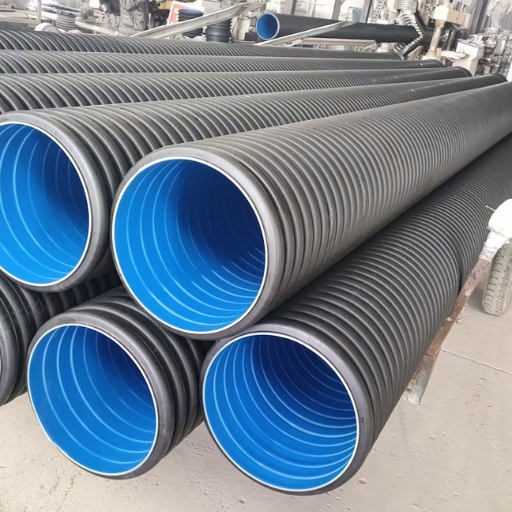

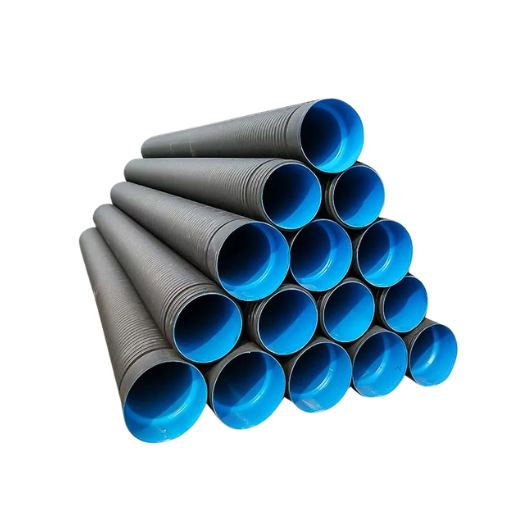

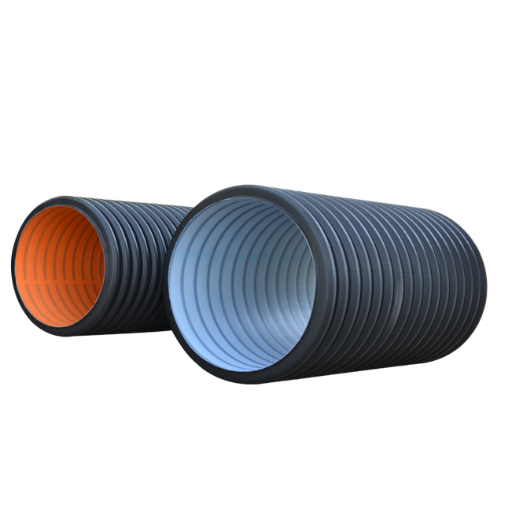

HDPE Double Wall Corrugated Pipe

Key Features of HDPE Double Wall Corrugated Pipe

- Durability: High Density Polyethylene (HDPE) double wall corrugated pipes are highly impenetrable to impact and environmental elements, which ensures long life spans even under the toughest conditions.

- Lightweight: These pipes weigh much less as compared with traditional materials thereby simplifying transportation and installation that in turn reduces labor charges.

- Hydraulic Efficiency: The smooth interiors of the pipes ensure excellent flow characteristics thus minimizing resistance and permitting good water drainage.

- Chemical Resistance: HDPE is by nature resistant to multiple chemicals; hence, these tubes can be used in different applications without any risk of damage.

- Flexibility: The flexibility during their installation process enables these designs to fit various terrains and land movements without endangering their integrity.

- Cost-Effectiveness: HDPE pipes offer an inexpensive solution for drainage systems due to low material costs, easy installation processes, and minimal maintenance requirements.

Advantages of HDPE corrugated pipe double wall

- Superior Strength Advantage: HDPE twin wall corrugated pipes are built to bear heavy loads thereby making them perfect for places with high movement of vehicles. This makes them capable of being pressed down by the external forces.

- Lesser Risk of Clogging: The interior surface is so smooth that it reduces friction and encourages useful flow. By doing this, clogging is minimized as such reliable drainage would be achieved throughout time.

- Ability to Withstand High Temperatures: HDPE pipe materials remain unaffected by different temperature ranges. This makes it possible for them to be used in various climates hence they always work consistently regardless of the surroundings.

- Sustainability: Being made from recyclable materials, HDPE pipes support environmental friendly construction methods. They can last for long periods without requiring much maintenance and therefore are among the greenest drainage solutions available.

Applications of Double Wall Corrugated HDPE Pipe

Double-wall corrugated HDPE pipes are extensively utilized in various fields due to their durability and effectiveness. They have several vital uses, such as;

- Stormwater Management: In urban areas that face flooding or heavy rainwater runoff, these pipes are best suited for transportation as they aid in efficient drainage by preventing water logging.

- Sewer System: These pipes can be used in municipal sewers because of their structural integrity and ability to allow smooth flow and prevent blocking.

