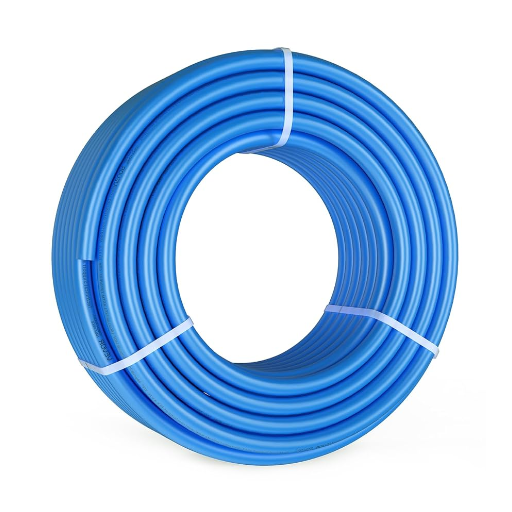

When it comes to modern plumbing and water distribution systems, PEX tubing has revolutionized the industry with its unmatched versatility, durability, and cost-effectiveness. Among the various options available, 3/4 PEX pipe, particularly in its convenient 100-foot rolls, stands out as a reliable and efficient choice for both residential and commercial applications. But what makes this specific size and length such a popular selection? How does it compare to traditional materials, and what are its strengths in different scenarios? This ultimate guide provides you with an in-depth understanding of 3/4 PEX pipe, exploring its composition, uses, installation methods, and why it has become a go-to solution for plumbing professionals and DIY enthusiasts alike. Whether you’re planning a new installation, looking to upgrade an existing system, or simply seeking to expand your knowledge of plumbing materials, this article will equip you with the essential details you need to make informed decisions.

Specifications and Description of 3/4 PEX Pipe

Overview of PEX Tubing

Different plumbing materials can be installed according to the project at home, commercial, or industrial worksite, given that PEX tubing is versatile and durable. It is manufactured from high-density polyethylene subjected to cross-linking. This structure gives the pipe the strength, greater flexibility, and temperature resistance required for it to be reliable under various conditions commonly associated with water supply lines, radiant heating, and hydronic heating systems.

Of course, one of the main advantages of 3/4″ PEX pipe is its flexibility, allowing for a less difficult installation process when compared to rigid materials like copper or PVC. Because of this flexibility, there is less need to use excessive fittings and connectors in the setup process, thereby reducing the time taken for the installation as well as limiting the number of weak points that can plague the system. In addition, PEX is resistant to corrosion, scaling, chemical exposure, sun exposure, and freezing weather, making it suitable for very long uses in cold and hot water distribution.

PEX tubing is much better at heat retention than many other materials traditionally used in plumbing systems to keep water temperature in the system. This compatibility with push-fit connectors and crimp rings makes it much easier to handle and install, fitting nicely into the portfolios of professional plumbers and DIY users. Being economical, sturdy, and easy to maintain, PEX tubing took center stage in modern plumbing systems and has increasingly replaced many traditional piping materials.

Dimensions and Pressure Ratings

PEX tubing is available in almost all standard sizes to satisfy the requirements of varied plumbing applications. Common sizes are 3/8-inch, 1/2-inch, 3/4-inch, and 1-inch, the best-selling size being the 1/2-inch tubing, as it is best suited for residential water supply lines. Instead of the diameter of the outside walls of the pipe, the nominal size refers to the diameter of the inside, which is slightly bigger on the outside owing to wall thickness. These sizes are all but certain to fit any given fixture or fitting while providing the calculated water flow rates used by system designs.

Pressure ratings are assigned to PEX tubing considering a particular temperature and in conformity with the ASTM, CSA, or any other set of standard testing guidelines. Generally, the maximum operating pressure is considered as 160 psi at 73°F, 100 psi at 180°F, and 80 psi at 200°F. This rating indicates its capacity to withstand various conditions of use, making it a candidate for cold and hot water distribution systems and for radiant heating systems as well.

