This article intends to enlighten professionals and DIY enthusiasts about various aspects of PEX tubing, particularly 1 ½ inches PEX pipe, which is vital for modern plumbing and heating systems. Additionally, it shows the advantages of PEX over other types of materials, how to install it, and what you need to consider before installing it. If you are considering remodeling your existing system or starting a new project, this manual will provide the necessary information for using PEX tubing efficiently.

What is PEX Tubing and How Does It Work?

Image source: https://www.vevor.com/

PEX stands for cross-linked polyethylene and is a flexible plastic piping material. This makes it more resistant to freeze damage than rigid pipes because it can expand and contract. The cross-linking process enhances its durability, enabling it to withstand high temperatures and pressure. It is used to deliver water from the main line that enters the house, for example, sinks, showers, etc., and may be easily installed through narrow angles and around complicated layouts due to its flexibility; hence, there is less need for many piping joints. Moreover, PEX pipes are lightweight and corrosion-free; thus, they have become ubiquitous in residential dwellings, commercial buildings, and domestic systems.

Understanding PEX Tubing for Heating and Plumbing

PEX tubes are increasingly considered versatile in heating and plumbing systems. PEX tubing is highlighted on several websites, such as Plumbing-Heating-Cooling Contractors Association (PHCC), Home Depot, and This Old House. The first thing that makes PEX great is that it can be used for radiant floor heating systems because it distributes heat evenly and efficiently. The heating method is also energy-efficient and provides a comfortable indoor environment. In traditional plumbing applications, the flexibility of PEX allows it to be installed in long runs without joints; this reduces potential leak points and improves water flow efficiency. Also, PEX comes in color-coded options (red for hot water, blue for cold water), which eases installation and distinguishes between supply lines more easily. It has better resistance to scale formation and chlorine than other materials when used for plumbing purposes, thereby enhancing the longevity of these products while maintaining good water quality over time. Ease of installation, efficient heating applicability, and durability distinguish PEX tubing, making it an attractive choice between experts and residents.

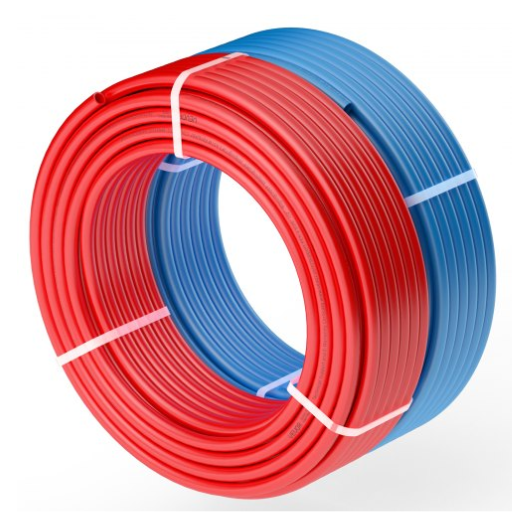

Types of PEX Tubing: Red, Blue, and Barrier Tubing

I must carefully consider all the various types of PEX tubing, including red, blue, and barrier tubes. Red signifies a hot water line, so it is easily identified within the plumbing system. Blue shows cold water lines, thus differentiating both supplies.

Alternatively, barrier tubing incorporates oxygen barriers to stop oxygen from getting into the water supply system, such as hydronic heating systems, where entry could lead to corrosion in heating components, among other problems. One must know how best to distinguish between these variables for proper installation so the plumbing system will perform optimally throughout its life span.

Non-Oxygen Barrier PEX: When to Use and Why

In my limited experience, PEX without an oxygen barrier is best suited for non-oxygen-sensitive applications like potable water systems. I love that it is cheap and flexible, making it a perfect choice for most residential plumbing installations. However, I don’t install non-oxygen barrier PEX in hydronic heating systems because of its lack of oxygen barrier, which may result in metal component corrosion over time. Nevertheless, it functions satisfactorily for conventional hot and cold water supply at a reasonable cost, making it one of the better choices for many projects.

How to Install 1 1/2 PEX Pipe?

1 1/2 PEX pipe installation consists of several simple procedures. First, gather all necessary tools such as pipe cutter, pex clamps, crimp rings, and crimp tools. Either measure or cut the PEX pipe to the required length, ensuring that both ends are clean and straight concerning the right fit connection. Afterward, slip a crimp ring over the end, then insert the fitting into place. For this purpose, the appropriate tools are used to secure the ring, thereby creating a tight seal. Continue this process when making any other additional connections. Finally, once all joints are secure, turn on the water supply and inspect for leakage to ensure successful installation has been carried out.

