HDPE dual wall pipes actually help to gain the title of an industry game changer for efficient and durable drainage systems. Equipped with strength, flexibility, and long life, these pipes can be considered innovations for draining systems in the fields of construction, agriculture, and even infrastructure.

Introduction to HDPE Dual Wall Pipe

What is HDPE Dual Wall Pipe?

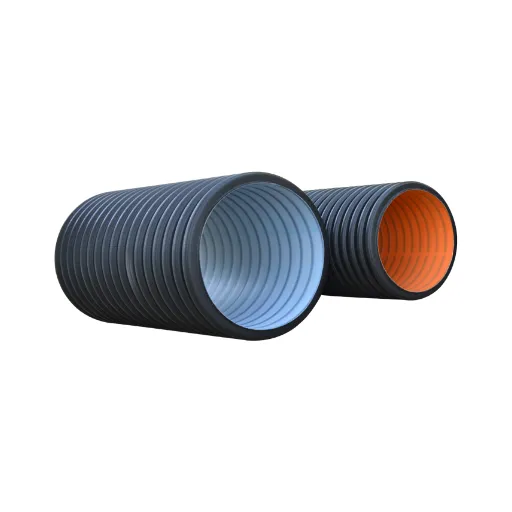

HDPE is a very modern and effective drainage solution manufactured using high density polyethylene. The dual wall pipe essentially has two walls-the inner wall is smooth to allow unobstructed flow of water, whereas the outer wall is corrugated for strength and durability. This is the best design to facilitate water flow in various applications, from stormwater management to agricultural drainage.

One advantage of HDPE dual wall pipe is its lightweight-yet-strong construction; thus, it can easily be carried and installed while still remaining genuinely functional. The material resists corrosion, chemical attacks, and environmental degradation, thus providing long-term service even under adverse conditions. Another advantage is that these pipes are flexible and can easily bend according to uneven terrain, thereby minimizing damages while maintaining structural strength even after some time.

The HDPE dual wall pipe remains preferred for infrastructure projects, commercial developments, and agriculture activities on account of being cheap and having a longer service life. Its heavy load capacity and the nature of the environment in which it works have made it an industry standard for superior drainage systems. HDPE dual wall pipe, with an amalgamation of modern design and practical benefits, is a handy and trusted answer to contemporary drainage problems.

Importance of HDPE in Drainage

High-Density Polyethylene proves essential for modern drainage systems due to traits such as durability and adaptability. The HDPE pipe is resistant to corrosion from chemical exposures and environmental stresses, thereby extending the lifespan of drainage systems even when subjected to harsh conditions. It is lightweight, making it easy to transport and install, thereby minimizing labor and time considerations. It is due to these properties that HDPE proves to be a cost-efficient solution for drainage projects of all scales.

Also, HDPE pipes are intended to transport high maps of water while retaining structure under pressure. The flexibility of HDPE reduces the chances of cracking or breaking under shifting soils and makes it very apt for those locations subjected to ground movements or harsh weather. Its smooth interior surface promotes fast water flow and prevents blockage, thus making it more efficient for agricultural, municipal, and industrial drainage needs.

Environmental Note: Another key issue revolving around environmental sustainability places importance on HDPE in drainage. HDPE pipes are recyclable and were often made using environmentally conscious methods in line with the growing need for sustainable infrastructure solutions. Having a longer service life allows fewer replacements, which, in turn, limits the production of waste and consumption of resources with respect to time.

Applications of Dual Wall Pipe Systems

Dual wall pipe systems are versatile and can be utilized in almost any industry and project due to being durable in all situations and performance regarded as a key criteria. Following are major five applications where dual wall pipe systems are widely installed:

🌧️ Stormwater Management

Dual wall pipes find great use in stormwater management, especially in managing water flow with the utmost efficiency. With high resistance to corrosion and abrasion, they fit very well to handle runoff of all magnitudes, mainly in urban and suburban areas where heavy rains are commonplace.

