In the realm of construction and infrastructure development, the use of high-density polyethylene (HDPE) pipes notable popularity due to their resiliehave, flexibility, and resistance to corrosion. However, understanding the minimum bending radius of these pipes is crucial for ensuring their integrity and performance during installation. This article will delve into the factors influencing the bending radius of HDPE pipes, the consequences of bending beyond recommended limits, and best practices for installation. By grasping these concepts, readers will be better equipped to make informed decisions that enhance the durability and effectiveness of their piping systems.

What is the Minimum Bend Radius for HDPE Pipe?

Definition of Minimum Bend Radius

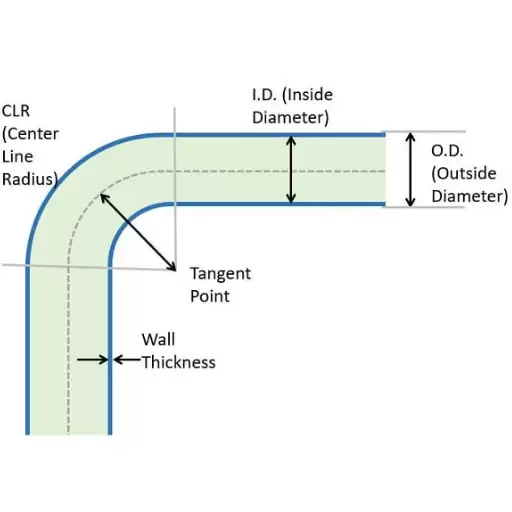

The smallest radius that HDPE pipes can be bent with minimum bend radius is a minimum bend radius is the t compromising their structural integrity, and performability is known as the minimum bend radius. This manufacin averts mishaps such as kinking that would lead to reduced flow ability or complete pipe failure. Generally, a minimum bend radius for HDPE pipes is 20 times the outer diameter; however, it varies depending on pipe size, wall thickness and specified applications. In this regard, it be, becomes necessary to follow these rules in order following to Influencing Minimum Bend Radius

Several key factors influence minimum bending radii of HDPE pipes. First, of all the, the diameter of the pipe plays a major role because larger diameters usually require significantly higher bending radii to remain structurally sound. Second, wall thickness also matters; thicker walls resist bending more strongly and allow tighter bends. Furthermore, installation conditions – temperature and external l loads – are also necessary because HDPE becomes flexible when crucial material formulation, including special is if grade, gives rise to its ductility, which influences the ability to withstand be flexibility without causing damage. Such knowledge helps establish safe and efficient installation procedures.

Why It Is Important To Adhere To The Minimum Bend Radius

Maintaining structural integrity and longevity of HDPE piping systems requires strict adherence to established minimum bend radiuses. Bending at angles that deviate from those indicated by suppliers can result in kinks or deformities which affect flow capacity, hence making them susceptible to flow capacity; bending can cause stress concentrations when not correctly done, leading to fatigue failures through cracks over time. Consequently, adhering to industry standards on minimum bend radii not only leads to best practices but also reduces safety hazards and maintenance costs by avoiding premature system disasters concerning pipeline networks. Proper following ensures overall efficiency as well as reliability of fluid transport systems.

How do you determine the bend radius for an HDPE pipe?

Determdo you do you determine the Bebend is radiused an on Pipipeiameter?

To calculate HDPE pipe bend radii, a rule of thumb is usually used that relates pipe diameter to minimum bend radius. The minimum bend radius usually is 25 times the Usuallymeter for standard installations. Therefore, if the diameter of a standard pipe is six inches, its minimum bend radius should be at least one hundred and fifty inches. This ratio ensures that structural integrity or flow capacity is not lost whenever pipes are amended.

In this notion, adhering to the manufacturer’s specifications and industry standards may be important because some types of HDPE materials allow tighter bends. In addition, environmental factors such as temperature must also be considered, as they could affect material flexibility during bending. Applying these recommendations will ensure safe and effective bending, avoiding possible problems later.

Standards & Specifications for HDPE Pipes

HDPE pipes are regulated by various standards so that quality, performance and safety can be ensured in their applications. One crucial specification is ASTM F714, which sets out requirements for HDPE piping systems in various contexts like water distribution and waste disposal. The dimensions, tolerances, and other physical properties of HDPE pipes are governed by ASTM D3035, ensuring uniformity across products (D3035). Moreover, industry standards often emphasize meeting the American Water Works Association (AWWA) requirements, especially AWWA C901 and C906, which provide for H, DPE pipes design installation, and testing procedures. Conformance with these will optimize functionality and improve the longevity and safety of those piping systems.

