In modern drainage systems, factors often considered include efficient operations, durability, and environment-friendliness. Now HDPE double wall pipes present one such new wonder that gives an entirely different approach to water management and drainage infrastructure. Known for their strength, long life, and versatility, these pipes have found their way into almost all project types-from residential drainage to industrial large ones. The article tries to weigh up why HDPE double wall pipe is the best alternative by explaining its comparison with other available pipes, their features, advantages, and their role in developing more sustainable and effective drainage systems.

Understanding HDPE Double Wall Pipe

What is HDPE?

HDPE, or High-Density Polyethylene, is a durable, heavyweight thermoplastic that has applications in materials of all kinds. It offers strength to weight ratio, which is the main reason that HDPE is preferred for manufacturing pipes, containers, and geomembranes. Due to its chemical nature, it resists corrosion, cracking, and chemical leaching and is, therefore, considered suitable for harsh environments.

Flexibility alongside tensile strength is another property of HDPE. Considering the flexural strength, HDPE materials like double wall pipes can endure heavy load bearing and external pressures without undergoing bending or deformation. In addition, it is non-toxic and non-reactive and hence can be utilized for potable water applications and environmentally sensitive projects.

In addition, HDPE does resist UV radiation and stresses from the environment. Hence, these factors increase the life span resulting from even harsh conditions. Yet, with its light weight, the materials can be transported anywhere leading to an increase in installation prices, unlike concrete or metal materials. Thus, these features of HDPE make it more suitable for infrastructures requiring a factor of endurance with an economic factor of efficiency.

Features of Dual Wall Pipe

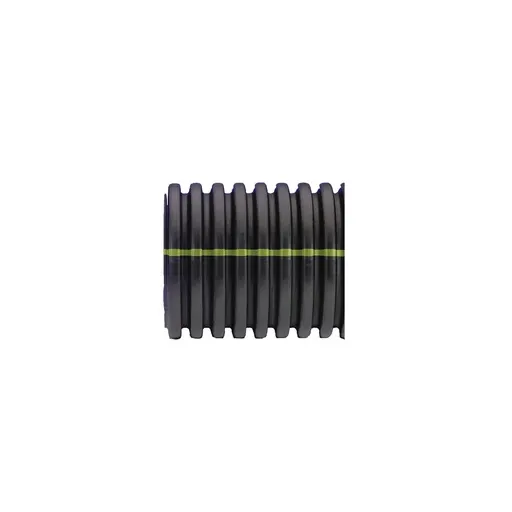

Dual wall pipes are considered to be highly durable and having good structural strength. The combination of a smooth inner wall and a corrugated outer wall allows for adequate water flow yet great resistance to external pressure and impact. Applications for installation of drainage systems, stormwater management, and wastewater rely on this system with utmost importance attached to its performance.

Another salient feature being light in weight and thus easy to handle during installation, they provide a cost-effective option for transportation. Contractors find that installation takes a fraction of the time, and labor costs are minimized when compared with traditional materials in concrete or steel pipes. Balancing the lightweight of the dual wall pipe will afford it capable load-bearing qualities attuned to either agricultural or industrial applications.

It is highly resistant to environmental conditions such as chemical action, corrosion, and temperature changes. Being highly durable with Maintenance free feature has practically made it a choice for modern infrastructure. Since the material is resilient, some repairs and replacements are prevented, making it an eco-friendly choice from a long-term economic perspective.

Benefits of Using Corrugated Pipe

1

Durability and Longevity

With disadvantages they offer, corrugated pipes can resist adverse environmental conditions that may include unusually heavy loads, extreme heat, or chemicals. Being robustly designed, the pipes provide service for more than 50 years in most installations, leading to less frequent can replacements.

2

Cost-Effectiveness

Being lightweight, corrugated pipes reduce transportation costs, and their ease of installation guarantees less labor. Their less maintenance need adds to their effect over another time.

3

Eco-Friendliness

Most corrugated pipes are produced with recycled materials and hence are an environmentally sustainable choice. Their extended durability further limits the amount of waste generated from their replacements and repairs.

4

Better Drainage Capacity

The idea behind the corrugations is to provide structural strength to the pipe while allowing free steel to flow; hence, they are excellent for drainage systems, clogging, and handling runoff water.

5

Versatile Applications

Corrugated pipes find their applications in a range of industries, that is, agriculture, construction, and infrastructure. With regard to irrigation, stormwater management, and culverts, they remain the best solution to consider due to their adaptability and reliability.

