HDPE smooth wall pipes represent the modern infrastructure’s life and provide unparalleled durability yet efficiency for appropriate application. From protecting sensitive fiber optic cables to converting and complicated underground utilities into one block, the innerduct conduit of HDPE stands as the most versatile and highly reliable solution. This article analyzes all the advantages of smooth wall HDPE pipe, only partly to explain why engineers, contractors, or utilities often end up using it in every pertinent situation. You’ll come across its unique properties and advantages in doing so, of which performance is practically one against or with any other quite popular pipe system.

Introduction to Smooth Wall HDPE Pipe

What is HDPE Pipe?

HDPE pipes are a durable piping medium made out of thermoplastic polymer and are known for their high strength-to-density ratio. This characteristic shears structural integrity from HDPE pipes, allowing them to be lightweight for easy handling. Apart from being used in various industries where they top the list of applications, such as water, gas, telecommunication, and electrical conduits, HDPE pipes offer resistance to corrosion, chemicals, and environmental conditions.

The most critical feature of HDPE pipe is certainly flexibility, which allows for easier installation through challenging terrain or in situations requiring trenchless technologies. Unlike rigid pipe systems, HDPE pipes must bend rather than break-with a decrease, therefore, in any additions to fittings, installation cost goes down. Also, this smoothness in its internal surface reduces friction considerably and ensures smooth flow, a quality that becomes essential in such systems that need consistency in performance over long distances.

Making good name for itself as HDPE pipe is preferred for its long service life and low maintenance. The chemical resistance property distinguishes HDPE from further materials and makes it impervious to rusting, rotting, and scaling-from steel to concrete. This also has given it a high resistance against UV radiation and change in temperatures. Together, these properties make HDPE one of the most widely used materials for any modern construction project.

Characteristics of Smooth Wall HDPE

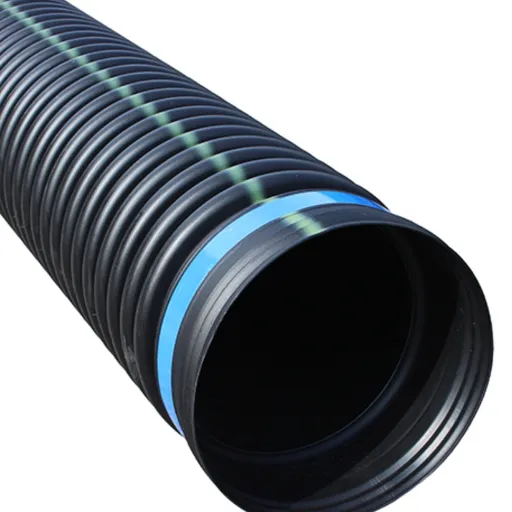

Smooth wall High-Density Polyethylene (HDPE) is meant to offer better strength and durability while being light. The smooth interior wall is there to reduce friction because of which fluids or materials can flow with minimum loss of energy. With this characteristic, it proves to be one of the most dependable systems for drainage, cable conduits, and fluid transport.

The primary advantage of smooth-wall HDPE lies in its superior resistance to chemical and abrasive actions. It can sustain attacks by aggressive chemicals that include acids, alkalis, and industrial solvents without losing its structural integrity. Furthermore, it remains highly resistant even to erosion caused by materials being transported through it under normal working conditions, thus ensuring operational efficiency with the least maintenance or repair at all times.

Smooth-wall HDPE, in turn, offers fine flexibility and adaptability to fill in shifting soils or seismic environments. All of the special site conditions can be easily absorbed by the material without cracking or generating any pressure resistance. Being lightweight also promotes ease of installation and less labor time, thus adding to its efficiency in infrastructure and industrial applications.

Applications in Various Industries

High-density polyethylene (HDPE) due to its high-end properties finds application in various industries. Some of the key industries in which the use of HDPE has significance are listed below:

Water and Wastewater Management

HDPE pipes are extensively used for conveying potable water, sewerage, or industrial wastewater. Their corrosion resistance and ability to withstand chemical exposure and leakages make them suitable for long-term use. Studies show that HDPE pipes have a service life of over 50 years with minimal maintenance and hence greatly reduce the operational costs.

