High-density polyethylene (HDPE) and polyethylene are widely used materials in industries ranging from packaging to construction, but what sets them apart? Understanding the differences between these two types of polymers is essential for selecting the right material for specific applications. This article dives into the unique properties, chemical structures, and practical applications of HDPE and polyethylene, providing a comprehensive guide for engineers, manufacturers, and decision-makers. Whether you’re looking to improve product performance or ensure cost-efficiency in material selection, this breakdown will help you make informed choices. Let’s explore the science and versatility behind these commonly used polymers.

Introduction to Polyethylene and HDPE

What is Polyethylene?

Polyethylene is a thermoplastic polymer made up mostly of long chains of ethylene monomers. Because of its versatility, resistance, and cheap manufacturing, it is among the most common plastics produced worldwide. Throughout its supply chain, this material finds its way into packaging, containers, pipes, and insulation, thereby indicating its versatility across industries.

Depending on its density and branching structure, polyethylene assumes several types, which, in turn, shape its properties and applications. Some of the common types include Low-Density Polyethylene (LDPE), which is pliable and hence used for film applications such as plastic bags and wraps, and High-Density Polyethylene (HDPE), which has a high strength-to-density ratio and is used for applications like milk jugs, bottles, and industrial piping. There exist other varieties such as Linear Low-Density Polyethylene (LLDPE), which situates itself between flexibility and strength and is used in stretch films and various other special applications.

Its simplicity leads to resistance to water, chemicals, or impact; thus, it is valued in areas like construction, healthcare, and consumer goods. The recycling possibilities further enhance the placement of this polymer on sustainability fronts. Polyethylene remains an indispensable substance for modern engineering and manufacturing processes by virtue of its very wide range of properties and forms.

Overview of HDPE

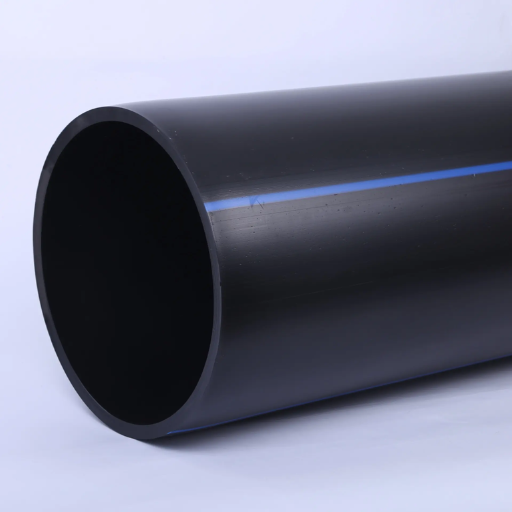

High-Density Polyethylene, commonly known in the industry as HDPE, is a sort of thermoplastic known for its high strength-to-density ratio. This substance gets created by polymerizing ethylene monomers, giving a linear structure with very little branching. Weighing somewhere between 0.93 to 0.97 g/cm³, the density—or more technically, the very high density-stiffness attribute of this polymer-gives it a characteristic hardness and brittleness, which finds applications in many different fields.

When stabilized, the polymer has a massive resistance to impacts, chemicals, moisture, and even UV radiation. Numerous industries benefit from these properties: packaging, construction, automotive industries, etc. Plastic bottles, corrosion-resistant pipes, geomembranes, and household containers are made out of HDPE. The lightweight and weather-resistant qualities make it very economically viable to use in most challenging environments.

By the sustainability consideration, HDPE is considered a recyclable material, and it is almost always designated with the code number “2,” which is an identification code for resin. Its ability to be recycled lessens the waste material that goes into the environment and also allows it to be reused in the manufacture of secondary products such as plastic lumber, pipes, and storage containers. Strength, versatility, and ecological aspects put HDPE in the spotlight as an important material for all modern industrial and consumer applications.