Applications of HDPE Double Wall Pipe

Drainage Systems

Stormwater Runoff Drainage

HDPE double wall pipes have a huge spectrum of uses for handling the stormwater runoff of urban and rural areas. They stand to remain in service for long periods while carrying massive volumes of water because of their very high resistance to corrosion and chemical attack.

Agricultural Drainage Systems

Farmer-agencies and agricultural industries use these pipes for field drainage and irrigation systems. They prevent waterlogging of land for better crop yields and soil management.

Road Drainage

It is necessary to maintain road durability and safety through the use of HDPE double wall pipes in the subsurface drainage systems. They direct water away from road surfaces to reduce any possible structural damage occurring because of infiltration of water.

Sewage and Wastewater System

Used for the efficient transportation of sewage and wastewater, the pipes have a smooth inner lining preventing the blockage and withstanding high-pressure conditions by virtue of sturdy construction.

Landfill Drainage

Landfills use these HDPE double wall pipes for leachate collection and drainage purposes. Such pipes resist chemicals and harsh environments, making them good candidates for handling landfill waste and protecting the surrounding ecosystems.

Soil Tight Systems

Soil-tight systems are especially manufactured for preventing soil particle infiltration and enabling free drainage. These systems are designed for numerous applications where soil retention and water management are of utmost importance. The five major soil-tight systems are as follows:

| System Type | Description |

|---|---|

| Perforated HDPE Pipes | Hence, these perforated pipes would allow full acceptance of water entering through the perforations but would not permit soil particles to clog the system. The pipes are generally used in the drainage of agricultural lands and foundation works. |

| Geotextile-Wrapped Pipe Systems | Drainage pipes are wrapped with geotextile fabrics to provide an additional level of filtration that enhances soil retention and the durability of the system. These would be perfect in areas where soil erosion is prevalent. |

| Gravel-Free Drainage System | The installation of a combination of HDPE pipes and lightweight aggregates constitutes an alternative bedding treatment to crest time while protecting soil permeability and drainage efficiency. |

| Double-Wall HDPE Systems | Designed with a smooth interior and corrugated exterior, they balance water flow toward soil stability hence used for municipal and industrial drainage. |

| Slot Drain Channels | Surface drainage systems comprising a narrow slot that collects water while keeping out debris and soil. They are suitable for parking areas, highways, and the like. |

Each system is tailored to application-specific use and verifies long-term performance in regards to soil infiltration and water flow management.

Use in Various Industries

Drainage systems encompass vital functions in service industries, ensuring water management and structural integrity. Here below are five major industries where these systems are routinely used:

-

1

AgricultureDrainage systems thus help in preventing soil erosion, managing water levels, and providing an environment conducive to crop growth. For instance, subsurface drainage with improved root aeration can lead to yield increases of up to 25% in waterlogged areas.

-

2

Construction and InfrastructureDrainage provisions, like trench drains and slot drains, hold importance for foundation building, roadways, and bridges. They reduce water pooling and diminish structural damage, thereby increasing the life of infrastructures.

-

3

Municipal and Urban PlanningDrainage systems drain off stormwater in urban areas, further reducing floods and revenue of sewage from the backups. Permeable pavements with integrated channels are increasingly popular solutions in city planning projects.

-

4

Industrial FacilitiesCommercial and industrial establishments are equipped with specialized drainage systems to accommodate water runoff, chemicals, and wastes, in turn sustaining compliance with environmental regulations and maintaining the safety of operations.

-

5

Recreational and Sports FacilitiesOutdoor drainage systems are provided to golf courses, stadiums, and parks to keep these places usable by preventing waterlogging and promoting the flow of water. For example, some sports fields have been designed with subsurface drainage to keep the turf playable after a heavy rain.

The customized drainage methodologies, thus, highlight the great diversity of applications and critical importance of proper water management in the public and private sectors.

Advantages of Using HDPE Double Wall Pipe

Durability and Longevity

✓ Corrosion-Resistant

In contrast to traditional metal pipes, HDPE double wall pipes are not subjected to various corrosion processes due to chemicals, moisture, or environmental factors. This allows the pipes to maintain their structural integrity over time, even under harsh working conditions.

✓ High Impact Strength

These pipe structures are able to resist cracking or breaking from heavy external loads or impacts, making them suitable for underground installations where the piping may be subjected to high pressure or soil shifting.

✓ UV Resistance

The HDPE materials provide good resistance against ultraviolet (UV) rays, preventing degradation due to extended sun exposure. Consequently, this quality endows them with a longer life in outdoor installations.