Oil and Gas Industry

HDPE is used for pipes and containment systems in the oil and gas industry. Its chemical resistance and ability to withstand extreme temperatures ensure a safe system of transport and storage of hydrocarbons, chemicals, and associated wastewater. Industry data reports that the use of HDPE pipes in this industry has reduced the failure rate of pipelines by 25%.

Agriculture and Irrigation

HDPE continues to be a key component for modern irrigation systems, such as drip or sprinkler types. High tensile strength assures that it will withstand usage for long periods, including during exposure to ultraviolet radiation and varying pressure. Such endurance further enables efficient irrigation and reduces frequent replacement of the equipment.

Mining and Slurry Handling

The mining industry depends on HDPE for transferring abrasive and corrosive slurries. Its resistance to wear is far superior to that of more conventional materials such as steel and concrete. HDPE pipes help to reduce downtime and repairs, especially in tough situations involving high-solid-content fluids.

Infrastructure and Construction

HDPE is used for stormwater drainage, culverts, and conduits for electrical and telecommunication cables. Its lightweight nature and flexibility enhance installation, making it cheaper relative to conventional materials. Evidence states that installation time for HDPE-based drainage systems is reduced by 40% at most, thus accelerating construction projects.

All such uses further illustrate the versatility of HDPE that plays a vital role in enabling sustainable and cost-effective solutions within various industries.

Specifications of Smooth Wall HDPE Pipe

Material Composition and Resin Quality

High-density polyethylene is a thermoplastic polymer noted for its strong physical properties and molecular structure. HDPE of grade I is produced from ethylene monomers by a catalytic polymerization process forming long chains of hydrocarbons with practically no branching. This unique structure bestows it with a high strength-to-density value, thus preferred for applications that require durability and flexibility. Its composition insures resistance from chemicals, moisture, and stress cracking-a requirement to carry liquefied or gaseous media at high pressure.

End-product performance and life-span, such as that of smooth wall pipes, depend greatly upon resin quality, HDPE being one. According to contemporary manufacturing trends, either virgin resin or high-grade recycled resin should be used. Vinyl HDPE resins assist in achieving higher tensile strength, impact resistance, and thermal stability of pipes by holding very tightly to molecular weights and density. Most first-grade resins are subjected to rigorous testing for melt flow rate-MFR and also for density to meet stringent specifications. Then, stabilized additives such as antioxidants and UV inhibitors can be added by advanced blending techniques to improve the resistance of the base resin against weathering and oxidative degradation.

Using advanced HDPE resins, the pipe design has been enhanced to the point it allows for easily thinner walls without sacrificing the structural integrity of the pipes into material cost. Current modification involves cross-linking technologies and co-polymerization to alter an HDPE’s mechanical properties to best suit its application in fields such as civil engineering, agriculture, and industrial process piping. Furthermore, the constant advancement of resin formulation accommodates both environmental and engineering demands, firmly establishing HDPE as a sustainable and efficient choice in various applications.

Comparison with Other Pipe Types

In most uses, however, HDPE pipes stand superior to PVC and steel pipes in flexibility, durability, corrosion resistance, and environmental impacts while PVC is better for tensile strength and steel for very high pressures.

| Aspect | HDPE | PVC | Steel |

|---|---|---|---|

| Flexibility | Excellent | Limited | Rigid |

| Longevity | 100+ years | Moderate | Short |

| Rust Resistance | High | High | Low |

| Sunlight Proof | Yes | No | N/A |

| Pressure Tolerance | Superior | Average | High |

| Affordability | Medium | Budget | Expensive |

| Mass | Lightweight | Moderate | Heavy |

| Setup Ease | Simple | Standard | Difficult |

| Sustainability | Green | Neutral | Negative |

Benefits of Using Smooth Wall HDPE Innerduct Conduit

Durability and Longevity

Smooth Wall HDPE Innerduct Conduit is highly durable and long-lasting, making it the ideal choice for rigorous applications. Five features lend it even greater durability and longevity:

Corrosion Resistance

HDPE is highly resistant to corrosion through environmental factors of moisture, chemicals, and saline conditions, unlike metallic alternatives. Usually, this ensures that the HDPE conduit stays useful in a particular environment for over a century.