The Importance of Understanding HDPE vs Polyethylene

High-Density Polyethylene (HDPE) is a particular variant of polyethylene, a widely used thermoplastic throughout the world. Polyethylene is generally divided into categories upon the density and branching, with HDPE being unique due to its high strength-to-density ratio. Any HDPE is polyethylene, but not all polyethylene is HDPE. This is a difference of structural and performance characteristics important to consider in industrial and consumer applications.

HDPE is characterized by a molecular structure that is tightly packed, leaving very little room for branching. Because of this, it has a highly crystalline structure, rendering it a hardy material. HDPE finds excellence in resisting chemical attacks, has very low permeability against moisture, and thus stands superior in tensile strength to other polyethylene types of lower density, such as LDPE (Low-Density Polyethylene) or LLDPE (Linear Low-Density Polyethylene). Such properties render HDPE fit for arduous service, heavy-duty piping, storage tanks, and containers for foods, while the softer polyethylene types may be utilized for plastic films and flexible packaging.

Knowing that HDPE is different from other types of polyethylene is important because that will ultimately affect the materials used for various applications. By way of example, HDPE would be used in structural components due to its high strength, while LDPE would be very flexible and thus is suitable for lightweight packaging. Thus, its recyclability and environmental benefits conferred in the long term make HDPE the material of choice for any sustainable design practice. Hence, given these various types of polyethylene, engineers and manufacturers can make the best choice with regard to performance, cost, and their products’ environmental footprint.

Characteristics of HDPE and Polyethylene

Physical Properties of HDPE

High-Density Polyethylene (HDPE) exhibits a rare blend of physical properties that find use in nearly every application area. HDPE has a high strength-to-density ratio, usually ranging from 0.93-0.97 grams per cubic centimeter. This low-density polymer provides a more considerable amount of stiffness while staying lighter.

HDPE has a high tensile strength, usually ranging from 20-37 MPa, being dependent on the manufacturing conditions and the specific grade. On the other hand, HDPE exhibits excellent impact resistance even at low temperatures, lending it durability in trying environmental conditions. It possesses a somewhat crystalline structure that renders it a high melting point of around 120°C to 130°C, making it fit for application states needing thermal stability.

Maybe the most important property of HDPE is its resistance to chemicals. It is inert to a large number of chemicals, including acids and bases, and most organic solvents. This ensures that HDPE can perform for a long time in an environment where possible exposure to such chemicals exists. Additionally, because of an extremely low rate of water absorption, HDPE is kept in its structural integrity in applications where exposure to moisture is probable, if not unavoidable, or in submerged conditions.

These physical properties make HDPE versatile and useful in construction, packaging, automotive, and medical device industries. From a performance point of view, HDPE still leads the way to remain the first choice for engineers and designers in search of guaranteed and adaptable material solutions.

Physical Properties of Polyethylene

Being one of the most popular thermoplastics, polyethylene also possesses some fascinating physical attributes, which make this polymer adaptable in different sectors. It is light, having a density of 0.91 g/cm³ and 0.96 g/cm³, depending upon the grade of polyethylene considered, like LDPE (Low-Density Polyethylene) and HDPE (High-Density Polyethylene). These low-density applications help in manual transport and in processing operations with great advantages.

The other essential property of polyethylene is its resistance to chemicals. It stands high, resisting solvents, acids, and bases, thus becoming ideal for use in chemical storage containers and piping systems. Polyethylene is also known for withstanding shock, brilliant even at below-zero temperatures factor that endorses its use where such physical endurance under stress is critical.

The thermal behavior of polyethylene is also noteworthy. Its melting point usually ranges from something like 115°C for LDPE up to 135°C for HDPE-that is, it is sufficiently stable for moderate temperature applications. Its low coefficient of friction and self-lubricating nature enhance polyethylene’s performance in applications where smooth motion is needed, such as conveyorized systems and mechanical liners.

In general, a plastic is polyethylene by its properties of low density, chemical inertness, impact resistance, and thermal stability. These properties have perpetuated their presence in all areas, from packaging and construction to the most advanced medical and technological applications.