Commthe on Mistakes When Calculating Bend Radius

In determining calculations for a bend radius on an HDPE pipe, common mistakes can lead to problems, ms during installation or operation. One mistake frequently made is underestimating what constitutes an acceptable minimum bend radius whereby stress is exerted on the pipe causing potential failure. It is essential to conform to the manufacturers’ guidelinesmanufacturers’ types of HDPE may have different tolerances for bending. Another mistake is ignoring environmental factors like temperature that can alter the material’s flexibility anmaterial’sy during installation. Further, failure to consider the pipe diameter and wall thickness when calculating the bend radius can result in poor performance. Therefore, it is critical to make accurate computations and consult relevant standards as ways of avoiding these mistakes.

What are the Ato avoid Pipe concerning Bend Radius?

Typical Applications for HDPE Pipe

HDPE pipes are used in many sectors because of their toughness and corrosion resistance. In water distribution systems, they guarantee a loWaterng and leak-free servcr sewer systems as well as stormwater drainage, HDPE pipes are vital due to their resilience against tough environmental conditions. Moreover, they frequently serve as gas distribution lines for safety and economy. They are installed easily on different terrains, hence the choice for utility installations and ag,ricultutheir uses such as irrigation systems. Lastly, HDPE pipes transport chems in industrial facilities due to their high chemical resistance.

How Bend Industrial Facilitiesidies dius Affects Installation

The success of HDPE pipe installation largely depends on its bend radius since it affects the pipe’s performance and dupipe’sty. The pipe’s performance could pipe’s much stress on the pipe, leading to deformation or failure over time. The application of bend radii recommended ensures that while maintaining tube inis integrity, effto ensure flow characteristics can persist within them. Furthermore, accurate calculation of the bend radius helps avoid kinks and potential blockages, facilitating a smoother installation process. Considering the suitable bending radius for varConsiderings makes the HDPE more flexible while reducing the chances of leakage and damage during operation, thus improving overall efficiency in installation,

Case Studies on Applications of HDPE Pipes

Successful applications have demonstrated how useful HDPE pipes have been in various industries. helpful stance, there was one remarkable case where they were used in a municipal water supply project because they proved highly durable even when subjected to corrosive environments, lowering maintenance costs and significantly extending life cycle costs simultaneously. Another example is when some highwaysimultaneouslyructed using HDPE pipes for stormwater drainage system inclusion instead of concrete culverts; this was attributed to their lightweight nature, which made them easy to install while being compatible with rugged terrains, thereby minimizing risks associated with their breakage. In an agricultural setting, HDPE pipinted for efficient irrigation systems, resulting in substantial water savings and improved crop yields, showcasing their effectiveness and versatility in diverse environments.

What is a Sweep Bend and How Does it Relate to HDPE Pipe?

Understanding Sweep Bends

A sweeping bend in the context of HDPE pipes is a gentle curve that eases the change compared to conventional fittings. This ensures no turbulence or drop in pressure in fluid flow, which would otherwise cause inefficiency in the piping system. When it is necessary to change directions without affecting the pipeline’s integrity, sweep bends are helpful because pipelines have the chance of stress points that may lead to leakage or destruction. They are often installed for better performance, especially in complex layouts or to meet natural land profiles. By applying them, engineers can attain the best flow conditions and prolong the life span of piping.

Benefits of Using Sweep Bends in HDPE Pipe Systems

Sweep bends are associated with several significant benefits when used in HDPE pipe systems. These bends help reduce hydraulic losses by providing a smoother flow passage, increasing fluid transportation efficiency. Besides, they make the system sturdy by lessening stress concentrations arising from orientation variations using standard fittings. It has been mentioned before that this minimization prevents leakages and extends the network’s service days. Moreover, their design facilitates easy main network inspection as gradual curves do not get blocked like those with sharp turns do most of the time. When incorporating sweep bends into an HDPE pipe system, one should expect improved operational efficiency, dependability, and long-term cost-effectiveness.

