Socket Fusion Ball Valves

Home » HDPE Pipe Fittings » HDPE Socket Fusion Fittings » Socket Fusion Ball Valves

Benefits of Socket Fusion Ball Valves

- Durable and long-lasting: The heat fusion method to join these valves ensures strong and leak-free connections that can withstand high pressure and temperature.

- Versatile applications: These valves can be used in various industries and applications, including plumbing, irrigation, water treatment, chemical processing, and more.

- Cost-effective: Due to their durability and low maintenance requirements, socket fusion ball valves are a cost-effective option for fluid control systems.

- Personalized customization: OEMs can customize color and size. This means that socket fusion ball valves can be tailored to fit specific project requirements, making them versatile for various applications.

Technical Notes

- Pressure Rating: A valve’s pressure rating is crucial for ensuring it can handle the system’s demands. Most socket fusion ball valves are available in class ratings, such as 200, 300, or 450 psi, depending on the material and application.

- Pipe Size Compatibility: Socket fusion ball valves are available in various sizes ranging from ½ inch to 12 inches in diameter. Matching the valve size with the corresponding pipe is essential to ensure proper fit and functionality.

- Operating Temperature Range: The valves must be suitable for the temperature of the fluid being controlled. For example, PVC fittings are not recommended for high-temperature applications, while CPVC can be used in hot water systems.

Standards & Certs

- ISO Certification: Many manufacturers obtain ISO 9001 certification, which indicates a commitment to quality management systems and continuous improvement processes.

- PVC (Polyvinyl Chloride): Must meet ASTM D1784 for rigid PVC, establishing the minimum physical properties required for durability and performance.

- CPVC (Chlorinated Polyvinyl Chloride): Should comply with ASTM F441 standards which specify the material’s requirements for hot and cold water systems.

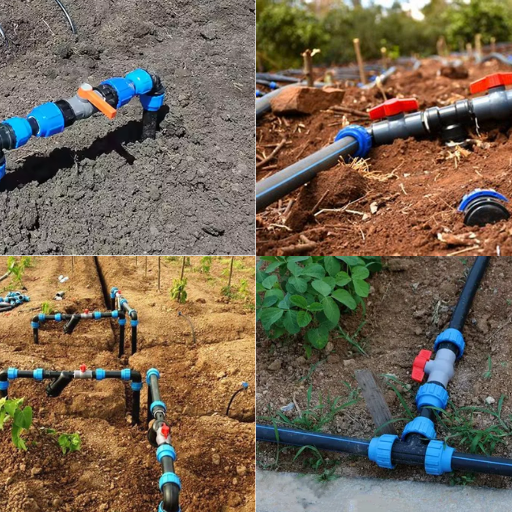

Socket Fusion Ball Valves Application Areas

These valves are commonly used in potable water systems and have found numerous applications due to their versatility and durability. Such areas include:

- Chemical Processing: Socket fusion ball valves are resistant to corrosion, making them compatible with different chemicals.

- Irrigation Systems can be used for residential and commercial irrigation, as they can withstand high pressure and unfavorable conditions.

- Industrial Applications: Socket fusion ball valves help control safety during various industrial processes, from chemical manufacturing plants to industrial water treatment plants, depending on the industry.

- HVAC Systems: Heating, ventilation, and air conditioning systems often employ socket fusion ball valves as these valves accommodate heating or cooled fluids.

- Oil and Gas Industry: This type of valve is used primarily to control the flow and pressure of pipelines and other equipment in the oil and gas sector.

- Food and Beverage Industry: In food processing industries mainly concerned with consumable products, socket fusion ball valves that meet NSF/ANSI standards are needed.

Socket Fusion Ball Valves Performance Description

| Performance Parameter | Description | Measurement Standards |

|---|---|---|

| Operating Pressure | Maximum pressure the valve can safely handle | ANSI/ASME |

| Temperature Range | Operating temperature limits for effective functionality | ASTM D1784 and ASTM F441 |

| Flow Coefficient (Cv) | Measure of the valve's capacity to flow water | Manufacturer specifications |

| Leakage Rate | Maximum allowable leakage under specified conditions | ANSI/ASME and NSF/ANSI |

| Durability | Expected lifespan under normal conditions and stresses | ISO 9001 compliance and material standards |

| Response Time | Time taken for the valve to fully open or close | Manufacturer tests |

| Corrosion Resistance | Resistance to chemical and environmental degradation | ASTM D2657 and material specifications |

In industrial applications, selecting the right valve is crucial for ensuring the efficiency and safety of fluid handling systems. The Socket Fusion Ball Valve is a reliable and durable choice, offering excellent resistance to pressure and temperature variations. This comprehensive guide will explore Socket Fusion Ball Valves’ key features, installation processes, and benefits, providing valuable insights for engineers and technicians aiming to optimize their industrial operations.

Socket Fusion Ball Valves Technical References

| Reference Standard | Application |

|---|---|

| ASTM D2657 | Installation techniques |

| ISO 9001 | Manufacturer certification |

| ASTM D1784 | Durability and performance of PVC |

| ASTM F441 | Standards for CPVC |

| ANSI/ASME Class 150 & 300 | Ensures safe handling of specified pressures |

| APSP/NSF/ANSI Standards | Safety assessments for valve leaching |

The Question

Common FAQ

Explore comprehensive information regarding Socket Fusion Ball Valves. Don’t hesitate to reach out to us for any inquiries.

Q: What is a Socket Fusion Ball Valve?

A: A Socket Fusion Ball Valve is a type of valve used in fluid handling systems, designed for seamless integration with thermoplastic pipes. It operates by using a spherical disc to control the flow of liquids or gases, ensuring a tight seal and reliable performance.

Q: What materials are Socket Fusion Ball Valves made of?

A: Socket Fusion Ball Valves are made from PE100, a high-density polyethylene material known for its excellent strength, durability, and resistance to chemicals and pressure. PE100 is ideal for demanding industrial applications, providing long-term reliability and safety.

Q: How do I install a Socket Fusion Ball Valve?

A: Installation involves heating the valve and pipe ends using a socket fusion tool, then pressing them together to form a strong, leak-proof bond. It is important to follow proper heating and cooling times as specified by the manufacturer to ensure a secure and durable connection.

Q: What are the advantages of using Socket Fusion Ball Valves?

A: Socket Fusion Ball Valves provide several benefits, including a permanent, leak-free connection, high resistance to corrosion and chemical attack, minimal maintenance requirements, and suitability for high-pressure and high-temperature applications.

Q: Can Socket Fusion Ball Valves be used in both hot and cold water systems?

A: Yes, Socket Fusion Ball Valves are designed to handle both hot and cold water systems. They are capable of withstanding a wide range of temperatures, making them versatile for use in various industrial settings.

Q: What sizes are available for Socket Fusion Ball Valves?

A: Socket Fusion Ball Valves made from PE100 are available in standard sizes, but they can also be OEM custom-made to meet specific project requirements. This flexibility ensures that the valves can be tailored to fit unique system specifications perfectly.