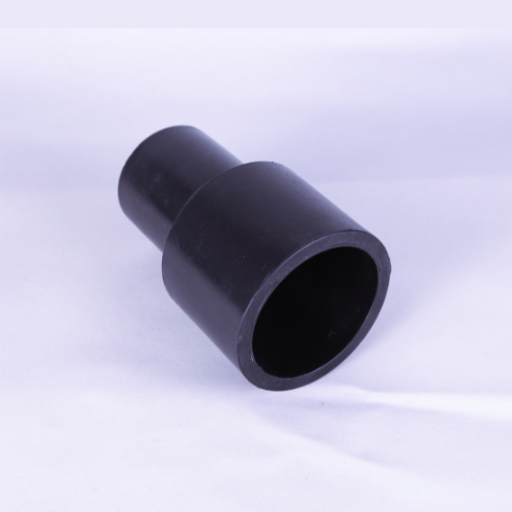

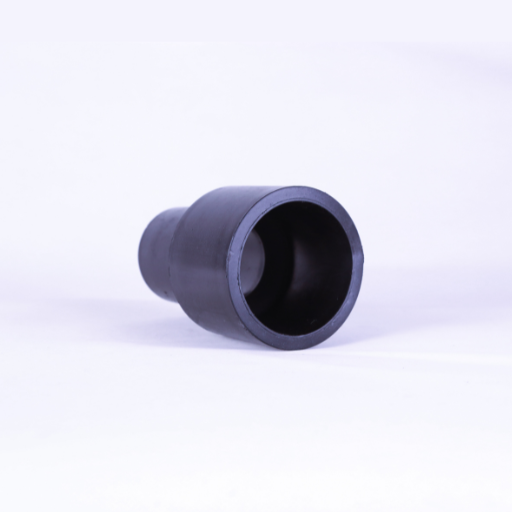

Butt Fusion Reducer Coupler

Home » HDPE Pipe Fittings » HDPE Butt Fusion Fittings » Butt Fusion Reducer Coupler

Butt Fusion Reducer Coupler Advantages at a Glance

- Hardy: Butt fusion reducer couplers are made from HDPE or other suchlike materials that have high levels of strength and durability, thereby making them resistant to abrasion, rusting, or any other kind of damage caused by harsh weather conditions or chemicals.

- Smooth internal wall: The smooth inner surface of butt fusion reducer couplers allows for efficient flow of fluid or gas through the pipes hence reducing friction and pressure loss.

- Simple installation: As a result, they are inexpensive and straightforward to install. Consequently, no special equipment is required, making them more affordable to companies in terms of labor time.

- Tailor-made customization: OEM requirements can customize color and size. This makes it possible for unique project requirements to be met better.

Technical Notes

- Butt fusion reducer couplers are essential components used to connect pipes of different diameters seamlessly. These fittings are designed for polyolefin materials, ensuring solid and durable joints that maintain the integrity of the piping system.

- The fusion process involves heating the ends of the pipes and the reducer coupler simultaneously, followed by pressing them together, which creates a monolithic structure.

- Proper ,pipe end preparation and the correct application of temperatures and pressures is crucial for achieving optimal fusion strength.

To prevent leaks and ensure a long service life, it is vital to follow manufacturer specifications and installation guidelines.

Standards & Certs

Butt fusion reducer couplers must comply with various industry standards to ensure reliability and performance. Key standards include:

- ASTM D2513: This specification covers the polyethylene gas pressure pipe standard, ensuring that the couplers’ materials can withstand required operating pressures and environmental conditions.

- ISO-9001: This international standard outlines the specifications for polyethylene pipes intended to convey water and other liquids under pressure. Compliance ensures quality manufacturing processes and suitability for water applications.

- API 15LE: This standard focuses on the design and performance specifications for thermoplastic piping systems used in oil and gas applications, ensuring couplers are suitable for conveying hydrocarbons.

