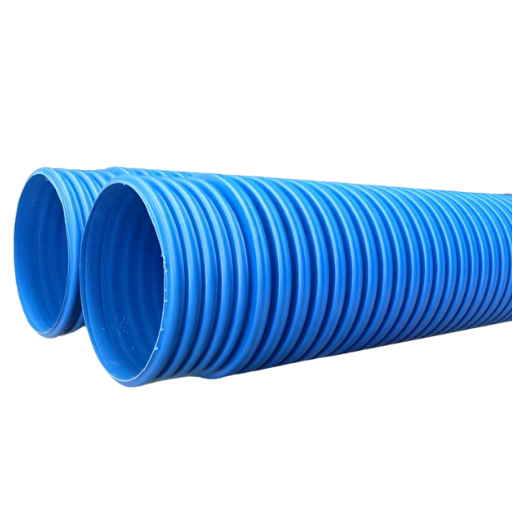

HDPE Drainage Pipe

Introduction and Features of HDPE Pipe for Drainage

High-density polyethylene (HDPE) pipes are widely recognized for their reliability and flexibility in drainage systems. They are nontoxic and environmentally friendly, making them suitable for both residential and industrial applications. They are manufactured using virgin materials that meet strict health standards, ensuring the delivery of clean and safe water.

Features

Non-toxic: HDPE material is non-toxic and tasteless, making it a safe choice for water supply systems. It does not corrode or scale, thereby improving water quality over time.

Low Flow Resistance: The smooth inner wall of HDPE pipes ensures low friction, which significantly enhances the flow capacity by up to 30% compared to traditional steel or glass-reinforced pipes.

- Leak-proof: The pipes are joined using butt fusion, socket fusion, and electrofusion techniques, which provide strong, leak-proof joints that are more durable than the pipe material itself.

Excellent Flexibility: HDPE pipes can be coiled for smaller diameters and slightly bent for larger diameters, making them easy to handle and install at the construction site.

Good Scratch Resistance: The wear resistance of HDPE pipes is four times that of steel pipes, which extends their service life and enhances economic efficiency.

Convenient Installation: HDPE pipes can be installed using various trenchless methods, which simplifies the construction process and reduces labor intensity.

Long Service Life: Designed to last for 50 years under rated temperature and pressure conditions, HDPE pipes offer a durable solution for drainage systems.

Lower Operation and Maintenance Costs: The ease of installation and maintenance of HDPE pipes reduces labor costs and enhances overall efficiency.

Applications of HDPE Storm Drainage Pipe

Urban Drainage Systems: HDPE pipes are extensively used in urban areas for underground drainage and sewer systems. They effectively transport domestic wastewater and sewage, ensuring a clean and efficient waste management system.

Industrial Waste Management: HDPE pipes are ideal for transporting industrial wastewater and effluents due to their high resistance to chemicals and corrosion. They ensure safe and efficient disposal of industrial waste without environmental contamination.

Stormwater Drainage: These pipes are used in managing stormwater runoff in urban and rural areas. Their smooth inner walls and high flow capacity make them effective in handling large volumes of rainwater, preventing flooding and waterlogging.

HDPE Drainage Pipe Size Description

| Series | Nominal outer diameter/mm | Average outer diameter/mm | Wall thickness/mm | ||

