HDPE pipe production involves melting granulated polymers and using extruders to form pipes of different diameters. Modern HDPE pipes are widely used globally for potable water conveyance and drainage systems. Understanding HDPE pipe costs is crucial for planners and site engineers budgeting water supply projects.

This comprehensive guide covers factors affecting HDPE pipe costs, including material features, manufacturing processes, market demand, and logistics. Whether you’re an engineer, contractor, or infrastructure developer, this guide will help you make informed investment decisions.

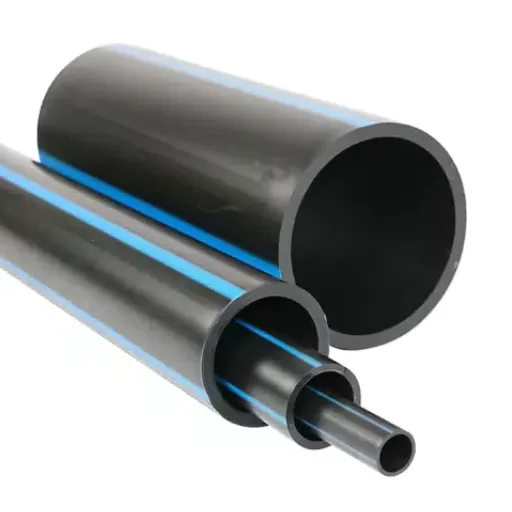

Overview of HDPE Pipes

What is HDPE?

High-Density Polyethylene (HDPE) is a versatile thermoplastic polymer extracted primarily from petroleum. It’s highly rated for its strength-to-density ratio and serves as an ideal material for extensive piping applications, including:

- Water supply systems

- Gas distribution networks

- Sewerage management

Key HDPE Characteristics:

- Lightweight: Superior performance with enhanced durability

- Chemical Resistance: Withstands exposure to corrosive chemicals

- Non-Corrosive: Does not corrode, rot, or scale

- Flexible: Accommodates soil movement and resists cracking

- Long-lasting: Expected lifespan exceeds 50 years

Benefits of HDPE Water Pipes

Corrosion Resistance

Unlike steel or iron, HDPE pipes have innate corrosion resistance properties, providing prolonged service life in corrosive environments. Studies indicate HDPE pipes can last more than 50 years in most environments.

Durability and Flexibility

The material’s ductility allows HDPE pipes to accommodate soil shifts without cracking. This makes them excellent for earthquake-prone areas, reducing damage risk during seismic events.

Leak-Free Joint Systems

Heat fusion creates seamless, leak-proof joints. Studies show leakage rates in HDPE fusion joint systems are almost negligible compared to mechanical joints.

Lightweight Installation

HDPE pipes are significantly lighter than traditional materials, making transportation and installation more economical while reducing labor and machinery requirements.

Chemical Resistance

Excellent resistance to acids, alkalines, and salts allows use in harsh chemical environments, extending pipe life across various applications.

Water Quality Preservation

Non-toxic material prevents contamination and leaching, ensuring water quality remains uncompromised throughout the distribution system.

Applications in Water Supply Systems

Potable Water Distribution

The majority is used in safe drinking water distribution with a 50+ year lifespan under standard conditions. Non-toxic properties prevent water contamination.

Irrigation Systems

High flexibility and environmental degradation resistance for agricultural applications. UV light resistance and leak-proof joints result in 30-40% water savings.

Fire Suppression Systems

Underground fire suppression pipelines withstand high pressures up to 150 PSI while maintaining chemical and corrosion resistance during critical situations.

Stormwater Drainage

Smooth inner surface provides exceptional hydraulic performance with up to 30% greater flow capacity than concrete or metal systems, reducing flooding problems.

Wastewater Transport

High chemical resistance handles abrasive materials and harsh industrial effluents. HDPE systems offer 20-25% lower maintenance costs over their lifespan.

