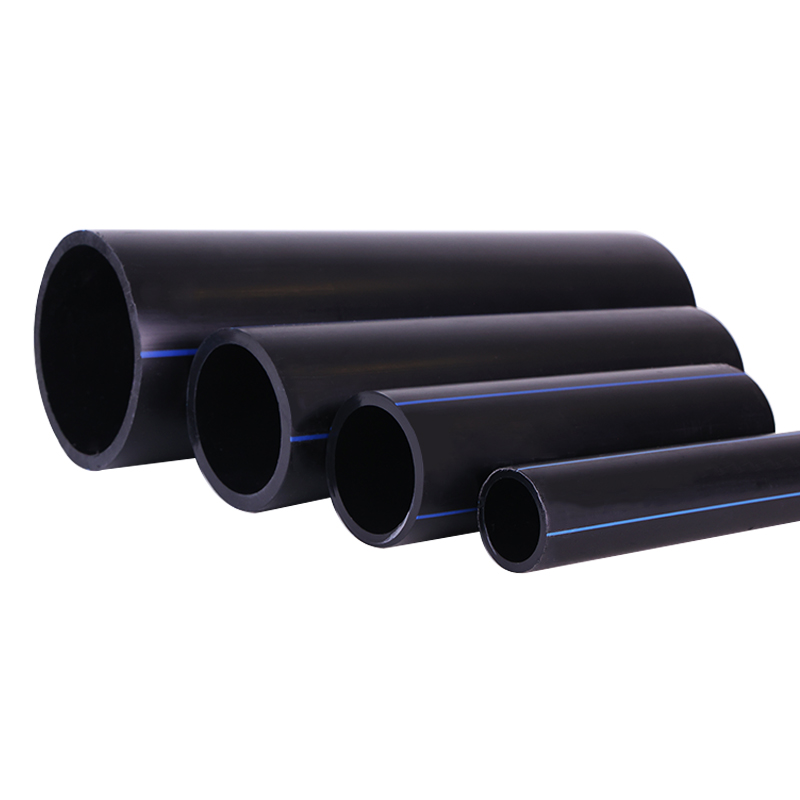

HDPE Pipe for Water Supply

Key Features of HDPE Water Supply Pipes

- Non-toxic: The HDPE material is non-toxic and tasteless. It belongs to green building materials and has passed strict health tests, effectively improving water quality and ensuring it meets your needs.

- Low Flow Resistance: The smooth inner wall makes pipeline transportation easy. Under the same conditions, HDPE pipe’s delivery capacity can be increased by 30% as its roughness is much less than that of steel and glass-reinforced pipes.

- No Leakage: HDPE pipe is connected by butt fusion, socket fusion, and electrofusion, which means the strength of the joint point is higher than that of the pipe itself.

- Excellent Flexibility: Small diameter HDPE pipes can be coiled, and large diameter products can be slightly bent, making them more convenient for construction sites.

- Good Resistance Ability for Scratch: HDPE pipe has four times the wear resistance of steel pipe, which means a longer service life and better economic efficiency.

- Convenient for Construction: PE pipes can be installed in a variety of trenchless ways, making construction and installation very convenient.

- Long Life-span: Designed for 50 years of service life under rated temperature and pressure.

- Lower Operation and Maintenance Costs: HDPE pipes are not only convenient to transport and install but also greatly reduce workers’ labor intensity and improve work efficiency.

Applications of HDPE pipe for water supply

Urban Area Water-Supply Work System: Large diameter HDPE pipe is healthy and non-toxic, making it more suitable for urban water supply main conduits and buried tubes.

Replacement of Cement, Iron, and Steel Pipes: HDPE pipes are ideal for renovation projects as they do not require large area excavation. They can be widely used in the pipe network reconstruction of old towns.

Industrial Materials Transmission Pipe: HDPE pipes are used in various industries including chemical, chemical fiber, food, forestry, pharmacy, light industry, papermaking, and metallurgical industries for raw material conveying.

Landscaping Water Supply Network: Landscaping projects require a large number of water supply pipes. HDPE pipes are the best choice for their toughness and low costs.

Sewage Discharge Pipes: HDPE pipes have unique corrosion resistance, making them suitable for industrial wastewater and sewage discharge.

Ore and Mud Transfers: HDPE pipes have high resistance to stress and wear, making them widely applicable in conveying ore, coal ash, and river mud.