✓ Abrasion Resistance

HDPE double-wall pipes provide an exceptional level of resistance to abrasion because of the contents they transport, be it gravel or debris carried by the flow of water. Therefore, this feature allows them to resist wear and tear over the years.

✓ Longer Life-span

HDPE double wall pipes have a service life in excess of 50 years given standard usage, thus presenting a low-cost alternative for infrastructure that mandates a long-lasting and reliable solution.

Cost-Effectiveness Over Time

| Cost Factor | Benefit |

|---|---|

| Low Maintenance Costs | Since corrosion, abrasion, or chemical attacks cannot hinder a pipe from performing its job, HDPE pipes can ordinarily be regarded as having very minor maintenance when compared to traditional piping systems, thereby reducing long-term maintenance cost burdens. |

| Energy Efficiency | The HDPE pipe system uses less energy during production when compared with conventional materials like steel or concrete, meaning production costs are kept low while beauty remains. |

| Great Reduction in Installation | HDPE pipes are lightweight and facilitate ease in handling and installing, thereby reducing hugging labor cost, equipment, and time for installation. |

| Longer Life Reduces Frequency of Replacement | Given that its expected working life exceeds 50 years under normal conditions, HDPE pipes do not need to be often replaced, thereby translating to huge savings during its decades of usage. |

| Recyclability | At the end of their life cycle, HDPE pipes are fully recycled and refurbished. This reduces waste disposal costs and thereby ensures sustainable practices, developing a dual front-bank of financial and environmental goodwill. |

Environmental Benefits

🌍 Reduced Carbon Footprint

In terms of their manufacture and transportation, HDPE pipes require lesser energy than conventional piping materials. Studies report that the making of HDPE pipes may involve an emission of 30% less greenhouse gases than steel or concrete pipe systems.

⚡ Energy Usage During Operations

With a smooth interior surface, HDPE pipes present the least friction among other pipes, thereby reducing the energy needed for pumping of fluids. This energy saving in operation continues for long-term energy saving for the whole system.

🌿 Non-Toxic and Environmentally Safe

HDPE pipes are one hundred percent free of harmful chemicals that would have otherwise leached toxic substances into the surrounding environment of the soil and water they contact. It preserves the ecosystem surrounding them while keeping them safe.

💪 Resilience to Environmental Stress

The durability of HDPE pipes makes them able to withstand cracking, corrosion, and damages imposed by the environment. Such durability lessens maintenance and replacement, and consequently the amount of waste generated.

♻️ Recyclability and Contribution to Circular Economy

HDPE pipes can be fully recycled into new products after their lifespan, thereby fostering a circular economy. Recycling reduces the demand for virgin materials and energy in the extraction and processing of such materials.

Installation Guidelines

Preparation for Installation

Properly preparing ahead of the installation of HDPE pipes ensures safe passage and efficient long-term performance. Carrying out a complete site survey comes first. Soil conditions, underground obstacles, and environmental conditions are the concern to find out the suitability of the place. Proper drainage down and a stable foundation would be the best to prevent damages to the pipe and for its structural integrity. Pre-plan also involves mapping the pipe layout to avoid interference with other utilities and infrastructure, allowing an easier installation process and fewer delays.

Materials and verification are equally important. All HDPE pipes and fittings must undergo the inspection for defects or damages prior to installation, such as cracking, scratching, or any deformities. Be sure to use the very best materials that have no defects to ensure system performance and durability. Also, check to make sure that all tools and equipment, such as fusion machines and protective gear, conform to working standards. Keeping fusion equipment accurately calibrated is very important to accomplish perfectly joined joints. It is equally important to make sure that the personnel working on the installation are trained sufficiently to apply industry standards and safety protocols.

The finalization of the installation plan-and-the timeline-will ensure the smooth, efficient running of the project. A timeline should, however, consider the following: site preparation, trench excavation, pipe laying, and joint fusion. Compliance with local laws and standards is an absolute must during each phase of installation. Further, proper material and procedure documentation will not only ensure compliance but will aid in resolving issues arising during or after the project. By strictly adhering to the above-mentioned preparation criteria, long-term viability and sustainability of HDPE piping systems can be served.

Best Practices for Installation

The installation of an HDPE piping system must proceed according to an established procedure and prescribed industry norms if the best results are to be obtained. Start by inspecting the site thoroughly, for irregularities concerning the environment or geology of the site that may affect the integrity of the pipeline. Set the HDPE pipes and fittings aside for inspection, to check further for any kind of manufacturing defects that really could affect their efficiency-warping, for instance, or unevenness in diameters.

