HDPE Electrical Conduit

Introduction of HDPE Electrical Conduit

HDPE power cable protective pipe is made of raw material which is modified polypropylene and combined with a unique formula and processing technique that results in an innovative composite pipe. The advantages of this kind of pipe are numerous: it has high strength, excellent heat resistance, is easy to install, convenient to construct, and economical, among others.

The main features of trenchless HDPE power cable protective pipe include its burial depth range from 2 to 18 m and conforming well with the development needs of modern cities.

Features and Benefits

The non-pollutant characteristic exhibited by trenchless construction technology makes it possible for those practicing it to incur less interference in terms of traffic flow while the networks have low failure rates due to reduced failures in the network’s tubings. This solution brings significant social and economic gains making urban spaces better.

Excavations and no-excavation areas are places where there is use for HDPE Power Cable Protective Pipe; these protect high pressure and ultra-high voltage power cables buried underground.

Uses of HDPE Electrical Conduit

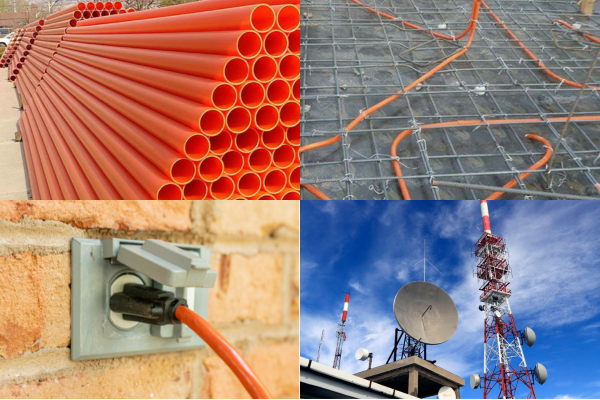

- Underground Cable Protection: Normally, HDPE electrical conduit is used to safeguard underground cables, thereby providing insulation and protecting them from physical impact.

- Concealed Wiring Systems: The use of HDPE conduit allows for concealed wiring systems within buildings, ensuring an organized and safe electrical connection.

- Outdoor Electrical Installations: In various environments, HDPE conduit provides wires and cables with protection that is resistant to weather elements, which is ideal for outdoor electrical installations.

- Telecommunication Infrastructure: The role of HDPE electrical conduit in supporting telecommunication infrastructure is vital as it helps in cable routing and protection.

Infrastructure development is fast-paced, so choosing suitable materials will ensure the effective functioning, durability, and longevity of power and communications systems is essential. One of the leading solutions in this context is a high-density polyethylene (HDPE) conduit with numerous unparalleled advantages over its traditional alternatives. This blog will highlight various benefits associated with HDPE conduit, including its corrosion and chemical resistance, flexibility, and ease during installation.

Product Performance Requirements and Test Parameters

| Project | Index |

|---|---|

| Density (g/cm3) | 0.91~005 |

| Coefficient of sliding friction | <0.3 |

| Tensile strength 23℃±2℃(Mpa) | ≥24.0 |

| Flexural strength 23℃±2℃(Mpa) | ≥37.0 |

| Flexural modulus (Mpa) | 1000~1200 |

| Flat test 1/2 | Not broken |

| Vicat heat (10N,50℃,h)℃ | 9 |

| Drop hammer impact test(20mm,3kg,2m) | 9/10 Qualified |

| Ring-chip thermal compression torce(KN) | 1.06 |

| Nominal wall thickness(≥0.8KN) | 1.06 |

Hdpe Electrical Conduit Fittings Catalog

Pipeline Related Articles

Common FAQ

Discover detailed insights on HDPE electrical conduit. Our expert team is here to address any queries you have about our products and their applications.

Q: What are the key benefits of HDPE conduit for power and telecommunications?

A: HDPE conduit’s benefits include its flexibility, durability, and resistance to chemicals and corrosion. It is the preferred material for power and telecommunications due to its ability to withstand harsh environmental conditions, thus ensuring a longer lifespan and lower maintenance costs.

Q: Are there different types of HDPE conduit available?

A: Yes, various types of HDPE conduit are available, including schedule 40, schedule 80, and SDR 13.5, each designed to meet specific needs. HDPE conduit types can be tailored based on application requirements, such as thickness, flexibility, and load-bearing capabilities.

Q: How does an HDPE conduit compare to a PVC conduit's performance?

A: HDPE conduit generally outperforms PVC conduit in several areas, including flexibility, impact resistance, and installation methods. HDPE conduit can be used in a broader range of temperature conditions and is more resistant to cracking and breaking.

Q: What installation methods are suitable for HDPE conduit?

A: Several installation methods are suitable for HDPE conduit, including horizontal directional drilling, plowing, and trenching. These methods allow for efficient, cost-effective, and minimally invasive installation in various environments.

Q: Why is HDPE conduit preferred for underground conduit installations?

A: HDPE conduit is preferred for underground conduit installations due to its high strength and resilience against soil movement, moisture, and chemical exposure. Its flexibility and ease of joining make it an ideal choice for underground applications.

Q: What makes HDPE conduit a high-quality option for conduit systems?

A: High-quality HDPE conduit is characterized by its robust construction, compliance with standards such as NEMA TC-7, and reliable performance over time. HDPE conduit systems provide superior cable protection, reducing the risk of damage and service interruptions.

Q: Can HDPE conduit be used for both power and telecommunications applications?

A: Yes, the HDPE conduit is suitable for power and telecommunications applications. It effectively houses and protects electrical power and telecommunications cabling, such as internet, CATV, and telephone lines.

Q: What are the features of an HDPE conduit make it reliable for long-term use?

A: HDPE conduit features include resistance to environmental stress cracking, flexibility to withstand ground movement, and a smooth inner surface that reduces friction during cable pulling. These qualities contribute to its reliability and longevity.

Q: Where can I purchase high-quality HDPE conduit?

A: High-quality HDPE conduit can be purchased from reputable suppliers like PuHui Industry and WL Plastics HDPE. For more information or assistance, feel free to contact us directly.

Q: What standards do HDPE conduit products need to meet?

A: HDPE conduit products must meet several industry standards, such as UL Listed and NEMA TC-7. Ensuring compliance with these standards guarantees the quality and safety of the conduit for various applications.