Key Differences between HDPE and LDPE

HDPE is heavy and dense with rigidity and strength, whereas LDPE is light and less dense with flexibility and impact resistance.

|

Aspect |

HDPE |

LDPE |

|---|---|---|

|

Density Level |

High |

Low |

|

Flexibility Level |

Stiff |

Elastic |

|

Durability |

Strong |

Moderate |

|

Shock Resist. |

Moderate |

High |

|

Clarity |

Opaque |

Semi-clear |

|

Heat Threshold |

120-160°C |

105-115°C |

|

Chemical Tolerance |

Excellent |

Good |

|

Eco-friendliness |

High |

Moderate |

|

Uses |

Pipes, Bottles |

Bags, Films |

|

Affordability |

Low |

Low |

Applications of HDPE and Polyethylene

HDPE in Pipe Systems and Construction

High-density polyethylene (HDPE) has given pipe systems and construction industries a new identity since it is durable and versatile as well as cost-effective. It is an excellent material for various engineering and infrastructural applications since it can resist chemicals, go through extreme heat, and hold under impact on the other hand. The following are the applications of HDPE usage in pipe systems and construction:

- Water Supply and Distribution Systems: This HDPE pipe can be commonly found in potable water distribution. An HDPE, with an average lifespan of more than 50 years, does not succumb to corrosion or biological growth; thus, it allows the operation of water supply systems safely and reliably. Also, having a very low friction coefficient allows for minimizing the pressure loss and water resistance during transportation.

- Sewerage and Drainage Systems: Corrosive wastewater makes its way into this chemical resistance HDPE for use in trace municipal and industrial drainages.Waterproof leak-proof jointing technicity almost had done contamination risks and system failures with a mere drop in flow rate.

- Gas Distribution Networks: Employing HDPE widely for non-mono gas and compressed air distribution. Its flexibility and resistance to crack propagation render it safer to use under variable pressure and environmental conditions, and in GTA gas visibility.

- Geothermal Heating and Cooling Systems: HDPE pipes are preferred for geothermal purposes, being thermally stable and having a long life. The system uses HDPE piping as circulation lines of water or refrigerant between the ground and the heat pumps, thus guaranteeing energy transfer efficiently for decades of operation.

- Stormwater Management Systems: In the construction of stormwater collection and retention systems, HDPE is used, weighing light but with great strength, while being easy to install. HDPE passes huge volumes of runoff during storms while preventing soil erosion and water contamination.

This, however, points to the very importance of the applications of HDPE in the modern engineering problems, where they take care of both the functional and sustainability aspects, along very strict performance criteria. The teaching in these areas continues to increase as material science advances provide new potentials.

Polyethylene in Packaging and Consumer Goods

Polyethylene plays a crucial role in the packaging and consumer goods sector because of its versatility, durability, and cost-efficient nature. Weighing considerably less compared to other materials, while being moisture-resistant and chemically stable, makes it ideal for various applications. Some applications of polyethylene in this sector are given below:

- Plastic Bags: Low-Density Polyethylene (LDPE) is another popular polymer used in manufacturing plastic grocery and retail bags, as it is flexible and can be easily processed. Over 500 billion plastic bags are manufactured in the world every year, mainly made of polyethylene.

- Food Packaging: Linear Low-Density Polyethylene (LLDPE), along with High-Density Polyethylene (HDPE), finds application chiefly in food packaging, for example, cling films, erosion films, along milk jugs. These packaging materials aid food preservation by acting as barriers against moisture and contaminants, thereby contributing to the reduction of food waste.

- Bottles and Containers: Since HDPE is a hard material, it is generally used for the manufacture of hard bottles and containers for beverages, cleaning materials, and personal-care products. Mayers notes that US data on plastics consumption show that HDPE accounts for about 30% of the material used in blow-molded bottles.