Agricultural Irrigation Pipe: HDPE pipes offer great flow and good impact resistance, making them the ideal tool for agricultural irrigation.

HDPE pipe for water supply specifications chart(PE100)

| Nominal Pressure | 0.4MPA | 0.5MPA | 0.6MPa | 0.8MPa | 1.0MPa | 1.25MPa | 1.6MPa |

|---|---|---|---|---|---|---|---|

| Standard dimension ratio(SDR) | SDR41 | SDR33 | SDR26 | SDR21 | SDR17 | SDR13.6 | SDR11 |

| Nominal Diameter DN(mm) | Thickness (mm) | Thickness (mm) | Thickness (mm) | Thickness (mm) | Thickness (mm) | Thickness (mm) | Thickness(mm) |

| 16 | 2 | ||||||

| 20 | 2 | 2.3 | |||||

| 25 | 2 | 2.3 | |||||

| 32 | 2.3 | 2.4 | 3 | ||||

| 40 | 2.3 | 2.3 | 3 | 3.7 | |||

| 50 | 2.3 | 2.9 | 3.7 | 4.6 | |||

| 63 | 2.3 | 3 | 3.6 | 4.7 | 5.8 | ||

| 75 | 2.9 | 3.6 | 4.5 | 5.6 | 6.8 | ||

| 90 | 3.5 | 4.3 | 5.4 | 6.7 | 8.2 | ||

| 110 | 4.2 | 5.3 | 6.6 | 8.1 | 10 | ||

| 125 | 4.8 | 6 | 7.4 | 9.2 | 11.4 | ||

| 140 | 5.4 | 6.7 | 8.3 | 10.3 | 12.7 | ||

| 160 | 6.2 | 7.7 | 9.5 | 11.8 | 14.6 | ||

| 180 | 6.9 | 8.6 | 10.7 | 13.3 | 16.4 | ||

| 200 | 7.7 | 9.6 | 11.9 | 14.7 | 18.2 | ||

| 225 | 8.6 | 10.8 | 13.4 | 16.6 | 20.5 | ||

| 250 | 9.6 | 11.9 | 14.8 | 18.4 | 22.7 | ||

| 280 | 10.7 | 13.4 | 16.6 | 20.6 | 25.4 | ||

| 315 | 12.1 | 15 | 18.7 | 23.2 | 28.6 | ||

| 355 | 13.6 | 16.9 | 21.1 | 26.1 | 32.2 | ||

| 400 | 15.3 | 19.1 | 23.7 | 29.4 | 36.3 | ||

| 450 | 17.2 | 21.5 | 26.7 | 33.1 | 40.9 | ||

| 500 | 19.1 | 30 | 29.7 | 36.8 | 45.4 | ||

| 560 | 21.4 | 33.9 | 33.2 | 41.2 | 50.8 | ||

| 630 | 24.1 | 38.1 | 37.4 | 46.3 | 57.3 | ||

| 710 | 27.2 | 42.9 | 42.1 | 52.2 | |||

| 800 | 30.6 | 47.7 | 47.4 | 58.8 | |||

| 900 | 34.4 | 57.2 | 53.3 | ||||

| 1000 | 38.2 | 66.7 | 59.3 | ||||

| 1200 | 45.9 | 23.9 | 70.6 | ||||

| 1400 | 53.9 | 26.7 | 82.4 | ||||

| 1600 | 61.2 | 76.2 | 94.1 | ||||

| 1800 | 69.1 | 85.7 | 105.9 | ||||

| 2000 | 48.8 | 60.6 | 76.9 | 95.2 | 117.6 | ||

| 2250 | 55 | 70 | 86 | 107.2 | |||

| 2500 | 61.2 | 77.7 | 95.6 | 119.1 |

Modern plumbing and water distribution systems have found a solution in High-Density Polyethylene (HDPE) water supply pipes. HDPE pipes are durable, flexible, and corrosion-resistant compared to traditional pipe materials. The purpose of this guide is to present all the aspects of HDPE pipes, covering their properties, manufacturing processes, installation techniques, and applications.

