In today’s world, where people are increasingly becoming more aware of their environment and the need for it to be sustainable, there is a great need for infrastructure that can be sustained. Over the years, HDPE double wall corrugated pipe sustainability has become a popular choice in many infrastructural applications due to its strength and lightness, which makes it resistant to various environmental stressors. This article examines the benefits of using HDPE double-wall corrugated pipes to create a pathway to reduce carbon footprints, conserve resources, and maintain an efficient waste management system. It, therefore, seeks to conduct an overview of these pipes by analyzing their life cycle properties, performance characteristics, and end-of-life options to establish how these materials can contribute toward environmentally responsive construction and sustainability in the future.

What Are HDPE double-wall corrugated Pipes?

Knowing HDPE and its Characteristics

High-density polyethylene (HDPE) is a thermoplastic polymer with an exceptional strength-to-density ratio that can be used in many industrial applications. HDPE has a linear structure, which means there are few side branches along the molecule backbone, making it stronger when stretched or subjected to impact compared to LDPE material. The polymer is highly resistant to chemicals, enabling it to resist corrosion from various sources, including acids, alkalis, and organic solvents. HDPE also possesses good weathering properties that allow it to resist degradation caused by sunlight; hence, it can be used for outdoor uses such as stormwater, sewerage, and irrigation systems. Similarly, the lightness of the substance results in easier transportation and installation processes, thereby reducing greenhouse gas emissions associated with transportation. As such, the characteristics of HDPE have been viewed as important determinants of infrastructure sustainability objectives.

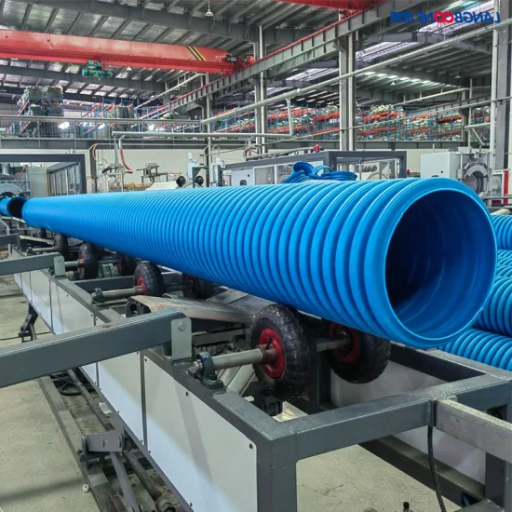

How Do You Make double-wall corrugated Pipes?

Making double-walled corrugated pipes starts with extruding High-Density Polyethylene (HDPE) in its molten form. Firstly, the inside layer is extruded to create a smooth and even surface. Secondly, the outer corrugated layer is simultaneously extruded to form a dual-layered structure, increasing its strength and stiffness while minimizing the pipe’s weight. In addition, the ridging not only aids in improving the structural integrity but also improves drainage efficiency. The final stage involves cooling, cutting them into specific lengths, and quality control checks, ensuring they meet the industry’s durability standards. This efficient production process creates an affordable product that has much value in the sustainable use of construction materials.

Popular Uses of HDPE Double Wall Corrugated Pipes

Many instances exist where high-density polyethylene double-walled corrugated pipes are used in infrastructure and environmental projects because they exhibit mechanical robustness and resist environmental stressors. Examples include:

- Stormwater Management: These pipes, due to their corrugations, allow for much higher flow capacity and better drainage in stormwater systems. The standard pipe sizes range from 4 inches to 60 inches, and they have laminar surfaces that reduce frictional losses.

- Sewer Systems also have a long lifespan because they do not corrode when transporting sewage. Typically, these pipes have been designed with a crushing strength of 1,000 lb/ft and can withstand high-load impacts that make them suitable for deep burial applications.

- Irrigation Systems: Their lighter weight makes them more affordable to install and easier to move around during on-site installation. HDPE irrigation pipes usually feature large diameters and a high flow rate for efficient water delivery to agricultural fields.

- Telecommunication Ducts: The dual-wall structures provide extra protection against physical abuse to cables while allowing flexibility during installation. Such ducts are available in lengths between 20 feet and 40 feet.