- Shrink and Stretch Wraps: The polyethylene films find their applications as shrink and stretch wraps to bundle and secure goods during transportation and storage. Due to its strength and elasticity, LDPE has the maximum share in the said market, thereby contributing towards protective packaging and the reduction of product damage.

- Consumer Goods: From toys to household items such as storage bins and kitchen utensils, polyethylene is a major raw material. Its flexibility and durability provide the manufacturers with cheap and durable products to meet every need of the customer.

The packaging and consumer goods industries widely use polyethylene, carving out a market for itself economically and functionally, and continuing to innovate toward sustainability and reducing its environmental footprint.

Other Industrial Uses of HDPE and Polyethylene

High-density polyethylene exhibits strong characteristics of durability, chemical resistance, and versatility, and is therefore widely applied across industries. In the construction business, one such application includes HDPE piping systems well well-known and common for water distribution, gas lines, and sewage. Their corrosion resistance, coupled with a high tolerance to temperature extremes, makes them suitable for harsh atmospheric conditions, being used in the handling and transportation of various fluids. These geomembranes are used in solutions that aid environmental engineers, landfill liner projects, and containment systems that protect ecosystems.

Other major uses of polyethylene fall within the auto industry. Being light and impact-resistant, polyethylene forms fuel tanks, bumper components, and under-hood parts. Weight reduction on any vehicle means an increase in mileage and a decrease in emissions. HDPE and or wire and cable sheathing are chemically alike in respect to insulation, thereby providing satisfactory protection in demanding environments, such as telecommunications and power infrastructure.

In agriculture, beyond the construction and automotive domains, HDPE and polyethylene play a vital role. They are used in the production of irrigation pipes, greenhouse films, and silage covers, ensuring optimization of crop growth and improving soil quality for farmers. Very good resistance to hazards imposed by environmental degrades, such as moisture and UV radiation, ensures their performance over a long period in outdoor orientation. Thus, together with top versatility, HDPE and polyethylene have never stopped helping to uplift highly industrialized landscapes.

Advantages and Disadvantages

Benefits of Using HDPE

- High Strength-to-Density Ratio: HDPE has very high strength-to-density metrics, enabling it to be an ideal material for structural and loading purposes. With densities ranging from 0.93 to 0.97 g/cm³, it proves to be immensely durable and resistant to external forces yet remains lightweight.

- Good Chemical Resistance: HDPE is highly resistant to a large variety of chemicals, such as acids, alkalis, and organic solvents. Hence, it fits into chemical storage tanks, piping, and industrial containers without any consideration of corrosion or degradation of material.

- Better Durability and UV-Resistance: HDPE is created to brave harsh environmental conditions like prolonged exposure to UV radiation and moisture. Being sturdy, it guarantees a longer service life for outdoor applications like agricultural films, geomembranes, and construction works, which boils down to lower costs in maintenance and replacement.

- Recyclability and Sustainability: HDPE is 100% recyclable and is often made into secondary products such as piping, plastic lumber, and containers. The recyclability of the material is considered very important to lessen the impact on the environment while promoting the sustainable use of materials in the industrial and commercial sectors.

- Impact Resistance and Flexibility: Impact resistance is one of the major attributes of HDPE, whereby it can absorb shock and heavy loads without cracking or breaking. With this feature and the presence of natural flexibility in it, HDPE is highly suitable for dynamic applications such as pipe systems where movement or shifting dynamics come into play.

Each of these benefits represents one of the versatility and reliability attributes of HDPE in industries ranging from agriculture and construction to packaging and infrastructure.

Drawbacks of HDPE

HDPE presents certain weaknesses that limit its applications; however, one great strength of this material is that its environmental stress cracking ability can be tested when exposed to harsh chemicals for extended periods or under harsh environmental conditions, including UV radiation. Without incorporating stabilization systems or additives against sunlight, this material will suffer degradation caused by UV radiation, possibly leading to reduced structural integrity.

