The efficiency, comfort, and grace with which the systems evenly disseminate heat in the residential and commercial environment have led to the downgrading in popularity of underfloor heating. The best pipe solutions allow for the utmost performance, durability, and reliability of a system. PE-RT pipes are considered to be among the most efficient and versatile options in this regard. This article walks through the technical benefits and the underpinning reasons as to why PE-RT pipes are the solution used with underfloor heating and an array of modern heating solutions. If you are a designer, contractor, or homeowner eager to make informed choices, this guide will help you understand the critical role PE-RT pipes play in ensuring efficient heat distribution and long-lasting performance.

What is PE-RT Pipe?

Definition and Composition of PE-RT Pipe

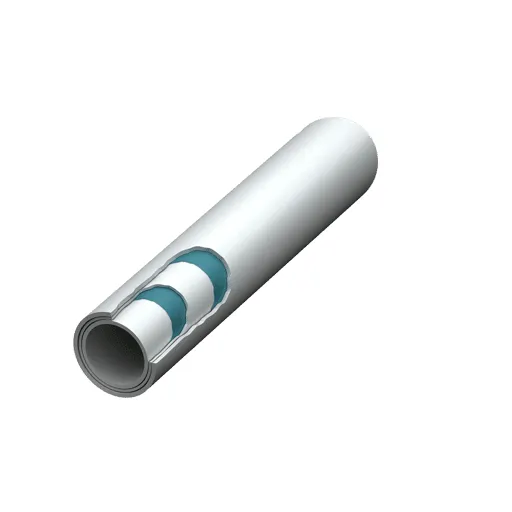

PE-RT pipe is a special kind of polyethylene pipe that is designed to resist high temperatures, thus rendering it desirable for heating applications. The resin in PE-RT pipes is formulated to offer excellent heat resistance without compromising flexibility and durability. This uncommon mix of qualities is a result of tight control over ethylene and comonomer molecules in the production process, allowing the material to withstand thermal stress.

The PE-RT pipe’s primary composition traces its roots back to polyethylene material endowed with properties that protect against raised temperature levels. Thus, it resists extended exposure to elevated temperatures, usually up to 180°F (82°C), without any damage to performance or structural integrity. A PE-RT pipe keeps itself corroding and chemically neutral, thus unable to bear losing in front of substances like oxygen or ordinary heating system chemicals. Its ability to bend supplies flexible installations even in tricky designs and locations.

These pipes are manufactured to very high standards and conform to ISO 22391 and ASTM F2769 for use in underfloor heating systems and other high-temperature applications. The durability of these pipes increases their life and lessens all leakage or failure chances in heating installations. Because of the thermal capability and adaptability of these pipes, PE-RT pipes have become a favored choice in today’s installations of underfloor heating and radiant heating.

Unique Features of PE-RT Pipe

PE-RT pipes acquire several unique features, which make for utility in modern heating and plumbing systems. Among their characteristic features is flexibility; hence, easy installation is one of the rigid alternatives. This flexibility helps the pipes to maneuver through tight spaces and complex layouts because of which is best for less labor and installation time.

The second feature is thermal stability and withstanding heat. These pipes can operate continuously at a temperature of 203°F (or 95°C), allowing underfloor heating systems and hot water distribution networks to fully rely on them. Stress stability of the pipe goes alongside it being made according to a robust process, subjected to certification like ISO 22391 and ASTM F2769, which is an excellent example of standard specs for quality and performance.

Finally, PE-RT pipes further great resistance to corrosion, scaling, and wear and tear through the durability and chemical resistance that they offer, thus guaranteeing a longer operating life, minimal maintenance, and reduced system cost. Their environmental performance is also great since PE-RT material is recyclable, thus endorsing sustainability in construction activities. Combined, these qualities make PE-RT pipes an extremely high-performance yet economical option in modern infrastructure applications.

Comparison with Other Piping Solutions

The comparison between PE-RT pipes and PEX, CPVC, copper, and traditional polyethylene pipe is based on flexibility, temperature resistance, cost, recyclability, and installation ease.

| Feature | PE-RT | PEX | CPVC | Copper | Polyethylene |

|---|---|---|---|---|---|

| Flexibility | High | Moderate | Low | Low | High |

| Heat Tolerance | High | High | Moderate | High | Low |

| Affordability | Moderate | Moderate | Low | High | Low |

| Recyclable | Yes | No | No | Yes | Yes |

| Ease of Setup | Easy | Moderate | Moderate | Difficult | Easy |

| Longevity | High | High | Moderate | High | Low |

| Rust Resistance | Yes | Yes | Yes | No | Yes |

| Eco-Benefits | Yes | No | No | Yes | Yes |

A quick and clear comparison of PE-RT pipes and other general piping solutions with respect to important aspects is presented in this table.

