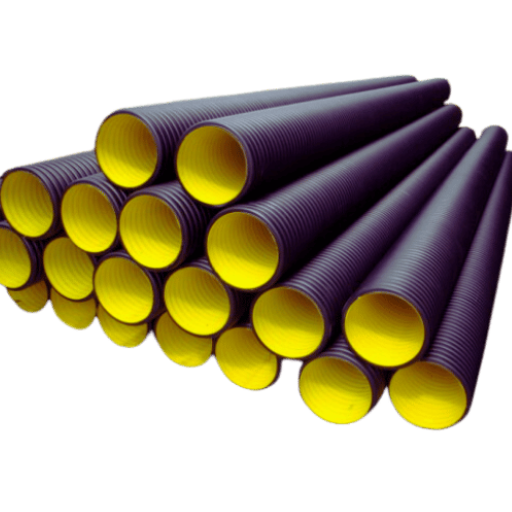

Corrugated High-Density Polyethylene (HDPE) pipe has become a pivotal solution in various industries due to its durability, flexibility, and efficiency. From large-scale infrastructure projects to residential drainage systems, this innovative material is reshaping how we approach fluid management and environmental sustainability. But what makes corrugated HDPE pipe stand out in a competitive market filled with alternatives like concrete, steel, and PVC? This article dives into the key benefits and wide-ranging applications of corrugated HDPE pipe, highlighting why it is trusted by engineers, contractors, and environmental planners around the world. Whether you’re looking to optimize a drainage system or explore cost-effective piping solutions, understanding the advantages of HDPE pipes is crucial for making informed decisions.

What are the Key Specifications of Corrugated HDPE Pipe?

How is Corrugated Pipe Manufactured?

The process of fabricating a corrugated High-Density Polyethylene (HDPE) pipe includes a sequence of steps to achieve optimum flexibility, strength, and performance of the pipe. The first step involves melting the applied HDPE resin and extruding it into pipe form. Choosing the right material is critical for the application to achieve desired targeting results, and in this case, the selected strip is ideal owing to its chemical resistance, strength-to-density ratio, and light weight.

The next step in the process is the overall refinement, which includes diagrammatic enhancement termed as the explosion of the pipeline, shaping of the pipe into a series of ridges and grooves in a longitudinal fashion. This is known to give additional load-bearing abilities owing to the outline design possessing greater flexibility and reduced risk of breakage when compared with standard models. The type of machinery required ranges from forming machines to standard mold heating devices capable of deforming innumerable consequent patterns.

The pipe further undergoes systematic verifications aimed at measuring dependability and uniformity post-corrugation. The pipes are required to be tested for wall thickness, internal pressure, and stress factors in the environment. Various other additional aspects must be measured. Custom coatings or liners can also be applied based on the requirements for intended additional enhancement. All of these help achieve the modern standard of versatility and durability expected from an HDPE pipe in use for modern-day agriculture, stormwater management systems, and drainage systems.

What are the Environmental Benefits of Using Recycled HDPE?

The use of recycled High-Density Polyethylene (HDPE) has a positive impact on the environment because it lessens the need to produce virgin plastic. Doing so preserves resources like petroleum and natural gas. Recycling helps in conserving energy as well as curbing the emission of greenhouse gases by minimizing the need for extracting and processing raw materials. Research indicates that the energy required for producing recycled HDPE is lower than that needed for producing new HDPE from virgin materials, which assists in reducing the carbon footprint.

Applying recycled HDPE plays a major role in curtailing plastic pollutants in landfills and throughout the environment, which serves as another significant benefit. The durability of HDPE makes it non-biodegradable and poses threats regarding its disposal. Converting HDPE waste into pipes, containers, or other construction materials allows it to be reused in another cycle while curbing pollution, helping conserve precious space in landfills.

Finally, the advocacy of using recycled HDPE contributes to sustainable manufacturing and promotes a circular economy. It further motivates businesses to devise new strategies that involve product life cycle design and closed-loop systems that perpetually recycle materials. With the widespread adoption of recycled HDPE, industries can reduce plastic waste, preserve natural ecosystems, and promote environmental stewardship for future generations.

How Does Dual-Wall Corrugated Pipe Improve Drainage Systems?

What is the Difference Between Single Wall and Wall Pipes?

Single-wall pipe tools are inexpensive, flexible, and lightweight, which makes them ideal for non-pressure-related tasks. Dual-wall pipes, on the other hand, are robust and more durable when compared to single-wall pipes and can be used for high-pressure and heavy-duty tasks.

|

Feature |

Single Wall Pipe |

Dual Wall Pipe |

|---|---|---|

|

Design |

Single layer |

Double layer |

|

Interior |

Corrugated |

Smooth |

|

Load |

Lower |

Higher |

|

Lifespan |

Moderate |

High |

|

Bendability |

High |

Moderate |

|

Expense |

Lower |

Higher |

|

Usage |

Drainage, irrigation |

Sewage, heavy drainage |

|

Pressure |

Low |

High |

|

Setup |

Easier |

Complex |

How Does the Smooth Interior Wall Enhance Flow?