Another aspect is its thermal performance. Since it has quite a low melting point (usually between 120°C and 180°C), HDPE cannot be used in applications where there are higher temperatures involved. Its inability to withstand deformation or fail under heat beyond this temperature range becomes a matter of concern.

Though HDPE can be technically recycled, recycling processes can be expensive and complex. Contamination during collection and processing can hurt the quality of recycled HDPE, making it less suitable for higher-demand applications. Finally, as with many polymers, HDPE production draws from petrochemical resources, thus having its share of environmental issues in the sustainability of the resources and greenhouse gas emissions. These areas need technologies to address and improve the limitations of HDPE.

Comparative Advantages of Polyethylene

Polyethylene, generally HDPE and LDPE, has an advantage owing to its inherent peculiar property inculcated into materials. Its chemical resistance is one of the major benefits, enhancing durability and safety in the storage and transportation of hazardous or reactive substances. Unlike metals that corrode and rust, polyethylene resists such actions and is therefore the choice of material for piping and chemical storage tanks.

Being lightweight, the material serves to reduce the cost of transportation, which in turn reduces energy costs during shipment. The tensile strength is high enough with HDPE grades to enable it to bear heavy weights without deformation. Polyethylene also has a balance of flexibility, whereby it could be used where both rigidity and adaptability are required, as in shrink films and flexible containers.

From a manufacturing standpoint, polyethylene can be molded, extruded, and thermoformed due to its low melting temperature and superior processability, thus ensuring inexpensive manufacturing on a massive scale. It is also amenable to recycling. To give an example, HDPE is one of the most recycled plastics and supports its recycling to a variety of applications, resulting in a circular economy: composite lumber, piping, or even automobile parts.

Moreover, polyethylene possesses thermal and electrical insulation properties, which are advantageous for wiring, cable insulation, and thermal barriers. With the polymers continuing to be improved, polyethylene will remain an ever-versatile and irreplaceable material in the industrial and consumer spheres.

Environmental Impact and Sustainability

Recyclability of HDPE and Polyethylene

Polyethylene, especially HDPE, is mainly recyclable. HDPE is highly preferred in the recycle stream because its strength is maintained even after further processing, so it can be recast into final products. In almost every country, 30% or more of the HDPE container products, such as milk jugs and detergent bottles, are recycled, a figure that has seen gradual improvement with enhanced technology and increased public awareness of recycling.

The process for recycling HDPE usually comprises collection, cleaning, sorting, and some form of mechanical reprocessing into pellets. The recycled pellets may be used to make new products, such as piping, plastic lumber, or even new containers, thus promoting the circular economy. Unfortunately, most polyethylene grades, including low-density ones, have limited recycling rates due to contamination, lack of uniformity in collection systems, and inadequate incentives to manufacturers to utilize recycled material.

Chemical recycling methods such as pyrolysis or depolymerization have recently emerged as solutions to these issues by breaking polyethylene back down into its monomers. This secondary form of recycling yields outputs of higher quality than mechanical recycling, and such outputs are required in more demanding applications. Nevertheless, commercial facilities are limited due to constraints related to economic and energy efficiencies.

The global recycling infrastructure, along with consumer education and materials development, must all improve in order to achieve the highest possible recycling rates for HDPE and polyethylene. Introducing common design principles for polyethylene products that prevent contamination and aid in the compatibility of contamination with recycling systems would be substantially better influenced by improved recycling. Sustainability indices, alongside perhaps lifecycle assessments, are among the metrics being implemented for polyethene and polymers to evaluate further their environmental impact, all in an attempt to find a channel in which polymer waste can be further managed.

