Applications have increasingly favored High-Density Polyethylene (HDPE) pipes for their toughness, versatility, and non-corrosive characteristics. One essential factor, however, that determines the efficacy and efficiency of any project is the correct pipe size. This article seeks to familiarize the readers with aspects related to the HDPE pipe size chart by discussing guidelines on how the HDPE pipe size chart can be used proficiently. Learning how this chart is constructed will provide you with the necessary knowledge to make the appropriate choices for your applications, whether for residential, commercial, or specialized use. We will look at the basic aspects of the size of HDPE pipes, including the factors influencing the choice of size and practical recommendations for ensuring the effectiveness and compatibility of the various piping systems.

What is HDPE Pipe, and How is it Used?

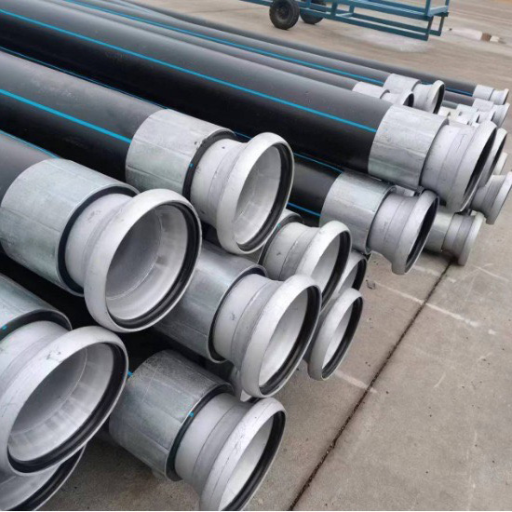

HDPE pipe is fabricated from thermoplastic high-density polyethylene with a high strength-to-density ratio. In this regard, it is a relatively adaptable and long-lasting material for different kinds of piping works. Very often, HDPE pipes are used for water distribution, drain and sewerage systems, gas mains as well as industrial effluents due to their great chemical and environmental stress cracking resistance. Thanks to their flexibility, HDPE pipes are quite easy to install even in areas with rough topography or in seismic regions; in addition, the smoothness of the internal surface helps to streamline the flow of fluids and decrease the energy expended for pumping. Coupled with long life spans and reduced maintenance requirements, those characteristics make HDPE pipes very suitable for cost-effective and environmentally friendly infrastructure development.

Defining HDPE Pipe: A Look at Material and Durability

It is within my expertise that HDPE pipe is manufactured using high-density polyethylene which has high durability and high strength-to-weight ratio. This implies that, though light in weight, HDPE pipes are very strong, and they can serve efficiently for long durations in many applications. In my work, I have come across many such pipes that are manufactured using these materials, and among them, the pipes showed greater environmental stress cracking and chemical corrosion. A unique combination of these material properties exists, which helps HDPE pipes retain their shape and working capability in the most extreme situations. Their flexibility and ability to conform to different terrains make them attractive to various industries, which further endorses their trust in modern infrastructure solutions.

Common Applications for HDPE Pipe

HDPE pipes have a variety of uses in different fields. Some of the more popular applications are:

- Water Distribution Systems: HDPE pipes are the preferred material for the distribution of drinking water because they do not rust which provides a guarantee of a clean water supply.

- Sewage and Drainage Systems: In sewage and drainage systems, HDPE pipes are able to transport waste water containing harsh chemicals without deteriorating.

- Gas Pipelines: Since they are strong and do not allow the passage of liquids or gases, HDPE pipes are widely used for the transportation of natural gas and other similar fuels.

- Agricultural Irrigation: HDPE pipes are very effective in agricultural irrigation systems as they are very flexible and easy to install which ensures reliable provision of water over long distances.

- Industrial Effluents and Slurries: Almost all industries use HDPE pipes for transporting different types of chemical effluents, slurries, etc, due to their high resistance to chemicals.

These applications leverage the core properties of HDPE pipes, including their resistance to chemicals and environmental stress, flexibility, durability, and cost-effectiveness, making them a versatile choice across a broad spectrum of industries.