🌾 Agricultural Drainage

These pipes find use in agricultural applications to improve soil drainage, prevent waterlogging, and thereby support crop growth. By channeling excess water away from agricultural fields, they set proper growing conditions and preserve soil structure.

🛣️ Road and Highway Drainage

Road and highway drainage projects require the use of dual wall pipes. Their robust nature allows them to resist heavy loads, to ensure the water is carried out, to increase the life of the roads, and to reduce maintenance costs.

🏠 Residential & Commercial Construction

In residential and commercial development projects, dual wall pipes serve as dependable conduits for wastewater and stormwater management. The lighter-weight nature of the pipe and simple installation ensure meeting time and cost considerations of the project.

♻️ Landfill & Wastewater Treatment

Dual wall pipe systems have been employed in landfill leachate collection and wastewater treatment systems. The architect manager of such a system must guarantee that these pipes are subjected to chemical exposure and high-pressure flows, so that the wastes are discharged, treated, and managed safely.

Understanding the Structure of HDPE Pipes

Corrugated Design and Benefits

With corrugated designs for extra strength and flexibility, HDPE pipes find their way into modern drainage and water treatment. The corrugations are designed for extreme strength, so the pipes can withstand outside load, from soil pressure to heavy vehicular traffic. These pipes find useful application in subsurface works where durability is paramount toward long-term performance. The lighter weight then further provides ease of handling and installation, saving on labor costs and time.

Key Benefits of Corrugated Design:

- ✓ High resistance to corrosion and chemical exposure

- ✓ Smooth inner walls for optimum hydraulic efficiency

- ✓ Lower chances of blockage

- ✓ 100% recyclable for sustainable construction

- ✓ UV resistance and enhanced longevity

ASTM Standards for HDPE Dual Wall Pipes

The ASTM standards ensure HDPE dual-wall pipes meet quality and performance requirements to be used for important infrastructure projects. Since these standards regulate matters concerning material compositions, manufacturing processes, and physical properties of the pipes to allow for uniformity of performance in different applications, some of the famous standards include:

ASTM F2648

Criteria for construction and use of corrugated HDPE pipe for stormwater applications

ASTM D3212

Joint tightness and structural integrity under pressure requirements

ASTM F2306

Dual-wall corrugated pipes with smooth interiors for severe environmental conditions

Comparison with Other Pipe Materials

Dual-wall HDPE pipes are compared with single-wall HDPE, ductile iron, and cast pipes on strength, durability, cost, and hydraulic performance.

| Key Point | HDPE Dual Wall | Single Wall HDPE | Ductile Iron | Cast Pipe |

|---|---|---|---|---|

| Strength | High | Moderate | Very High | Moderate |

| Durability | Excellent | Good | Excellent | Good |

| Cost | Moderate | Low | High | Moderate |

| Hydraulics | Smooth | Rough | Smooth | Smooth |

| Flexibility | Moderate | High | Low | Moderate |

Applications and Uses of HDPE Dual Wall Pipes

Drainage Systems in Various Environments

These pipes are used in different environments because of their strength, durability, and hydraulic efficiency. Following are the main applications of HDPE dual wall pipes in drainage systems:

- Agricultural Drainage: HDPE dual wall pipes control the water flow in agricultural fields. They drain excess water and help soil aeration to ensure maximum crop yield.

- Urban Stormwater Management: Primarily these pipes are installed in urban areas to collect and drain stormwater runoff to prevent flooding during heavy rainfall.

- Highway Drainage: Highway drainage through HDPE dual wall pipes allows the surface water to be drained away, thereby enhancing road safety and preventing damage to the infrastructure.

- Industrial Drainage Systems: Such pipes are used in industries to drain excess water, chemicals, or waste liquid with minimal risk of leakage due to their excellent durability and resistance to corrosion.

- Residential Drainage: Reaction to water systems of homes and establishments; certain drainage is welcomed through these HDPE pipes.

