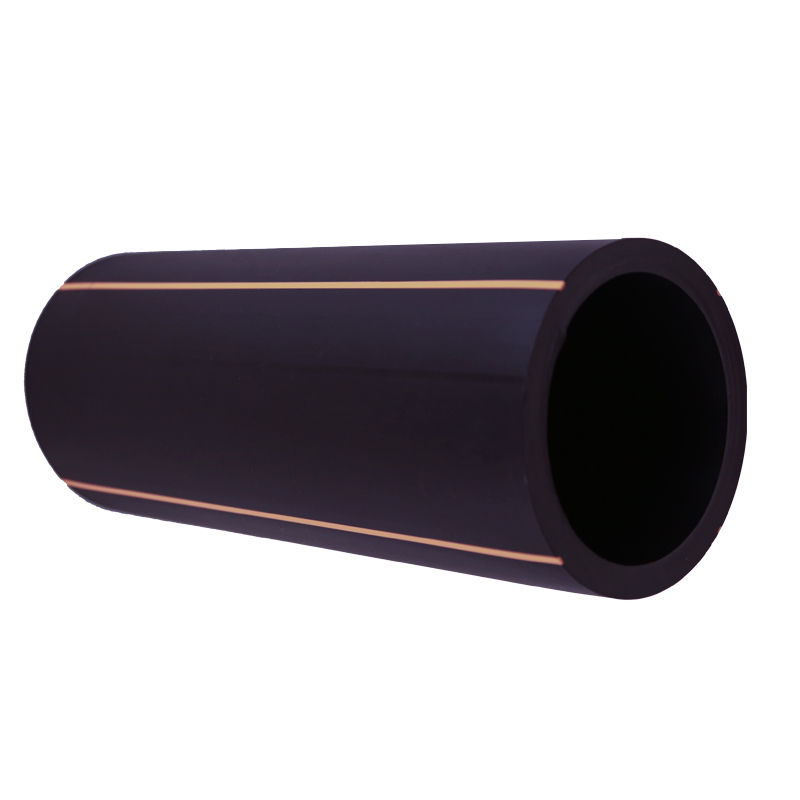

HDPE Gas Pipe

HDPE Gas pipes offer a flexible, durable, and corrosion-resistant solution for safe and efficient gas distribution systems.

- Urban and Rural Gas Distribution

- Industrial Applications

- Pipeline Replacement Projects

HDPE Mining Pipe

HDPE mining pipes are highly durable, flexible, and corrosion-resistant, making them ideal for transporting abrasive materials and handling various mining applications.

- Slurry Transportation

- Tailings Management

- Water Supply and Dewatering

- Heap Leaching

- Process Water and Chemical Transport

- Ventilation Systems

HDPE Electrical Conduit

HDPE Electrical Conduit pipes provide a durable, flexible, and corrosion-resistant solution for safely housing and protecting electrical power and telecommunications cables in various environments.

- Power Distribution

- Telecommunications

- Urban and Rural Infrastructure

- Industrial Applications

- Renewable Energy Projects

HDPE GSHP Pipe

HDPE GSHP pipes provide an efficient, durable, and environmentally friendly solution for ground source heat pump systems, ensuring reliable thermal exchange and reduced energy consumption.

- Ground Source Heat Pump (GSHP) Systems

- Horizontal and Vertical Ground Loops

- Open and Closed Loop Systems

- Industrial and Institutional Buildings

- Environmental and Sustainable Projects

HDPE Double Wall Corrugated Pipe

HDPE Double Wall Corrugated Pipes provide superior strength, flexibility, and resistance to corrosion, making them ideal for various drainage and sewage applications.

- Sewage Systems

- Rainwater Drainage

- Industrial Wastewater

- Road and Highway Drainage

- Agricultural Irrigation and Drainage

- Electrical and Communication Ducts

HDPE Drainage Pipe

HDPE drainage pipes offer exceptional durability, flexibility, and resistance to corrosion, making them the ideal solution for efficient drainage systems in various applications.