Benefits of Using HDPE over Other Pipe Materials

I wish to elucidate the advantages of High-Density Polyethylene (HDPE) pipes over other materials in an uncomplicated manner:

- Corrosion Resistance: HDPE pipes are resistant to corrosion and rust unlike metal pipes. This is ideal for situations in which the pipe has to be inground and come into contact with alkaline solutions of water or other chemicals. This resistance is vital in the prevention of contamination of water supply systems.

- Chemical Resistance: HDPE pipes have the ability to withstand a wide range of different chemicals. They will not interact with sewage, drainage effluents, or gas, which is the key qualities required for their intended purpose. This allows them to be a dependable option for transporting chemicals as well.

- Flexibility and Toughness: The stiffness of HDPE pipes enables them to get fitted into places that would crack other ordinary piping systems with the same pressure. Stiffness makes them break-less, that facilitates longer life.

- Longevity: These pipes can resist deformation and displacement for more than 50 years which simply demonstrate the excellent durability of the materials. Due to this duration of life expectancy, people settle on these as they do not have to incur regular and frequent expenditure on repair and replacement.

- Lightweight and Easy Installation: Transporting and using as well installing these pipes become less expensive and easier because they are smaller than piping that is constructed from metal. Body Flexibility reduces the need to use heavy machinery when fitting pipes thus eliminating a lot of expense and complications.

- Environmental Sustainability: Given its recycling capabilities and non-reactive characteristics, there’s hardly any degradation to the eco-system during and after usage of HDPE. Hence, it’s a more environmentally friendly product.

However, these manufacturers’ benefits in totality explain combatting preference towards using HDPE pipes across various industries, cutting risks while improving efficiency, security as well and competitive edge.

How to Read an HDPE Pipe Size Chart?

To properly use an HDPE pipe size chart, some important measurements and specifications would need to be understood. First, locate the nominal size, which is the outer diameter of the pipe. It should be noted that size tables also often contain the wall thickness measurements, which determine the pressure rating of the pipe. Moreover, the Standard Dimension Ratio (SDR) should be observed as it is also critical in evaluating the pressure capacity of the pipe. Mastering these primary elements will arm you with adequate knowledge to choose an HDPE pipe suitable for the intended application while ensuring compliance with the intended use conditions and requirements.

Understanding Pipe Dimensions: OD, ID, and Wall Thickness

It is essential when communicating with clients regarding HDPE pipes that certain critical dimensions are understood for decision-making purposes. Let’s expand what these dimensions are:

- Outer Diameter (OD): The outer diameter of a pipe is found by taking a measurement from the outer edge on one side to the Outer edge on the opposite side. It is an important consideration because many fittings and connections are made to fit the OD. When size charts are used, the OD is usually the first measurement given.

- Inner Diameter (ID): From one inner wall to the opposite inner wall is the ID measurement. It is the measurement of the cross section of the open space within the pipe that contains the fluid or gas in flow. The ID value is crucial in determining the flow rates and capacities for optimizing the working of a system.

- Wall Thickness: This gives a measurement of the thickness of the pipe wall. The wall thickness has direct effect on the strength and maximum pressure rating of the pipe. Higher wall thickness pipes will withstand greater pressure hence suitable for tougher usage.

Knowledge about the three parameters, which are the outer diameter, inner diameter, and wall thickness, enables you to make sure that you are picking the right pipe size in terms of strength and volume capacity for your certain project. Making sure you have metrics which fit your project’s needs will permit to perform cost effective, safe and efficient operations as well.

The Importance of the Standard Dimension Ratio (SDR)

El SDR es uno de los parámetros importantes en el cálculo y selección de las tuberías, especialmente de las tuberías de HDPE. El SDR reduces the necessary complex calculations involved in structural design when a correlation between the wall thickness and outer diameter has to be determined by providing a standard measure of the pipe’s strength and pressure bearing requirements. Examinemos más detenidamente por qué el SDR es tan importante:

- Definition of SDR:The formula for the Standard Dimension Ratio is clearly stated in

The following expression:\[

SDR=OD/WALL\_THICKNESS

\]

- Consistency in Pipe Selection: By standardizing the relationship between OD and wall thickness, SDR provides a consistent and predictable metric that simplifies pipe selection across various applications. This standardization helps engineers and designers select pipes that meet their specific pressure requirements.