Industrial Applications

HDPE pipes find extensive industrial applications due to their high durability and flexibility and are resistant to chemical corrosion. Here are five important industrial applications:

🧪 Chemical Transportation

HDPE pipes are a good option for transporting several chemicals since they are non-reactive and corrosion resistant. They are used to transport acids, alkalis, and other hazardous chemicals safely.

⛽ Oil and Gas Pipelines

These pipes are reliable conduits in the oil and gas industry. They resist high pressure and extreme environmental conditions making them the preferred solution in the industry.

⛏️ Mining Operations

In mining, HDPE pipes transport slurries and dewater due to their wear-resistant properties and ability to handle abrasive materials. This ensures effective and long-lasting operation in harsh mining environments.

🏭 Treatment of Effluents and Sewage

Many industries use HDPE pipes for effluents and sewage. They resist chemical action and remain intact under high pressures, so leaks and failures cannot occur.

❄️ Cooling Water Systems

HDPE pipes are used by manufacturing units for their cooling water systems since they withstand high temperature variations and efficiently transport water with minimum heat loss.

Residential Use Cases

HDPE pipes are being widely used in residential applications because of their durability, flexibility, and being cheaper. Following are the important residential applications:

- 🚿

Plumbing Systems: HDPE pipes are increasingly used in residential plumbing systems for hot and cold water supply. They do not get eroded, offering therefore a corrosion-free and maintenance-free alternative compared to conventional metal pipes. - 🌱

Irrigation for Home Gardening: For owners of home gardens, HDPE pipes make a great drip irrigation or sprinkler system. Down to their flexibility, they are easy to install and can withstand various weather conditions without sustaining any damage. - 🚰

Sewer and Drainage Systems: HDPE pipes are best suited for residential sewage and drainage systems. Their leak-proof joints and smooth inner walls facilitate efficient transportation of wastes while preventing unauthorized blocking. - ☔

Rainwater Harvesting Systems: Whether in a rainwater harvesting system or in irrigation, the HDPE pipes are used in residential property setups. Because of their light weight, they are used to collect rainwater and direct it into storage ponds. They resist algae growth and rusting. - 🔥

Gas Distribution: Yet another use of HDPE pipes is in residential gas lines. Withstanding high pressures, they provide a non-corrosive, safe, and reliable means of supplying natural gas or LPG to houses.

Advantages of Using HDPE Dual Wall Pipe

Durability and Longevity

HDPE dual wall pipes are tremendously reputable for durability and longevity, thus making them beneficial to satisfy various infrastructural requirements. Let me point down some factors that confer durability and longevity to HDPE dual wall pipes:

🛡️ Corrosion Resistance

HDPE material has high resistance to chemical and environmental corrosion; thus, funds allow pipes to function even with aggressive soil or water conditions for many decades.

💪 Strong Impact Resistance

These HDPE pipes can resist heavy impact without cracking or breaking, even under cold conditions, so they can easily be installed in different climates.

🔄 Flexibility and Stress Resistance

Being flexible, HDPE pipes of dual walls can resist stress applied externally such as ground movement load coming from some external source, without damaging the pipe.

⏰ Long Lifespan

As inferred from studies, HDPE dual wall pipes can last for an estimated 100 years in usual conditions, depending largely on the need for replacements.

✨ Abrasion Resistance

The smooth inner channel surface, combined with the fine structural material, ensures a high level of resistance to abrasion from transported materials during long-continued usage.

Cost-Effectiveness Over Time

The cost-efficiency analysis helps in bringing a conclusion in favor of HDPE dual wall pipes when taken into consideration during the entire life cycle of an infrastructure project. There are five points and data to highlight their economic advantages:

- Lower Maintenance Costs: Being corrosion resistant and durable, HDPE dual wall pipes need less maintenance. Keeping this factor in focus, studies show that up to 30% of maintenance costs can be reduced when compared to materials traditionally used for piping.

- Longer Service Life: As they could last for about 100 years, such pipes need less frequent replacements compared to others, while further proving saving on costs for that matter.