- Agricultural Drainage: Farmers use double-wall HDPE pipes in a drainage system that helps prevent soil saturation, thus improving crop yield by ensuring optimum levels of soil moisture.

- Industrial Applications: Other industrial uses, including handling certain fluids and draining spills, demonstrate the adaptability and reliability of these pipes even in severe conditions.

- Landfill Management: Another common use for this product is efficiently guiding leachate out of landfills. It has applications such as this one, where it is used instead of other products because it does not contaminate the ground.

- Mining Applications: Effective operations require dewatering and slurry transport systems that incorporate the use of HDPE double-wall pipe for safe extraction processes, among other things.

These pipes can also provide Telecommunications Ducts for underground communication cables, ensuring an easy path while still protecting them against external factors that may affect their functionality.

Double wall hdpe corrugated pipe Specifications

| Nominal Diameter (mm) | Inner Diameter (mm) | Outer Diameter (mm) |

|---|---|---|

| 200 | 192 | 210 |

| 300 | 290 | 310 |

| 400 | 384 | 420 |

| 500 | 480 | 530 |

| 600 | 570 | 630 |

| 800 | 760 | 840 |

| 1000 | 950 | 1050 |

| 1200 | 1140 | 1260 |

| 1500 | 1430 | 1580 |

| 1800 | 1710 | 1890 |

| 2000 | 1910 | 2100 |

| 2250 | 2150 | 2360 |

| 2500 | 2390 | 2630 |

HDPE (High-Density Polyethylene) double-walled corrugated pipes have become a popular choice for various applications due to their versatile, durable, and cost-effective nature. These pipes consist of two layers of HDPE material with a corrugated outer layer and a smooth inner layer.In this guide, we will discuss everything you need to know about double-walled corrugated HDPE pipes, including their benefits and applications.

Double Walled Corrugated HDPE Pipe Features

| Feature | Single Wall Applications | Double Wall Applications | Specifications |

|---|---|---|---|

| Higher mechanical resistance due to the structure | Subsurface drainage | Subsurface drainage | 100mm - 800mm diameters |

| Excellent chemical resistance | Highway Edge Drains | Drainage pipe and Culvert | Bell-end spigot for ease of jointing |

| Excellent abrasion resistance | Golf Courses | Storm Water and Water Storage Tank | Ring stiffness SR24 (4 / 8 / 16 kN/m2) |

| Economical and Cost Effective | Parks | Sewerage Application | |

| Excellent physical properties | Playing fields | Manhole System | |

| Lightweight and easy to handle | Industrial Wastewater | ||

| Excellent Hydraulic Flow Capacity | |||

| Strong and flexible, capable of customized modular length |

HDPE Double Wall Corrugated Pipe Fittings Catalog

Pipeline Related Articles

The Question

Common FAQ

Discover detailed insights on HDPE double-wall corrugated pipes. Feel free to contact us with any questions or inquiries.

Q: What is an HDPE double-wall corrugated Pipe?

A: HDPE Double-Wall Corrugated Pipe is a type of drainage pipe with a corrugated exterior for strength and a smooth interior for efficient flow. It is commonly used for soil-tight and stormwater management systems.

Q: What are the advantages of using dual-wall HDPE pipes?

A: Dual wall HDPE pipes combine a corrugated exterior for strength and durability with a smooth interior for optimal flow efficiency. This design ensures high performance and longevity in various applications, including drainage and sewage systems.

Q: What is ADS N-12 20' and what are its applications?

A: ADS N-12 20′ refers to a 20-foot-long dual-wall HDPE corrugated pipe designed for efficient water flow and durability. It is used in applications such as stormwater drainage, agricultural drainage, and sanitary sewer systems.

Q: Are there specific ASTM standards for HDPE double-wall corrugated pipes?

A: Yes, HDPE double-wall corrugated pipes adhere to ASTM standards such as ASTM F2648, which ensures quality and performance in drainage applications. These standards help maintain consistency in pipe manufacturing and functionality.

Q: How does a dual wall n-12 pipe compare to a corrugated metal pipe?

A: Dual wall N-12 pipes offer superior corrosion resistance to corrugated metal pipes. They also provide a smoother interior for better flow efficiency, making them a preferred choice for many drainage and sewer applications.

Q: What types of fittings are available for dual-wall HDPE pipes?

A: Various pipe fittings, including couplers, elbows, tee fittings, and reducers, are available for dual-wall HDPE pipes. These fittings ensure secure and leak-free connections, enhancing the drainage system’s overall functionality.

Q: How are dual wall corrugated HDPE pipes installed?

A: Dual wall corrugated HDPE pipes are typically installed using trenching methods or with the help of specialized machinery. Installation involves proper bedding, backfilling, and ensuring the pipe maintains its alignment and gradient for adequate drainage.

Q: What is the role of a stopper in dual-wall HDPE pipes?

A: A spigot is an end feature of dual-wall HDPE pipes designed to connect with other pipe sections securely. It ensures a tight fit and prevents leakage, which is crucial for maintaining the drainage system’s integrity.