Benefits of Using PE-RT Pipe

Durability and Longevity

PE-RT pipes show great durability and serviceability when compared to other pipe materials. Performance and reliability can be considered the result of two factors: materials engineering on one hand and inherent material properties on the other. As such, here are five essential characteristics for the durability and service life of PE-RT pipes:

- Thermal Resistance: PE-RT pipes do have better thermal stability, so they can withstand temperatures as high as 180°F (82°C) at long-term applications in hot and cold water delivery systems.

- Stress Crack Resistance: PE-RT pipes are engineered to be more flexible and have better stress crack resistance than others, thus functioning efficiently under pressure and lessening the possibility of material fatigue or sudden failure with time.

- High Flexural Strength: These pipes have very good flexural strength and can withstand mechanical stresses during installation and working without destruction.

- Corrosion Resistance: Unlike metal pipes, PE-RT pipes cannot corrode due to water or chemical additives, and thus increase the lifespan within a variety of settings.

- Low Material Degradation: The polyethylene base, aided by the high-temperature resistance property, ensures very little degradation of materials over decades and maintains uniform performance throughout its life span.

On this account, such properties make PE-RT pipes suitable for the application and often present durability and life expectancy beyond the industrial standards. Thus, their excellent qualities make them a trustworthy option for modern piping solutions.

Flexibility and Ease of Installation

The PE-RT piping system provides extraordinary potentials for flexibility and ease of installation, making it preferable for various applications. These are the five attributes that majorly give it superior performance during installation:

- Versatility: PE-RT pipes have exceptional flexibility and require fewer fittings and connections, thus allowing for longer continuous pipe runs, which may further minimize leakage points and installation time.

- Light in Weight: Being much lighter, PE-RT pipes can be handled and transported even in difficult field environments. This evidently reduces labor costs and further increases the speed of installation.

- Compatibility with Existing Systems: Crafted to be compatible with existing plumbing and drainage systems through standard fittings and tools, PE-RT pipes are thus installed without any hassles.

- Resistant to Thermal Expansion and Contraction: The material’s stability for enough time under changing conditions of temperature negates the compensator or additional installation adjustments; hence, structural integrity is borne with time.

- Ease of On-Site Shaping: Being made for shaping directly at the construction site, PE-RT pipes ease installation, especially when complex layouts are involved, and continue to be structurally and functionally reliable.

All these collectively lower the installation complexity and costs while ensuring long-term reliability, making it through a vast range of operating conditions.

Cost-Effectiveness in the Long Run

Though a myriad of advantages would contribute to the economic and operational benefits of PE-RT piping systems over lengthy periods of use, five such factors that assist in defining their cost efficiency will be looked into further:

- Lower Initial Material Cost: The advanced materials from which PE-RT pipes are produced are cheaper than conventional metallic piping system materials. This brings down the procurement cost while ensuring durability and serviceability.

- Lower Installation Cost: Being lightweight and flexible in nature makes PE-RT pipe handling and installation simple. Such an approach discards the use of heavy machinery or specialized tools and thus greatly brings down labor costs and time for installation.

- Excellent Resistance to Corrosion and Scaling: Unlike metallic counterparts, polyethylene PE-RT pipes are less prone to corrosion and scaling, thus avoiding expensive chemical treatments and regular maintenance. This factor ends up lowering the operational costs in the longer term in systems where water requirements are much stricter.

- Extended Service Life: By design, PE-RT pipes can withstand higher temperatures and pressures without degradation. Hence, due to an extended life not least 50 years under usual working conditions, the occurrences of replacement and maintenance are far reduced.

- Energy Saving: Being a thermally insulated material, PE-RT offers minimum heat loss in hot water installations, thus conferring the best situation for implementing energy conservation as time goes by. Huge money can therefore be saved on energy bills for applications such as domestic heating or industrial-grade fluid transportation.

These factors continue to clearly emphasize the PE-RT pipes as being cost-efficient in the long run; thus, they are preferred choices for modern piping across various industries.

Applications of PE-RT Pipe

Plumbing Systems

Apart from their adaptability, flexibility, and versatility in providing thermal solutions, PE-RT pipes are one of the desirable pipes for the modern plumbing setup. These pipes are manufactured in a way that allows them to operate under different temperature and pressure conditions, thus cementing their utility in many domestic and commercial applications. Below is a detailed list charging five specific uses of PE-RT pipes for permissible plumbing installations:

Hot and Cold Water Distribution

The PE-RT pipe is best suited for supplying hot and cold water. It resists thermal expansion and contraction so that under continuous cycles of increasing and decreasing temperatures, these pipes will retain their design life. Studies have also shown that PE-RT pipes have less heat loss than conventional materials, so that energy efficiency for the delivery system of water increases.