- Transportation Cost: The weight factor makes the transportation of HDPE dual wall pipes more economical when compared with any other. Comparatively, transportation costs could be 20–25% less with the heavier materials of concrete or steel.

- Faster Installation: HDPE pipes require less time for installation, giving an opportunity to save labor costs of at least 40% during construction projects.

- Energy Efficiency in Manufacturing: HDPE pipe production processes require less energy as compared to the process used for manufacturing traditional materials. For instance, HDPE manufacturing takes 25% less energy, thereby resulting in a reduced carbon footprint.

Environmental Benefits

🌱 Reduced Carbon Footprint

HDPE pipes tend to cause less carbon emission through the production due, mainly to the energy requirement measurements wherein 25% less energy is necessary compared to traditional materials such as concrete or steel.

♻️ Recyclability

HDPE pipes are completely recyclable, so technically they do not present the usual pollution problems that would arise from their disposal in landfills, considering that at the end of their life cycle, they can be reutilized for the production of other materials.

⏳ Durability and Longevity

Resisting adequate corrosion and chemical degradation makes HDPE pipes last longer as compared to the traditional ones. This longevity leads to a depression in the need for replacement and repair.

💧 Lower Leakages

The joint integrity of HDPE dual wall pipes is at an excellent level and helps in greatly reducing water leakage in the pipeline system, safeguarding water. Water conservation becomes very important mainly in areas that suffer from scarcity.

🚛 Easy to Transport

Due to its light weight, it is easier to transport HDPE pipe, requiring fewer fuel and lower emission during delivery; hence, it is an eco-friendly option for vast distribution and installation.

Considerations When Choosing HDPE Dual Wall Pipe

Factors to Evaluate Before Purchase

On selecting HDPE dual wall pipes, several key considerations must be taken into account for optimal performance and cost-effectiveness:

- Pipe Diameter and Load Capacity: The diameter and load capacity of the pipe depend on the type of application involved-whether it is drainage, culvert systems, or wastewater management. Also, the pipe must meet stress and structural requirements for long-term use.

- Compliance with Standards: Check that the HDPE pipe complies with industrial standards like ASTM F2648 or AASHTO M294 so the pipe may be accepted as high-quality, reliable, and safe for usage under different environments.

- Environmental Resistance: Consider the pipe’s resistance to environmental factors-based on UV light, temperature changes, and chemicals it might be exposed to. HDPE will fit in well as a material resisting corrosive conditions.

- Installation Requirements: HDPE dual wall pipes are designed to be installed with ease; nevertheless, installation issues such as joint connections or fittings could affect the performance.

- Lifespan and Maintenance: Consider the lifespan of the material and its maintenance requirements. HDPE pipes require minimal maintenance and are, therefore, cost-effective in the long run.

- Cost Consideration and Availability: Cost and availability locally should be compared. Balance the upfront cost with long-term savings to choose one that suits the project objectives.

Proper evaluation of factors coupled with research into current standards and supplier options guarantees that you will choose the suitable HDPE dual wall pipes for your needs.

Future Trends in HDPE Pipe Technology

As far as I consider the HDPE pipe technology in the future, innovation would continue to improve both material performance and environmental aspects. Improvements in manufacturing techniques have led to the development of pipes with better strength-to-weight ratio and increased durability. They could enhance the performance of HDPE pipes in hardware and industrial applications and, at the same time, reduce material wastage and costs lowered.

🔬 Smart Technology Integration

Another trend should find smart technology getting integrated into pipeline systems, which include HDPE dual wall pipes. Sensors installed inside the pipelines allow one to obtain flow-dynamic data, pressure-level information, and details on possible leakage, thus ensuring maintenance-safety disruption. The resulting union of HDPE resilience with smart monitoring systems is a very big step forward in pipeline management and efficiency.

