The very nature of working with PVC piping requires connections made to withstand leakage, keeping systems running for the long haul. Among the more important considerations is the correct treatment of glue, commonly known to many as PVC solvent cement. The choice of adhesion, seemingly a minor detail, can greatly compromise the strength of your plumbing, irrigation, or construction job. Consider this article your go-to guide to PVC glue: how it operates, the varieties available, and how to apply it. Whether one is a seasoned plumber or merely a DIYer, one has to be conversant with this in order to mount pipes efficiently and securely for the long haul.

Types of Pipe Glue

PVC Cement

PVC cement is simply a type of special solvent cement used to make permanent and watertight bonds between PVC pipes and fittings. It softens the surface of the PVC material with a chemical reaction so that the pipe and fitting become fused as it cures. This makes the joint extremely strong and able to bear pressures and changes in the environment.

Under the typical classification, there are three types of PVC cements based upon their viscosity and intended use: regular-bodied, medium-bodied, and heavy-bodied. Regular-bodied cement is used for small diameter pipes (up to 2 inches) and non-pressure systems. Medium-bodied is the general-use cement, used for pipes up to 6 inches in diameter. Heavy-bodied cement is for large PVC pipe and high-pressure systems where utmost strength and reliability are demanded.

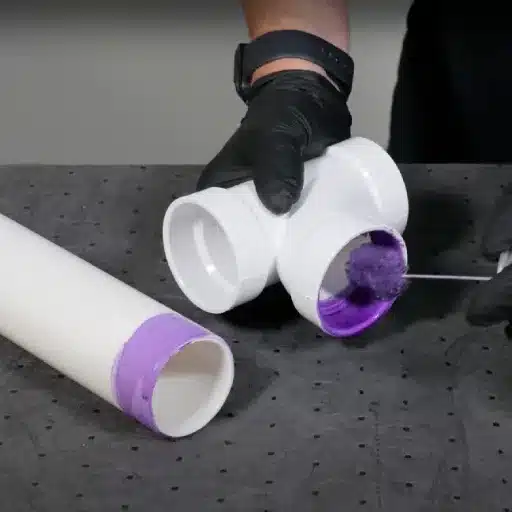

Proper preparation and application technique are important in order to have the best results in applying PVC cement. Ensure that pipe and fitting surfaces are cleaned well, free of dirt or grease, using a PVC primer, which assists in softening the material for a better bond. After applying cement to both the pipe and the fitting, insert the pipe into the fitting with a quarter-turn twist and hold the parts for a few seconds to let them set. Let the curing time finish as prescribed by the manufacturer before applying pressure to the joint. This way, your PVC pipe installation can perform well for years down the road.

CPVC Adhesives

CPVC adhesives or solvent cements are specially formulated for use with CPVC pipes and fittings. These products chemically weld the pipe and fitting by softening their surfaces and, through curing, form an integrated, water-tight seal. In contrast to regular PVC adhesives, solvent cements for CPVC are developed at elevated temperatures and are hence rated for systems that handle both hot and cold water, as well as chemicals. System performance and durability rest firmly on making the right choice for the right application.

Choose a CPVC adhesive depending on pipe size or system specifications and operating conditions. CPVC solvent cements are usually classified according to viscosity types, examples of which are regular, medium-bodied, and heavy-bodied, and temperature limitations. Heavy-bodied cements are generally used for larger pipe sizes and systems that work under pressure or high temperature because they need a very strong bond. Always check whether it meets the standards ASTM F493, which deals specifically with the performance of CPVC solvent cements for pressure pipes.

First, prepare the pipe and fitting surfaces using a CPVC primer if required by the cement. Apply solvent cement to both surfaces and insert the pipe full length into the fitting. Rotate the pipe a quarter turn to ensure even coverage and hold the joint together for a few seconds until the solvent cement sets. Further, abide by the curing time as given by the solvent cement manufacturer before putting any pressure or service upon the joint to avoid failure and hence assure system life. Installation done correctly also ensures high performance and reliability of CPVC piping systems.

Epoxy-Based Glues

Epoxy-based adhesives consist of two distinct substances: a resin and a hardener; a chemical reaction occurs between the two when mixed, resulting in an immensely strong and durable bond. Being high in versatility and resistance to heat, chemicals, and moisture, these adhesives find applications from industrial heavy-duty work to construction and to small-scale repairs. Epoxy glues offer superior strength that could, in most cases, stand against or even surpass the tensile and compressive properties of the joined materials, guaranteeing long-term reliability.