Increasing temperatures mean the maximum allowable pressure will go down—a typical behavior of thermoplastic materials. It is essential to follow these ratings to ensure the design and operational life of the system. For safety and function, the design engineer and system installer shall determine the maximum anticipated operating pressure and temperature conditions under actual working conditions so as to select the size and type of PEX tubing to be used for particular applications.

Types of PEX: PEX-A vs PEX-B

PEX types include PEX-A, PEX-B, and PEX-C, differing by manufacturing method and hence flexibility, burst resistance, and cost.

|

Key Point |

PEX-A |

PEX-B |

|---|---|---|

|

Method |

Peroxide (Engel) |

Silane (Moisture) |

|

Flexibility |

High |

Moderate |

|

Burst Resist. |

Up to 500 PSI |

Lower |

|

Cost/ft |

$0.35 |

$0.21 |

|

Fittings |

Expansion |

Crimp |

|

Flow Restrict. |

None |

Yes |

|

Kink Repair |

Heat Gun |

Replace |

|

Cold Climate |

Slower Contraction |

Consistent |

Benefits of Using 3/4 PEX Pipe

Durability and Flexibility

PEX pipes in the 3/4-inch size are designed for long-term performance under various conditions. Durability is attained through their resistance to corrosion, scaling, and pitting, which are typical ailments of traditional metal piping systems. In particular, cross-linked polyethylene presents a greater mechanical strength to withstand pressures even up to 500 PSI (in the case of PEX-A), while resisting cyclic loading even time.

Flexibility is a big factor because PEX pipes can be bent around obstructions without requiring fittings, thus easing installation and lessening a source for potential leaks. The variation in flexibility depends on the type of PEX, with PEX-A being the most flexible as it is manufactured via the peroxide (Engel) process. This material also holds up against climate effects, contracting comparatively slower than other piping materials, thereby reducing its risk of cracking or breaking in subzero temperatures.

These qualities combined make PEX piping a perfect fit for residential applications, including commercial and industrial ones, where reliability and adaptability are essential design and performance criteria.

Cost-Effectiveness in Plumbing Projects

Arguably, the most talked-about reason for using PEX piping is that it is inexpensive and has made it one of the favorite selections for modern plumbing projects. PEX, in general, is much cheaper compared to copper or PVC when we talk about material and labor costs. Being less expensive is largely attributed to its simpler manufacturing and the use of polyethylene, which is cheaper than metals such as copper. Also, this piping being flexible makes PEX faster to install because fewer joints and connectors are needed, resulting in lower labor costs.

With more freedom to maneuver in the smallest of crawlspaces, PEX piping can be routed around obstacles with minimal effort and almost without special tools or major structural disruption during installation, consequently shortening the project duration and further bringing down the costs. Furthermore, it remains largely unscaled and non-corrosive, thereby reducing maintenance costs over its lifespan and thus providing owners and businesses with savings.

Another perspective shows that installation costs for residential plumbing can drop up to 60% with PEX systems compared to copper. Giving the plumbing profession top marks for its durability, energy-saving properties (e.g., lower thermal conductivity means better maintenance of water temperature), and ease of installation, PEX gives you the best performance at the lowest price in a plumbing project, regardless of its scope.

Chlorine Resistance and Warranty Considerations

PEX pipes are rather chlorine-resistant, a feature considered extremely important for systems using treated municipal water. Chlorine is a disinfectant generally injected into water supplies, and the typical plumbing materials can widely degrade over time because of it, ultimately leading to leaks and failures in such systems. PEX, on the other hand, has been engineered specifically to withstand prolonged contact with chlorinated water without compromising its integrity. Tests carried out by independent bodies show that, depending on time, concentration, or temperature conditions, PEX pipes will still perform adequately even after long exposures to chlorine, thus providing a secure alternative to a plumbing system setting for both residential and commercial applications. Such a factor weighs PEX favorably in areas working with heavily chlorinated water supplies.