Stiffness against Impact

HDPE has excellent stiffness against impact, not allowing breakage or cracks from dynamic loads or sudden changes in pressure. Its flexibility absorbs shocks that would shatter rigid materials.

UV and Sunlight Stabilization

The presence of UV stabilizers in the material of conduits protects them from degradation from direct exposure to sunlight over longer durations, thereby preventing structural damage outdoors.

Chemical Resistance

The characteristics of hard and smooth wall HDPE makes it capable of withstanding a variety of chemicals such as acids, alkalis, and hydrocarbons and so could be reliably used in industrial and underground locations wherever temperature elevation due to exposure to such chemicals occurs.

Crack and Abrasion Resistance

Smooth Wall HDPE is made to resist the formation of surface cracks due to abrasion or stress so that they give a long life even in high-pressure or abrasive circumstances.

Such features name Smooth Wall HDPE Innerduct Conduit as a fitted solution for long-lasting and sustainable installations.

Cost-Effectiveness and Installation Ease

Smooth Wall HDPE Innerduct Conduit boasts a number of concrete advantages in the cost-cutting and ease-of-installation domains. The said benefits arise from the unique material properties and design features that reduce the labor and material costs while golangly optimize the installation procedures. Highlighted below are five key points that contribute to the innerduct’s cost-effectiveness and ease of installation:

- Lightweight Nature

Being relatively lighter in nature, transporting and handling becomes easier than if it were heavy, like metal or concrete. This further means it takes less time to position during the installation processes, which seals cost-wise.

- Bends and Flexibility

The very high flexibility of the Smooth Wall HDPE conduit means that there is no need to borrow complex jointing or bending equipment much to the ease of routing around obstacles and drastically reduces installation labor

- Thermally Welded Joints

Using heat fusion for making joints in HDPE pipes ensures seamless connections that are quicker to implement and more economical, as no sealing materials or fittings are necessary.

- Compatibility with The Existing Infrastructure

Its ability to be compatible with the existing ducts and conduit systems will minimize possible extended alterations or added equipment and thus save very valuable time and budget during installations or upgrades.

- Extended Service Life Lessen Replacement Costs

Being resistant to corrosion, cracks, and environmental stresses, Smooth Wall HDPE will indeed carry long-term maintenance and replacement costs less, making it an environment-friendly and economic alternate throughout its lifecycle.

These characteristics ensuring that Smooth Wall HDPE Innerduct Conduit will forever be available at the lowest cost while simultaneously maintaining ease and reliability of installation, even in adverse conditions.

Environmental Impact and Sustainability

While designing HDPE smooth wall innerduct conduit with sustainability in mind, many advantages contribute to lessening environmental effects and promoting resource efficiency. Below are five key environmental and sustainability attributes of this goods:

Lower Carbon Footprint

HDPE requires less energy to be produced than other conduit materials such as metal or PVC, meaning that fewer greenhouse gases are emitted during the manufacturing process.

Recyclability

HDPE is recyclable 100% and can be reprocessed time and again without compromising structural integrity; hence supporting circular economy principles and preventing landfills.

Durability and Resource Conservation

Because of its extended lifespan and resistance to natural wear, Smooth Wall-HDPE Innerduct Conduit requires fewer replacements over time, thereby placing less demand on raw materials and energy in production.

Light in Weight

Being lightweight, HDPE limits transportation emissions and energy consumption. Trucks can carry more units on a trip as opposed to heavier conduit materials, hence reducing fuel consumption.

Leakage Contaminant Resistances

Being impermeable, HDPE doesn’t let hazardous materials inadvertently enter the environment. It also stops such leaks in irrigation or utility-protection applications that would otherwise damage nearby ecosystems.

These are the reasons Smooth Wall HDPE is considered a sustainable solution: it works toward environmental preservation, offering support to both industry and ecology.