The application requires adherence to the manufacturer’s instructions with measured precision. Firstly, the surfaces to be bonded would have to be well cleaned and degreased, and where possible and necessary, they should be roughened. Now, the resin and the hardener would be weighed or measured in volume as advised by the manufacturer so that adequate chemical reactions will be produced; it would then be mixed. The mixture would have to be applied to the surfaces within working time or pot life, and the surfaces would have to be clamped or held firmly in place until full curing of the adhesive is accomplished. While curing time depends on environmental conditions and formulation, it usually ranges between 15 minutes and several hours.

It is a well-known fact that the epoxy offers the strength required for structural bonding, but bearing the limitations comes with the use. Sometimes it needs the environment to be perfect for performing well, and in some instances, even slight surface contamination or an improper mixing ratio could weaken the bond. Cured epoxy bonds are quite rigid and allow no movement, so would not be suitable for applications where they would need to be flexible; however, when properly applied, an epoxy adhesive can offer the strongest combination of durability and resistance to wear, making such adhesives indispensable across numerous industries.

Applications of Pipe Glue

Best Uses for PVC Pipes and Fittings

PVC pipes and fittings are well known for their cheap versatility across industries. In the major applications, pipes are placed in plumbing systems for residential, commercial, and industrial usage. In terms of excellent chemical resistance, lightweight nature, and the lowest cost possible, they are used for the conveyance of potable water, wastewater, and irrigation fluids. Owing to strong drainage purposes and exposures to weathering, PVC pipes are the choice in any drainage system that demands corrosion resistance.

In another major application, they are used in electrical conduit systems. As good insulators, PVC conduits are non-conductive and guard the electrical wiring against moisture and physical damage. With PVC systems for the HVAC system considered the industry standard, PVC pipes are great for condensate drainlines because of their resistance to cracking and excellent thermal properties. PVC pipes are, however, increasingly used in the agricultural sector for drip irrigation and efficient water distribution systems beyond these common applications. A smooth interior minimizes friction to guarantee maximum flow rates and minimum energy losses.

Considerations for purchasing PVC pipes in any application include diameter, pressure ratings, and manufacturing grade (for example, Schedule 40 or 80). They serve to ensure compatibility and longer operational life in their intended use while, at the same time, making PVC formulations advanced, like with CPVC (Chlorinated PVC), to perform in areas of high temperature and high pressure. PVC pipes have, therefore, gained much adaptation under a wide range of conditions, making them suitable in any modern working infrastructure.

Joining PVC vs. Other Materials

Attaching PVC involves solvent welding, while other materials such as CPVC, ABS, and some kinds of metals can be adhered, and require mechanical fittings, soldering.

| Material | Joining Method | Key Features | Applications | Limitations |

|---|---|---|---|---|

| PVC | Solvent Welding | Durable, Quick | Plumbing, DIY | Requires Primer |

| CPVC | Solvent Welding | High Temp | Hot Water Pipes | Costlier |

| ABS | Solvent Welding | Lightweight | Drainage | Not for Pressure |

| Metal | Welding/Fittings | Strong, Durable | Industrial | Corrosion Risk |

| PEX | Crimp Fittings | Flexible | Residential | UV Sensitive |

Professional Plumbing Repairs

Plumbing repairs necessitate the trained proficiency of knowledge in material compatibility, with advanced tools, and adherence to industry standards. Choosing the piping material appropriately is important because every piping material, be it PVC, CPVC, ABS, metal, or PEX, exhibits different properties that are compatible with particular applications. Research and development in plumbing technology provide better means of doing things with minimal nuisance to the end user, such as pipe relining and trenchless sewer repairs.

For example, the pipe relining technique eliminates the necessity for excavation of the damaged pipe by providing a cured-in-place resin lining within it, hence serving as a good technique on account of being durable yet cost-effective as compared to other traditional methods. On the other hand, new tools like leak-detection sensors and high-definition inspection cameras can pinpoint problems within complex plumbing systems more accurately.

However, it remains important to consider how water quality impacts the durability of the pipes. For instance, mineral build-up, pH levels, or chemical additives can serve to enhance corrosion or decrease the material over time. All repairs should ensure compliance with local plumbing codes and standards for training, efficiency, and safety within plumbing repair activities. Respecting the aforementioned principles, fused with the use of modern techniques, should stand for professionals capable of presenting their work in better quality with longer durability.