🌿 Sustainability Focus

Lastly, with sustainability becoming the major concern in HDPE pipe technology, that is what, in my opinion, will fuel new growth in the future. Recycling, use of bio-based materials, etc., in the manufacture of HDPE, are all growing along these lines of reducing the carbon footprint of infrastructure projects. Many companies are now looking for greener solutions such that any new technology in HDPE pipe performs, but also is friendly toward our future.

References

-

MDPI – Study on the mechanical responses of plastic pipes made of high-density polyethylene (HDPE)

This study explores the mechanical behavior of HDPE pipes, highlighting their suitability for water supply networks. -

MDPI – Numerical and experimental investigation of the effect of traffic load on HDPE double-wall corrugated pipe

This research examines the mechanical response of HDPE double-wall pipes under external loads, including traffic. -

ProQuest – Evaluation of HDPE and PVC pipes used for cross-drains in highway construction

This evaluation compares HDPE and PVC pipes in highway construction, focusing on their installation and performance. -

Springer – Value Analysis on the Utilization of HDPE Pipes as an Alternative to Reinforced Concrete Pipes

This study discusses the cost-effectiveness and advantages of HDPE pipes over conventional reinforced concrete pipes. -

ScienceDirect – Butt-welding technology for double-walled polyethylene pipe

This article investigates the welding technology and applications of HDPE double-walled pipes in sewage line construction.

Frequently Asked Questions (FAQ)

❓ What is an HDPE dual wall pipe?

An HDPE dual wall pipe is a type of drainage pipe having a smooth interior wall and a corrugated exterior wall. While the pipe comes with these physical features, its hydraulic properties are excellent enough to warrant its use in any application requiring efficient drainage solutions.

✅ What are the advantages of using HDPE dual wall pipes?

They stand for performance and durability. They are also lightweight, corrosion-resistant, intent in environment with resistance, and some conditions. A smooth interior wall minimizes friction, thus providing higher flow rates than would occur with a traditional pipe.

🏗️ Where are they used?

These pipes are generally used in drainage systems for stormwater management, agricultural drainage, and sewerage systems. It serves as an alternative to reinforced concrete pipes in applications where weight and ease of installation do matter.

📏 How to calculate the correct size of an HDPE dual wall pipe?

The size should be calculated keeping in view the flow and the material being transported as well as the site conditions. The best thing would, however, be to get some reference from colleagues or manufacturer guidelines to know what is best suited for the application.

📦 Is it possible to order HDPE dual wall pipes in different sizes?

Yes; these pipes come in a variety of sizes and diameters, including the very popular N-12 dual wall pipe. This enables designing custom solutions for specific project requirements.

⚙️ How does the installation of HDPE dual wall pipes compare with other types?

The installation of HDPE dual wall pipes-easy and quick-is much easier and quicker compared to installing corrugated metal pipes (CMP) or those made of reinforced concrete. Being lightweight reduces the need for the use of heavy machinery, so construction sites prefer it for many reasons.

🛒 Where are HDPE dual-wall pipes sold?

The HDPE dual wall pipe can be bought from various suppliers in India, be it a local hardware store or a plumbing-specialized supplier. One must weigh all options for price and availability.

⏰ How long can an HDPE dual wall pipe last approximately?

HDPE dual wall pipes can last for a very long time, more than 50 years if installed correctly and maintained. Their life span is greatly enhanced by the fact that they’re anticorrosive and are resistant to environmental effects.

⚠️ Any drawbacks to consider when using HDPE dual wall pipes?

Whereas there are many advantageous aspects of HDPE dual wall pipes, a few challenges such as correct installation methods or considering thermal expansion may arise. If one is facing these problems and wishes to ensure the performance from these pipes, applying the knowledge of experts will be the way forward.

Conclusion

HDPE dual wall pipes represent the pinnacle of modern drainage technology, offering unmatched durability, cost-effectiveness, and environmental benefits. Their versatile applications across residential, commercial, and industrial sectors make them the preferred choice for contemporary infrastructure projects. By understanding their advantages and proper implementation considerations, stakeholders can make informed decisions that ensure long-term success and sustainability.