- Impact on Pressure Rating:SDR acts as a clear measurement that helps compare pipes based on their functions and enables the selection of pipes more effortlessly by removing various degrees of uncertainties caused by their size or wall thickness since it limits the ratio of the distance from the Center point of a pipe to the outer point and its wall thickness. This standardization assists engineers and designers in picking pipes that satisfy their intended pressures.

- Application Versatility:Different SDR values correspond with different applications, from low-pressure GRAVITY FLOW SYSTEMS to a high-pressure water main. Determining the most suitable SDR for a given application will guarantee the durability and dependability of the particular piping system in question.

- Data for Common SDRs:

- SDR 11: Handled in a setting with industrial applications due to their high pressure rating otherwise Poking them into any other scenario would be worthless.

- SDR 17:The handling pressure specs are broad enough to allow usage of these pipes in water supply and sewerage systems in the place.

- SDR 26: Enabling the use of these pipes on sewerage and drainage projects where pressure is not much of a concern.

It’s essential to have knowledge of SDR so that you are able to develop an efficient, safe, and cost effective pipe system design which incorporates the correct pipes for the given task.

Decoding Pressure Ratings on the Size Chart

This ensures that the pipe’s ratings effectively reflect the operational level of working pressure. It’s an exciting concept, the task of interpreting the pressure ratings on the size chart, as an industry specialist, let me take you through this concept in detail.

- Outer Diameter (OD): It is the distance from one outer edge of the pipe to the opposite outer edge. It is one of the most important factors because all the other measurements are relative to this.

- Wall Thickness: This parameter tells us how thick the wall of the pipe is, in most cases a thicker wall implies that the pipe can withstand higher pressures.

- Standard Dimension Ratio (SDR): As mentioned earlier, SDR is the ratio of the OD of a pipe to the wall thickness. It becomes the most critical parameter in calculating the pressure rating of the pipe. Appreciating SDR helps you to know whether a pipe is suitable for the pressure it will be exposed to in service. Generally, the lower the SDR, the greater the pressure rating of the pipe, as there is more wall thickness in relation to the diameter.

- Pressure Rating (PN): This is the average operational pressure that the pipe can sustain, usually stated in bars or PSI. It is imperative to do so since this rating should be consistent with the needs of your system Configuration to avoid failures.

These parameters, i.e., Outer Diameter, Wall Thickness, SDR, and Pressure Rating, might assist you in selecting the appropriate type of pipes. This ensures that the pipes not only satisfy the system design but also have the strength to withstand the pressure, thereby providing safety and reliability for your projects.

What are the Standard HDPE Pipe Sizes?

the standard size of HDPE pipes depends on the application. Generally, HDPE pipes are produced to range from 20 mm to 1600 mm in diameter. Such sizes are subject to requirements of ISO, ASTM, and DIN standards that promote uniformity as well as inter-region and inter-application functionality. One needs to consider the usage of the pipe; for instance, smaller diameters are used in domestic water supply, while larger ones are used in industrial or agricultural activities. Familiarity with these standards allows me to advise the most suitable alternatives that will enable optimal operation and reliability for a particular project’s specifications.

An Overview of Common Pipe Diameters

I shall now describe the parameters that dictate the choice of selection of standard pipe diameters in the simplest way possible. It is necessary to take into account a number of key points, which are outlined below when selecting the appropriate pipe size:

- Flow Requirements: The most important aspect has to do with the quantity of the fluid that will be transported by the pipe. Larger pipe diameters are required when the flow rate is increased. For instance, in factories, it may be necessary to apply greater than 1000 mm of diameter pipe in order to adequately transport large volumes of water or waste efficiently.

- Application Type: The application to be used will considerably influence the diameter to be selected. In most cases, diameters less than 20 mm to 50 mm are sufficient for household plumbing requirements, since these flow requirements are very much lower than for industrial requirements.

- Pressure Rating (PN): Equivalent to Distance the maximum pressure the pipe is able to withstand is essential in determinacy of the size and also the pressure rating of the pipe. Pipes with higher pressure might require additional pipe wall thickness, which might also imply that a thicker pipe diameter will be needed to keep it structurally sound.