Step-by-Step Instructions for Applying Pipe Glue

Preparation of Surfaces

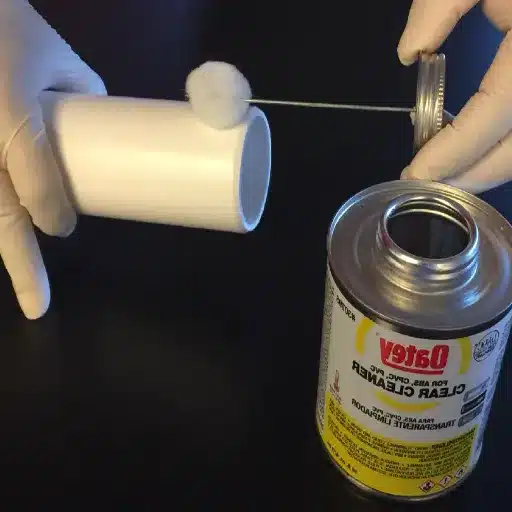

Surface preparation has to be done properly to ensure a secure and leak-free bonding when applying pipe glue. First, check out the pipe glue you are going to use, for it may be PVC, CPVC, or ABS pipe glue. Whether glue and pipe type are compatible is vital for the long-term effectiveness. Surfaces to be joined should be dust and dirt-free, and oil or moisture can appear as contaminants that reduce adhesive strength or give rise to a compromised seal.

A clean cloth or lint-free material should be used to wipe soil and stains from the bonding surface-and if possible, use an appropriate chemical cleaner or primer for the pipe material to clean off residues and “condition” the surface for bonding. Scuffing the pipe ends and fittings lightly by fine-grit sandpaper or with a special pipe preparation tool will result in a rough surface, helping the adhesive to mechanically grip it.

With each clean and abraded, inspect every part for cracks, deformities, or irregularities that could compromise the connection. Only after all surfaces have become dry and prepared to rigid standards will you want to consider says glue application. Hence, prematurely applying glue on a compromised or wet surface would basically mean that joint failure would definitely occur at some point. Hence, these important steps are the very foundation on which a long-lasting professional pipe joint must be built.

Cleaning Pipe and Fitting

A thorough cleaning of pipes and fittings ensures a longer life and better use of the piping system. Cleaning begins with the removal of all visible contaminants, such as dirt, grease, or oil, which can hinder the bonding of an adhesive solvent cement or epoxy compound. For this purpose, use an industrial-grade degreaser or isopropyl alcohol. Then use an abrasive pad or fine-grit sandpaper to lightly scour the surfaces of the pipe and fitting. This is significant in eliminating the oxidized layer while also slightly roughening the surface to acquire superior adhesion during bonding.

Once the physical cleaning is carried out, it is considered good practice to use a high-purity cleaning solution that has been specially formulated for the type of material involved (such as PVC, CPVC, or metal). These cleaners work by dissolving and clearing away microscopic contaminants that cannot be washed away by mechanical means alone. Apply the solution evenly onto the surfaces, either by using a lint-free cloth or an applicator. Allow ample air-drying time for the surfaces; moisture retention might bring about premature bond failure or adverse chemical reactions that affect the joint quality.

Following pertinent industry standards during cleaning procedures will lead to uniform results. The use of properly cleaned surfaces drastically lowers the chances of leaks, hence guaranteeing the longevity of the piping installation.

Curing Process for Optimal Bond

In the installation of pipes, the curing process is pivotal in the estimation of a durable and long-lasting bond. Curing refers to the interval during which the adhesive or sealant is allowed to set completely to achieve maximum strength and chemical resistance. The curing period may vary depending on a number of factors, such as ambient temperature, level of humidity, or adhesive formulation. Typical solvent-based adhesives will require a solvent evaporation time and curing time of 24 to 48 hours in standard conditions, whereas a two-component epoxy may cure in less time but requires the two components to be mixed in the correct proportions to perform adequately.

To achieve industry-standard performance, curing should, under all circumstances, be conducted according to the manufacturer’s recommendations as described in the product technical data sheet. Any deviation from the recommendations may lead to inadequate curing and, therefore, weaknesses in the system. The bond strength should be tested after curing, for example, by performing a hydrostatic pressure test, to ensure the robustness of the installation before the system is commissioned for full operational service.

Environmental conditions during curing must be very strictly controlled. For example, temperatures below 40°F may cause very long cure times or no cure at all, whereas high humidity levels can alter the chemical makeup of the adhesive. Often, therefore, controlled cure environments or heating facilities are installed for critical applications to circumvent these problems, thus guaranteeing consistent results irrespective of external conditions. By tightly observing curing standards and controlling curing conditions, practitioners will be assured of bonds that meet or exceed the required industry standard for strength and durability.

