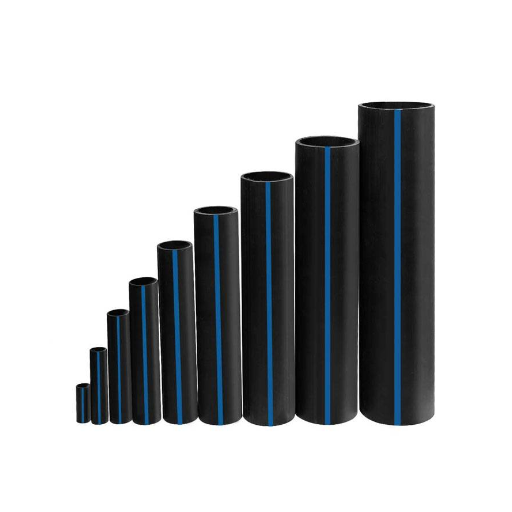

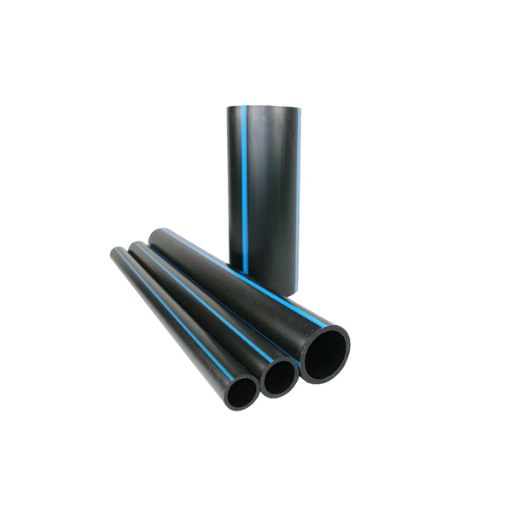

HDPE Mining Pipe

Introduction to HDPE Mining Pipes

Mining pipes manufactured by SinoPipe Industries are made using a unique flame-proof and anti-static type of polyethylene. They are produced through the use of high temperature-based extrusion technologies. Our company goes by the national coal industry standard MT588.1-2005 (Part 1: PE pipe), MT181-88, AQ1071-2009 for safety regulations on plastic mining pipes. We display our mines with pride by exhibiting Coal Mine Safety Signs (MA) over our polyethylene mining pipe manufacturing outlet.

Advantages Of Pipe Mining

- It is perfect for use in flammable and explosive environments due to its flame-retardant qualities and electrostatic dissipation.

- Its mechanical properties are superior, including high strength, impact resistance, anti-aging, and crack resistance.

- The smooth interior of the pipes reduces fluid friction, which in turn can increase the flow rate by up to 30%.

- These products are environmentally friendly when it comes to their tightness against water.

- This type of product is both durable and lightweight hence very easy to install.

Applications of HDPE Pipes for Mining

- Water Supply and Drainage Systems: HDPE pipes are significant in the coal mining process primarily because they can provide an efficient water supply and drainage system.

- Ventilation Conduits: In mining operations, HDPE pipes serve as a main ventilation conduit enabling air to pass through either positively or negatively.

- Spray Systems: To meet varied operational needs effectively, HDPE tubes serve as spray conduits during mining processes.

- Gas Drainage Systems: These pipes are part of gas drainage systems used in mining thus ensuring that gases are safely released and managed.