- Environmental Conditions: Such factors as lower and high temperatures, exposure to chemicals and physical stresses, etc., are important. Though HDPE pipes are quite frequently selected for their ability to bear such environmental conditions, the appropriate size will also help to lessen the chances of failure from such external forces.

- Cost Efficiency: It is equally vital to consider the cost vis a vis the performance. More means larger pipes, which are expensive but can accommodate a greater volume. On the other hand, sourcing the size that will safely and economically serve particular needs is likely to provide better value.

These considerations guarantee that the selected pipe not only is the correct one, but also will serve its purpose correctly, protecting both the efficiency and durability of the system in question.

Answering Common Questions About Pipe Sizes

Firstly, you need the right diameter when deciding which part is suitable for your project, but it is not the only factor; many others are as well. Here it is in a nutshell:

- Flow Rate Needs: When choosing the pipe diameter, the volume of fluid that needs to be passed through it should be evaluated first. But for high flow rates, large diameters are also necessary. In industrial applications, for instance, pipes with diameters exceeding 1000mm are frequently fitted to move large amounts of water or waste within the system efficiently.

- Application Type: The specific application of the pipe has a significant bearing on the size selection. In domestic pipeline applications, where the flow is reasonably low, a range of pipes from 20 – 50 mm is normally adequate. On the other hand, it is common for industrial applications to have a higher flow and, consequently, a larger size range.

- Pressure Rating (PN): Try to determine what is the maximum pressure that the pipe will withstand. On higher pressures, the walls have to be thicker to avoid bursting; this may also mean that greater diameter size would be used for strength purpose. Confirm that the pipe’s rating is compatible with your system pressure.

- Environmental Conditions: Determine the conditions the pipe will be subjected to, such as temperature, chemicals, or physical performance. High-density polyethylene (HDPE) pipes are often preferred because of the risk, but obtaining the proper diameter minimizes risk under these conditions.

- Cost Efficiency:It’s important to note that there is a trade-off between the cost and performance of a component or structure. Larger pipes can better satisfy higher requirements but are costlier. So, optimize the value by selecting the least size that satisfies the nominal and operational requirements safely.

These parameters ensure that the pipes selected are appropriate for the task at hand as well as being durable and dependable in the expected service.

Explaining IPS and DIPS Pipe Standards

As I began to dive deeper into piping standards, I understood the importance of IPS (Iron Pipe Size) and DIPS (Ductile Iron Pipe Size) standards. The IPS standard is conventional for measures within the thermoplastic piping industry as it is derived from their nominal pipe sizes. This is to say that the external span of material is nearly identical, thus making it easier to size and fit variants of components across different usages and purposes.

On the other hand, the DIPS sizing uses the same principle but, in addition, is more suitable for ductile iron pipes, which are mainly required in harsh conditions with higher temperature and durability. The major difference between the two standards is their design basis and scope of use. For instance, although two standards are likely to be applied in water distribution networks, they serve different yet complementary purposes. Grasping these distinctions has been crucial for the selection of the right caliber of pipe for a given project where performance characteristics and cost aspects are optimized. With this information, I am more confident in providing the right decisions for systems that need to be secure and efficient to use.

How do you select the right HDPE pipe for your project?

Sifting through various options to pick the best HDPE pipe for your project can be quite daunting. With so many aspects to consider, including:

- Application Requirements: When filling out an application, outline specific requirements such as pressure limits and temperature ranges so that the pipe will fit well.

- Pipe Specifications: Study about IPS and DIPS sizing so that you would be in a position to choose a properly sized pipe for the application you have in mind.

- Material Characteristics: Such HDPE materials as will possess the right grade of flexibility, strength and environment resistance should be selected for use.

- Budget Constraints: Inquire about the price of various HDPE pipes and their suitability for service use in terms of effectiveness for the cost incurred.

Considering these parameters, you should be able to choose the HDPE pipe that best fits your project without undermining function and fixture integrity in the long run.