To optimize hydraulic performance, the twin-wall dual-wall corrugated pipes’ internal wall is smooth. Single-wall pipes, in comparison, have an interior that is uneven or corrugated, which increases turbulence. Unlike single-wall pipes, dual-wall pipes have smoother interiors, which reduces resistance to flow and allows for more efficient movement of liquids through the pipes. This allows for lower energy costs and enables consistent flow rates even when large amounts of liquid are siphoned out. Reduction in the resistance faced by dual-wall pipes directly improves the flow capacity of the pipes, which increases their effectiveness when used for large-scale drainage tasks.

Pipes that have rougher surfaces tend to accumulate sediments over time, which causes drainage blockages. It is less likely for sediments, debris, and other blockages to stick to the internals of these pipes, which helps sustain their operational efficiency and reduces the amount of maintenance required. Other than stormwater management, agricultural irrigation, and wastewater systems, this design feature is extremely valuable where long-term reliability is needed.

The application of dual-wall corrugated pipes with smooth interiors can reduce operational costs from a cost-effectiveness perspective. These systems are economical over their service life because they aid in maintaining optimum flow dynamics and minimize the need for constant cleaning or repair. Furthermore, dual-wall pipes, owing to their strong structural integrity, provide a holistic answer for modern drainage problems, thereby underscoring their significance in infrastructure undertakings.

What are the Common Applications of Corrugated HDPE Pipe?

How is Corrugated Pipe Used in Drainage Systems?

The design and function of modern drainage systems cannot be imagined without the use of HDPE pipes. These pipes are best suited for stormwater control, agricultural field drainage, and culvert installation due to their lightweight, extreme durability, and resistance to chemicals and other outside factors. They ensure smooth water flow even under heavy pressure, making them ideal for both surface and subsurface drainage applications.

Manufacturers have honed refinement techniques to further enhance these pipes’ performance. Double-wall and triple-wall corrugated pipes are equipped with a smooth inner lining that minimizes hydraulic resistance, thus enabling burst flow rates for high volume drainage. The external structure is reinforced with corrugation for added structural support that enables the pipes to withstand substantial external pressures without losing structural integrity.

These pipes are now standard for municipal, commercial, and residential drainage projects. For example, the use of corrugated HDPE pipes becomes prevalent in urban areas during storms for effective flood mitigation. The pipes also serve a beneficial purpose in fields by averting waterlogging to maximize productivity. The overall infrastructure system benefits from the integration of these pipes by enhanced efficiency and extended service life, reinforcing their value in different engineering applications.

What Role Does Corrugated HDPE Play in Culvert Construction?

Due to their unrivaled flexibility, strength, and cost efficiency, the use of High-Density Polyethylene (HDPE) corrugated pipes has become a critical part of modern culvert construction. These pipes are built to resist considerable structural stresses while enduring wear, chemical exposure, and environmental damage. Their flow manageability is optimal in tough geographies with heavy traffic due to their superior strength to relative weight ratio.

Compared to traditionally used concrete or steel pipes, the transport and installation of HDPE pipes is much easier, which greatly reduces labor and project timelines. In addition, HDPE pipes are extremely lightweight, which enhances their portability and makes them less expensive overall. Because of their efficiency in containing corrosion from acidic soils and saline regions, these materials are ideal for infrastructure use in a wide range of geographic locations. Their flexibility also permits site requirement adaptation, so any changes in soil placement or minor seismic activity don’t affect the structure’s integrity.

Research shows that HDPE culverts, when maintained in optimal conditions, surpass the serviceable performance milestone of 50 years, which makes them a cost-effective, sustainable option for municipal and industrial drainage systems. In addition, new advancements in manufacturing, like dual-wall construction with a smooth inner wall, reduce hydraulic flow resistance, leading to better control over how water or other substances are expelled, which results in superior hydraulic performance. These factors explain why corrugated HDPE is essential in modern culvert construction by providing engineers and ecological planners with a flexible and high-performance answer to modern infrastructural issues.

Is Corrugated Plastic Pipe Suitable for Agricultural Use?

Plastic pipes, especially those constructed from high-density polyethylene (HDPE), have emerged as a durable, flexible, and cost-effective option for agricultural applications. These pipes are extensively used in the construction of drainage and irrigation systems on account of their chemical resistance to corrosion, UV destruction, and abrasion, all of which are potential factors of environmental damage during farming activities. Moreover, their ease of handling aids in transportation and installation, therefore saving costs on tools and equipment.