Step-by-Step Installation Guide for PEX Pipe

Gathering the necessary materials is my first step when installing 1 1/2 PEX pipe. These include the pipe itself, fittings, crimp rings, and a PEX crimp tool. Using a tape measure, I take measurements on where to cut the required pipe lengths using a tube cutter for clean square cuts. Then I insert one end of a crimp ring onto one end of the tube and push in an appropriate fitting, positioned rightly, before sliding the ring up into position against that fitting, which should be fully seated inside this connection point. At this stage, I compress around all sides equally without any under-crimping or over-crimping by checking if they are evenly done, sealing tight enough my crimps around these parts using my crimper tool. Once all connections have been made so far from start to finish, such as between pieces themselves plus those connecting different sections somewhere along its length wherever applicable according to local plumbing codes, then test pressure integrity by hooking the system up to water supply sources pressurizing according to region’s building stipulations but always ends with insulating pipes outdoors or other exposed areas against freezing damage thereby ensuring reliable plumbing installations.

Essential Tools and Fittings for PEX Installation

Many tools are needed to install PEX piping successfully. These tools include a cutting ratchet style PVC tubing cutter, proper size crimps and crimper, and well-measuring tapes to ensure correct lengths are cut every time. Also, different elbow tee connectors based on what configuration is needed within any given installation plumbing job may require an expansion method either with a pex expander tool or otherwise. Having them readily available will speed things up quite a bit while still maintaining high standards throughout the entire project, so be sure not to forget about having everything ready at hand always before starting work since it helps a lot when trying to complete work efficiently, especially those involving large-scale systems.

Common Mistakes to Avoid During Installation

I have learned a couple of mistakes to avoid while doing my PEX installation. First, I don’t over-tighten the crimp rings since this could weaken the joint and result in leakages. Again, I always make sure that I am using the right size fitting for my PEX pipe because any mix-up at this point might cause failure in the entire system. Last, I consider where it is being installed; if left unattended, pipes can freeze in low temperatures, which can be prevented by insulating them with appropriate materials, as learned. In simple words, these are some common blunders that should be considered during plumbing work.

What Are the Advantages of Using PEX Tubing?

PEX tubing has become more prevalent in recent years due to its many benefits for plumbing systems. One of these advantages is adaptability, which allows bending around corners without joints, reducing the possibility of leakage points during installation. Another merit is non-reactivity, which makes it resistant to rusting or scaling even when exposed to different water conditions, thus ensuring a longer service life span. Moreover, this material’s excellent heat insulation properties help retain the hotness levels of fluids conveyed through pipes, reducing energy usage in areas where insulation may be required. Additionally, copper usually needs more equipment than pex, and fast completion during building projects saves money.

Benefits Of Traditional Copper and PVC Pipes

PEX tubing has many advantages over copper and PVC pipe. Firstly, it is much more flexible than either copper or PVC pipes, which means they can be bent around corners and other obstructions without using as many joints. This bendiness also reduces the chance of leaks occurring because there are fewer places where connections could fail over time. Secondly, pex does not rust and is not prone to pitting like copper pipes, saving money on repairs that would have been needed if those types were used instead. Thirdly, pex has better freeze resistance – when temperatures drop, it can stretch without breaking, unlike rigid PVC or copper pipes. Lastly, pex usually comes cheaper overall – both in material costs and labor hours required for installation, making plumbing solutions cost-effective.

PEX Tubing’s Durability and Flexibility

One thing about PEX tubing stands out most for me is how long-lasting this stuff is! It doesn’t rust easily at all nor does scale build up within the tube walls themselves; even freezing point isn’t dangerous because unlike traditional materials P.E.X can expand n contract with temperature change thus greatly reducing chances of pipe bursting during winter months when everything freezes up outside. Another thing I love about it is its adaptability feature which allows easy fitting into tight spaces where otherwise lotsa fittings would’ve been required just to navigate through an obstruction alone – like say behind a vanity unit under bathroom sink etc., moreover being pliable such quality gives opportunity for hassle-free installation process even around different objects along its route hence why these two qualities combined makes it strong enough to use in both domestic and commercial environments without worrying about frequent breakdowns or maintenance issues cropping up every now then.

Cost-Effectiveness of PEX Pipe

I have seen that PEX pipe is the most cost-effective plumbing solution. If you compare the total costs of PEX with those for traditional materials like copper or PVC, it becomes clear that this option can save both money spent at the beginning and in the long run. The price difference for materials alone, combined with reduced installation time, leads to significant savings on labor charges. At the same time, strongness and resistance towards leakages and corrosion mean fewer fixes during the life cycle of a plumbing system. In conclusion, using PEX may bring substantial financial gains, making it a wise decision for any plumbing project.

