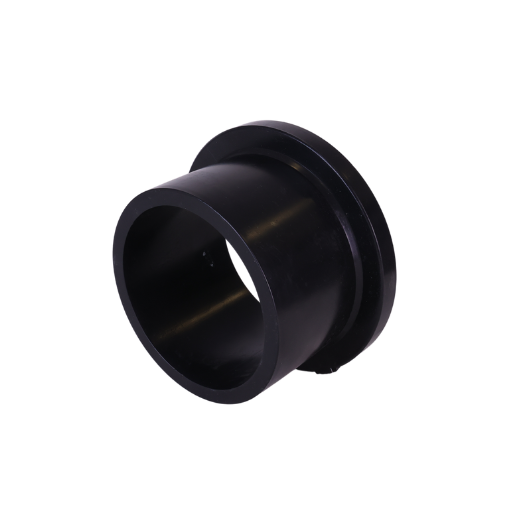

Socket Fusion Flange

Home » HDPE Pipe Fittings » HDPE Socket Fusion Fittings » Socket Fusion Flange

Advantages of Socket Fusion Flange

- Leak-Proof Connection: The flanges in a socket fusion process create a leak-proof connection between pipes. This is very important since it helps to prevent probable leaks that can lead to destruction and distract the flow of liquids or gases within a piping system.

- Versatility: Socket fusion flanges come in different sizes and materials; hence, they can be used for various types of pipe systems. Additionally, they can be applied to connecting pipes made up of various materials, thus giving room for flexibility during design and construction.

- Cost-Effective: Inexpensive alternatives include socket fusion flanges due to their installation ease and durability. They do not require much maintenance and usually have longer lives, reducing the need for regular replacement.

- Personalized customization: A change in color is also available as per OEMs’ wishes on its size. In addition, company logos or labels may be customized on the socket fusion flange to enhance brand recognition and improve the overall look of a piping system.

Technical Notes

- Material Compatibility: Socket fusion flanges are typically made from thermoplastics such as PVC, CPVC, or PE. Ensure that the materials of the flange and connected pipes are compatible to prevent degradation over time.

- Pressure Rating: These flanges generally come with pressure ratings that can range from 150 psi to 300 psi, depending on the material and size. This rating indicates the maximum pressure that can be safely handled.

- Temperature Resistance: Socket fusion flanges can usually withstand temperatures up to 140°F for PVC and up to 180°F for CPVC. Evaluate the operating environment to guarantee that these limits will not be exceeded.

Standards & Certs

- Certifications such as ISO 9001 can indicate that a manufacturer adheres to quality management principles, ensuring consistency in production.

- Socket fusion flanges often come with various pressure ratings (e.g., 150 psi at 73°F for PVC), which indicate the maximum pressure they can safely handle.

- The temperature range for socket fusion flanges typically varies by material; for example, CPVC can handle temperatures up to 200°F.

About Socket Fusion Flange Application Areas

A variety of sectors utilize socket fusion flanges because they have been designed with solid build and proven performance. Some examples of these include:

- Water Distribution Systems: These flanges support piping in municipal water supply systems due to their ability to handle high pressures (normally up to 150 PSI) and temperatures (up to 180°F). Heat fusion creates a seamless joint with no leaks.

- Chemical Processing: For situations where resistance to chemical attack is critical, socket fusion flanges provide a trustworthy connection that can be used with corrosive and non-corrosive fluids. Such materials may include PVC, CPVC, or PVDF, which can withstand different concentrations of chemicals at various temperature levels.

- Wastewater Treatment: Socket fusion flanges are incredibly durable and strong, making them suitable for municipal and industrial wastewater systems. They also secure the joints even in extreme environments, preventing any unwanted seepage.

- Irrigation and Agricultural Systems: Socket fusion flanges are very popular in the agriculture sector because they are easy to install, allowing quick assembly/disassembly whenever necessary. This enhances their effectiveness since such a system operates under varying pressure levels.

When installed properly, these sockets form solid bonds, which help maintain the integrity of pipe systems in all mentioned applications.

Socket Fusion Flange Performance Description

| Performance Parameter | Description |

|---|---|

| Pressure Rating | Typical maximum ratings up to 150 psi |

| Temperature Range | Functionality within -40°F to 140°F |

| Material Compatibility | Compatible with PVC, CPVC, and PPR pipes |

| Joining Method | Heat fusion process for durable connections |

| Installation Time | Quick installation; generally completed in under an hour |

| Maintenance | Low maintenance; periodic inspections recommended |

| Life Expectancy | Designed for long-term use with proper installation |

Socket fusion flanges are a critical component in the piping systems, particularly when dealing with thermoplastic materials like polyethylene (PE). This process involves the heating of the pipe and flange simultaneously until they reach a melting point, allowing them to be fused together seamlessly. The resulting connection is both robust and leak-proof, making socket fusion an ideal technique for creating durable, long-lasting pipelines in various industries, including gas distribution and water supply. Understanding the nuances of this method is essential for ensuring reliable and efficient pipeline installations.

Socket Fusion Flange Stub Stub End

| Size | D(mm) | d(mm) | H(mm) |

|---|---|---|---|

| 50 | 85 | 63 | 30 |

| 63 | 98 | 78 | 34 |

| 75 | 121 | 94 | 40 |

| 90 | 125 | 110 | 44 |

| 110 | 160 | 126 | 50 |

The Question

Common FAQ

Explore comprehensive information regarding Socket Fusion Flange. Don’t hesitate to reach out to us for any inquiries.

Q: What is a socket fusion flange, and how does it work?

A: A socket fusion flange is a type of fitting used to connect thermoplastic pipes, such as polyethylene (PE), through a process that involves heating both the pipe and the flange to their melting points. Once melted, the components are fused together, creating a strong and leak-proof joint.

Q: What are the benefits of using socket fusion flanges?

A: Socket fusion flanges provide a durable and reliable connection that is resistant to leaks and corrosion. The fusion process creates a seamless bond, ensuring the longevity and integrity of the pipeline, which is essential in industries like gas distribution and water supply

Q: Which materials are compatible with socket fusion flanges?

A: Socket fusion flanges are typically used with thermoplastic materials such as polyethylene (PE) and polypropylene (PP). These materials are ideal due to their ability to melt and fuse when heated, forming a strong and durable connection.

Q: Do socket fusion flanges require any special equipment for installation?

A: Yes, installing socket fusion flanges requires specialized equipment, including a fusion machine that can heat the pipe and flange to the correct temperature. Proper training is also essential to ensure that the process is performed correctly and safely

Q: How long does the socket fusion process take?

A: The socket fusion process is relatively quick, with heating and fusion typically taking just a few minutes. However, the exact time can vary depending on the pipe size, material, and environmental conditions

Q: Are socket fusion flanges suitable for all types of applications?

A: Socket fusion flanges are ideal for a wide range of applications, particularly in systems that require reliable, leak-proof connections, such as gas distribution, water supply, and industrial piping. However, they may not be suitable for high-pressure applications without proper reinforcement.