Comparing Environmental Footprints of HDPE vs Polyethylene

From a carbon perspective, HDPE has fewer emissions, can be recycled to a far more extent, and is more energy-efficient than general polyethylene.

|

Aspect |

HDPE |

Polyethylene |

|---|---|---|

|

Carbon Emissions |

Lower |

Higher |

|

Recyclability |

High |

Moderate |

|

Energy Use |

Efficient |

Higher |

|

Durability |

Long-lasting |

Moderate |

|

Waste Impact |

Minimal |

Higher |

|

Eco-Friendliness |

Better |

Moderate |

Sustainability Considerations in Plastic Use

Recent advancements in plastic recycling technologies have played a pivotal role in achieving sustainability in plastic use. Chemical recycling methods of depolymerization and pyrolysis, for example, allow the breaking down of plastic that was once not recyclable into its monomer components, which are then used to produce high-quality, virgin-equivalent polymers. This solves many issues faced by traditional mechanical recycling, whose methods cause contamination and degradation of polymer materials that end up being of lower grade.

In addition to that, AI and machine learning are being implemented in sorting plants for better identification and separation of plastics based on the type and resin grade. These cutting-edge technologies have been proven to provide a sorting accuracy of up to 98%, greatly reducing contamination within recovered streams and fostering a closed-loop recycling scenario.

Furthermore, collaboration among industries and regulatory frameworks is making the use of recycled content mandatory in products, thereby driving demand for high-recycled-content resins. For example, the European Union’s Circular Economy Action Plan envisages a 50% recycling target for plastic packaging by 2025, thus creating incentives for innovations improving both quantity and quality of recycling. These technological and policy adjustments can be exploited for making the lifecycle of plastics more sustainable both vitally environment-wise and economically worldwide.

References

Frequently Asked Questions (FAQ)

Q: What is the difference between HDPE and polyethylene?

A: HDPE, or high-density polyethylene, is a specific version of polyethylene characterized by its linear structure and high density. Polyethylene, on the other hand, encompasses various forms, including low-density polyethylene (LDPE) and medium-density polyethylene (MDPE). The primary difference lies in their density and structural properties, affecting their applications and suitability in various industries.

Q: What are the applications of HDPE?

A: HDPE is commonly used in a variety of applications, including the production of high-density polyethylene pipes used for water transportation, beverage bottles, and piping products in the industrial sector. Its high chemical resistance and versatility make it an ideal material choice for both consumer and industrial products.

Q: Is HDPE resistant to chemicals?

A: Yes, HDPE is known for its high chemical resistance, making it suitable for transporting a wide range of substances, including corrosive chemicals. This property is one of the key reasons it is frequently used in the pipe industry for applications that require robust piping materials.

Q: How is HDPE produced?

A: HDPE is produced through the polymerization of ethylene gas, which creates a dense molecular structure. This process results in a material that is easy to process and can be molded into various forms, such as pipes, sheets, and containers.

Q: What are the similarities and differences between HDPE and other types of polyethylene?

A: While HDPE shares some characteristics with other forms of polyethylene, such as being a versatile material, it differs mainly in its density and structural properties. Unlike LDPE, which has a branched structure and is more flexible, HDPE has a linear structure, resulting in higher strength and rigidity.

Q: Can HDPE be welded?

A: Yes, HDPE can be welded, which is a critical aspect when it comes to joining pipes and fittings in the piping industry. The ability to weld HDPE allows for seamless connections that enhance the integrity and durability of the piping system.

Q: How does HDPE compare to polypropylene (PP)?

A: When comparing HDPE to polypropylene (PP), both materials exhibit high impact resistance and versatility. However, HDPE is generally more resistant to chemicals than PP, making it a preferred choice for applications involving harsh substances. Each material has its unique advantages depending on the specific application requirements.

Q: What types of products are made from HDPE?

A: HDPE is used to create a wide array of products, including plastic pipes, large sheets, containers, and various consumer goods. Its durability and resistance to environmental stress make it ideal for outdoor applications and products that require extended service life.

Q: Why should one choose HDPE over other materials?

A: Choosing HDPE over other materials like PVC or LDPE is often due to its superior strength, heat resistance, and high chemical resistance. Additionally, HDPE is easy to process and can be efficiently utilized in injection molding, making it a practical choice for manufacturers looking for reliable and durable materials.