HDPE Pipe Pricing Breakdown

Typical Price Ranges for Different Sizes

HDPE pipe prices vary significantly based on diameter, wall thickness, pressure ratings (SDR classifications), and manufacturing standards. Here are the general price ranges:

| Pipe Category | Diameter Range | Price Range (USD/ft) | Common Applications |

|---|---|---|---|

| Small Diameter | 1″ – 3″ | $0.50 – $2.00 | Domestic irrigation, potable water, drainage |

| Medium Diameter | 4″ – 12″ | $2.50 – $8.00 | Large irrigation, municipal distribution, and industrial |

| Large Diameter | 14″ – 24″ | $9.00 – $20.00 | Municipal works, large-scale drainage, wastewater |

| Extra-Large Diameter | 24″+ | $25.00+ | Industrial works, large water mains, stormwater systems |

Detailed Price List by Diameter

| Diameter (inches) | Price Range (USD/foot) | Application Notes |

|---|---|---|

| 1″ | $0.50 – $1.50 | Small-scale irrigation and low-pressure applications |

| 2″ | $1.00 – $3.00 | Residential water supply systems |

| 4″ | $4.00 – $8.00 | Industrial and commercial piping systems |

| 6″ | $6.00 – $12.00 | Medium-scale municipal waterworks and drainage |

| 8″ | $8.00 – $15.00 | Large-scale industrial and municipal projects |

| 10″ | $10.00 – $20.00 | High-capacity fluid transport systems |

| 12″+ | $12.00 – $25.00+ | Heavy-duty applications, main pipelines |

Important Note: Prices are subject to market fluctuations and additional costs, including transportation, regulatory compliance, and installation expenses.

Factors Influencing HDPE Pipe Prices

Key Cost Drivers

- Raw Material Pricing: Polyethylene resin costs directly impact pipe prices, influenced by global petrochemical markets and crude oil prices

- Manufacturing Technology: Extrusion technology precision, adherence to ASTM, ISO, and AWWA standards affect pricing

- Diameter and Wall Thickness: Larger diameters and thicker walls (SDR ratings) require more material, increasing costs

- Supply and Demand: Market requirements from water distribution, gas transmission, and infrastructure projects influence availability and pricing

- Geographic Location: Transportation costs and distance from manufacturing facilities significantly impact final prices

- Special Applications: Custom designs for chemical resistance or high-pressure environments increase production costs

Manufacturing Processes Impact on Cost

Blow Molding

Heating and melting polyethylene resin, then pressing it through dies. Temperature control and die setup accuracy influence costs and material usage efficiency.

Cooling and Calibration

Rapid cooling systems (water or compressed air) maintain pipe shape and structural features but require energy consumption and equipment maintenance.

Material Mixing

Polyethylene resin incorporation with performance-enhancing additives increases costs but improves environmental resistance and lifespan.

Quality Testing

Hydrotest and inspection procedures require specialized equipment and skilled personnel, reducing production rates but ensuring compliance.

Material Comparisons

HDPE vs. PVC Pipe: Cost and Performance

| Aspect | HDPE | PVC |

|---|---|---|

| Initial Price | Higher | Lower |

| Longevity | Superior (50+ years) | Moderate (~50 years) |

| Flexibility | High | Low |

| Temperature Range | -40°C to 140°C | 0°C to 45°C |

| UV Resistance | Yes | No |

| Connection Method | Heat welding | Glue bonding |

| Maintenance | Minimal | Moderate |

| Chemical Tolerance | Extensive | Limited |

Metal Pipes vs. HDPE: Cost Analysis

| Aspect | HDPE | Metal Pipes |

|---|---|---|

| Upfront Cost | Higher | Lower |

| Durability | Corrosion-free | Prone to rust |

| Weight | Lightweight | Heavy |

| Installation | Easy | Complex |

| Maintenance | Minimal | Frequent |

| Lifespan | 50+ years | Variable |

| Environmental Impact | Recyclable | High carbon footprint |

| Pressure Handling | Moderate | High |

Installation and Regional Considerations

Installation Expense Factors

HDPE pipe installation costs vary significantly based on several complex factors:

- Soil Conditions: Rocky or stiff soils require elaborate trenching methods, increasing excavation costs

- Urban vs. Rural: Urban areas may require trenchless methods like directional drilling, which is more expensive initially

- Labor Availability: Regional wage scales and skilled workforce availability affect costs

- Environmental Regulations: Local environmental protection and building standards may require additional measures

- Climate Conditions: Weather can cause construction delays and affect project timelines

- Material Delivery: Transportation logistics and distance from suppliers impact total costs

Case Studies and Industry Insights

Successful HDPE Implementations

Urban Water Distribution Success

HDPE pipes in urban water distribution systems have demonstrated superior performance over steel and PVC, providing safer and more cost-effective water supply with reduced repair costs and extended system life.

Agricultural Irrigation Achievement

A major Australian agricultural project replacing steel pipes with HDPE resulted in a 30% decrease in water losses due to leakage, significantly improving water efficiency and reducing environmental impact.

Storm Water Management

Southeast Asian flood-prone localities using HDPE for stormwater drainage have significantly reduced urban flooding incidents and associated financial impacts.

Expert Recommendations

Industry experts consistently recommend HDPE for water distribution systems due to:

- Strength-to-weight ratio: Exceptional durability in demanding applications

- Corrosion resistance: Long-lasting solutions in aggressive environments

- Fusion welding capability: Leak-proof joints with enhanced system stability

- Reduced maintenance: Lower life-cycle costs compared to traditional materials

- Sustainability: Recyclable material supporting eco-friendly practices

Future Trends

The HDPE pipe industry continues evolving with:

- Smart Technology Integration: Embedded sensors for real-time pressure, leak detection, and flow monitoring

- Enhanced Longevity: Improved formulations targeting 50-100 year lifespans

- Sustainable Manufacturing: Increased use of recycled materials and eco-friendly production

- Urban Adaptability: Specialized designs for high-density urban installations

Frequently Asked Questions

A: HDPE pipe costs are influenced by pipe diameter, wall thickness, pressure ratings, current market prices, installation requirements, and regional demand/supply conditions. Raw material costs and manufacturing specifications also significantly impact final pricing.

A: While HDPE pipes may have higher initial costs than PVC or some metal alternatives, they significantly reduce installation and maintenance expenses over their lifetime. The corrosion resistance and longevity of HDPE systems often result in a lower total cost of ownership.

A: Absolutely. HDPE pipes are highly recommended for municipal water systems due to their durability, corrosion resistance, and cost-effectiveness. They require less frequent repairs and have extended lifespans compared to traditional materials.

A: Various HDPE fittings are available, including electrofusion and butt fusion fittings. These create leak-proof connections that integrate seamlessly with the pipe system, providing reliable joints throughout the network.

A: Yes, HDPE pipes are excellent for agricultural irrigation due to their durability, chemical resistance, and flexibility. Their UV resistance and leak-proof joints can result in 30-40% water savings compared to traditional systems.

A: HDPE pipes are well-suited for high-pressure applications due to their flexibility and durability. They can withstand extreme external conditions while maintaining structural integrity, making them ideal for pressurized water transport systems.

References

Assessment of the Compliance of the High-Density Polyethylene Pipe

This report contains information relevant to the costs and quality levels of HDPE pipes, touching on the differences between various grades, such as PE 63 versus PE 100.

Specification of Construction Renovation with the Use of HDPE Pipes in Pipe Bursting in Particular

This research work deals with cost reduction and technical considerations arising during the use of HDPE pipes, which applies to municipal water networks.

Plastic Pipes for Low Stress Ethanol Pipes: What is feasible and what is not

This research focuses on the cost efficiency that accrues when using ethylene HDPE as a laying conduit vis-a-vis the traditional material, which is carbon steel.