Another factor critical to be considered is the warranty about PEX systems, as at times, it is representative of what could reasonably be expected of the life-span and performance of the said materials affected by real-world conditions. Leading manufacturers typically offer between 20 years and a lifetime warranty, assuming that installation and usage adhere to the provided standards. This warranty encourages the end user, whether it be a homeowner or a professional, to place an investment, one supported by rigorous durability testing and meeting stringent industry standards like ASTM F876 and F877. Hence, it is of utmost importance to pick bona fide PEX products, following the installation methods outlined to maintain that warranty over the long haul.

This, combined with cheap price and high performance, low maintenance requirements of PEX, together with its resistance to frequent water contaminants, establishes it as a prime choice in present-day plumbing. Providing assurance against degradation by chlorine and offering extended warranties, PEX brings in assured cost savings to the table, hence being the number one choice for new constructions and retrofitting, outranking any other traditional materials, comparatively, as copper and PVC in terms of reliability and long-term returns.

Installation Tips for 3/4 PEX Pipe

Tools Needed for Installation

Tools used in the installation of 3/4 PEX pipe are critical for efficiency and greater performance potential. A PEX pipe cutter should be your priority, as it helps to make clean cuts without any distortion of the pipe. Precision is very important, as an uneven cut can affect the strength of the fittings and the connections. One may also use a deburring tool or reamer if the pipe edges come out rough; this prepares the edges for fittings.

A crimping or cinch tool is the second-most essential tool, which is used to make the connections between the PEX pipe and fittings secure. You could either be crimping with the rings or cinching with the clamps. Each has an associated tool that compresses the connection and holds it tight so there is no leak. Using a set of go/no-go gauges for verification of every connection builds an added layer of reliability.

In the situation where the installation uses the expander fitting method, you will also need a PEX expansion tool. This tool expands the pipe evenly, allowing fittings to be inserted with little effort. With expansion rings, this method provides one of the strongest and most trustworthy connections once the pipe contracts around the fitting. Marking tools, a tape measure, and fastening clips should complete the list to ensure neat routing and positioning of the pipes. Hence, preparing these tools in advance would help in a smooth early installation and ensure the longer life of the PEX system.

Best Practices for Cutting and Connecting

Cutting and connecting PEX pipes must be done with precision and consistency to achieve the best performance and the most lasting system. First, one needs to use a pipe cutter dedicated to PEX pipe to make sure the edges are clean and square; if the ends are jagged or uneven, the connection loses integrity and may leak. The pipe end should be examined for any deformity or debris, and if present, they must be removed before fitting so that it may seal properly.

Calibrate the expansion tool fully as per the manufacturer’s instructions prior to making direct connections, so that the pipe is uniformly and properly expanded around the fitting. Failure to do so might cause the fitting to contract unevenly around the expanded pipe and result in poor sealing. Use good quality fittings, preferably of brass or polymer, conforming to ASTM F1960 standards, which assure fitting durability and corrosion resistance.

Best practices for pipe routing include maintaining generous bend radii to avoid kinking and adhering to recommended pipe spacings to prevent thermal interference. Clip intervals should be 32 inches on horizontal runs and 4–6 feet on vertical runs to adequately support the pipe while minimizing stress. Finally, a pressure test shall be performed to specifications of the local building code submission before signaling the system to make sure that all fittings are well-tightened and free from leakage. Following such conscientious measures ensures that the installation will be up to industry standards with reliable performance.

Avoiding Common Installation Mistakes

Common mistakes should be avoided to ensure the smooth installation of piping systems. One mistake often observed is the failure to account for thermal expansion and contraction. Without proper installation of expansion loops, bends, or compensators, the pipe and joints may experience excessive stresses and thus undergo premature failure. Another thing to look out for is wrong sealing techniques. When joints are under-torqued or over-torqued, the seal integrity gets compromised, making leakage a strong possibility. Following the manufacturer’s specifications for torque and application of sealing materials can alleviate this problem.