Trench preparation must be accurate. Trenches must be excavated to the specified depth and width, depending on the pipe diameter, so that backfill can be placed correctly and will not stress the pipes. The bottom must be level and free of sharp objects that can scrape or puncture them.

Strict observance should be paid to pipe alignment and joint fusion enhancement. Ensure that surface temperature, pressure, and fusion time for butt fusion or electrofusion methods comply with their standard values, thereby allowing the creation of a perfect and free-leak connection. Also, any variation caused by temperature during installation will have a great influence on the fusion quality: thus, these conditions should be observed and corrected where necessary.

Backfilling has to be done properly, using good soil, preferably a granular material, compacted in layers to give the best support. Avoid materials capable of damaging the pipe, like large, sharp stones. It is highly recommended that hydraulic testing be done after installation, thereby ensuring pressure rating and detecting leakage before starting operations.

Installation steps should be documented. An accurate record of the procedure, tests, and inspections provides evidence of regulatory requirements and may later serve as a reference for maintenance or troubleshooting. When the rigorous technical procedure is combined with systematic monitoring, the long-term usability and reliability of the HDPE piping system improve greatly.

Common Mistakes to Avoid

❌ Insufficient Surface Preparation

Inadequate cleaning and preparing of the joining surface of HDPE pipes can lead to welds that are prone to leaks. All surfaces must be cleansed appropriately of any dirt, grease, or oxidation layers by using approved cleaning agents and tools before proceeding to fusion or any installation measure. Establishing the connection without cleaning seriously undermines the integrity.

❌ Wrong Parameters Used in Fusion

Any divergence from the recommended period of heating, pressure application during heating time, and cooling will evidently yield a poor joint. The specifications recommended by the heat platelet manufacturer concerning temperature, pressure, and cooling time should be strictly followed in order to ensure the satisfactory joint between the two surfaces.

❌ Ignoring Pipe Alignment

Failure to properly align and maintain that alignment until fusion can generate stress within the pipe or joint, leading to gradual failure.

❌ Being Neglectful of Pressure Testing

Missing out on a hydrostatic or pneumatic test after installation could lead to leakage detection systems not coming to the conclusion, and to the recognition of weak points in the system. Pressure test rigorously as per agreed standards to ensure the working capacity of the system with operating loads.

❌ Improper Handling and Storage

Improper handling of HDPE pipes and improper storage conditions (e.g., direct sunlight with no UV protection for long durations) can physically damage or degrade their materials. Therefore, these pipes must be handled with care and be placed into storage in a suitable environment that will preserve the end property.

❌ Does Not Consider Thermal Expansion

HDPE pipe systems expand and contract thermally. If expansion loops, offsets, or appropriate anchoring systems are not provided, this situation will lead to unnecessary strain on and damage to the pipes during temperature fluctuations.

By methodically looking at these common problems and employing rigorous QA practices, the operators can come to possess a sturdy, long-lasting, and nigh-efficacious piping system made of HDPE.

Competitive Insights and Market Trends

Emerging Trends in Drainage Solutions

Today, integrating sustainable and eco-friendly practices within system design and implementation stands out as one trend in drainage solutions. I do see more preference being given by people to go with those kinds of materials and techniques that are least impacting the environment, such as permeable pavement and green infrastructure systems to handle stormwater in a natural way. These are developments which go parallel with global attempts to lessen flooding risks while endorsing natural water cycles and groundwater recharge.

Furthermore, drainage management is being increasingly enhanced by automation and smart technologies. They collect real-time data, enable predictive maintenance, and manage water efficiently to assure system adequacy even during adverse weather conditions. These innovations bring about greater accuracy and reliability in drainage functions, curtailing downtime and maintenance costs.

Lastly, there has been a rising clamor for modular and prefabricated drainage components. I’ve seen these put in use to smooth out installation on-site, promote shorter completion times, and foster quality that never wavers. Application of advanced manufacturing techniques and durable materials makes modern drainage systems stronger and more adaptable. These developments show that the industry is leaning toward efficient, flexible, and sustainable ways to solving drainage issues globally.

Future Innovations in HDPE Technology

With the rapid developments of material sciences and growing global demand for sustainable solutions, HDPE technology continues to grow by the day. One major field of study focuses on the enhancement of the polymer structure of HDPE to improve its performance when subjected to extreme temperatures and high stresses. New techniques of co-polymerization are being experimented with to synthesize HDPE grades having higher tensile strength, greater flexibility, and better resistance to environmental stress cracking. In fact, such properties make this polymer material highly versatile, which finds applications in masses of industries, ranging from water management to construction to industrial piping.