Applications of HDPE Innerduct in Utility Projects

Cable in Conduit (CIC) Systems

CIC system is regarded as one of the most efficient options when it comes to cable protection and organization for utility projects. CIC systems allow the electrical, communication, or fiber optic cables to reside safely within the strong HDPE conduit, giving good protection against hazards on installation, with several options for the installer to choose from, to maximize installation speed and long-term guarantee. The disadvantage of traditional installation techniques is that sometimes while running cables, they might get damaged or scrapped during the procedure, and these risks are all negated by cable and conduit running together in an integrated structure. Five other main advantages of CIC systems are given below:

- 1

Further Cable ProtectionThe CIC system offers protection to their cables against damage or adverse environmental consequences maybe also through abrasive interaction with the neighboring soil. In other words, the HDPE conduit acts as a protective barrier; thereby, considerably reducing the risk of moisture ingress, impact, or chemical exposure.

- 2

Easy Installation ProcessPre-installed conduit cables require less labor and equipment on site for utility projects. More so, the integrated design allows deployment to proceed at a much quicker pace and cuts down the complexities of pulling cables through separate conduits during installation.

- 3

Cost-EfficiencyCombining the cable and conduit as one product in CIC systems results in a reduction in the cost of the entire project. Reduced number of steps during installation, downtime, and maintenance results in huge cost savings in the lifecycle of the entire project.

- 4

Longer Life Span and Better ReliabilityWith great density and resilience, HDPE materials resist extreme weather conditions such as temperature changes, soil movements, or chemical exposure, thereby assuring increased life span and good performance of the system.

- 5

Applications FlexibilityThe CIC systems offer ample versatility to be adjusted for any kind of utility project, including power distribution lines, telecommunication networks, and fiber installation. The HDPE conduit being flexible and customizable is the best choice for any installation, despite the terrain and environmental atmosphere.

Concerning these benefits, CIC systems offer a smooth transfer for utility projects concerning increased durability, efficiency, and finally, cost-effectiveness.

Broadband Infrastructure Expansion

Expanding broadband infrastructure is essential in bridging the digital divide while maintaining the high-speed internet hurry under demand. The implementation of advanced technologies such as HDPE conduit and Cable-in-Conduit (CIC) systems in infrastructure projects can meet the increasingly demanding requirements of both urban and rural spheres. Here are five more elements and benefits that drive broadband infrastructure expansion:

- 1

Connectivity Being Enhanced in Rural AreasAs a part of the upgrades in the broadband infrastructure, we realize a reduction in the connectivity gap in underserved areas, thus granting reliable Internet access to rural communities. Economic development, access to education, and telemedicine, as well as other useful services, can thus be extended.

- 2

High-Speed Data TransmissionTomorrow’s broadband systems are made for highly data-intensive applications. Giving fiberoptic cables a strong conduit always ensures top-notch speed performance demanded by commercial establishments, schools, and homes that require streaming, cloud computing, and communication-based tools.

- 3

Environmental AdaptationOptimized for hostile environmental conditions like temperature, floods, and erosion using materials such as HDPE, broadband networks will stand for such terrains.

- 4

Cost-Effective ExpansionPreinstalled CIC systems save time during installation and therefore save on ALL the labor costs involved, thus offering a cheaper way to disseminate broadband networks and reduce financial barriers for fast-growing infrastructure.

- 5

Scalability for Future GrowthModern broadband solutions are designed not only to incorporate yet-to-be-defined upgrades but also to harmonize with future technology. One major aspect of this scalability is the ability to simply integrate future technologies such as 5G with minimal infrastructure disruption.

In these areas, broadband infrastructure expansion will nourish economic development, ensure the progress of technology, and provide equal access to the fiber-optic internet for all.

Drainage Systems and Utility Ducts

Drainage systems and utility ducts are of utmost importance for present urban setting to assure good water really management and the safe contraceptives for cables, phone wires, gas lines, or maybe any other specific set of utilizations. In addition, if there is a drainage system that can keep water in the streets during heavy rains or flooding from the streets and buildings, it will save these from water damages and concurrently also put a health hazard on it due to stagnant water acting as the breeding grounds for the insects that carry diseases. Applying stormwater management principles with permeable surfaces and retention basins among others to control runoff will further alleviate pressure on municipal drainage systems.

Utility ducts, usually installed along with drainage infrastructure or by themselves as conduits, give a safe and organized means of routing crucial services past urban areas. The ducts are prepared to shield cables and pipes from environmental conditions, mechanical harm, or even intruders. New-age utility duct systems have been made stronger for corrosion resistance, primarily reinforced concrete or HDPE, to assure the longevity of these infrastructures. Their modular systems make them easier for upgrades and maintenance, thus reducing interruptions in urban areas.