How to Choose the Right PEX Tubing?

Consider these points when choosing which type of PEX tubing is best suited for your needs:

- PEX Types: There are three types of pex – A, B, and C – each having its unique properties; while being highly flexible and resistant to kinking, PEX-A is more expensive than the other two but also has a higher burst pressure rating compared to them; on the other hand, pex-b is cheaper than a but less flexible so it’s often used where cost matters most such as commercial buildings while still possessing good strength qualities which makes this product suitable even for industrial applications.

- Size: Measure up what diameter will work best in your case, depending on where you plan to install these pipes—larger ones could be needed where main water lines come into play, while smaller sizes can suffice at branches off from those mains.

- Application: Depending upon whether a hot or cold water distribution system is intended, some specific types of pex may better suit high-temperature conditions.

- Local Codes: Always consult local building codes before proceeding because they might have different requirements concerning compatibility between certain materials and methods used within their jurisdiction; make sure, therefore, that any chosen product complies fully with all relevant regulations stipulated by such authorities; otherwise, there could arise profound legal implications later down the line should anything go wrong during the installation process itself or after completion thereof due non-compliance issues relating directly related thereto.

- Installation Environment: If installing PEX in areas with extreme temperatures or exposure to UV light, choose products rated for those conditions.

By looking at these factors closely enough, you should be able to identify which type of PEX tubing will work well within your plumbing requirements while ensuring the best performance possible.

Choosing Between Red, Blue, and Barrier PEX

You should know what each is good for when choosing between red, blue, and barrier PEX tubing. Usually, a red PEX pipe is used for hot water lines, while a blue PEX pipe is used for cold water lines so it can be easily identified during installation and maintenance. Barrier PEX, on the other hand, prevents oxygen from diffusing through the walls of the tube, which makes it perfect for preventing oxidation in plumbing systems with metal components that would be damaged by exposure to oxygen.

In general, when making your decision about what kind of pipes to use in your plumbing system, consider first what those pipes will need to do; if they only have to carry hot or cold water, then stick with either red or blue respectively – but if there’s any risk at all of oxygen getting into contact with metals inside them because of where these parts are situated along their length or due to some other reason altogether – pick barriers everywhere such situations could occur. Remember also about local building codes and specific environmental conditions where you will install this stuff.

Understanding PEX Pipe Sizes and Ratings

Speaking about sizes and ratings of PEX tubing – I have to consider both diameter measurements and pressure values since they can significantly influence how well my plumbing works. These types have three standard diameters: 3/8 inch, 1/2 inch, and 3/4 inch (with 1/2” being most commonly used in residential applications). Which one I go for depends on flow rates required by various fixtures within the house, plus lengths traveled by pipes between them. Moreover, one has also paid attention to ASTM F876 & F877 ratings, which ensure that the chosen product meets specific safety standards set out by the American Society For Testing And Materials (ASTM). So it would be a good idea to check the temperature rating alongside the maximum working pressures indicated on the packaging before buying any particular brand – otherwise, leaks might occur along the pipe length due to excessive temps or reduced flow caused by pressure drop.

Evaluating PEX Tubing for Different Applications

Considering the variety of PEX tubing available for plumbing, factors such as type, size, and application must be considered. Non-barrier PEX is typically used with cold water systems in residential settings, while barrier PEX is recommended for hot lines because it has better oxidation resistance. Many professionals suggest using PEX-a for radiant heating applications due to its flexibility and ability to resist kinking.

Selecting the suitable diameter is crucial to matching flow rates and minimizing pressure drop; usually, 1/2-inch pipes will suffice for most homes. Additionally, choosing materials wisely means considering exposure to UV light or chemicals, so continually evaluate where exactly it will be installed at any given time. Last but not least, local codes must be followed so that everything complies with them and works well together.

What Are Common Issues and Solutions with PEX Tubing?

A common problem with this kind of tube is its vulnerability to damage caused by ultraviolet radiation, which breaks down material after some time spent outside under sunlight influence. Therefore, one should install it in areas hidden from direct sun rays or substitute regular PEX with increased UV protection when planning outdoor applications. Another typical issue refers to freezing temperatures widespread in colder climates where houses are not adequately insulated against cold weather conditions; therefore, all exposed sections should be wrapped up tightly using appropriate insulation materials while ensuring even temperature distribution throughout the premises. All these notwithstanding flexibility itself may become limiting factor during installation if done incorrectly leading into twisted loopings blocking free flow of water along the channel. To avoid such errors, follow bending radiuses given by manufacturers and employ adequate support mechanisms where necessary. Finally, joints may sometimes leak due to faulty connections or excessive tightening; thus, use the correct joining technique without overtightening, thus keeping them watertight seals forever.