With reference to overall efficiency, the ribbed structure of corrugated plastic pipes allows free drainage and flow of water. They are made to endure different soil pressures and heavy weights, which makes them suitable for various regions with differing agricultural practices. Research has proven that they are fully functional over decades of use, thus validating the long-term dependability of the pipes for the enhancement of irrigation management, water surplus control, preserving crop yield, and maintaining soil health.

In comparison to older materials such as concrete or metals, these newer materials, like corrugated plastic pipe,s offer greater resistance to varying temperatures and soil shifts. This property is particularly useful in areas that experience harsh climates or seasonal variations. Along with continuous progress in the technologies of mechanical engineering and material science, corrugated plastic pipes are transforming cross-sectional agriculture, thus becoming an essential element in the infrastructure of sustainable agriculture.

How to Ensure Proper Installation of Corrugated HDPE Pipes?

What are the Best Practices for Fitting and Joint Connections?

I have checked every section of the pipe and all fittings before proceeding with the installation because it is crucial to follow the correct methods for installing corrugated pipes. Principles of undamaged parts must form the basis for my assessment. Each pipe section must be free of damage, smear, deformities, and cracks, as they would disrupt the integrity of the entire pipe system. Furthermore, I double-check that all joint connections correspond with the particular pipe’s size and type. To prevent weakness or gaps that may lead to destructive leakage, all gaps between the ends of the pipes must be aligned perfectly.

After confirming the correct fittings, I prepare the pipe fittings and ends, making sure to clean all surfaces of any smudges, dirt, or mud because a leak-proof seal requires the ends to be completely clean. Depending on the connection type, either snap or bell-and-spigot, pipe distortion may occur from lubricant application and hence must be approached cautiously. While assembling bell-and-spigot joints, I ensure sealing gaskets are placed meticulously in the correct position for water retention impermeability without compromise.

Finally, I ensure that all the joints are tested after assembly by performing either a moderate pressure test or a water infiltration test, depending on project specifications. Doing so verifies that the seals are functioning correctly, and any fittings can be modified before backfilling. I also follow the instructions put forth by the manufacturers regarding the pipe bedding and backfill materials because insufficient support can cause the joints to fail over time. Adhering to these procedures guarantees proper, long-lasting performance of the installation, its durability, and the installation’s longevity and performance.

How to Maintain the Integrity of Gasket Seals?

Preservation of seal integrity from gaskets is achieved through meticulous installation practices, inspections, and regular maintenance interventions. To avoid material degradation or failure, first check that the operating environment – its temperature, pressure, as well as the fluid or gas being transported – is compatible with the gasket materials. During the installation phase, it is imperative to tighten the bolts in a cross-pattern sequencing manner while achieving equal pressure on all bolts to avoid uneven compression, which can adversely affect a seal.

Borders on the gauges should permit passage of any wear contour and define cracks, deformation, or even chemical degradation of the surface. Any changes should incur immediate action for repair to plug leaks or pressure loss in the system. For compliance, manufacturers’ recommendations should always be verified alongside specifications and torque guidance provided.

Appropriate gaskets should be properly stored away from moisture, direct sunlight, and extreme temperatures, as these can damage the gasket material over time. Enhanced ultrasonic leak detectors can help uncover minute imperfections and advance the preventative maintenance practices even more. By using these techniques consistently, the effectiveness and durability of gaskets can be maximized.

How Does Corrugated HDPE Pipe Compare to Concrete and Metal Pipes?

What are the Advantages of Using Corrugated Polyethylene Drainage?

Like other pipes, Polyethylene (HDPE) pipes are used for the transportation of liquid substances, but are far more advantageous than traditional concrete or metallic pipes. Below are the most crucial advantages of using polyethylene over concrete or metallic pipes:

- Minimal Effort During Installation

The weight of a corrugated polyethylene pipe is substantially lower than other metallic and concrete pipes, and translates into lower costs associated with installation. Additionally, a 24-inch HDPE pipe with 20 20-foot length weighs about 165 pounds, while a concrete pipe with the same dimensions exceeds 2,000 lbs, making it easier for construction workers to lift. Furthermore, this decrease in weight improves the safety of construction workers, allowing them to work without the jeopardy of heavy machines.

- Exceptional Resistance To Harmful Chemicals

Because polyethylene’s structure is noncorrosive, it does not rust or weaken during harsh chemical conditions, leading to a longer life span compared to metal pipes.

- Greater Durability and Flexibility

Due to the ductile characteristic of HDPE, it does not break due to heavy loads or ground shifting. This is especially useful for areas vulnerable to earthquake movement or weak soil regions where concrete would crack. Laboratory work has vouched for HDPE’s efficacy under loads of up to 15% deformation.