Areas of application for Butt Fusion Reducer Coupler

Butt fusion reducer couplers are multi-purpose components that are used widely across diverse sectors due to their dependability and efficiency in joining pipes with different sizes. Common areas of use are as follows:

- Water Distribution Systems: These couplers enable change from one pipe size to another while maintaining a good seal which is important for efficient flow through municipal and industrial water distribution networks.

- Natural Gas Distribution: In gas pipeline systems, butt fusion reducer couplers are extensively used under high pressure conditions and are crucial in safely carrying natural gas to homes and businesses.

- Oil and Petrochemical Industries: The couplings have been developed to handle hydrocarbon fluids, thus making them essential for refineries and chemical plants where pipelines of varying diameters are common, ensuring safe non-leaking joints.

This versatility of application underscores the need for high-quality butt fusion reducer couplers that enhance system performance and longevity.

Butt Fusion Reducer Coupler Performance Introduction

| Performance Factor | Description |

|---|---|

| Versatility | Suitable for multiple applications, including water, gas, and oil transmission. |

| Joint Strength | Provides strong, leak-free joints, ensuring the integrity of the pipeline. |

| Ease of Installation | Designed for straightforward installation, reducing project time and costs. |

| Chemical Resistance | Capable of withstanding various chemicals, making them ideal for diverse fluid types. |

| Longevity | High durability and resistance to environmental stress lead to an extended lifespan. |

| Cost-Effectiveness | Competitive pricing and reduced maintenance costs over time enhance overall value. |

The HDPE Butt Fusion Reducer Coupler is crucial for connecting pipes of different diameters, offering a durable, leak-proof solution ideal for water, gas, and industrial systems. With its strong, corrosion-resistant build, it ensures long-lasting performance in various applications. Learn how this key component can enhance your pipeline’s efficiency and reliability.

Butt Fusion Reducer Coupler Specifications

| Specification | Description |

|---|---|

| Material | Polyethylene (PE) |

| Connection Type | Butt Fusion |

| Size Range | 1 inch to 18 inches |

| Pressure Rating | Up to 160 psi |

| Standard Compliance | ASTM D2513, ISO 9001, API 15LE |

| Application Areas | Oil and gas, water systems, industrial |

| Lifespan | Typically 50 years or more |

The Question

Common FAQ

Explore comprehensive information regarding Butt Fusion Reducer Coupler. Don’t hesitate to reach out to us for any inquiries.

Q: What is an HDPE butt fusion reducer coupler?

A: An HDPE butt fusion reducer coupler is a type of pipe fitting used to connect two pipes of different diameters. It is commonly made from high-density polyethylene (HDPE) and is used in various applications where a reduction in pipe size is needed.

Q: How does HDPE butt fusion reducing work?

A: HDPE butt fusion reducing works by heating the ends of two black HDPE pipes and the reducer coupler until they melt, then fusing them. This creates a robust and seamless joint as strong as the pipe itself.

Q: What are the benefits of using HDPE butt fusion fittings?

A: The benefits of using HDPE butt fusion fittings include a leak-proof connection, high durability, and the ability to withstand harsh environmental conditions. They are also resistant to chemicals and have a long service life.

Q: Are there any specific pressure ratings for HDPE butt fusion reducer couplers?

A: Yes, HDPE butt fusion reducer couplers are available in different pressure ratings, such as SDR11-PN16. Selecting the correct pressure rating based on the application requirements is crucial.

Q: How can I obtain HDPE butt fusion reducer couplers for my project?

A: To obtain HDPE butt fusion reducer couplers, please get in touch with us. We have stock available for regular sizes and can accommodate customers’ urgent demands. For specialized requirements, you can also contact us for more details.

Q: What applications are HDPE reducer fittings typically used in?

A: HDPE reducer fittings are widely used in various industries, including water supply, gas distribution, sewage systems, and industrial piping. Their high durability and chemical resistance make them suitable for multiple applications.