⚠️ Safety Precautions During Application

Working in Well-Ventilated Areas

Ensuring that there is adequate ventilation around the workspace is an important safety measure to be taken, especially when handling various adhesives containing VOCs. These substances tend to vaporize during the application or curing period, thereby releasing fumes that may prove toxic to human health. The inhalation of these toxic fumes for a prolonged period can lead to adverse effects such as headaches, dizziness, respiratory problems, or even chronic adverse effects due to toxicity.

To abolish such scenarios, a very good airflow should be maintained within the workplace, as per the industrial ventilation standards by the occupational safety authorities. This could be through the installation of exhaust fans, fume hoods, or other mechanical means to ensure that vapor fumes do not cross the work area into the position of human zest. PPE may also be favored in application; such items include respirators rated for chemical protection.

Good ventilation practices, thus, will help to ensure compliance with workplace-based safety laws, in addition to prolonging equipment life and improving air quality for the people working there. You may also seek counsel from ventilation and health safety consultants to design optimized systems that suit the specific requirements of the adhesive applications in your use case.

Protective Gear Recommendations

While working with adhesives, particularly those bearing VOCs or any other hazardous materials, one must ensure that suitable protection is provided to the working personnel. The major items of recommended personal protective equipment (PPE) include:

- Respiratory Protection: PAPRs or half-mask respirators with organic vapor cartridges should be used in environments with high levels of chemical fumes. To ensure maximum protection, always consult the SDS of the adhesive being used to confirm adequate respiratory protection of the chosen equipment.

- Eye/Face Protection: Safety goggles should be worn to prevent splashes from reaching the eyes. They must comply with ANSI Z87.1 standards. Otherwise, use a face shield that will cover the entire face, especially during mixing or application.

- Hand Protection: Disposable or reusable chemical-resistant gloves made from nitrile, butyl rubber, or similar materials serve as a barrier to adhesive substances. Gloves should be selected based on the anticipated duration of wear and breakthrough time for the chemicals involved, which is usually given in the SDS.

- Skin and Body Protection: Wear long-sleeved chemical-resistant coveralls, aprons, or lab coats that resist chemical penetration. Disposable protective suits should be used in high-risk applications to prevent any form of contamination.

- Foot Protection: In an industrial adhesive setting, shoes containing chemical-resistant materials further serve against any accidental spill or splash.

These protective measures go a long way in the prevention of exposure to harmful chemicals, while also guaranteeing conformity with OSHA and other regulatory bodies. There is a need to ensure that the workforce is properly trained in the use, maintenance, and disposal of protective gear so that a culture of safety is promoted at all times in industrial or lab settings.

Handling and Storage of Pipe Glue

Improper handling and storing of pipe glue can degrade the product and pose a hazard during use. Since pipe glue may consist of VOCs and strong solvents, it must be applied in an environment with adequate ventilation to minimize exposure to harmful fumes. At the time of applying pipe glue, PPE such as chemical-resistant gloves, safety goggles, and, when necessary, respiratory masks must be worn to guard against skin irritation, eye damage, and respiratory problems.

Storage methods follow the manufacturer’s directions and safety data sheets. The pipe glue should be stored in tightly closed containers to prevent evaporation or contamination, in a cool and dry place far away from any potential ignition sources, away from direct sunlight, and from temperature extremes. Usually, the temperature should range between 40 and 80 °F (4 and 27 °C) because heat may alter its chemical properties, and freezing will change its consistency and performance. Moreover, containers holding the pipe glue must be clearly marked and stored away from incompatible materials such as strong oxidizers or acidic substances in order to avert unintentional chemical reactions.

If complying with the workplace, the storage areas must meet OSHA and NFPA standards and have the appropriate fire hazard classification, as some pipe adhesives are flammable. Spill kits must be on hand, together with ventilation systems, to address accidental leaks or spills. Regular inspections of the storage containers and adherence to the shelf life of the product are key to maintaining product integrity and safety in use.

💡 Expert Tips for Selecting Pipe Glue

Choosing the Right Glue for PVC Pipes

When choosing the right glue for PVC pipes, I always first consider how compatible the glue is with that particular type of PVC. There are different grades of PVC glue based on their viscosity, such as medium-bodied and heavy-bodied glues, each corresponding to particular pipe sizes and pressure ratings. I make sure that I go through the manufacturer’s recommendations because some of them will specify the type of pipe and the application the adhesive is good for, whether it be for high-pressure systems or non-pressurized connections.