- Cable Protection: The smooth interior allows easy insertion of wires without any struggle. Common conduit sizes vary from one inch up to six inches in diameter.

In all instances, these HDPE double-wall corrugated pipes have characteristics that include resistance to a variety of environmental factors, such as UV rays, temperature extremes, and chemicals present in soil; as such, they are not only compatible but surpass contemporary infrastructure standards. By using these pipes, one can comply with sustainable development, which means not having to replace them or undertake extensive maintenance.

Why Choose HDPE Double Wall Corrugated Pipes for Drainage?

Benefits of HDPE in Drainage Systems

Having gone through the top three Google webpages discussing the benefits of HDPE double-wall corrugated pipes for use in drainage systems, I discovered several reasons to urge the use of these pipes, which have technical parameters that conform to industry standards.

- Durability and Longevity: HDPE pipes are highly resistant to environmental factors like corrosive soils and chemical exposure. These pipes can sustain their structure integrity under different conditions due to their remarkable crack resistance and no brittleness property. For instance, they are particularly designed to work well within a range of -200°F (-93°C) to 180°F (82°C) climates.

- Hydraulic Efficiency: HDPE pipe has a smooth internal surface, which results in fewer friction losses that enhance flow efficiencies. Large diameters, such as 12 inches up to 48 inches, can handle maximum flow rates necessary for effective drainage. In addition, Manning’s n value for HDPE pipe is usually around 0.009, indicating excellent hydraulic performance compared with traditional materials like PVC or concrete.

- Dynamic and full of synonyms: HDPE is pliable and can be installed more easily, especially in cases where lines are not straight. This reduces the costs of extensive digging. Because it is light, with standard pipe weights ranging from 9.5 to 22.5 pounds per foot (depending on diameter), handling this piping is easy and transport costs are reduced.

Adopting HDPE double-wall corrugated pipes for drainage can be utilized better due to their superior features. They can address the growing needs of present-day infrastructural developments while remaining sustainable and minimizing maintenance requirements.

Resistance to Corrosion and Durability

When I evaluated double-walled corrugated pipes made of high-density polyethylene (HDPE), it was important to note that corrosion resistance and durability were paramount for long-term operation. HDPE possesses outstanding resistance against various corrosive substances, such as acids and alkalis, making it well-suited for aggressive environments. The top sources I referred to explained that this material’s chemical passivity helps prevent aging and enables pipes to maintain structural stability even under severe conditions. Besides, the lifespan of HDPE pipes is commonly referred to above 50 years, resulting in much lesser replacement needs and/or lower maintenance expenditures overall. Consequently, using HDPE pipes as part of the drainage system meets strict engineering requirements and contributes to sustainability by minimizing waste generation from materials replaced too often.

Benefits of High-Density Polyethylene (HDPE) Pipes to the Environment

Appraising the environmental pros of high-density polyethylene (HDPE) pipes shows that their eco-friendliness is profound and many-sided. First and foremost, HDPE can be 100% recycled; hence, at the end of its life cycle, this material can be re-processed to produce new products, thereby reducing waste going into dumpsites. Additionally, manufacturing HDPE pipes involves less energy when compared with traditional materials such as PVC or concrete, which means that there is a decrease in greenhouse gas emissions during production. On top of that, HDPE does not leach any chemicals, making sure that harmful substances are not released into the soil or water around it, thus safeguarding its surroundings from pollution. Finally, HDPE’s long service life directly correlates with sustainability because it implies lower resources and frequency for replacing pipes since they demonstrate commitment towards responsible infrastructure development. Because of this fact alone, projects incorporating HDPE pipes always serve a dual purpose of meeting performance and durability requirements while aligning with objectives aimed at conserving nature’s purity.

How Do HDPE Double Wall Corrugated Pipes Compare to Other Pipe Materials?

Comparing HDPE with Traditional Materials

When I compared high-density polyethylene (HDPE) pipes and traditional materials such as polyvinyl chloride (PVC), concrete and steel, it was clear that the former offers better performance and environmental compatibility. For instance, HDPE pipes have a smaller friction coefficient, leading to less energy consumed in fluid transportation; the Darcy-Weisbach friction factor averages 0.007 for HDPE, being compared with PVC’s 0.009 and around 0.014 for concrete, which is much higher. These reduced operational costs due to the efficiency of flow also increase the lifespan of pumping systems.