Other points are improper alignment during installation. Unevenly aligned pipes create stress points that may shorten the lifespan of the system or provide grounds for early failure. Employ laser alignment tools or string lines to secure the proper alignment of pipe sections. In addition to that, a lack of scrutiny about the compatibility of piping materials with the fluids being delivered could be detrimental. For instance, piping materials that are incompatible with the transport of acidic or alkaline fluids stand a great chance of experiencing faster corrosion.

Last but not least, failure to ensure adequate support spacings leads to sagging or undue stress concentrations along the piping system. Follow recommended support spacings based on pipe material and diameter to the letter. Addressed accurately and coupled with best practices, these considerations enable installers to have a sturdy and durable piping system that is technically compliant.

Comparative Analysis of 3/4 PEX vs Other Pipe Materials

Advantages of PEX Over Copper

- Cost-Effectiveness: PEX is much cheaper compared to copper, concerning both material and labor costs. The most cited data source in the industry states PEX tubing costs up to 60% less than copper pipe per linear foot. PEX, being flexible, lessens the installation time, and thus, labor costs are also reduced.

- Ease of Installation: The flexibility of PEX enables the material to be bent around corners and installed with far fewer fittings than copper, which is rigid. This significantly reduces the use of expensive joints and soldering. Also, long continuous runs can be made using PEX, minimizing the possibility of any leaks occurring at the joints.

- Resistance to Corrosion and Scalability: When exposed to acidic or highly mineralized water, copper corrodes and gets scaled. PEX resists these inconveniences. Chemically speaking, the material does not lose its integrity over time, in particular when applied to troubled waters.

- Superior Thermal Resistance: PEX pipe offers much better thermal insulation compared to its copper counterpart. PEX with lower thermal conductivity keeps the unwanted loss of heat from the hot water system down, thereby improving energy efficiency. PEX also resists freezing because, unlike copper pipes, it can expand without cracking.

- Noise Reduction: PEX pipes are generally quieter in operation since they do not have water hammer noises or expansion noises found in copper piping systems. This makes it a good choice in a residential setup where noise is a considerable factor.

Saving a considerable amount of cash, offering greater durability, and ease in maintenance, PEX stands for a modern, trustworthy replacement of the old copper piping systems.

PEX vs PVC: Which is Better?

PEX has flexibility and durability that the jittery PVC must lack, especially when it comes to hot water; whereas PVC-rigid, cheap-PVC pipes fit best for cold water and drainage.

|

Key Point |

PEX |

PVC |

|---|---|---|

|

Flexibility |

High |

Low |

|

Durability |

High |

Moderate |

|

Hot Water |

Yes |

No |

|

Cold Water |

Yes |

Yes |

|

Cost |

Higher |

Lower |

|

Installation |

Easy |

Moderate |

|

Eco-Friendly |

Yes |

No |

|

Lifespan |

40-50 yrs |

70 yrs |

Considerations for Different Applications

While considering the PEX versus PVC plumbing debate, one must really consider the unique project requirements and conditions. PEX presents highly flexible solutions and resistance to heat, thus making it truly best for applications of hot water systems and particularly in residential settings where the ease of installation and longevity matter greatly. Its ability to withstand freezing without considerable risk of cracking makes it a dependable option in areas with extreme weather fluctuations.

However, PVC offers a lesser degree of versatility but presents the advantages of economy. It is hence preferred for cold water and drainage systems. PVC’s rigid nature provides for sturdy installation where straightforward configurations prevail, rendering it economic in large infrastructure projects or where systems present simple routing options. The inability of PVC to withstand high temperatures limits its applications in any setting that requires the same.

Other parameters influencing material choice include the environmental factor. As far as PEX is concerned, its being eco-friendly and recyclable places it with green building initiatives, whereas PVC, though longer in some cases, is an option of a higher environmental impact when it comes to manufacture and disposal. Grasping these subtle differences guarantees that the right material is chosen in the performance, cost-effective, and sustainable aspects pertinent to various plumbing scenarios.