Chart Detailing Pipe Mining Specifications

| Nominal outer diameter | Wall Thickness(mm) | ||||

|---|---|---|---|---|---|

| DN(mm) | |||||

| 0.6Mpa | 0.8Mpa | 1.0Mpa | 1.25Mpa | 1.6Mpa | |

| 32 | 3 | ||||

| 40 | 3.7 | ||||

| 50 | 4.6 | ||||

| 63 | 4.7 | 5.8 | |||

| 75 | 4.5 | 5.6 | 6.8 | ||

| 90 | 4.3 | 5.4 | 6.7 | 8.2 | |

| 110 | 4.2 | 5.3 | 6.6 | 8.1 | 10 |

| 125 | 4.8 | 6 | 7.4 | 9.2 | 11.4 |

| 140 | 5.4 | 6.7 | 8.3 | 10.3 | 12.7 |

| 160 | 6.2 | 7.7 | 9.5 | 11.8 | 14.6 |

| 180 | 6.9 | 8.6 | 10.7 | 13.3 | 16.4 |

| 200 | 7.7 | 9.6 | 11.9 | 14.7 | 18.2 |

| 225 | 8.6 | 10.8 | 13.4 | 16.6 | 20.5 |

| 250 | 9.6 | 11.9 | 14.8 | 18.4 | 22.7 |

| 280 | 10.7 | 13.4 | 16.6 | 20.6 | 25.4 |

| 315 | 12.1 | 15 | 18.7 | 23.2 | 28.6 |

| 355 | 13.6 | 16.9 | 21.1 | 26.1 | 32.2 |

| 400 | 15.3 | 19.1 | 23.7 | 29.4 | 36.3 |

| 450 | 17.2 | 21.5 | 26.7 | 33.1 | 40.9 |

| 500 | 19.1 | 23.9 | 29.7 | 36.8 | 45.4 |

| 560 | 21.4 | 26.7 | 33.2 | 41.2 | 50.8 |

| 630 | 24.1 | 30 | 37.4 | 46.3 | 57.3 |

| 710 | 27.2 | 33.9 | 42.1 | 52.2 | |

| 800 | 30.6 | 38.1 | 47.4 | 58.8 | |

| Carried Standard:MT558.1-2005 |

Efficiency and sustainability are significant in the ever-changing mining landscape. High-density polyethylene (HDPE) pipes are game-changers, especially during tailing management stages. This article focuses on the transformative role of HDPE piping systems by highlighting their distinct features, which include durability, corrosion resistance, and lightweight nature.

Product Performance Requirements and Test Parameters

| Project | Unit | Experimental conditions | Indicators | |

|---|---|---|---|---|

| Percentage elongation at break | % | ≥300 | ||

| Anti-hydraulic strength | MPE80 | 20℃,100h,9.0Mpa | No broken | |

| MPE100 | 20℃,100h,12.4Mpa | No broken | ||

| Antistatc properties NH-VV22 | The average of the outer surface resistivity | Ω | 3℃,65% Relative humidity | ≤1.0x109 |

| The average positive pressure ventilation surface resistance,spray tube inside and outside | Ω | 23℃,65% Relative humidity | ≤1.0x108 | |

| The average gas pipe surface resistance | Ω | 23℃,65% Relative humidity | ≤1.0x106 | |

| The average surface resistancetube | Ω | 23℃,65% Relative humidity | ≤1.0x106 | |

| Retardant properties | Alcohol lamp burning time 3+1,3+2,4+1 | S | Flame height:150mm Temperature:960℃ | Flaming combustion 1 pc≤10s,6pcs≤18s |

| S | Flame height:150mm Temperature:960℃ | Flameless combustion 1 pc≤60s,6 pcs≤120s |

HDPE Mining Pipe Catalog

Pipeline Related Articles

The Question

Common FAQ

Discover detailed insights on HDPE Mining Pipe. Feel free to contact us with any questions or inquiries you may have.

Q: What makes HDPE pipes a suitable choice for mining operations?

A: HDPE pipe, or high-density polyethylene pipe, is widely used in mining due to its high resistance to abrasion, flexibility, and ability to withstand high external loads. It is especially effective for tailing solutions where the pipe must endure demanding conditions.

Q: How does HDPE pipe compare to PVC and ductile iron pipes in mining applications?

A: Unlike PVC and ductile iron pipes, HDPE pipe offers superior abrasion resistance and flexibility, making it more suitable for mining environments. It can be used in submerged or floating configurations, allowing for more versatile applications in the field.

Q: What are the advantages of using PE pipe for mining over other materials?

A: PE pipe is advantageous for mining due to its lightweight nature—it is only one-eighth steel density—making it easier to handle and install. Additionally, it is highly resistant to chemicals and abrasion, which are essential factors in mining operations.

Q: How is HDPE pipe installed in mining applications?

A: HDPE pipe is typically installed using methods such as HDPE butt fusion, which involves joining two pieces of pipe by heating and pressing them together. This creates a seamless, leak-proof connection ideal for mining and industrial applications.

Q: What are the maintenance requirements for HDPE mining pipes?

A: HDPE mining pipes require minimal maintenance compared to rigid PVC and ductile iron pipes. Their high durability and resistance to wear reduce the frequency of repairs and replacements, extending the pipeline’s life and reducing maintenance costs.

Q: Why is abrasion resistance an essential feature in mining pipes?

A: Abrasion resistance is crucial in mining pipes because transporting slurries and tailings can cause significant wear and tear on the pipeline. HDPE pipe’s high abrasion resistance ensures longer service life and lower maintenance costs.

Q: Can HDPE pipe be used in extreme environmental conditions?

A: HDPE pipes can withstand high external loads and resist various environmental factors such as temperature fluctuations and chemical exposure. This makes it suitable for a wide range of industrial and mining applications.

Q: What roles does HDPE pipe play in the mining industry's water management?

A: HDPE pipe is used in mining applications for water transportation, including drainage and tailings management. Its flexibility and durability make it an ideal choice for handling the demanding conditions of mining operations.

Q: Are HDPE pipes an environmentally friendly option for mining?

A: HDPE pipes are considered environmentally friendly because they are recyclable and have a lower carbon footprint than traditional materials. Their long lifespan and reduced maintenance needs contribute to fewer environmental impacts over time.

Q: What are the standard sizes and configurations for HDPE pipes used in mining?

A: HDPE pipes for mining are produced in straight lengths and can be of various sizes depending on the application’s specific requirements. They can also be configured in submerged or floating pipe systems to adapt to different mining environments.