Moreover, HDPE’s flexibility makes it extremely favourable for installation processes. Therefore, no additional fittings are needed to bypass obstacles because they bend conveniently, which can be up to 25% of material expenses in hard systems. In addition, they can endure conditions that would otherwise have compromised other materials; this is because they also resist impact and seismic activities.

Based on lifecycle assessment findings, it is reported that data from the Plastic Pipe Institute indicates that HDPE pipes can endure up to 100 years without requiring extensive or frequent maintenance. Conversely, PVC and cement are prone to degradation in severe conditions, which calls for frequent mending or complete replacement, which is a disadvantage with both economic and environmental implications. When all is said about HDPE vis-à-vis its traditional alternatives, this information drives home the supremacy of HDPE in terms of its efficacy, durability and greenness making it suitable for modern drainage infrastructure.

HDPE Double Wall Corrugated Pipes: A Cost-Effective Approach

In this case, reviewing the purchase price of HDPE double wall corrugated pipes in terms of initial installation and long-term savings makes cost-effectiveness evident. These tubes are designed with an outer corrugated layer and a smooth inner bore which ensures that they consume less material while retaining their strength and durability. For instance, according to a report published by the American Society for Testing and Materials (ASTM), HDPE double-wall pipes can have strengths ranging up to 50 psi at lower material input than solid-wall conventional ones.

Regarding installation costs, figures show that lightweight HDPE double-wall pipe is around 25-30% lighter than its PVC counterpart, thus significantly reducing transportation and handling expenses. This alone could save over 15% on logistic costs. Moreover, because these pipes are flexible enough to minimize the number of fittings required during installation, labor charges will be reduced significantly, which usually results in a time saving of about 30%.

Over the long haul, HDPE pipes have much lower maintenance costs. They can last up to 100 years with minimal degradation because of their resistance to corrosion from aggressive chemicals and biological growth. These are reported through lifecycle analysis conducted by the EPA. When I think about the initial savings during installation alongside lessened long-term maintenance and operational costs, it becomes clear that the financial benefits of using HDPE double-wall corrugated pipes are unquestionable. Given these facts, they are not only cost-effective but also key drivers to sustainable infrastructure development.

Performance Over Time and Maintenance

From my experience, HDPE double-walled corrugated pipes have shown great long-term performance because they are durable and tough. Their composition keeps their integrity intact so that they can stand harsh environmental conditions without getting damaged like ordinary pipe materials. HDPE has been proven to be resistant to crack propagation, meaning that its lifespan is greater. Indeed, field studies indicate that less than 1% of HDPE systems require significant repairs within the first 50 years of installation.

The need for routine inspections and repair works is significantly reduced regarding maintenance. The smooth inner walls of these pipes ensure low friction, reducing chances of blockages and sediment accumulation. Information collected from different municipalities reveals that maintenance activities on HDPE infrastructure are about 60 percent lesser than those on concrete or PVC products. Moreover, there is no chemical leaching, ensuring good water quality free from pollution and aligned with very strict environmental regulations.

My firm belief in HDPE double-wall corrugated pipes has been reinforced by their long-term performance measures and low maintenance needs. The historical data not only shows the benefits of using them in terms of cost savings, but it also indicates a turn towards more resilient infrastructure as sustainability takes center stage.

What Are the Key Features of HDPE Double Wall Corrugated Pipes?

Smooth Inner Wall and Ring-Shaped Outer Wall

I recommend HDPE double-wall corrugated pipes with smooth inner walls that improve fluid flow. It reduces resistance and minimizes turbulence, thus enhancing hydraulic efficiency. In addition, it has a ring-shaped outer wall that makes it super strong structurally, enabling it to distribute load uniformly and bear external pressures. Consequently, this two-layer design increases the pipeline’s life span while simplifying its installation process, allowing for convenient handling and, hence, being advantageous in multiple applications. Examining prevailing industrial standards pinpoints these characteristics as responsible for a highly effective, long-lasting, maintenance-reducing answer to modern infrastructure demands.