Installation Techniques for Sweep Bend

Proper installation of sweep bends in HDPE pipe systems is essential to ensure optimal performance and longevity. To maintain a continuous flow path, a sweeping bend must be aligned with existing piping accurately while fusing heat must be used effectively between two ends of pipes without dirt or other contaminants that might weaken joins produced by fusion bonding. It is also advisable to employ heat fusion machines or extrusion welders when joining these sections to achieve proper temperatures capable of forming strong bonds between them; otherwise, joining may not happen if the wrong temperature settings are used. Moreover, the bends’ integrity should be maintained by providing suitable support and anchorage to avobends’rational movements or stresses. Lastly, during and after installation, regular checking can eliminate alignment and fitting problems in time, thus maintaining a reliable pipe network.

What are the Consequences of Exceeding the Minimum Bending Radius?

Dangers of Twisting and Ruin

The considerable risks come with exceeding the minimum bending radiupipe systems, mainly leading to kinking and structural damage. Kinking is when the pipe is subjected to excess when it bends, making it weaker. As a result, flows may reduce when the weakening in the system goes up, thereby causing the system’s pressure to go up; this can be costly, leading to downtimes and increased operations. As before, it is esssystem’so observe the recommended bending radius for optimal performance and long life of the piping system.

Pipe Performance: The Long-Term Effects

Exceeding the minimum bending radius has both immediate consequences on pipe integrity and long-term implications on pipe performance too. My observation indicates that pipes instantly constantly bend more than necessary and frequently wear prematurely due to problems such as leaks or material fatigue over time because of stress concentration factors. Furthermore, these stresses also lower the overall efficiency of pipelines, resulting in decreased flow rates and increased energy consumption. In addition, prolonged exposure to these conditions would call for expensive maintenance as well as replacement needs, which significantly affects operations. Hence, ensure you maintain the minor possible bend, maintaining the functioning of HDPE pipes throughout their lifespan.

Tips on How Not To Exceed Minimum Radius

I have discovered several ways to avoid exceeding the minimum betoPE pipes. First, bends must be gradual when designing the layout of piping systems, avoiding any sharp angles at all costs. Such fittings as elbow joints ensure smooth transitions hence reduce stress on a pipe. Moreover, it would minimize pipe stress. The installation team is well versed in handling HDPE materials since they need to understand what minimum bending radii mean about non-observance effects. Finally, I would suggest inspecting piping systems regularly so that any signs of tear or stretch can be detected and dealt with quickly. Adopt these practices and we sh,all be able to substantially reduce the likelihood ofdamagingof damagingpipe systems.

Reference sources

- How to Calculate the Bend Radius of HDPE Pipe

- Flexibility and Bend Radius of HDPE Pipe

- What is the bend radius for the HDPE Pipe?

These sources provide detailed information on calculating and understanding the bend radius for HDPE pipes.

Frequently Asked Questions (FAQs)

Q: Can HDPE pipes be installed using trenchless methods?

A: Yes, HDPE pipes are usually employed for trenchless installations because they are pliable and durable. They are suitable for this type of installation mainly because the bending radius needs to ensure the tubes can move through a bore without getting damaged.

Q: What is the significance of following ASTM standards when bending HDPE pipes?

A: Adherence to ASTM standards when bending HDPE pipes guarantees they satisfy the highest quality thresholds regarding safety, performance, and durability. This helps avoid problems like cracks or failures during fitting.

Q: How does the soil type affect the bending radius of HDPE pipes?

A: Soil type may affect HDPE pipe installations focusing on trenchless constructions. Softer soils allow for tighter bends, while more complex soils may necessitate larger bending radii so as not to damage the tubing throughout its installation.

Q: What equipment is necessary for bending HDPE pipes?

A: Bending this kind of pipe could require specialized apparatuses like pipe benders, heat sources, and stabilizers to ensure it is handled correctly and has an acceptable radius that does not compromise its strength.

Q: Are there different bending radii for various sizes of HDPE pipes?

A: Certainly, more giant-size tubes tend to require higher minimum radii than smaller diameter piping, which can be flexed more efficiently than them.

Q: How can I ensure the quality of bent HDPE pipes?

A: Good materials should be used, manufacturer recommendations should be followed, and industry benchmarks such as ASTM should be heeded if one guarantees high-quality products. In addition, proper inspection and testing will enable this level of quality control to ensure maintenance.