Key Features of DR11 HDPE Pipes

Material Composition

DR11 HDPE pipe has been manufactured from a set grade of polyethylene resin known as PE4710. This resin has been chosen for its high performance, which ensures that the product gains strength and durability under the stress of heavy working conditions.

Key Material Benefits:

- Chemical Resistance: Resists cracking from chemical corrosion and abrasive materials

- Thermoplastic Properties: Can be remelted and reshaped for installation flexibility

- Environmental Stress Resistance: High resistance against temperature and pressure variations

- Hydrostatic Strength: Maintains structural integrity over decades of use

- Lightweight: Reduces transportation and handling costs compared to steel or concrete

- Eco-Friendly: Non-toxic and recyclable at the end of service life

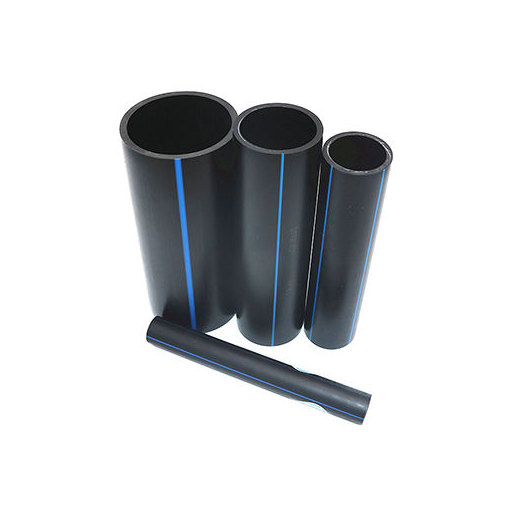

Pressure Ratings and Sizes

DR11 HDPE pipes are designed to sustain very high pressure while being durable and reliable over time. The pressure rating depends on the pipe’s dimensions, especially the wall thickness about the outside diameter of the pipe.

| Specification | Range/Rating | Application |

|---|---|---|

| Pressure Rating | Up to 160 PSI | Medium to high-pressure applications |

| Diameter Range | 2 inches to 54 inches | Residential to industrial scale projects |

| Custom Sizes | Above 54 inches | Large-scale municipal and industrial projects |

Unique Characteristics of DR11 Pipes

- High Pressure Rating: Suitable for intense applications requiring robust performance

- Balanced Design: Optimal balance between rigidity and flexibility

- SDR 11 Rating: Consistent wall thickness to diameter ratio for pressure resistance

- Chemical Durability: Superior resistance to corrosion and physical wear

- Installation Flexibility: Compatible with trenchless techniques like directional drilling

- Dynamic Stress Absorption: Handles vibrations without cracking or bursting

- Environmental Sustainability: Recyclable with long service life

Applications of DR11 HDPE Pipes

Water Distribution Systems

Due to their incomparable hydraulic performances and long-term sustainability, DR11 HDPE pipes form the backbone of modern water systems.

Water Distribution Advantages:

- Smooth Internal Surface: Reduces friction and energy consumption in pumping systems

- Flexibility: Absorbs pressure surges and ground movements efficiently

- Corrosion Resistance: No rust or scale development, maintaining water quality

- UV Resistance: Suitable for underground and above-ground installation

- Leak-Free Joints: Fusion welding eliminates water losses

- Economic Benefits: Lower transportation and installation costs

Gas Pipeline Installations

Gas pipe installation requires materials with exceptional safety, efficiency, and longevity capabilities. DR11 HDPE pipes excel in natural gas transportation due to their superior mechanical properties.

| Feature | Benefit | Impact |

|---|---|---|

| Seamless Fusion Welding | No leak points | Enhanced operational safety |

| High Pressure Resistance | Regulatory compliance | Reliable high-pressure service |

| Lightweight Design | Reduced installation time | Lower equipment and labor costs |

| Soil Compatibility | All soil conditions | Versatile environmental installation |

Industrial Uses and Versatility

Pipeline systems serve advanced applications across multiple industries due to their tough design, efficiency, and adaptability.

