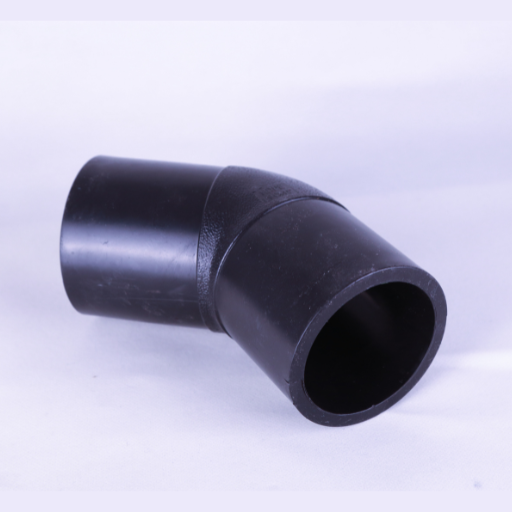

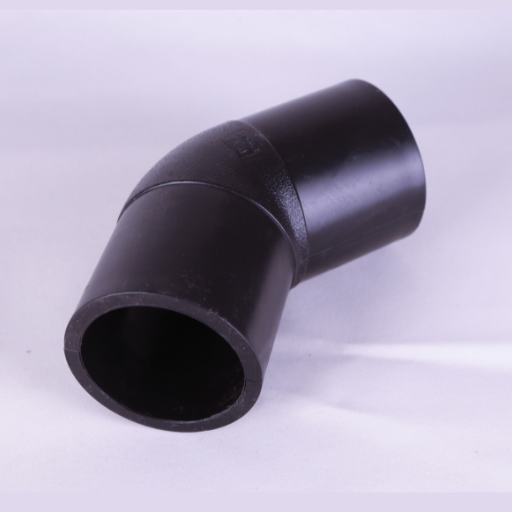

Socket Fusion 45° Elbow

Home » HDPE Pipe Fittings » HDPE Socket Fusion Fittings » Socket Fusion 45° Elbow

Socket Fusion 45° Elbow Advantages at a Glance

- Chemical Resistance: Polyethylene (PE) and polypropylene (PP) that go into making socket fusion fittings, has fantastic chemical resistance hence suitable for industries that work with highly corrosive chemicals.

- Easy Installation: No special tools or equipment are necessary to install socket fusion fittings. The procedure consists of heating the fitting and the pipe independently before joining them by hand.

- Personalized customization: OEM can customize color and size as per the customer demands. This makes it possible to apply socket fusion 45° elbows in a number of different contexts due to their design and functionality’s enhanced flexibility.

- Leak-proof Joints: Socket fusion 45° elbows’ welded joints formed during melting are not just leak-proof but also very dependable. In this case, melted materials from both the fitting and pipe mix together creating solid bonding without necessarily applying other sealants or adhesives.

Technical Notes

- Material Specifications: Typically manufactured from high-density polyethylene (HDPE) or polypropylene, ensuring durability and resistance to corrosion.

- Dimensional Standards: The elbow generally adheres to standards such as ASTM D2672 for PVC sockets or ASTM F2509 for PE sockets. For example, standard sizes include 2″, 3″, and 4″ diameters.

- Fusion Temperature: The recommended fusion temperature range is between 400°F to 450°F (204°C to 232°C) to secure a proper bond without degrading the material.

Standards & Certs

When considering Socket Fusion 45° elbows, it is essential to adhere to relevant industry standards and certifications to ensure quality and compatibility. Key standards that apply include ASTM F1056, which outlines the specifications for socket fusion fittings in thermoplastic piping systems, and ISO 9001 for quality management systems.

Socket Fusion 45° Elbow Application Areas

Owing to their flexibility and trustworthiness, socket fusion 45° elbows have found extensive use in different applications. The following are the main application areas:

- Water Distribution Systems: For municipal water supply and irrigation networks, these are excellent at directing flow path and reducing resistance.