- Time and Cost Efficient

Although the flexible plastic pipes may cost more than other alternatives, the savings accrued from maintenance, repair, and replacement in the long run express their cost-friendliness. The RIT study points out that HDPE drainage systems have a service life of 50 to 100 years with little degradation, which is far longer than traditional pipe materials.

- Sustainable and Environmentally Friendly

The manufacturing of corrugated polyethylene pipes consumes less energy when compared to steel or concrete, making it more recyclable. Furthermore, smoother interior surfaces of HDPE pipes decrease water leakage, further conserving the resource.

These benefits in agriculture, infrastructure, and stormwater management make corrugated polyethylene drainage systems useful where performance, cost efficiency, and sustainability are vital.

How Does Corrugated Metal Pipe Differ in Performance?

Compared to polyethylene pipes, CMP pipes have different performance characteristics due to variances in their structural details and materials. Made from steel or aluminum, CMP pipes possess high load-bearing capacity, making them ideal for durable applications such as bridges, road culverts, and industrial drainage systems. Moreover, the corrugated metal’s rigidity means it can endure extreme external pressure and erosive conditions, which is important in areas vulnerable to heavy rainfall or flooding.

CMP, however, is at risk from corrosion and abrasion, particularly when in contact with high salinity environments or soils that are acidic soils. These risks can be reduced with the use of protective coatings like galvanized or polymer coatings, which extend the service life of the pipes. The structural strength of the CMP systems is also beneficial; their capacity for improving load distribution over a large area lowers the likelihood of deformation due to stress. Such attributes make CMP a dependable solution for civil and geotechnical engineering projects that prioritize longevity and structural integrity.

Because of their internal surfaces, corrugated metal pipes CMP may be less efficient than polyethylene pipes with regard to hydraulics because they may induce greater friction and lower flow rates. Therefore, when considering CMP versus polyethylene piping systems, engineers have to factor in more than just installation costs and environmental conditions. CMP and polyethylene piping systems have other differences that, one way or another, have an impact on performance and sustainability issues in the specific application of the piping system.

References

Frequently Asked Questions (FAQ)

Q: What are the key product details of corrugated HDPE plastic pipe?

A: Corrugated HDPE plastic pipe is made from high density polyethylene, known for its durability and flexibility. It is widely used for drainage applications due to its lightweight nature and resistance to corrosion. Product specifications often include single wall and N-12 dual wall designs, which cater to different drainage needs.

Q: How does corrugated HDPE drainage pipe compare to traditional materials like RCP?

A: Corrugated HDPE drainage pipe is an excellent alternative to reinforced concrete pipe (RCP) due to its lightweight and flexible nature. It is easier to install, requires less heavy equipment, and provides superior resistance to chemicals and abrasion, making it ideal for various underground applications.

Q: What are the typical applications of HDPE pipe products?

A: HDPE pipe products are commonly used in stormwater management, agricultural irrigation, culvert pipe installations, and roadway drainage systems. They are also used in waterworks projects and as an underground storage solution due to their water-tight and durable nature.

Q: What are the standards and specifications for HDPE drainage pipe?

A: HDPE drainage pipe products typically conform to standards such as ASTM D3212, ASTM F2306, AASHTO M252, and AASHTO M294. These specifications ensure the pipe’s quality, performance, and compatibility with pipe and fittings for various drainage applications.

Q: What are the advantages of using N-12 dual-wall HDPE pipe?

A: N-12 dual wall HDPE pipe offers enhanced strength and durability compared to single wall pipe. Its smooth inner surface facilitates efficient water flow, while the corrugated outer wall provides structural integrity. This design makes it ideal for high-volume drainage needs and heavy-duty applications.

Q: Are there different types of perforated pipe available in HDPE products?

A: Yes, HDPE pipe products are available in both perforated and non-perforated configurations. Perforated pipes are typically used for sub-surface drainage systems, allowing water to enter the pipe through small holes, which helps efficiently manage water levels in agricultural or landscaping applications.

Q: What is the significance of the bell and spigot design in HDPE pipe and fittings?

A: The bell and spigot design in HDPE pipe and fittings ensures a secure and leak-proof connection between pipes. This design is crucial for maintaining water-tight systems, particularly in drainage and wastewater applications, where preventing leaks and infiltration is essential.

Q: What role does the drainage handbook play in selecting HDPE plastic pipe?

A: The drainage handbook provides comprehensive documentation on the selection, installation, and maintenance of HDPE plastic pipe. It offers guidance on product specifications, design considerations, and application best practices, helping engineers and contractors make informed decisions for their drainage projects.