Common Applications of 3/4 PEX Pipe

Residential Plumbing Uses

3/4 PEX pipes are generally considered highly flexible, long-lasting, and economical, making them a good choice in most residential plumbing applications. Below are five common uses for 3/4 PEX pipes, along with the technical details in their favor:

- Main Water Supply Lines: 3/4 PEX pipes are used as main supply lines for residential plumbing due to their capacity to allow large water volumes to flow and handle high water pressure. They offer greater resistance to corrosion than copper pipes, thus ensuring that the pipes last longer.

- Hot and Cold Water Distribution: PEX, being resistant to temperatures ranging from -40°F to 200°F, can be used for hot and cold water installations. The thermal resistance of PEX decreases heat losses for hot water systems.

- Radiant Floor Heating Systems: The 3/4 PEX pipes are quite flexible, which allows them to be easily installed for radiant heating systems. PEX functions well for heat conduction; this way, it improves energy efficiency in residential heating systems and diminishes utility costs.

- Outdoor Plumbing: Resistance to freezing temperatures allows 3/4 PEX pipe to be highly reliable for outdoor plumbing, such as irrigation systems or hose-bib connections. The durability of the material guarantees the performance even in adverse conditions.

- Water Heater Connections: These PEX pipes will work as well as copper pipes when connecting to water heaters. Their high-pressure tolerance and resistance to scaling will ensure their performance remains consistent and requires less maintenance as time passes.

The above practical uses illustrate the preference of 3/4 PEX pipes in modern residential plumbing projects. These technical properties address the key requirements of durability, resistance to temperature, and efficiency, which makes them high atop traditional types of piping material.

Commercial Plumbing Applications

The 3/4 PEX pipes serve equally well within various commercial plumbing systems. Their capability to withstand extremely high water pressures and varying temperatures makes them suitable for diverse commercial setups. Given below are the five main uses of 3/4 PEX pipes in commercial plumbing:

- Hydronic Heating Systems: PEX pipes are commonly chosen for hydronic heating applications for their flexibility and ability to withstand both high temperatures and pressure. Their insulation properties prevent unwanted heat loss, ensuring energy-efficient transfer of required heat into the working space; hence, they become a cost-effective solution to meet the large-scale heating needs of commercial buildings.

- Potable Water Supply: Being certified for potable water supply, PEX pipes are a tried-and-tested option for all kinds of commercial installations involving water supply, such as hospitals, schools, and office complexes. Their non-corrosive nature and durability guarantee the keeping of water free from contaminants and safe for consumption throughout the service life.

- Multi-Story Plumbing Systems: 3/4 PEX pipes are lightweight yet very robust in nature to provide water to multi-story buildings such as hotels, various apartment complexes, and corporate towers. Their installation being easy reduces the cost of labor and hastens the construction processes.

- Radiant Cooling System: PEX pipes serve well for radiant cooling systems in commercial applications. This system chills water that is circulated through PEX tubing to cool floors or ceilings. It is a silent and energy-efficient approach to retaining comfort in large areas.

- Compressed Air Piping: Because of their high tolerance for pressure and corrosion resistance, PEX pipes find increasing usage in commercial applications for compressed air. These pipes serve as a lighter, safer, and cost-saving alternative to traditional materials like steel or copper, especially for industrial and manufacturing plants.

All these applications demonstrate how 3/4 PEX pipes are very versatile and dependable in sustaining demanding commercial plumbing systems by adding to their usability,y yet reducing costs and maintenance requirements.

Role in Radiant Heating Systems

PEX pipes are, indeed, the heart of radiant heating systems because of their properties: efficiency, longevity, and flexibility. Systems distribute heated water through tubes that are placed under the floor; the water then gets heated and radiated onto the surface level. PEX pipes are suitable to be chosen for such high-level applications wherein thermal conductivity and resistance to thermal expansion are required by installation for a more consistent heating application. Here are five crucial properties and data points that describe the efficacy of PEX pipes in radiant heating systems:

- Thermal Conductivity: Heat gets transferred efficiently from hot water in PEX pipes to the floor materials, and heat is spread evenly across the whole floor. Their low thermal resistance works in favor of the system’s energy efficiency.