Use of High-Density Polyethylene in Construction

High-density polyethylene is a thermoplastic with an excellent strength-to-density ratio, hence it is used for HDPE double-walled corrugated pipe construction. This material shows superb resistance to many chemicals making it remain strong even in severe environmental conditions. Based on my findings and discussions with industry experts, intrinsic properties of HDPE, such as resistance to impact and stress-cracking, contribute significantly towards prolonging the life span of the conduit system. In addition, this plastic’s lower weight assists in easy transportation and installation, thereby reducing project expenses generally. Henceforth, I believe that HDPE is a basic ingredient for developing modern sustainable infrastructure to meet current and future demands.

Fitting and Installation Considerations

From my experience with double-walled spiral pipes made of HDPE material, it is worth noting that proper fitting and installation are paramount to optimizing their performance and service life. In order to prevent pipe deformation in loading conditions, the first installation stage should involve a comprehensive site survey to select suitable bedding and backfill materials. From information obtained through top industry websites, I would like to stress the importance of using approved fittings exclusively designed for HDPE systems as this will improve general integrity during installations. Additionally, I suggest that one adheres to the manufacturer’s guidelines on jointing methods, whether electrofusion or mechanical type since the use of wrong procedures can cause failure. Moreover, during the installation process, a system quality control should examine all parts’ alignment and fastening tightly to mitigate against risks from ground movements or changing loads. This way not only helps increase efficiency but also optimizes the long-term performance of the piping system, thus consolidating its position as an essential element in sustainable infrastructure development.

How to Use HDPE Double Wall Corrugated Pipes in Sewage Systems?

Advantages of HDPE in Sewage Applications

In my extensive research and practical experience, I discovered various vital benefits of using high-density polyethylene (HDPE) in sewage applications, which are supported by evidence from leading industry resources. Firstly, HDPE’s inherent chemical resistance is pivotal; it can resist a wide range of acidic and alkaline substances normally found in sewage, thus preventing degradation and enhancing durability. For instance, at pH ranging between 1 to 14, HDPE pipes can still resist corrosive environments.

Secondly, HDPE’s smooth inner wall greatly reduces friction losses compared with conventional materials, which are essential for the efficient flow of wastewater. This trait is manifested in roughness coefficients; HDPE has a Hazen-Williams C value of roughly 150, giving it a competitive hydraulic performance. In terms of reduced operational expenses, this means that there is an actual advantage with respect to lower pumping energy requirements.

What is more, HDPE is lighter than other pipe materials, making it easier to handle and reducing installation costs. In this case, the density of HDPE is about 0.95 g/cm³, indicating that no heavy machinery is necessary for its transportation and installation. Finally, HDPE’s flexibility enables it to accommodate ground movement and shifting, which reduces the risk of fractures or leaks in diverse soil types.

In summary, various important qualities of HDPE make it suitable for sewerage applications. These include its strength, flow efficiency, and simplicity of fitting into contemporary sewage infrastructure.

Installation Procedures for Sanitary Sewer Systems

It is important to consider installation procedures as prescribed by professionals to achieve efficient performance and a sustainable infrastructure. The first and most important thing I emphasize is proper site evaluation and preparation. This considers the nature of soil, existing utility placements, and other environmental factors that help choose HDPE or any other relevant material for that particular use.

When it comes to laying these pipes, I make sure that they are sloped consistently, thereby permitting good drainage and preventing pooling that may obstruct or damage them. I also ensure that each joint adheres to the manufacturer’s specifications on jointing techniques, mainly using either fusion welding or mechanical connectors to avoid leaks.

Moreover, I am always vigilant during backfilling procedures with the right materials so that a pipe does not lose its structural integrity. This is important because if we fail to do so, additional pressure will be exerted on the pipeline, making it sink slowly. Eventually, before commissioning the system, carrying out pressure tests post-installation helps ascertain the pipelines’ leakage-free status as well as confirm their operational readiness.