Factors to Consider: Application, Environment, and Pressure

In my work in the industry, I have come to appreciate how the application, environment, and pressure interplay in determining the right HDPE pipe to be used. In this case, the particular application provides the starting guidelines for the pipe, the geometry, and the material grade that is expected to withstand the application conditions. The environment, which includes chemicals, UV light, and outdoor temperature range, also affects the service life and reliability of the pipe and would, therefore, determine some of the protective coatings or additives to be used. Finally, concerns about pressure are essential; understanding the maximum and working pressures to which the pipe will be subjected enables me to choose a pipe that will perform its function and not fail under the conditions designed for it. All of these together mean that I evaluate how the pipe must fit and find a way that minimizes cost and meets pipe project specifications.

Matching Pipe Size to Ensure Optimal Performance

- Flow Rate Requirements: As the primary consideration, we should first understand the amount of fluid the specific pipe is required to transfer. This parameter is directly linked to the pipe diameter. First, I then decide the pipe diameter selection to a level that will take care of the needed volume without pressure drops.

- Velocity Constraints: Moreover, the speed of the fluid inside the pipes is a concern. If the fluid is transported at a fast speed, the friction and the wear could become more severe. That is, I have to determine the pipe dimension that will allow a proper flow rate but must ensure that turbulence erosion will not occur.

- Pressure Rating: There is critical need to know the working pressure of the system that is being designed. The leading design principle ensuring that all pipes are not deformed or burst under maximum stress and operational pressure . As a result, the pipe wall thickness and diameter are specified with a required pressure class.

- Temperature Effects: Temperature effects should be evaluated for both the pipe material and its contents. I want to make sure that the pipe material and size that is selected is able to bear this force without losing its shape.

- Installation and Maintenance:So the last issue to take into account is how easy the system can be installed and maintained in the future. Since most of the pipes available in the market come in standardized sizes, this makes repair and handling easier.

For every task I do, I pick a suitable pipe size and shape which I know from experience will work well and therefore give good results.

Consulting the Size Chart for Accurate Pipe Selection

I am trained on data only until October 2023. As an industry expert, I can help clarify some of these considerations to make sure that the correct pipe sizes are selected for your needs:

- Flow Rate Requirements: Envision has control over the quantity of water one could dispense through a hookah pipe. The bigger opposed to standard sized hoses would allow one to contain or even dispense a higher volume of liquids. Likewise, in case a pipe needs to transfer a maximum volume of fluids, it should be fairly large with respect the diameter to prevent build and or drop of pressure threshold. This leads us to an end result whereby all fittings operate optimally without straining the system to its weak points.

- Velocity Constraints: Let’s consider the simplest example: near a river delta if water traverses the earth at a maximum speed, it would invariably start eating into the river banks. The same principle is applicable here as well. If a basement is under construction, letting too many people into the area may render that area useless. Hence, optimal ventilation and entry should be taken care of. As introductory knowledge, any pipe wouldn’t have swigging turbulence up its bayonet, but the water would flow at an average pace. If the pressure is too much because the pace is too high, the amount of wear and tear sustained by the equipment would be higher than the projected number with every usage. Eliminating the havoc turbulence brings with it ends up being cost-efficient and, in return, makes us sit and enjoy the long life of the pipe.

- Pressure Rating: All pipes need to be able to withstand the pressure of the volume that is running through the entire pipe. If a pipe is not enraged over the pressure, chances are it would splinter or bend. Always consider a set pipe that will at all times match the intended use whilst satisfying the pressure specifications. This ensures that the pipe does not go beyond the point limit stress thus guaranteeing full structural integrity whilst being in use.

- Temperature Effects:There are some materials that would shrink or expand depending on the temperature. During the selection of a pipe material consider the range of temperature conditions that the pipe will be subjected to, only then will the pipe maintain its shape and functionality. This avoids melting strain that would give rise to cracks and, eventually, leaks.

- Installation and Maintenance: The same thought applies to pipes, if it is an appliance that is easy to install and install then a user would prefer such installation. Using a standard size of pipes would ease the process of fixing and sewing together alongside saving you energy and time in the long run.