|---|---|---|---|---|---|

| S12.5 Tube Series Dimensions | 32 | 32 | 32.3 | 3 | 3.3 |

| 40 | 40 | 40.4 | 3 | 3.3 | |

| 50 | 50 | 50.5 | 3 | 3.3 | |

| 56 | 56 | 56.5 | 3 | 3.3 | |

| 63 | 63 | 63.6 | 3 | 3.3 | |

| 75 | 75 | 75.7 | 3 | 3.3 | |

| 90 | 90 | 90.8 | 3.5 | 3.9 | |

| 110 | 110 | 110.8 | 4.2 | 4.9 | |

| 125 | 125 | 125.9 | 4.8 | 5.5 | |

| 160 | 160 | 161 | 6.2 | 6.9 | |

| 200 | 200 | 201.1 | 7.7 | 8.7 | |

| 250 | 250 | 251.3 | 9.6 | 10.8 | |

| 315 | 315 | 316.5 | 12.1 | 13.6 | |

| S16 Tube Series Dimensions | 200 | 200 | 201.1 | 6.2 | 6.9 |

| 250 | 250 | 251.3 | 7.8 | 8.6 | |

| 315 | 315 | 316.5 | 9.8 | 10.8 |

The significance of having functional and efficient drainage systems cannot be underestimated in the modern world of construction and infrastructure. HDPE (High-Density Polyethylene) drainage pipes have become more popular due to their durability, elasticity, and resilience to rusting. This comprehensive guide provides an in-depth understanding of HDPE drainage pipes by discussing their features, advantages, installation processes, and typical applications.

Specification For HDPE Corrugated Drainage Pipe

| Nominal Diameter(mm) | Average Outer Diameter(mm) | Maximum Ovality(mm) | Minimum Wall Thickness(mm) |

|---|---|---|---|

| 32 | 32 | 32.3 | 3 |

| 40 | 40 | 40.4 | 3.7 |

| 50 | 50 | 50.4 | 4.6 |

| 63 | 63 | 63.5 | 5.8 |

| 75 | 75 | 75.5 | 6.8 |

| 90 | 90 | 90.7 | 8.2 |

| 110 | 110 | 110.8 | 10 |

| 125 | 125 | 125.9 | 11.4 |

| 140 | 140 | 141 | 12.7 |

| 160 | 160 | 161.1 | 14.6 |

| 180 | 180 | 181.2 | 16.4 |

| 200 | 200 | 201.3 | 18.2 |

| 225 | 225 | 226.5 | 20.5 |

| 250 | 250 | 251.6 | 22.7 |

| 280 | 280 | 281.8 | 25.4 |

| 315 | 315 | 317.1 | 28.6 |

HDPE Drainage Pipe Fittings Catalog

Pipeline Related Articles

The Question

Common FAQ

Explore comprehensive information regarding HDPE drainage pipe. Don’t hesitate to reach out to us for any inquiries.

Q: What is an HDPE drainage pipe?

A: HDPE stands for high-density polyethylene, a type of plastic known for its durability and long life. HDPE drainage pipes are commonly used for various applications, including stormwater management, agriculture, and industrial drainage.

Q: What are the advantages of using HDPE drainage pipes?

A: HDPE drainage pipes provide superior durability, flexibility, and resistance to corrosion compared to other types of pipe. Their smooth interior wall and corrugated exterior allow for efficient water flow and structural strength. Additionally, they are lightweight and easy to install.

Q: Can HDPE drain pipes connect to existing copper fittings?

A: HDPE drain pipes can be connected to existing copper fittings using specialized adapters, which ensures a secure and leak-free connection.

Q: How do I join HDPE drain pipes together?

A: HDPE drain pipes can be joined using various methods, such as mechanical couplings, HDPE fittings, and welding. The method you choose will depend on your drainage system’s specific requirements.

Q: Is there a suitable adhesive for HDPE drain pipes?

A: HDPE usually doesn’t require adhesive due to its natural flexibility and watertight joints. However specific types of glue can be used if needed, but it is not the most common practice.

Q: Can I use HDPE drain pipes for interior and exterior drainage?

A: HDPE drain pipes are suitable for interior and exterior applications. Their corrugated exterior provides strength for exterior use, while the smooth interior wall ensures efficient water flow inside buildings.

Q: What makes HDPE triple wall pipes unique?

A: HDPE triple wall pipes have a structure that includes a smooth interior wall and corrugated exterior, offering additional strength and durability. They are an excellent alternative to reinforced concrete for specific applications.