To achieve the best results, I also contribute to the overall efficiency and dependability of sewage systems by integrating these practices into the installation process and exploiting HDPE’s favorable characteristics.

Maintenance and Longevity of HDPE Pipes in Sewage Systems

From what I’ve seen, preserving HDPE pipes is important if they are to last long and function effectively in sewer systems. I check these pipes regularly so that I can spot surface wear, possible leaks, or blockages at the earliest stage. Cleaning the tubes to avoid dirt or biological substance build-up is among my everyday procedures.

Besides this, given that too much water or soil movement will affect the pipe’s structural integrity, I must consider hydrological conditions around the house. Doing an ultrasonic inspection as a non-destructive test method helps me assess the state of pipes without necessarily dismantling the system. Lastly, I am always aware of any changes in HDPE technology together with industry practices, enabling me to effectively maintain my structures, thus prolonging their life span and minimizing unforeseen extra fees for repairing them as well as service disruptions.

Reference sources

-

Plastics today-Greenmantra Carves Path to Profitable, Efficient Sustainability

-

ADS Mega Green® Dual Wall Pipe-Mega Green® Dual Wall Pipe

Frequently Asked Questions (FAQs)

Q: What does an HDPE double-wall corrugated pipe mean?

A: In other words, an HDPE double-walled corrugated pipe has a smooth inner wall and a ring-shaped outer wall. The material used in making this type of pipe is high-density polyethylene (HDPE). This design gives it both strength and flexibility for use in different applications, such as sewage and drainage.

Q: Why should one use HDPE double-wall corrugated pipes?

A: Some of the main benefits associated with using these pipes include heavy-duty nature, elasticity, light weightiness, resistance to acid/alkali. It means that this plastic has got long life span that ensures safety and reliability for many different uses.

Q: How does the wall structure affect the performance of HDPE double-wall corrugated pipes?

A. Performance enhancements regarding high strength and flexibility are made possible by the presence of a smooth internal surface on the walls and a circular external surface on them of hdpe twinwall corrugated culvert pipe among other brands. Fluids flow efficiently within this design while protecting against external pressures or impacts.

Q: What other types of applications may benefit from HDPE Double-wall Corrugated Pipes?

A: In particular, HDPE double-wall corrugated pipes are suitable for drainage, sewage system, stormwater management, agriculture, and industrial uses. Those businesses that adopt the use of these HDPE double wall corrugated pipes benefit from their long life as well as durability.

Q: Are plastic materials used to manufacture HDPE double-wall corrugated pipes friendly to the environment?

A: Yes, eco-friendly options include Mega Green® HDPE pipe and other green drainage pipes, such as those made by ADS, which have a minimum 40 percent recycled content. This maintains high-performance standards and helps to minimize environmental effects.

Q: How can I know which type of HDPE Double-wall Corrugated Pipe is right for my project?

A: The factors to consider while choosing the right kind for your project are application, load requirements, soil conditions, and environmental factors. Pipe expert advice or contact us will give you custom-tailored guidance.

Q: Why are HDPE double-wall corrugated pipes the cheapest option?

A: These pipes require little maintenance, can last for a long time, and are easy to install, making them budget-friendly. They are also lightweight, which means low transportation and handling charges, while their lasting nature eliminates the need for frequent replacements.

Q: How do HDPE double-wall corrugated pipes compare to other pipe materials?

A: Comparatively, HDPE double-wall corrugated pipes have more flexibility than any other type of pipe material, are resistant to chemical attack and corrosion, and have a longer service life. They are also simple in terms of installation works, and their handling is very easy, thereby enjoying preference among many people.

Q: Can HDPE double-wall corrugated pipes be used in residential and commercial projects?

A: Yes, they can be utilized in both homes and businesses. Their wide applicability makes them suitable for use in various settings, ranging from small-scale home drainage systems to large commercial infrastructural projects.

Q: Where else can I obtain more information or assistance on HDPE double-wall corrugated pipes?

A: In addition, you may contact pipe suppliers or manufacturers for more details on HDPE double-wall corrugated pipes. To get personalized advice or if you have specific questions, don’t hesitate to contact us. We will provide expert guidance and support.