Product Performance Requirements and Test Parameters

| No. | Item | Requirement | Test Parameter |

|---|---|---|---|

| 1 | Melt Mass-Flow Rate (g/10 min) | MFR change before and after processing not more than 20% | Load Mass: 5 kg Test Temperature: 190℃ |

| 2 | Oxidation Induction Time | ≥ 20 min | Test Temperature: 210℃ |

| 3 | Dimensional Stability | ≤ 3% | Test Temperature: 110℃ Sample Length: 200 mm |

| 4 | Carbon Black Content | 2.0% ~ 2.5% | |

| 5 | Carbon Black Dispersion/Pigment Dispersion* | ≤ Grade 3 | |

| 6 | Impurities | ≤ 0.1% | Test Temperature: (850 ± 50)℃ |

| 7 | Elongation at Break | ≥ 350% ≤ 5 mm | Sample Type: Type 2 Test Speed: 100 mm/min |

| 8 | Elongation at Break | ≥ 350% 5 mm < d ≤ 12 mm | Sample Type: Type 1' Test Speed: 50 mm/min |

| 9 | Elongation at Break | ≥ 350% d > 12 mm | Sample Type: Type 1' Test Speed: 25 mm/min |

| 10 | Increase in Length after Immersion | ≤ 5 mm (Total Test) < 10 mm/24 h | |

| 11 | Increase in Length after Pressure Test | None | Test Temperature: 80℃ Internal Test Pressure: PE 80.SDR 11 - 0.80 MPa PE 100.SDR 11 - 0.92 MPa Test Time: 500 h Test Medium: Water-Water |

HDPE Pipe for Water Supply Catalog

Pipeline Related Articles

The Question

Common FAQ

Explore comprehensive information regarding HDPE Pipe for Water Supply. Don’t hesitate to reach out to us for any inquiries.

Q: What is HDPE, and why is it used for water supply?

A: HDPE, or high-density polyethylene, is a type of plastic known for its strong yet lightweight properties, making it ideal for water supply applications. It is also resistant to corrosion and chemical leaching and has a long service life, making it a popular choice for potable water piping systems.

Q: What are the features of HDPE pipes?

A: HDPE pipe features include high durability, flexibility, resistance to corrosion, and a long service life. These pipes are also lightweight, easy to transport, and suitable for various installation methods, such as trenchless technology.

Q: What is SDR11 200 PSI in HDPE pipes?

A: SDR11 refers to the Standard Dimension Ratio, which indicates the relationship between the pipe diameter and wall thickness. A 200 PSI SDR11 HDPE pipe means it can withstand an internal pressure of 200 pounds per square inch, making it highly suitable for both potable water supply and industrial transmission systems for potable water.

Q: How does HDPE pipe compare to other potable water piping systems?

A: Compared to other potable water piping systems, such as ductile iron pipes, HDPE pipes offer lower potential leak points due to fewer pipe joints. They are also more resistant to chemical reactions, have a longer service life, and are easier to install and maintain.

Q: Can HDPE pipes be used for raw water and industrial applications?

A: HDPE pipes are suitable for raw water and industrial applications. Their durability and chemical resistance make them an excellent choice for various potable and non-potable water transmission systems.

Q: What sizes of HDPE pipes are available?

A: HDPE supply pipes are available in various sizes to accommodate different needs. Pipe diameter options can vary greatly, allowing the HDPE pipe to be used in multiple applications, from potable water supply to large-scale industrial projects.

Q: What installation methods can be used with HDPE pipes?

A: HDPE pipes are compatible with multiple installation methods, including traditional trenching, pipe bursting, directional drilling, and horizontal boring. This versatility allows the HDPE pipe to be installed in various situations, including areas where conventional methods may not be feasible.

Q: Are black HDPE pipes suitable for potable water?

A: Yes, black HDPE pipes are suitable for potable water supply. They are manufactured to meet stringent standards that ensure their safety and suitability for transporting potable water, making them a reliable option for municipal and residential water distribution systems.

Q: What are potential leak points in HDPE piping systems, and how are they minimized?

A: Potential leak points are typically found at pipe joints and connections. HDPE piping systems minimize these leak points through heat fusion, creating a seamless connection between pipes and fittings and significantly reducing the risk of leaks.

Q: Why is HDPE pipe the perfect solution for water supply applications?

A: HDPE pipe’s long service life, resistance to environmental stressors, and ease of installation make it the perfect solution for water supply applications. Its durability and flexibility ensure reliable performance under various conditions, meeting the demands of both potable and raw water transmission systems.