Radiant Floor Heating Systems

PE-RT pipes cater to the transmission of hot liquids, being used mainly for underfloor heating. Thanks to their internal smoothness, pressure loss is kept to minimum; their flexibility eases installation under floors. The pipe systems help in keeping the heat exchange uniform for comfort and energy savings.

Potable Water Distribution

PE-RT pipe systems meet severe hygienic standards for the transportation of potable water. Corrosion resistance and inert material nature would assist in ensuring contamination never gets to the water; thus, the water is clean and safe for domestic use. Also, PE-RT systems would help minimize future maintenance and replacement costs.

Hydronic Heating and Cooling Systems

These pipes find extensive application in hydronic heating and cooling because of their greater thermal conductivity and stress-crack resistance. Temperature variations are kept constant by the PE-RT systems in residential, commercial, and industrial environments, hence promoting energy efficiency and better comfort levels.

Hospital and Healthcare Water Systems

Hospitals and health centres being critical environments require durable and reliable solutions. The pipes being non-corrosive ensure that water or medical-grade fluids flow uninterrupted without contamination risks; hence, they satisfy the strictest safety and performance requirements of any installation.

Such versatility and strength of PE-RT pipes make them the hardest potential solution to present problems relating to plumbing, thus placing a higher emphasis on performance in another application while opening up a cheaper solution over time.

Heating Applications

Due to their thermal stability, durability, and efficiency, PE-RT pipes find widespread use in heating systems. These pipes work efficiently at high temperatures and find their application in a huge array of other processes. There are five peculiar heating purposes where PE-RT pipes have an advantage:

- Underfloor Heating Systems: PE-RT pipes are employed in radiant floor heating systems. Their flexibility and thermal conductivity allow the efficient distribution of heat over large floor surfaces that would otherwise consume a lot of energy to be kept within a comfortable indoor temperature.

- Hydronic Radiator Connections: For hydronic heating systems, PE-RT pipes have always been a good choice for connections to the radiators. They afford the thermostat long life, and leak-proof service under high operating temperatures and pressures.

- District Heating Networks: District heating systems employ PE-RT pipes to discharge hot water or steam to residential or industrial zones. Their high thermal resistance and advanced durability ensure bearing little maintenance, perhaps ever, and surviving over an extended time in highly demanding environments.

- Geothermal heating systems: This set of pipes is best suited for the manufacturing of geothermal heating systems. They perform well at transferring heated water or transferring energy from geothermal sources; temperature fluctuations are withstood, causing them to perform consistently underground.

- Snow melting systems: PE-RT pipes are highly suited for snow and ice melting systems in outdoor applications such as driveways, sidewalks, and sports arenas. Their strength in sub-zero temperatures values the transfer of heated fluids to remove ice formations safely and truly.

The use of PE-RT pipes in these applications highlights the technological capabilities that make them most suitable for modern heating systems with efficient energy consumption. When these pipes are submitted to thermal stress, the ability to consistently perform is what sustains the heating systems.

Underfloor and Radiant Heating Solutions

Contemporary climate control in any modern building has underfloor heating as one of its highest expressions. Heat is evenly distributed into the surrounding atmosphere by conduction by circulating warm water through a system of pipes embedded within the floor or by electric heat generation. PE-RT pipes are preferred in these installations due to their extreme flexibility and resistance against thermal stress, which also makes installation easy and assures a long life.

These thermal studies finally give room to suggest about 15% energy savings that could be realized by employing underfloor heating systems over conventional forced-air systems. The operational temperatures under underfloor heating are lower when maintaining the same degree of thermal comfort since heat is generated all through the floor surface; thus, this system ensures higher efficiency. Additionally, the efficient operation of this system is guaranteed by the fact that in low-temperature radiant applications, the use of PE-RT pipes results in extremely low heat loss.

Theoretically, advanced thermostatic controls present the opportunity to design systems for zoned heating, whereby energy is saved by concentrating it solely on a few areas in a building. In the long term, the service life and flexibility of PE-RT pipes for underfloor provisions make them an indispensable part of any sustainable and energy-efficient heating solution for residential and commercial purposes.