- Flexibility and Installation Ease: Being flexible, PEX pipes help ease the installation by allowing for tighter bends and modifications to suit irregular layouts, thereby saving on labor and installation time.

- Durability and Longevity: Resistant to cracking, scaling, and corrosion under standard conditions, PEX pipes have an estimated service life of 50 or more years, thereby reducing maintenance or replacement requirements.

- Temperature Resistance: PEX pipes maintain operating temperatures of up to 200°F (93°C) and pressures of up to 80 psi, better fitting the requirements of radiant heated floors without giving out any sort of performance.

- Cost-Effectiveness: PEX costs less than copper in terms of materials and labor. Being light, the PEX pipes require fewer shipping charges and are also easier to handle at the job site.

All these attributes have cemented the PEX pipes as popular and worthy options for radiant heating systems, thereby driving the cause of energy-efficient buildings.

References

Frequently Asked Questions (FAQ)

Q: What is a 3/4 PEX pipe 100′ used for?

A: A 3/4 pex pipe 100′ is commonly used for plumbing systems, including both hot and cold water supply lines. Its flexibility makes it ideal for various applications such as radiant floor heating and connecting fixtures in residential and commercial buildings.

Q: What are the benefits of using a 3/4 PEX pipe 100′?

A: The benefits of using 3/4 PEX pipe 100′ include its resistance to corrosion and scale buildup, ease of installation due to its lightweight nature, and ability to expand and contract, which reduces the risk of bursting in freezing conditions. It also has a high chlorine resistance, making it suitable for potable water systems.

Q: How does the color of a 3/4 pex pipe 100′ indicate its use?

A: The color of a 3/4 pex pipe 100′ often indicates its intended use. For instance, red tubing is typically used for hot water applications, while blue is used for cold water. This color-coding helps in easily identifying the type of water system in which the pipe is installed.

Q: What is the maximum pressure rating for a 3/4 PEX pipe 100′?

A: The maximum pressure rating for 3/4 PEX pipe 100′ is generally around 300 psi at 73°F. However, this rating can decrease at higher temperatures. It’s essential to check the specifications of the specific product for accurate ratings.

Q: Can a 3/4 PEX pipe 100′ be used for radiant floor heating?

A: Yes, 3/4 pex pipe 100′ is ideal for radiant floor heating systems. Its flexibility allows it to be easily installed in concrete or under flooring, providing efficient heat distribution throughout the space.

Q: What is the difference between PEX-A and PEX-B pipe?

A: The primary difference between PEX-A and PEX-B pipe is the method of production. Pex-a is produced using the silane method, which creates a more flexible and expandable tubing. Pex-b, on the other hand, is manufactured through a different method that provides good chlorine resistance but may not be as flexible as PEX-A.

Q: Is a 3/4 PEX pipe 100′ certified for drinking water?

A: Yes, a 3/4 PEX pipe 100′ can be certified for drinking water use if it meets the NSF (National Sanitation Foundation) standards. It’s essential to look for certification markings on the pipe to ensure it is suitable for potable water applications.

Q: What is the typical warranty period for a 3/4 PEX pipe 100′?

A: The typical warranty period for 3/4 pex pipe 100′ varies by manufacturer but often ranges from 25 years to a lifetime warranty, depending on the product specifications and intended use.

Q: How should I connect a 3/4 PEX pipe 100′ to fittings?

A: To connect a 3/4 PEX pipe 100′ to fittings, you can use crimp rings or push-fit connectors. It’s crucial to ensure a secure connection to prevent leaks, and you may need a pipe cutter to achieve clean, square cuts for the best fit.

Q: What are the temperature limits for using 3/4 PEX pipe 100′?

A: The temperature limits for using 3/4 PEX pipe 100′ generally range from a minimum of -40°F to a maximum of 180°F. Always check the manufacturer’s specifications to ensure it meets the requirements for your specific application.