Drying and curing time, being another consideration, is something I weigh depending on the project. My choice goes to adhesives that cure really fast if assembly time has to be minimal. However, I usually choose an adhesive that can take its own time if what I want is a bond that will offer greater durability and strength. Temperature and environmental conditions are equally considered. If a glue is validated for a broad range of temperatures, the assurance is given that it will perform well even at extreme cold or heat important characteristic if used on the exterior or industrial systems.

Lastly, I carefully evaluate the solvent content as well as certification compliance. Low VOC emission products are preferred due to concerns about risks to health and better indoor air quality during application. I also check for standards the glue conforms to so that it can be considered a safe adhesive-perfect in performance. These are the processes I go through in making a confident decision in using the best glue in my PVC pipe cases.

Common Mistakes to Avoid

⚠️ Critical Warning: Avoid These Common Errors

Working with PVC pipe applications and adhesives involves a whole range of common errors that may endanger safety or affect the performance of the system. First, there is a tendency to neglect the cleaning and preparing of the pipe surfaces before the application of adhesives. Dirt, grease, or moisture adsorbed onto the pipe surface will weaken the adhesive bond, leading to maximum possible leakage or system failure. It also becomes another case of the wrong type of adhesive being used with the PVC grade or under environmental conditions: temperature and pressure do matter as well.

Improper curing times also constitute a big problem area: sometimes there is so much rushing to use the pipes without letting the adhesive compound cure well enough that bonding ends up incomplete, and this invariably lessens system strength. Too much or too little glue cannot be good either; heaps of glue can be messy and affect how the parts fit together, and very little then can’t flex adequately. It is good practice to strictly adhere to any manufacturer’s specifications to circumvent these problems.

Finally, failing to consider certification standards and environmental issues, such as VOC content, would open the system for health hazards and non-conformance under local regulations. Concentrating on these things ensures a secure and efficient PVC piping system.

❓ Frequently Asked Questions (FAQ)

Q: What is pipe glue, and what is it used for?

A: Pipe glue, also known as PVC cement or adhesive, is a specialized type of glue that plastic pipe workers use to glue plastic pipes together during plumbing jobs. Such glue forms a strong bond that resists water and pressure, thereby best suited for bonding hose fittings, drain lines, and water supply systems.

Q: Is pipe glue meant for use with PEX pipes?

A: Pipe glue is not intended for use on PEX pipes. PEX is generally installed using crimp fittings or push fittings. If you are installing PEX piping, then you should indeed use proper coupling methods that are specifically designed for this type of piping.

Q: How do I prepare pipes for the application of pipe glue?

A: You should clean the surfaces of the pipe to be joined thoroughly and apply a primer if needed, to prepare the pipes for the glue. This makes sure that the adhesive is bonded properly. After this cleaning, apply the glue and push the pipes together firmly.

Q: Is pipe glue waterproof?

A: A pipe glue typically makes a waterproof seal for all situations, either inside or outside plumbing. Once cured, the bond created by pipe glue remains the channel for water-induced pressure and prevents leakage.

Q: When do I need piping work from a professional plumber using pipe glue?

A: Otherwise, one should have a professional plumber on salary for advice and to perform a complex installation of plumbing services if one has any doubts about assembling his installation.

Q: How does one replace a pipe glue section?

A: Begin by cutting away the damaged section. Next, clean the edges of the existing and the new pipe. If needed, apply the primer, followed by the pipe glue. Connect the new pipe to the existing piping with appropriate couplings.

Q: Can glue be used just to hold something temporarily?

A: No, a glue will make a more or less permanent bond. For temporary connections, good hose clamps or quick-connect fittings might be used so the pieces can be easily taken apart without using glue.

Q: What insulation is best insulating glued pipes?

A: You will want to bear in mind the type of insulation when using pipe glue. Foam pipe insulation is a common choice to protect pipes from either heat or cold temperatures. Just make sure that the insulation is not going to prevent them from expanding and contracting.

Q: What if the taped pipe leaks shut?

A: In the event of leaks with glued pipes, the glue must be guaranteed to have cured. If the leak persists, it may be necessary to cut back the joint and reassemble with fresh glue, ensuring all surfaces are clean and all necessary primer is applied before using the glue.

📚 References

-

The Oregon State University Library: Development of an adhesive patch for polyethylene gas pipe

This source dwells upon adhesive applications and considerations with respect to polyethylene gas pipes.

-

Oregon State University Library: Testing and repairing polyethylene natural gas distribution pipe

This paper explores the use of adhesives in the repair of natural gas distribution pipes.

🔧 Ready to Start Your Next Plumbing Project?

With this comprehensive guide, you now have the knowledge to select and apply the right pipe glue for your specific needs. Remember to always prioritize safety and follow manufacturer instructions for the best results.