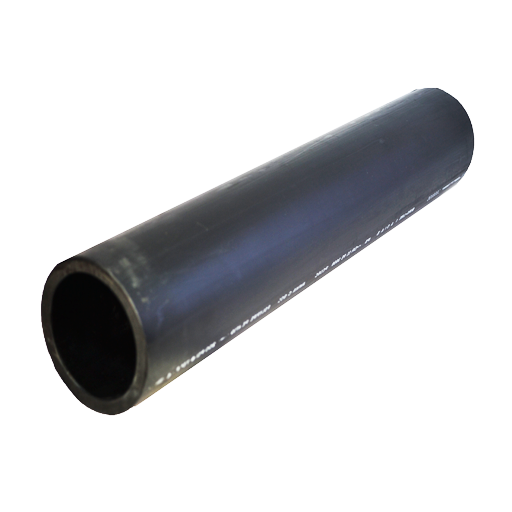

Key Advantages of HDPE Pipes

Exceptional Corrosion Resistance

One of the major advantages offered by HDPE sewer pipes is their exceptional corrosion resistance. Unlike metals and concrete, which are prone to corrosion, HDPE is chemically inert, making it an ideal choice for sewer applications where pipes are continually exposed to:

- Corrosive wastewater

- Various chemicals

- Varying pH levels

- Environmental factors

Superior Leak-Proof Features

HDPE pipes are highly regarded for their leak-free capabilities, which stem from reliable sealing and jointless techniques:

- Butt Fusion Welding: Creates joints with strength equal to the pipe itself

- Flexibility: Allows movement with ground motion and thermal expansion

- Solid Joint Design: Eliminates common leakage points found in mechanical systems

Outstanding Durability and Longevity

HDPE pipes are engineered with materials that withstand varied environmental and operational challenges:

- Resist corrosion, chemicals, and abrasion

- Maintain flexibility under stress

- Adapt to ground movements and temperature variations

- Provide smooth interior surfaces that discourage scaling and microbial growth

- Expected service life: 50-100 years

Industry Applications of HDPE Pipes

Water Distribution Systems

HDPE pipes have become essential components in modern water distribution infrastructure due to several key advantages:

- Lightweight yet strong: Easier installation with lower labor costs

- Fusion welding system: Creates leak-free connections

- Smooth interior surface: Prevents mineral deposits and maintains water purity

- UV stabilized options: Suitable for outdoor applications

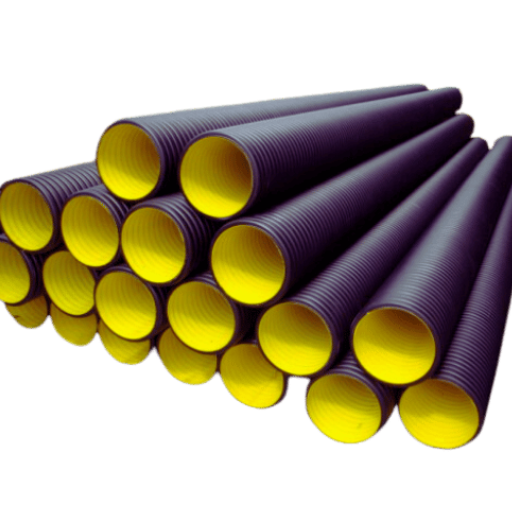

Advanced Drainage Solutions

HDPE pipes excel in drainage applications by offering:

- Resistance to chemical corrosion and abrasion

- Ability to handle heavy loads and high temperatures

- Lightweight nature for easier transportation and installation

- Permanent joint systems preventing leakage

- Efficient water flow due to smooth interior surfaces

Comprehensive Wastewater Management

HDPE pipes have revolutionized wastewater management systems through:

- Chemical attack resistance in harsh environments

- Heat-fusion jointing techniques prevent infiltration/exfiltration

- Lightweight design reduces transportation and installation costs

- Recyclable materials promoting circular economy principles

Installation Process for HDPE Sewer Pipes

Preparation and Planning Phase

Successful HDPE pipe installation begins with thorough preparation:

- Site Assessment: Comprehensive evaluation of terrain and soil conditions

- Environmental Impact: Preservation of natural ecosystems

- System Design: Proper pipe sizing and capacity calculations

- Compliance: Adherence to construction standards and regulations

Step-by-Step Installation Process

- Site Preparation:

- Clear the area of debris and vegetation

- Conduct a comprehensive site survey

- Mark the pipeline route accurately

- Trenching and Excavation:

- Use appropriate equipment along the marked route

- Ensure proper depth and width compliance

- Maintain stable trench walls

- Pipe Inspection and Preparation:

- Inspect all pipes and fittings for defects

- Clean surfaces to ensure proper connections

- Cut pipes to the required lengths

- Pipe Laying and Alignment:

- Lower pipes into the trench with proper grade

- Support pipes with spacers or bedding materials

- Create secure joints through fusion welding

- Backfilling and Compaction:

- Backfill trench with selected materials in layers

- Compact each layer thoroughly

- Restore the surface to its original condition

- Testing and Quality Control:

- Conduct pressure and leakage tests

- Record results for quality control

- Address any identified issues immediately

- Final Inspection and Handover:

- Complete thorough system inspection

- Ensure compliance with specifications

- Provide proper documentation

Common Fittings and Connections

Essential components for optimal system performance:

- Elbows: Change flow direction in pipelines

- Tees: Branch system into multiple directions

- Reducers: Join pipelines of different diameters

- Couplings and Unions: Connect pipe sections for repairs/extensions

Connection Types:

- Threaded Connections: Suitable for low-pressure systems

- Welded Connections: Permanent, leak-free joints for high-pressure applications

- Flanged Connections: Strong yet detachable joints for maintenance access

Maintenance Guidelines for HDPE Pipes

Routine Inspection Procedures

Regular maintenance ensures optimal performance and longevity:

- Visual Inspections: Check for cracks, deformation, and discoloration

- Performance Monitoring: Assess pressure levels and flow rates

- Non-Destructive Testing: Use ultrasonic inspection for hidden flaws

- Environmental Monitoring: Check soil conditions and chemical exposure

Cleaning and Care Techniques

Proper maintenance extends pipe life and maintains efficiency:

- Regular Flushing: Remove deposits and contaminants

- High-Pressure Jetting: Efficient removal of stubborn buildup

- Chemical Cleaning: Use HDPE-compatible cleaning agents

- Physical Cleaning: Specialized brushes for interior surfaces

- UV Protection: Coatings for exterior pipes exposed to sunlight

Comparative Analysis: HDPE vs. Other Materials

HDPE vs. PVC Pipes

| Aspect | HDPE | PVC |

|---|---|---|

| Flexibility | High | Low |

| Durability | Excellent | Moderate |

| Corrosion Resistance | Resistant | Susceptible |

| Initial Cost | Higher | Lower |

| Installation Complexity | Complex | Easy |

| Lifespan | Long (50-100 years) | Moderate |

| Pressure Tolerance | High | Moderate |

| Environmental Impact | Sustainable | Less Eco-friendly |

HDPE vs. Concrete Pipes

| Aspect | HDPE | Concrete |

|---|---|---|

| Weight | Lightweight | Heavy |

| Flexibility | High | Low |

| Durability | Moderate | High |

| Corrosion Resistance | Resistant | Susceptible |

| Load-bearing Strength | Moderate | High |

| Installation Ease | Easy | Complex |

| Cost | Lower | Higher |

| Lifespan | 50-100 years | 100+ years |

| Environmental Impact | Sustainable | Higher Carbon Footprint |

Cost-Benefit Analysis

HDPE Investment Strategy: While HDPE pipes have higher initial costs, they provide long-term savings through reduced maintenance, longer lifespan, and superior corrosion resistance. This makes them ideal for high-pressure applications and hostile environments where performance outweighs initial installation costs.

PVC Budget Solution: PVC pipes offer lower purchase and installation costs, making them suitable for budget-conscious projects with moderate pressure requirements. However, shorter lifespans and higher maintenance costs should be considered for long-term planning.

Frequently Asked Questions

A: HDPE sewer pipes offer unique advantages, including chemical resistance, flexibility, and high tensile strength. They’re corrosion-resistant and suitable for various applications in water and wastewater management. Fused joints provide leak-proof installation with minimal maintenance requirements.

A: While ductile iron has been traditional in sewer and water distribution, HDPE offers advantages in being lightweight, easy to handle, and flexible. This enables easier installation methods such as horizontal directional drilling and pipe bursting, reducing both labor and installation time.

A: HDPE sewer pipes can be installed using various methods, including traditional trenching, horizontal directional drilling, and pipe bursting. This versatility allows installation in challenging locations where other pipe types may pose difficulties.

A: Yes, HDPE pipes are designed to withstand thermal extremes. Built with high-density polyethylene, they demonstrate excellent durability and resistance to temperature changes, ensuring reliable performance in all climate conditions.

A: HDPE pipes are often more cost-effective compared to traditional materials like ductile iron or metal pipes. Installation costs are particularly reduced due to lightweight properties and easier handling, enhancing overall cost-effectiveness.

A: Chemical resistance makes HDPE pipes ideal for industrial applications with exposure to harsh substances. This property ensures structural integrity and functionality across various industrial uses, preventing degradation from chemical exposure.

A: HDPE sewer pipes are available in various dimensions to meet different installation requirements. The flexibility of polyethylene material permits custom sizing, allowing pipes to be shaped according to specific project needs and specifications.

References and Technical Standards

- Iowa State University – Section 9B-3: Flexible Pipes

Guidelines on flexible pipe applications emphasizing HDPE’s advantages in drainage and storm sewer applications requiring adaptable installation conditions. - Bowling Green State University – Pipe Bursting Specifications for HDPE

Detailed technical specifications for HDPE pipe installation through pipe bursting processes, highlighting durability and versatility in sewer main upgrades. - Texas A&M University: Underground Piping Design Standards

Comprehensive design standards for HDPE pipe installation in underground systems for potable water, chilled water, and sewer systems, emphasizing lightweight, durable, and easy installation characteristics.

Conclusion: HDPE sewer pipes represent the future of modern infrastructure with their exceptional combination of durability, flexibility, and cost-effectiveness. Whether for municipal water systems, industrial applications, or residential drainage, HDPE provides reliable, long-term solutions that meet today’s environmental and performance standards while offering sustainable benefits for future generations.