Introduction to PVC and HDPE

What is PVC?

Polyvinyl chloride (PVC) is an artificial thermoplastic polymer formed by polymerizing vinyl chloride monomer. Due to its versatility, strength, and affordability, it ranks among the most widely manufactured plastics in the world.

Key PVC Characteristics:

- Types: Rigid PVC (construction/piping) and Flexible PVC (cables/flooring)

- Strengths: Superior corrosion resistance, chemical resistance, environmental stress resistance

- Applications: Water supply lines, drainage systems, sewage installations

- Benefits: Lightweight, easy installation, low thermal conductivity

Performance Limitations:

- UV degradation with prolonged exposure (requires UV inhibitors for outdoor use)

- Cannot withstand high temperatures (starts melting at lower temperatures)

- Limited use in high-heat applications

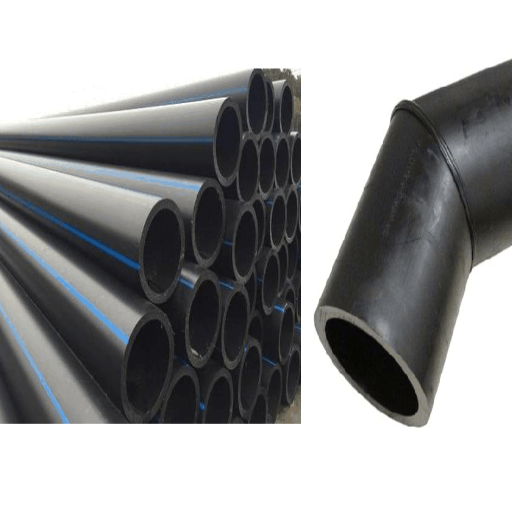

What is HDPE?

High-Density Polyethylene (HDPE) is a thermoplastic polymer produced from hydrocarbons. Characterized by a high strength-to-density ratio, HDPE is classified as linear polyethylene with minimal branching in the polymer chain, providing higher tensile strength and impact resistance.

Key HDPE Characteristics:

- Structure: Linear polyethylene with weak branching

- Strengths: Durability, chemical resistance, moisture resistance

- Benefits: Lightweight, high strength, recyclable, thermally stable

- Applications: Piping systems, storage tanks, consumer containers

Considerations:

- UV degradation under prolonged exposure (unless treated with stabilizers)

- Requires proper treatment for outdoor applications

Common Applications

PVC Applications

- Construction & Plumbing: Piping, window frames, flooring

- Electrical: Cable insulation, electrical conduits

- Medical: Blood bags, IV tubing (biocompatible versions)

- Industrial: Chemical handling, waste management

HDPE Applications

- Packaging: Plastic bottles, containers, bags

- Infrastructure: Water supply, gas distribution, irrigation

- Environmental: Geomembranes, environmental protection

- Automotive & Industrial: Parts requiring durability and thermal stability

Comparative Analysis: PVC vs HDPE

Physical Properties Comparison

| Property | PVC | HDPE |

|---|---|---|

| Density | 1.3 – 1.45 g/cm³ | 0.93 – 0.97 g/cm³ |

| Weight | Heavier, more stable | Lighter, easier handling |

| Tensile Strength | 50+ MPa | 26-37 MPa |

| Max Working Temperature | 140°F (60°C) | 176°F (80°C) |

| Flexibility | Rigid | Flexible |

| Chemical Resistance | Good | Excellent |

Mechanical Properties

PVC Mechanical Characteristics:

- Higher tensile strength: ~7,450 psi (51.4 MPa)

- Greater stiffness and dimensional stability

- Ideal for structural and load-bearing applications

- Higher elastic modulus

HDPE Mechanical Characteristics:

- Lower tensile strength: 3,200-4,500 psi (22.1-31 MPa)

- Superior impact resistance and flexibility

- Elongation at break: up to 800%

- Better fatigue resistance

- Superior abrasion resistance with lower friction coefficient

Durability and Lifespan

| Aspect | PVC | HDPE |

|---|---|---|

| UV Resistance | Limited (requires stabilizers) | Excellent (naturally resistant) |

| Chemical Resistance | Good | Superior |

| Impact Resistance | Moderate | Excellent |

| Service Life | 50+ years (controlled conditions) | 50+ years (all conditions) |

| Temperature Sensitivity | More sensitive | Better tolerance |

Specific Pipe Applications

PVC Pipe Applications

- Water Distribution Systems

- Handles pressures up to 200 psi

- 50+ year lifespan when properly installed

- Corrosion resistant

- Sewage and Drainage Systems

- Smooth inner walls prevent clogging

- Resistant to biological degradation

- Cost-effective for urban infrastructure

- Irrigation Networks

- Lightweight and easy assembly

- Uniform flow rates under varying pressure

- Ideal for agriculture and landscaping

- Electrical Conduits

- Excellent insulation properties

- Protection from moisture and chemicals

- Fire resistant

- Industrial Chemical Handling

- Resistant to acids, bases, and salts

- Safe handling of hazardous substances

- Cost-effective solution

HDPE Pipe Applications

- Water Distribution Systems

- 50+ year service life

- Smooth interior walls reduce friction

- Enhanced flow efficiency

- Gas Distribution

- 90%+ of new global gas installations use HDPE

- Chemical inertness and high-pressure resistance

- Superior safety and reliability

- Sewage and Drainage Systems

- Crack resistance and blockage prevention

- Lightweight for easy installation

- Superior to concrete or steel alternatives

- Agricultural Irrigation

- UV resistant for outdoor use

- 20% reduction in water leakage

- Long-distance water transportation

- Industrial Fluid Transportation

- Chemical corrosion resistance

- High temperature and pressure tolerance

- Reliable operation in demanding environments

Advantages and Disadvantages

Benefits of Using PVC

Top 5 PVC Advantages:

- Durability and Longevity

- 50+ years lifespan

- Withstands UV radiation, moisture, and chemicals

- Reliable for long-term applications

- Cost-Effectiveness

- Up to 30% savings compared to metal solutions

- Lower production, installation, and maintenance costs

- Excellent value proposition

- Chemical Resistance

- Excellent resistance to acids, alkalis, and salts

- Ideal for chemical plants and wastewater treatment

- Suitable for harsh substance handling

- Lightweight Design

- 50% lighter than equivalent ductile iron pipes

- Reduced logistics and installation costs

- Easier transportation and handling

- Recyclability

- Fully recyclable material

- Supports circular economy

- Non-toxic formulations available

Benefits of Using HDPE

Top 5 HDPE Advantages:

- High Strength-to-Density Ratio

- Lightweight yet impact resistant

- Handles high pressure without rupture

- Minimizes maintenance costs

- Superior Chemical and Corrosion Resistance

- Resists acids, alkalis, and extreme conditions

- No degradation from corrosive agents

- Essential for chemical processing applications

- Exceptional Longevity

- 50+ years minimum performance life

- Resilient in UV exposure and temperature extremes

- Ideal for outdoor infrastructure

- Environmental Sustainability

- Fully recyclable into new products

- Supports environmental conservation

- Reduces the need for raw materials

- Leak-Proof Flexibility

- Seamless joining without lap joints

- Easy installation reduces labor costs

- Excellent for water and gas delivery

Material Drawbacks

| Material | Primary Drawbacks | Impact |

|---|---|---|

| HDPE | • UV degradation without stabilizers • Limited thermal resistance • Potential plastic pollution if improperly disposed of |

• Requires UV treatment for outdoor use • Not suitable for high-temperature applications • Environmental concerns with waste management |

| PVC | • Chemical additives (phthalates) • Toxic substance release during manufacture/incineration • Less flexible, prone to cracking under stress |

• Environmental and health concerns • Dioxin emissions pose ecological risks • Reduced durability in dynamic applications |

Cost-Effectiveness and Sustainability

Comprehensive Cost Comparison

| Aspect | PVC | HDPE |

|---|---|---|

| Upfront Price | Lower | Higher |

| Production Complexity | Easier | Complex |

| Energy Demand | Lower | Higher |

| Recycling Capability | Minimal (~1% recycled) | Significant |

| Material Strength | Moderate | Superior |

| Maintenance Frequency | More Frequent | Less Frequent |

| Expected Longevity | 50+ years | 100+ years |

| Environmental Impact | Limited | More Sustainable |

| Installation Expense | Lower | Higher |

| Overall Long-term Value | Moderate | Excellent |

Sustainability Considerations

Environmental Impact Assessment:

- PVC Production: Involves chlorinated chemicals, leading to GHG emissions and dioxin concerns during incineration

- HDPE Production: Made from carbon and hydrogen, generally lower environmental impact during manufacturing

- Recycling Rates: PVC ~1% recycled globally vs HDPE with established worldwide recycling systems

- End-of-Life: HDPE offers better recyclability and circular economy potential

Future Sustainability Trends:

- Bio-based HDPE development

- Less toxic PVC additive alternatives

- Enhanced lifecycle analysis (LCA) tools

- 30% carbon savings potential through improved recycling

- Microplastic pollution mitigation strategies

Frequently Asked Questions (FAQ)

Material Selection & Properties

Q: What are the main differences between PVC and HDPE pipes?

A: The key difference lies in composition and flexibility. PVC is a rigid vinyl polymer, while HDPE is a flexible thermoplastic. HDPE’s flexibility makes it suitable for applications requiring bending, unlike rigid PVC pipes.

Q: Which material is better for trenchless installation?

A: HDPE is superior for trenchless installation due to its flexibility and crack resistance. It can absorb shock waves better than PVC, which has a higher failure rating during installation.

Q: How do failure ratings compare between the materials?

A: PVC has a failure rating of one, indicating a higher likelihood of failure under certain conditions. HDPE offers better durability and is less prone to failure, making it more reliable for demanding applications.

Installation & Applications

Q: Can PVC pipes be used for direct burial?

A: Yes, but they require proper support to prevent bending or breaking. HDPE pipes are often preferred due to their higher impact resistance and flexibility in buried applications.

Q: How are the pipes joined differently?

A: HDPE pipes use fusion techniques, creating seamless joints, while PVC pipes typically require fittings with gaskets or glue. This affects overall system integrity and longevity.

Q: Which is better for water supply applications?

A: Both are effective, but HDPE is often preferred for its ability to withstand higher pressures and environmental conditions, making it more reliable for water supply systems.

Cost & Performance

Q: Are HDPE pipes more expensive than PVC?

A: Generally yes, due to advanced properties and manufacturing processes. However, HDPE’s long-term benefits and durability can offset initial costs, providing better value over time.

Q: What industries commonly use each material?

A: Both are used in municipal water systems, sewage, and industrial piping. PVC is common in low-pressure applications, while HDPE suits higher pressure and more demanding environments.

Conclusion

The choice between PVC and HDPE ultimately depends on your specific application requirements, budget considerations, and environmental factors. PVC offers excellent cost-effectiveness and rigidity for controlled environments, while HDPE provides superior flexibility, chemical resistance, and long-term durability for demanding applications.

Key Decision Factors:

- Choose PVC for: Budget-conscious projects, rigid structural applications, controlled environments

- Choose HDPE for: High-pressure systems, outdoor installations, chemical resistance requirements, long-term value

Both materials will continue to play crucial roles in modern infrastructure development, with ongoing innovations in sustainability and performance driving their evolution in the marketplace.