How to Address Leaks Down the Road

To solve the problem of leakage in PEX, you must first discover the cause of the leak. Sometimes, you can tighten the connection and stop the leak if it is a minor one around a fitting, but be careful not to overtighten it. If this does not work, you could replace the damaged part with another fitting or tube section. For freezing damages, allow the pipes to defrost and then fix any visible splits naturally; nevertheless, inspecting my PEX system frequently during different seasons has helped me prevent such leaks. If they occur too often, involving an expert who will assess the whole system for further repairs and improvements that ensure durability and performance over time might be necessary.

UV Resistance and Direct Burial Concerns

I have always treated PEX tubes meant for direct exposure to sunlight with UV resistance so as not to reduce their longevity according to manufacturers’ requirements. Extended periods under direct rays may harm these materials; hence, I install them where they can shade themselves most of the time. However, I only use UV-resistant PEX tubing grades when this cannot be avoided. According to local rules, burying such pipes should follow specific guidelines like recommended depth protection against freezing temperatures through insulation, which are all observed during my burial processes, thereby taking care of potential threats before they become problems. By doing this, I can minimize instances where the plumbing material, pex, wears off because of environmental factors.

Handling PEX Tubing in Extreme Temperatures

When you think about extreme heating, looking at how PEX tubing behaves is necessary. PEX can work within an extensive range of temperatures, which are usually from 40°F to 200°F (from 40 °C to 93°C). Nevertheless, when the water inside freezes in freezing conditions, PEX can expand without breaking, thus reducing the chances of bursting. To keep from freeze protection on pex lines, insulating and keeping them in warmer areas as much as possible is recommended. In sweltering conditions, direct exposure to sunlight should be avoided so as not to degrade thermally or lose its integrity altogether. In summary, this means that good installation practices and good insulation provide excellent performance for pex pipes under extreme temperatures.

Reference sources

- PEX tubing technical specifications and general installation

- PEX Pipes: A Complete Guide

- PEX Plumbing Pipe: Everything You Need to Know

Frequently Asked Questions (FAQs)

Q: What is 1 1/2 PEX pipe typically used for?

A: 1 1/2 PEX pipe is primarily used for plumbing and heating applications, including radiant heating and cold water plumbing. It is versatile and suitable for a variety of applications, including other heating and potable water systems.

Q: Can I get 1 1/2 PEX pipe in a roll of 500 feet?

A: Yes, 1 1/2 PEX pipe is available in rolls of 500 feet. This listing is for one roll of 500 feet, which offers convenience and flexibility for larger projects.

Q: What are the pressure ratings for 1 1/2 PEX pipe?

A: The pressure ratings for 1 1/2 PEX pipe are generally 100 psi at 180 degrees Fahrenheit and 80 psi at 200 degrees Fahrenheit. These ratings ensure the pipe can handle high-pressure plumbing and heating systems.

Q: What is nonoxygen PEX, and where is it used?

A: Nonoxygen PEX, also known as nonoxygen barrier PEX, is designed to prevent oxygen from penetrating the tubing. This type of PEX is used in applications where oxygen could cause corrosion in metal components, such as in radiant heating systems.

Q: How does PEX tubing compare to traditional plastic pipe?

A: PEX tubing is more flexible and durable than traditional plastic pipe. It is easier to install, resistant to scale and chlorine, and has a longer lifespan. PEX also has UV resistance, which adds to its durability.

Q: Can I use crimp fittings with 1 1/2 PEX pipe?

A: Crimp fittings can be used with 1 1/2 PEX pipe. Crimp fittings provide a secure and reliable connection, making them popular for plumbing and heating applications.

Q: Is 1 1/2 PEX pipe suitable for potable water systems?

A: Yes, 1 1/2 PEX pipe suits potable water systems. It is certified to meet the necessary standards for safe drinking water applications.

Q: What does the term “BHS PEX tubing is made” mean?

A: “BHS PEX tubing is made” refers to the manufacturing process and quality standards of the PEX tubing. This indicates that the tubing is made to the specifications and standards set by ASTM and other regulatory bodies.

Q: What is the difference between red PEX tubing and blue PEX tubing?

A: Red PEX tubing is typically used for hot water lines, while blue PEX tubing is used for cold water lines. This color coding helps identify and organize the piping system during installation and maintenance.

Q: How do I install 1 1/2 PEX pipe using push-fit fittings?

A: To install 1 1/2 PEX pipe using push-fit fittings, simply cut the pipe to the desired length, ensure the ends are clean and free of burrs, and push the pipe into the fitting until it is securely seated. Push-fit fittings provide a quick and reliable connection without special tools.