With advancements in technology like GIS and intelligent monitoring sensors, optimizations of one system have become interchangeable with a similar reason to optimize the other-geographical locations of drainage systems and utility ducts. GIS allows planners to select the least environmentally intrusive and space-efficient siting locations, while these real-time sensors supply information on the operational aspects of the systems, such as flow rates, blockages, or structural deterioration. Consequently, this information-based reliability and resilience improvement for a system makes urban infrastructure more capable of meeting tomorrow’s requirements imposed by population growth, climate change, or technological progress.

Comparing Smooth Wall HDPE Pipe to Other Materials

Advantages Over PVC and Steel Pipes

HDPE pipe walls smooth, whereas PVC and steel pipe walls have to cope with abrasion, fatigue, and chemical corrosion. It is considered with proper treatment, HDPE pipes may function for 50 to 100 years in contrast to steel pipes rusting with time and PVC degrading due to long exposure to UV rays.

Flexibility and Strength

In terms of ductility, HDPE pipes are extraordinarily high and is flexible enough to allow for any movement of the ground in seismic activity and thermal expansion. In contrast to PVC pipe systems, which are brittle, and steel pipes, which under stress would maintain deformity, HDPE pipes bounce back to an initial deformation without sustaining damage.

Lightweight and Easy Installation

Light from steel, HDPE pipes being lighter makes its transport and installation more cost-efficient. Another feature that offers time and labor cost savings during installation is less number of fittings needed because of HDPE’s flexibilities as opposed to those systems made up of PVC and steel.

Leak-Free Jointing System

HDPE pipes use heat fusion techniques to produce strong and thick joints with no leakage, which is a common problem with steel pipes whose joints are basically threaded or welded; and PVC pipes whose joints are essentially solvent-welded or gasketed.

Resistance to Chemicals and Corrosion

HDPE is resistant to a wide variety of chemicals, and therefore, HDPE is used in many corrosive or acidic applications where PVC materials gradually degrade and also where steel, on the other hand, rusts, especially under moist conditions or in the presence of some kinds of salts. This resistance also ensures low-maintenance levels and increased service life.

Performance in Adverse Conditions

High-Density Polyethylene (HDPE) pipes afford great performance in unfavorable environmental conditions, thus making them the pipes of choice for critical applications. HDPE, by nature, is a flexible material and may bend or flex gently with ground movements arising from seismic activity, soil settlements, or frost heaves, without cracking or rupturing. This flexibility is of great advantage in earthquake-prone regions and those with highly variable climatic conditions where PVC or steel pipes may grow old and suffer brittle disintegration. Also, due to the low coefficient of thermal conductivity exhibited by HDPE, there exists less opportunity for heat loss or heat gain and hence better efficiencies are obtained, especially when the application demands extreme temperature differentiation.

HDPE remains highly resistant to impacts even at sub-zero temperatures, providing survival capacity under cold conditions. That is unlike materials that lose their toughness and fracture when exposed to freezing temperatures, HDPE sustains its integrity and thus becomes a very trustworthy material for water, gas, and sewage conduits under cold climates. Further, resistance to degradation brought on by ultraviolet (UV) radiation lengthens the operating life of the pipe laid above ground without the necessity of other protective coatings or heavy maintenance.

HDPE combined with resistant characters, shows long-term reliability when an aggressive chemical environment, for example, high salinity or acidic soils is present. For instance, HDPE pipes will remain functional and intact for the better part of decades in an industrial setup or coastal setup where corrosive threats exist. Advances in technology have greatly enhanced the performance of HDPE, both by increasing in material composition and manufacturing techniques, highlighting again that it is strongly favored as one of the best practical, cost-effective, and sustainable materials for more demanding infrastructures.

Configurations for Specific Applications

When selecting HDPE pipes for any specific application, diameter, wall thickness, and pressure rating are essential factors to consider. These are adjusted according to the working conditions and project requirements. For example, pipes with thicker wall constructions are considered suitable for high-pressure systems, which ensure safety and durability by resisting internal forces. Likewise, the selection of pipe size is based on flow rate, which is of utmost concern to urban water supply systems or large irrigation schemes. These possibilities thus allow HDPE pipes to offer a highly customized solution that possesses versatility for all kinds of industrial and civil applications.