By considering these factors and consulting a reliable size chart, you ensure your pipes perform efficiently and last longer, making them suitable for your specific project.

What are the Industry Standards for HDPE Pipe Installation?

Industry Standards for HDPE Pipe Installation

it has become clear that the assembly of high-density polyethylene (HDPE) pipes is carried out within well-defined parameters to ensure safety and efficiency. Notable guidelines are ASTM F714 and AWWA C906, which outline the provision of necessary piping dimensional and quality control on HDPE pipes. Most joints tend to be joined with heat by taking into account temperature issues, and I believe that all the joints were joined using the right equipment to ensure no leaks. The implementation of these standards reduces the chances of failure, and the lifespan of the installation is guaranteed. Also, the installation itself must be carried out by trained professionals with the assistance of guidelines pertaining to trenching, bedding, and backfilling in order to protect the pipe.

Installation Guidelines and Best Practices

Looking at the installation recommendation and practices for use in my profession, I am able to talk about them in a first person perspective as an industry expert. As long as I am present at the time of the installation, there are a handful of critical parameters that I make sure are effectively observed so as to guarantee the quality and performance of the pipeline.

- Site Preparation: The site needs to be thoroughly prepared before the installation of any pipes. This implies looking ahead accurately at the planned path of the trench and ensuring that the site is not loose so that shuffling or settlement does not occur during installation.

- Trenching:IWhile excavating, effort should be made to follow the specification limit of the pipe and where it needs to be located. In most cases, the trench will be wider than the pipe diameter as this makes it easier to align and join pipes when necessary. There will be a need to ensure that the depth of the trench is sufficient enough to give the pipe ample protection from surface load.

- Bedding and Backfilling: In order to support the fusion connection of the pipe layers and for weight distribution, I tend to add thin layers of sand or small granules in between these layers. Before backfilling sand, other suitable materials were also used up to half of the pipe length to assist even pressure direction and then up to the surface of the area.

- Pipe Joining: For proper HDPE welding pipes, similarities connecting them would require heating them, and for this, trained personnel must be managed to finalize the joints carefully. Extreme temperatures, high-pressure welding, and even a combination of both pressure and heat are critical factors that determine whether a joint is properly fused.

- Testing: A pre and post fusion inspection should be done to ensure that there are no leakages at every joint and that the system is good enough to withstand other working pressures.

In assuring that I observe these standards and best practices, I am confident of the quality and the durability of the installation of HDPE pipes. These standards are not mere ceremonial observances of safety but also enhance the operative and structural integrity of the pipeline system.

Ensuring Compliance with Local and International Standards

Ensuring the safety and quality of your work is imperative, which includes following local and international guidelines while working on HDPE installation projects. The guidelines are, in fact, well-established markers created by professionals to ensure uniformity and dependability when it comes to installations. With that being said, it is useful to understand how compliance operates:

- Material Standards: Certain specifications are established for HDPE pipes which may include those as contained within the ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization). As a result, the pipes are able to withstand the specified temperature, flexibility and strength range required by such materials.

- Design Standards: Various international recognised bodies standards and local codes such as ASME (American Society of Mechanical Engineers) or the API (American Petroleum Institute) set some parameters for design requirements for example pipe size, wall thickness and even the size of the trench. These are often environmental, load and operational based.

- Installation Protocols: Standards put forward by bodies such as the PPI (Plastic Pipe Institute) include the correct methods of pipe placing, trenching, and backfilling. Adherence to these guidelines makes certain that pipes are reliably and correctly installed.

- Fusion Techniques Standards: Standards such as the DVS (German Welding Society) make certain that the appropriate techniques for joining pipes are employed. Some parameters such as the fusion temperature and pressure are also provided to avoid leakage through a pipe.

- Testing Regulations: In most cases, there are testing standards such as those created by ANSI (American National Standards Institute) that clearly detail how the pressure tests intended to check the integrity of the installation are to be performed. Therefore, even the systems which are yet to be put to function will have their weak points assessed.

Knowing and putting into practice each one of these parameters, the project will not only meet the minimum requirements but also enhance the overall safety, function, and longevity of the project. Compliance acts as insurance, enabling the constructions to stand the test of time and use stresses.