Comparative Analysis: PE-RT vs. PEX and CPVC

Advantages of PE-RT over PEX Pipe

The PE-RT allows better recyclability than other options, easier installation, and no crosslinking, along with lower energy consumption in production, and also with comparable flexibility and durability.

| Feature | PE-RT | PEX |

|---|---|---|

| Recyclable | Yes | No |

| Installation | Easier | Moderate |

| Crosslinking | Not Needed | Required |

| Energy Use | Lower | Higher |

| Flexibility | High | High |

| Durability | High | High |

| Eco-Friendly | Yes | No |

Disadvantages Compared to CPVC

With respect to heat resistance, the PE-RT is far inferior compared to CPVC; it also has lower pressure ratings and chemical resistance.

| Feature | PE-RT | CPVC |

|---|---|---|

| Heat Tolerance | Moderate | High |

| Pressure Limit | Lower | Higher |

| Chemical Resist. | Moderate | High |

| UV Resistance | Low | High |

| Durability | Moderate | High |

Choosing the Right Pipe for Your Needs

In selecting the pipe material for a specific job, I have to consider a few variables for it to perform properly and for the expected life span. Usually, factors considered in making the selection according to the application are the environment in which it is to work, the budget, and the working conditions imposed by the system. For example, CPVC could be an acceptable alternative in applications where fluids at high temperatures or with resistance to chemicals may be conducted. Being highly UV-resistant and very durable, it works well outdoors or in locations of maximum demand.

To the contrary, PE-RT comes into consideration when installation is a breeze, flexibility counts, and the budget is a constraint. The flexibility of the material results in faster installations, demanding less work while satisfying serious performance requirements under moderate temperatures and pressures. However, it fails in dealing with aggressive chemicals and prolonged exposures under direct sunlight unless a higher level of stress and durability demands are considered.

The choice depends upon the thorough assessment of details particular to the project. CPVC will always be the ultimate choice for the long-term reliability of demanding systems. However, for smaller job applications with fewer stress requirements or in cases where budget holds primary concern, PE-RT can be perfectly well utilized. If these factors are adequately weighed, one can be assured of choosing the product that addresses the need at present and also stands the test of time.

Current Trends and Innovations in PE-RT Pipe Technology

Recent Developments in PE-RT Manufacturing

In recent PE-RT (Polyethylene of Raised Temperature Resistance) manufacturing developments, polymer engineering innovations have been utilized to improve material performance and system efficiency. An important innovation has been the use of advanced catalyst types during the polymerization reaction. These catalysts provide better control of molecular weight distribution and branching in polymer chains, thus imparting better thermal resistance, flexibility, and durability.

The advancement in extrusion techniques, on the other hand, ensures the production of multi-layer PE-RT pipes with walls varying in thickness and homogeneity at will, and so they minimize defects in the material while improving hydraulic function. This is backed by stringent quality control procedures based on in-line scanning and real-time monitoring technologies to maximize consistent product integrity.

Moreover, other practices also include working with sustainable methods of keeping recycled polymers and reducing energy consumption in production. Thus, these innovations follow a set of environmental standards while offering cost-efficient methods of production without compromises on quality. Under these advancements, PE-RT becomes an extremely adaptable material in modern piping applications, even under high temperature and high stress.

Industry Trends Impacting PE-RT Usage

Changing trends in construction and plumbing greatly influence the effective emergence of demand for and application of PE-RT piping systems. One interesting aspect is the more recent emphasis on decarbonization in the building industry. Regulatory frameworks involving products and systems with the least carbon footprint could be given preference, are encouraging energy-efficient materials, whereas PE-RT, being lightweight, with lesser emissions during production, fits the bill perfectly. Further, underfloor heating has been on the upswing due to green building and preference for efficient thermal transfer systems, thus providing an increased level of applications to PE-RT pipes because of their very good flexibility and resistance to temperature changes.

Another factor shaping PE-RT use is this emphasis on longevity and life-cycle performance of piping materials. Systems that will have the lowest probable maintenance costs and are not likely to fail under extreme usage are the developers, a domain where the durability and temperature resistance of PE-RT stand out. Manufacture improvements have further increased the polymer’s resistance against creep and stress fractures, thus making it preferred more and more for high-demand applications.

Finally, with all pressures on the global supply chain and varying material costs, more demand is being created for materials that are readily available and adaptable, such as PE-RT, capable of providing versatility without affecting quality or performance. In addition to fusion joints, PE-RT is compatible with conventional piping systems, providing a very cost-effective option as the fluctuations in market conditions continue, hence maintaining its relevance to various end uses.