Another emerging scenario in HDPE technology is the inclusion of smart materials into the manufacturing process. Researchers have been looking into the possibility of incorporating sensors and nanomaterials within the HDPE matrix itself. This advance could, in theory, allow for the monitoring of integrity, fluid flow, and the temperature of HDPE-based systems in real-time. These innovations enhance operational efficiency, and provide insights for predictive maintenance to avert sudden system failures. For instance, smart sensor-embedded HDPE pipelines could be able to report remotely about the presence of any form of leak or blockage, thus reducing environmental and operational downtime.

Environmental sustainability remains at the core of future HDPE innovations. Efforts to use recycled HDPE in new products without compromising on the quality of the material are becoming intense. Sophisticated sorting and processing techniques, along with chemical recycling methods, ensure that closed-loop recycling systems foster a circular economy. In the meantime, bio- or green-based HDPE from renewable sources such as sugarcane or vegetable oils provides another option that is low-carbon in comparison to conventional petroleum-based plastics. With regulatory frameworks and public awareness stressing sustainable practices, these innovations would substantially contribute to the future of HDPE technology and its industrial adoption.

References

- Response of buried HDPE double-wall corrugated pipe in sand – A study on the adoption of HDPE double-wall corrugated pipes for sanitary and stormwater applications.

- High density polyethylene pipe in highway applications – A review of HDPE pipe applications in culvert installations, highlighting its advantages.

- Reliability Estimation for Double Containment Piping – Discusses the reliability and leakage prevention of double containment piping systems.

- Section 9B-3 – Flexible Pipes – Covers the properties and applications of flexible pipes, including HDPE pipes.

- Research on the Mechanical Behavior of Buried Double-Wall Pipes – Examines the mechanical behavior of buried HDPE double-wall corrugated pipes, focusing on material and structural factors.

Frequently Asked Questions (FAQ)

Q: What is HDPE double wall pipe?

A: HDPE double wall pipe is one type of piping system made of high-density polyethylene (HDPE) and having a two-layer build yielding much higher durability and strength. Such a design is particularly useful in applications that are resistant to corrosion and abrasion.

Q: How does HDPE double wall pipe differ from N-12 dual wall pipe?

A: The HDPE double wall pipe and the N-12 dual pipe are both made for stormwater management and drainage applications. The N-12 pipe is a particular dual wall pipe that provides exceptional hydraulic qualities with smooth interior walls and is thus the most preferred for various projects.

Q: Why would an HDPE double wall pipe be preferable?

A: HDPE double wall pipes offer well-apclaimed advantages, such as resistance to corrosion and abrasive actions, lightweight, and easy to install. Also, the double wall construction offers good structural integrity as compared to other customary pipe systems such as reinforced concrete.

Q: Is it suitable for stormwater management installations?

A: Indeed, HDPE double wall pipe is most suitable in the treatment of stormwater. It can provide great drainage and flows for HP storm and other drainage systems.

Q: Can this be a suitable alternative to reinforced concrete?

A: Yes, it can. HDPE double wall pipe is many times preferred as an alternative to reinforced concrete piping because of its lightweight qualities and resistance to environmental stresses. It handles applicable applications very well and at reduced cost of installations.

Q: How does having a smooth interior wall assist the performance of HDPE double wall pipe?

A: Smooth interior walls of HDPE double wall pipe promote the flow of fluids, provide less friction, and offer less chances of clogging. This feature becomes important in drainage and wastewater systems to maintain the finest hydraulic performance.

Q: How much service life is given to HDPE double wall pipe?

A: HDPE double wall pipe is comparatively long-lived, with service life often exceeding 50 years if appropriately installed and maintained. Its resistance to corrosion and its environmental friendliness contribute to the durability over time.

Q: Are there any specifications related to the installation of HDPE double wall pipe?

A: Yes, proper laying of HDPE double wall pipe calls for trench design considerations, bedding materials, and backfilling methods. The manufacturer guidelines and industry best practices should be seriously considered so as to maintain the expected performance of the piping system.

Choose HDPE Double Wall Pipe for Superior Performance

With exceptional durability, cost-effectiveness, and environmental benefits, HDPE double wall pipes represent the future of drainage infrastructure. Make the smart choice for your next project.