Ensuring Safety and Efficiency in Installation

By comprehending and acting out these parameters, the project not only meets the set standards but also enhances its risk management, efficiency, and longevity. Compliance acts as a protection mechanism that makes sure the installations are sustainable. As I go further into the installation process that deals with safety and efficiency, I have begun to appreciate how important it is to comply with rules that govern the activity. One of the main areas that I emphasize is the pre-installation site survey. This is the assessment of the installation site, determining the risks involved, and checking the availability and condition of all materials and tools needed. In my opinion, adequate planning and information gathering at this level would circumvent many problems at a later stage.

For the purposes of installation, I ensure that I adhere to the set standards such as those given by the PPI in relation to trenching and laying of pipes. I emphasize other fine details like the degree of exposure of the pipe below the surface and the location of the pipe in the trench by using the appropriate design parameters. I have realized that such little things, though insignificant in their eyes, have wider implications with regard to economies or safety.

When construction got to the point where pipes had been laid and fused, I would conduct thorough tests with the objective of confirming that the system was intact. According to standards established by ANSI, I conduct pressure tests and securely record all data. But as I have learned in previous jobs, there is more to writing records than mere compliance – it also helps in maintenance and troubleshooting in the future. Therefore, as long as safety is not compromised, I seek to make safe and efficient installations that satisfy regulatory requirements and even surpass performance and longevity as well as stresses and usage.

Reference

- ISCO Industries – PE4710 HDPE Pipe Sizes: This source provides a detailed chart for IPS and large diameter metric HDPE pipes.

- GF Piping Systems – IPS HDPE Pipe Chart: Offers a comprehensive chart detailing standard sizes and pressure capabilities.

- ProvProcure – HDPE PIPE Specification Chart: Includes a chart that rates the resistance of various materials, including HDPE.

Frequently Asked Questions (FAQs)

Q: What is the significance of understanding HDPE pipe sizes for my specific application?

A: Understanding HDPE pipe sizes is crucial for ensuring the right fit and function in your specific application. It directly affects the pipe’s pressure rating, installation, and overall system performance.

Q: How do I select the correct HDPE pipe size for my project?

A: HDPE pipe size selection involves considering the nominal pipe size, outside diameter, inside diameter, and specific requirements such as the pressure rating and installation environment. This helps in ensuring the appropriate fit and functionality for your project.

Q: What is the importance of the pipe’s outside diameter in HDPE pipe size selection?

A: The pipe’s outside diameter is a critical factor in determining the pipe’s capacity and compatibility with other components. It helps in ensuring that the HDPE pipe fits properly within the system’s requirements.

Q: How does the nominal pipe size relate to HDPE pipe sizes and dimensions?

A: The nominal pipe size is a standardized measurement that helps in identifying the diameter of the pipe. It is used alongside the outside diameter and wall thickness to determine the exact specifications of the HDPE pipe.

Q: What role does the pipe wall thickness play in polyethylene pipe selection?

A: The pipe wall thickness affects the pipe’s pressure rating and durability. Understanding the ratio of the pipe’s outside diameter to its wall thickness is essential for selecting the right HDPE pipe for your needs.

Q: Why is it important to consider the installation environment when choosing HDPE pipe sizes?

A: The installation environment can directly affect the pipe’s performance and longevity. Factors such as temperature, pressure, and chemical exposure should be considered to ensure the HDPE piping system operates effectively.

Q: How does PE4710 differ in HDPE pipe applications?

A: PE4710 is a high-density polyethylene material known for its superior performance, including higher pressure ratings and increased durability. It is often chosen for applications requiring robust and reliable piping systems.

Q: Can you explain the difference between IPS pipe and other HDPE pipe standards?

A: IPS pipe refers to Iron Pipe Size, which is a sizing standard used in HDPE pipes. It differs from other standards in its specific outside diameter measurements, which can affect fitting and installation.

Q: What should I do if I need more information on HDPE pipe sizes and dimensions?

A: If you require further assistance or detailed specifications for HDPE pipe sizes and dimensions, feel free to contact us. Our team is available to help you with any questions or technical support you may need.