- Building Drainage Systems

- Urban Drainage

- Sewage Treatment Plants

- Industrial Drainage

- Road and Highway Drainage

HDPE Dredging Pipe

HDPE dredging pipes offer exceptional durability, flexibility, and resistance to abrasion and corrosion, making them ideal for transporting dredged materials such as sand, gravel, and slurry in marine and inland waterway projects.

- Dredging and Reclamation Projects

- Mining Operations

- Agricultural Irrigation

- Industrial Fluid Transport

- Marine Engineering

Dredging Rubber Hose

Dredging Rubber Hoses are highly durable, flexible, and abrasion-resistant solutions designed to efficiently transport dredged materials such as silt, sand, and gravel in various dredging operations.

- Port and Dock Operations

- Mining and Quarrying

- River and Lake Dredging

- Reclamation Projects

- Industrial Applications

Our Quality Assurance

Total Quality Management System

We implement a comprehensive Total Quality Management (TQM) system and adhere to Standard Operating Procedures (SOPs) to achieve “zero defect” products.

Third-Party Inspections

Third-party inspections, including those from CIO and SGS, can be arranged according to customer requirements to ensure the highest standards of quality and compliance.

Certifications

We are a certified manufacturer with CE, ISO9001, ISO14001, and OHSAS18001 certifications, which demonstrate our commitment to quality, environmental management, and occupational health and safety.

Compliance with International Standards

Our products successfully pass international third-party tests, meeting standards such as ISO 4427, ASTM D3035, AS/NZ 4130, and EN 12201.

HDPE Pipe Sizes & Specifications Sheet

| Nominal Pressure | 0.4MPA | 0.5MPA | 0.6MPa | 0.8MPa | 1.0MPa | 1.25MPa | 1.6MPa |

|---|---|---|---|---|---|---|---|

| Standard dimension ratio(SDR) | SDR41 | SDR33 | SDR26 | SDR21 | SDR17 | SDR13.6 | SDR11 |

| Nominal Diameter DN(mm) | Thickness (mm) | Thickness (mm) | Thickness (mm) | Thickness (mm) | Thickness (mm) | Thickness (mm) | Thickness(mm) |