Other configurations of HDPE pipeline are dictated by the kind of jointing method required for a particular project. Between butt fusion and electrofusion, two of the most widely used methods, a leak-proof and corrosion-resistant bond is established. With long pipeline runs generally being butt-fused in open spaces, electrofusion is preferred for confined spaces or when joining onto existing infrastructure. Knowledge of these techniques enables optimal engineering solutions consistent with the constraints and needs of particular operational environments.

Anything like atmospheric condition affects an acceptable HDPE pipe formation. UV stabilization is present in the material to provide durability when placed outside under exposure from sunlight for long hours. In underground cases, proper bedding and backfilling must be arranged so that loads from soils and stresses from the environment will be minimized. These considerations being properly addressed will make HDPE pipes a really versatile solution suitable to potable water systems, chemical transport systems, and so on.

References

- 2D-2 – Storm Sewer Sizing (Iowa State University)

This document discusses various pipe materials, including HDPE pipes with smooth walls, and their applications in storm sewer systems.

- The Basics of Agricultural Tile Drainage (University of Wisconsin)

This resource covers the use of smooth wall HDPE pipes in agricultural drainage systems, including their design and functionality.

- Pipe Installation | Highway Knowledge Portal (University of Kentucky)

This article provides insights into the installation and characteristics of HDPE pipes, including smooth interior designs.

- SCDOT Pipe Installation and Acceptance (Tri-County Technical College)

This document outlines standards and specifications for HDPE pipes, including smooth wall types, used in construction projects.

- Does a Smooth Bore Pipe Have More Capacity? (Cornell University)

This source compares the capacity of smooth bore pipes, such as smooth wall HDPE, to other types, providing technical insights.

Frequently Asked Questions (FAQ)

Q: What is a smooth wall HDPE pipe?

A: A smooth wall HDPE pipe is a type of high-density polyethylene pipe that possesses a smooth inner surface, thus reducing friction loss between the fluid and the pipe during flow. It is used extensively in different applications, including water distribution and underground utilities.

Q: What are the advantages of using smooth wall HDPE pipe?

A: Some advantages offered by smooth wall HDPE pipes are their ability to offer better resistance to corrosion, being lightweight, and flexibility. They also provide long-term protection to underground cables and are pressure-rated for a variety of applications.

Q: What sizes are available in smooth wall HDPE pipe?

A: Smooth wall HDPE pipes come in a variety of sizes issued for varying SDR ratings like SDR 13.5. It can vary from a small diameter for residential usage to a large diameter for industrial usage.

Q: How do smooth wall HDPE pipes differ from corrugated HDPE pipes?

A: Since the smooth wall HDPE pipe has a smooth interior to reduce friction, the corrugated HDPE pipe is ribbed to develop strength and flexibility. Selecting one of the two types depends mostly on the requirement of a special project or an application.

Q: What standards are followed by smooth wall HDPE pipes?

A: Smooth wall HDPE pipes are manufactured following a string of specifications, including ASTM D3350 and ASTM F-2160. These standards assure the pipe in reliability and performing under different applications.

Q: Are smooth wall HDPE pipes used for optical fiber cables?

A: Yes, smooth wall HDPE pipes can be utilized for conduiting the optical fiber cables. The smooth interior protects the cables with ease while allowing installation and maintenance.

Q: What does smooth wall conduit of Dura-Line do in cable applications?

A: Dura-Line’s smooth wall conduit is specifically designed to meet or exceed standards for cable installation instead of working as an accepted code. It offers a pathway for cables to be laid down while withstanding the wear and tear from ambient conditions.

Q: What is the significance of cell classification in HDPE pipes?

A: Cell classification refers to the grouping of polyethylenes according to their physical and performance characteristics. Smooth wall HDPE pipes ensure that all materials used conform to requirements for strength and durability.

Q: How are smooth wall HDPE pipes extruded?

A: Smooth wall HDPE pipes are extruded by heating high-density polyethylene resin and forcing it through a mold of a specific pipe shape and dimensions. This maintains uniformity and consistency of the product.