- Technical Parameters: Pressure ratings often need to meet or exceed 150 PSI, with temperature limits from 32°F to 140°F.

- Chemical Handling: They are applicable in industrial settings for conveying chemical solutions that do not react with them.

- Technical Parameters: In cases of this nature, HDPE or similar materials are preferred because they resist chemicals; however, the fittings should be rated based on specific chemical compatibility for a given process.

- Wastewater Management: These ensure that wastewater flows smoothly through sewer lines and drainpipes even under pressure fluctuations.

Socket fusion 45° elbows comply with the pertinent technical parameters in every case where they have been applied thus ensuring high efficiency, safety as well as durability in their respective systems.

Socket Fusion 45° Elbow Performance Parameter

| Performance Parameter | Description |

|---|---|

| Flow Capacity | Designed to maintain optimal flow rates with minimal turbulence. |

| Chemical Resistance | Resistant to a wide range of chemicals, suitable for various applications. |

| Impact Resistance | Capable of withstanding impacts due to its material properties, ensuring durability. |

| Joint Strength | Achieves strong fusion joints, minimizing leakage potential under pressure. |

| Long-term Stability | Maintains performance and integrity over prolonged periods, even in harsh environments. |

| Maintenance Requirements | Low maintenance needs, simplifying installation and long-term usage. |

When it comes to piping systems, achieving reliable and durable connections is crucial. One of the essential components in this process is the Socket Fusion 45° Elbow. This fitting not only facilitates a change in direction within a piping system but also ensures a leak-proof connection when installed correctly. In this guide, we will delve into the details of Socket Fusion 45° Elbows, covering everything from their applications to the installation process, providing you with comprehensive knowledge to ensure successful implementation in your projects.

Socket Fusion 45° Elbow Technical Parameters

| Parameter | Description |

|---|---|

| Material | High-Density Polyethylene (HDPE) or Polyvinyl Chloride (PVC) |

| Size Range | ½" to 12" in diameter |

| Pressure Rating | Specific PSI levels based on diameter and material |

| Joining Method | Socket fusion process for connections |

| Color | Typically black, but may vary based on manufacturer |

| Standards Compliance | ASTM F1056, ISO 9001 |

The Question

Common FAQ

Explore comprehensive information regarding Socket Fusion 45° Elbow. Don’t hesitate to reach out to us for any inquiries.

Q: What is a Socket Fusion 45° Elbow used for?

A: A Socket Fusion 45° Elbow is used to change the direction of a piping system by 45 degrees. It is commonly employed in plumbing, gas distribution, and water systems to efficiently redirect the flow of fluids or gases.

Q: What material are Socket Fusion 45° Elbows made from?

A: Our Socket Fusion 45° Elbows are made from high-quality PE100 material, known for its excellent strength, durability, and resistance to corrosion and chemicals, making it ideal for various demanding applications.

Q: How do I install a Socket Fusion 45° Elbow?

A: Installation involves heating both the pipe and the elbow using a fusion tool until the material becomes molten, then joining them together to create a strong, leak-proof connection. Proper alignment and cooling are crucial to ensure a secure bond.

Q: Are Socket Fusion 45° Elbows compatible with all pipe types?

A: Socket Fusion 45° Elbows made from PE100 are compatible with pipes of the same material. It is important to use PE100 pipes to ensure a secure and long-lasting connection.

Q: What are the advantages of using a Socket Fusion 45° Elbow?

A: The main advantages include a strong, seamless joint that minimizes the risk of leaks, high pressure tolerance, and excellent durability. The 45° angle also allows for smoother flow direction changes, reducing turbulence in the system.

Q: What sizes are available for Socket Fusion 45° Elbows?

A: We offer OEM customization for Socket Fusion 45° Elbows, allowing you to specify the exact dimensions required for your project. Standard sizes are available, but we can manufacture according to your specific needs.