| 16 | 2 | ||||||

| 20 | 2 | 2.3 | |||||

| 25 | 2 | 2.3 | |||||

| 32 | 2.3 | 2.4 | 3 | ||||

| 40 | 2.3 | 2.3 | 3 | 3.7 | |||

| 50 | 2.3 | 2.9 | 3.7 | 4.6 | |||

| 63 | 2.3 | 3 | 3.6 | 4.7 | 5.8 | ||

| 75 | 2.9 | 3.6 | 4.5 | 5.6 | 6.8 | ||

| 90 | 3.5 | 4.3 | 5.4 | 6.7 | 8.2 | ||

| 110 | 4.2 | 5.3 | 6.6 | 8.1 | 10 | ||

| 125 | 4.8 | 6 | 7.4 | 9.2 | 11.4 | ||

| 140 | 5.4 | 6.7 | 8.3 | 10.3 | 12.7 | ||

| 160 | 6.2 | 7.7 | 9.5 | 11.8 | 14.6 | ||

| 180 | 6.9 | 8.6 | 10.7 | 13.3 | 16.4 | ||

| 200 | 7.7 | 9.6 | 11.9 | 14.7 | 18.2 | ||

| 225 | 8.6 | 10.8 | 13.4 | 16.6 | 20.5 | ||

| 250 | 9.6 | 11.9 | 14.8 | 18.4 | 22.7 | ||

| 280 | 10.7 | 13.4 | 16.6 | 20.6 | 25.4 | ||

| 315 | 12.1 | 15 | 18.7 | 23.2 | 28.6 | ||

| 355 | 13.6 | 16.9 | 21.1 | 26.1 | 32.2 | ||

| 400 | 15.3 | 19.1 | 23.7 | 29.4 | 36.3 | ||

| 450 | 17.2 | 21.5 | 26.7 | 33.1 | 40.9 | ||

| 500 | 19.1 | 30 | 29.7 | 36.8 | 45.4 | ||

| 560 | 21.4 | 33.9 | 33.2 | 41.2 | 50.8 | ||

| 630 | 24.1 | 38.1 | 37.4 | 46.3 | 57.3 | ||

| 710 | 27.2 | 42.9 | 42.1 | 52.2 | |||

| 800 | 30.6 | 47.7 | 47.4 | 58.8 | |||

| 900 | 34.4 | 57.2 | 53.3 | ||||

| 1000 | 38.2 | 66.7 | 59.3 | ||||

| 1200 | 45.9 | 23.9 | 70.6 | ||||

| 1400 | 53.9 | 26.7 | 82.4 | ||||

| 1600 | 61.2 | 76.2 | 94.1 | ||||

| 1800 | 69.1 | 85.7 | 105.9 | ||||

| 2000 | 48.8 | 60.6 | 76.9 | 95.2 | 117.6 | ||

| 2250 | 55 | 70 | 86 | 107.2 | |||

| 2500 | 61.2 | 77.7 | 95.6 | 119.1 |

It is important to note that high-density polyethylene (HDPE) pipes are significant in many industries as they offer a flexible and durable solution for different pipework demands. This fully inclusive guide intends to ensure that the readers are well informed about the HDPE piping systems, their composition uses, and how they outdo other conventional materials.

HDPE Pipe Fittings Catalog

Pipeline Related Articles

The Question

Common FAQ

Don’t hesitate to contact us whenever you need any further clarification. Our team of committed experts is always there for support and guidance. We are here for you, whether you require assistance in translating something or have some inquiries about our services or even if you would like to tell us what you think about them.

Q: What is an HDPE pipe?

A: HDPE (High-Density Polyethylene) pipe is a type of plastic piping solution known for its durability, flexibility, and resistance to corrosion and UV radiation. It is commonly used in a wide range of applications, including water systems, drainage, and oil and gas pipelines.

Q: What are the advantages of using HDPE piping solutions?

A: HDPE piping solutions are cost-effective, durable, and resistant to corrosion and UV radiation. They offer a leak-free and flexible solution that can withstand various environmental conditions. HDPE pipes are also lightweight, making them easier to transport and install.

Q: How do HDPE pipes compare to PVC and ductile iron pipes?

A: HDPE pipes are more flexible and resistant to corrosion than PVC and ductile iron pipes. While PVC pipes are also commonly used for water applications, HDPE pipes offer better flexibility and impact resistance. Ductile iron pipes are strong and durable but can be prone to corrosion, unlike HDPE pipes.

Q: Can HDPE pipes be used for potable water?

A: Yes, HDPE pipes are safe for potable water applications. They are resistant to corrosion and do not leach harmful chemicals into the water, making them suitable for drinking water systems.

Q: What sizes are available for HDPE pipes?

A: HDPE pipes come in a wide range of sizes, from small-diameter pipes used for residential water systems to large-diameter pipes used for industrial applications. Their inside diameter and outside diameter typically measure the dimensions.

Q: How are HDPE pipes joined together?

A: HDPE pipes are commonly joined using a process called polyethylene fusion. This process involves heating the ends of the pipes and then pressing them together to form a robust and leak-free bond. This method is widely used to ensure durable and reliable connections.

Q: Where can I purchase HDPE pipes?

A: HDPE pipes can be purchased from suppliers, including WL Plastics, ISCO, and other specialized retailers. You can also shop by price and compare products online to find the best deals. Many suppliers offer various pipe products and fittings to meet different needs.

Q: Have there been any recent advancements in HDPE piping solutions?

A: Yes, recent advancements in HDPE piping solutions include the development of profile-wall HDPE pipes, which offer enhanced structural integrity and performance. These pipes are designed to meet specific industry standards and are suitable for a wide range of applications, including drainage and water systems.