Future Prospects for PE-RT Pipes in Construction

The PE-RT pipes find affinity for the construction trades mainly due to their versatility, economic factors, and reliable efficiency. Being favored as the greener choice, growing sustainable building practices are advocation toward PE-RT piping systems, given that the materials used for pipes are recyclable and consume lower energy in the manufacturing process compared to metallic systems. The material itself has the properties of being able to resist heat and pressure, thereby allowing it to be used for advanced underfloor heating and efficient hot water delivery.

Market data shows that demand shows higher adoption of PE-RT pipes as considered by the manufacturers, giving rise to demand for light-weight and durable piping solutions that would be easily installed in residential, commercial, and industrial projects. Innovations in extrusion techniques and polymer formulation are expected to broaden the operational temperature range and improve the lifespan of PE-RT pipes, further cementing the role of these materials in modern methods of construction. Furthermore, regulatory frameworks emphasizing the use of non-corrosive and energy-efficient materials for the next generation of plumbing and HVAC systems would further strengthen the growth of the PE-RT market.

Worldwide, the major growth in urban infrastructure projects in emerging economies and the equally major refurbishment work in mature markets present significant opportunities for growth. PE-RT is of strategic importance in the development of energy-efficient building solutions, in accordance with current standards, because it can be easily laid out in different plumbing patterns and can be used with renewable energy systems such as solar water heaters.

Frequently Asked Questions (FAQ)

Q: What is a PE-RT pipe, and what are its applications?

A: The PE-RT pipe, an abbreviation for polyethylene raised-temperature resistance pipe, is a highly flexible plastic pipe intended for various applications ranging from water supply to plumbing. It is perfect for hot and cold water systems and hence suitable for use in residential and commercial buildings.

Q: How does the PE-RT pipe differ from other types of plastic pipes?

A: In comparison, PE-RT pipe possesses better flexibility over other types of plastic pipes, such as HDPE or PE,X and is specifically designed to resist high temperatures; hence, it is best suited for heating pipe systems and radiant heating systems where its resistance to high temperature is of utmost importance.

Q: What are the advantages of PE-RT tubes in water distribution systems?

A: PE-RT tubing has several other advantages with water distribution systems: excellent resistance to slow crack growth, non-toxic characteristics, and an easier installation process. Its flexibility simplifies the routing around obstacles, hence minimizing the need for fittings.

Q: Can PE-RT pipe be used for heating applications?

A: Absolutely! PE-RT pipe is most suitable for heating applications such as PEX floor heating and radiant heating system installations. Being high-temperature resistant, PE-RT can be used for both hot water and heating applications.

Q: What is the standard specification for polyethylene of raised temperature resistance?

A: The specification standard for polyethylene of raised temperature resistance defines the criteria for the material properties and performance and standard test methods, thereby ensuring that the PE-RT pipe is sufficiently qualified for legal use as a plumbing material in the market.

Q: How are PE-RT pipes manufactured, and what kind of raw materials are used in their making?

A: PE-RT pipe uses a very high-quality polyethylene resin, specially formulated for elevated temperature applications. Advanced extrusion techniques make the product, ensuring uniformity along with performance in differing set-off scenarios.

Q: What makes PE-RT an excellent pipe to supply potable water?

A: Since PE-RT pipe is non-toxic and satisfies all safety standards, it is ideally used in supplying pure water. PE-RT pipe does not leach any harmful substances into the water, thereby keeping the drinking water safe for human consumption.

Q: What does one do for the installation of PE-RT pipe within plumbing systems?

A: Installing PE-RT pipe within plumbing systems is, to say the least, an easy task since the pipe is flexible and uses hot melt connections. It is best to get advice from a professional plumber for careful installation techniques compliant with all local codes.

Q: What sizes the PE-RT pipe are available?

A: The PE-RT pipe is manufactured under various nominal sizes for different plumbing applications. These options for sizing allow for the design of water distribution systems around the specific needs for residential and commercial projects.

References

- ASME Digital Collection: PE-RT: A new class of polyethylene for industrial pipes – In support of PE-RT in the domain of industrial and domestic piping.

- ASME Digital Collection: Advanced Applications for HDPE Pipe With New PE-RT Material – Describes the expansion of the HDPE pipe into new applications using PE-RT.

- ScienceDirect: Experimental study on the thermostable property of aramid fiber reinforced PE-RT pipes – Explores the thermostable properties of PE-RT pipes under high-temperature conditions.

- ASME Digital Collection: Assessing residual stresses in PE-RT pipes and annealing temperature sensitivity analysis – Studies are made regarding the residual stresses in PE-RT pipes and annealing temperature sensitivity.

- ScienceDirect: Enhancing the performance of flexible pipeline materials through PE-RT nanocomposites – Investigates nanocomposites to improve the performance of the PE-RT materials.