- Energy Distribution: Natural gas supply to power generation, residential, and industrial areas

- Chemical Transport: Carrying raw materials like ethylene, propylene, and ammonia

- Water Management: Urban and agricultural water distribution

- Advanced Monitoring: Compatible with IoT sensors and real-time analytics

- Predictive Maintenance: Integration with modern control systems

Advantages of Using DR11 HDPE Pipes

Flexibility and Ease of Installation

DR11 HDPE pipes are renowned for their exceptional flexibility, allowing them to bend and shape according to natural topology and challenging terrain without losing structural integrity.

Installation Advantages:

- Terrain Adaptability: Conforms to soil movement, seismic activity, and uneven ground

- Reduced Fittings: Fewer joints are needed compared to rigid materials

- Lightweight Handling: Easy transportation and positioning

- Long Continuous Lengths: Available in coiled or straight sections

- 90% Joint Reduction: Compared to conventional materials

- Seamless Joining: Fusion welding provides leak-free connections

Corrosion Resistance and Longevity

The corrosion resistance of DR11 HDPE pipes is essential for ensuring performance and durability across multiple applications.

| Resistance Type | Capability | Service Life Impact |

|---|---|---|

| Chemical Resistance | Acids, bases, salts | No degradation in aggressive environments |

| UV Resistance | Prolonged sunlight exposure | Maintains integrity above ground |

| Temperature Cycling | Thermal expansion/contraction | Prevents stress-induced failures |

| Abrasion Resistance | Internal fluid flow wear | Extended operational life |

Cost-Effectiveness Compared to Traditional Materials

Cost-benefit analysis shows significant advantages of DR11 HDPE pipes over conventional materials like concrete, steel, or ductile iron.

Short-term Cost Benefits:

- Lower installation costs due to lightweight properties

- Minimal machinery requirements compared to rigid materials

- Reduced labor time and effort

- Lower transportation costs

Long-term Economic Advantages:

- Minimal maintenance requirements

- No corrosion-related repairs

- Extended asset longevity

- Reduced water loss through leak-free joints

- Lower life-cycle costs

Installation Processes for DR11 HDPE Pipes

Step-by-Step Installation Guide

Preparation of the Worksite

Visit the installation site to locate hazards, assess soil conditions, and identify existing utilities. Make excavations according to local safety and construction codes with dimensions suitable for the pipe and required bedding.

Trench Specifications:

- Width: Minimum 1.5 times the pipe diameter

- Depth: Pipe diameter plus 6 inches (150 mm) minimum bedding material

Material Inspection

Conduct a thorough inspection of all pipes and fittings to detect physical damage or defects before installation. Ensure pipes are free from foreign materials with square-cut ends for proper joining.

Placing the Bedding

Prepare an even bedding layer with granulated material or sand. Ensure proper load distribution and prevent localized stresses. Compact bedding material to at least 90% of maximum density per standard proctor test.

Pipe Handling

Use specialized equipment and lifting devices designed for HDPE pipes to prevent deformation and stress. Never drag pipes on rocky surfaces to avoid abrasion damage.

Heat Fusion Jointing

Follow manufacturer’s specifications for heat fusion methods (butt fusion, socket fusion, or electrofusion). Ensure proper alignment and calibration of heating equipment.

Pipe Placement and Alignment

Place fused pipe sections in the trench to rest uniformly on the bedding layer. Maintain proper slope per system design guidelines and avoid sharp bends or kinking.

Backfilling the Trench

Backfill with fine material up to the spring line, maintaining compaction to ensure uniform support. Use layered backfilling with equal compaction to prevent pipe crushing.

System Testing and Pressure Evaluation

Perform hydrostatic or pneumatic tests to verify structural integrity and joint strength according to local standards. Test pressure should not exceed 1.5 times the working pressure.

Final Inspection and Commissioning

Conduct a detailed post-installation inspection, checking for misalignments, signs of leakage, or deformities unknown during installation.

Best Practices for Safety

Essential Safety Measures:

- Personal Protective Equipment: High visibility clothing, helmets, gloves, safety goggles

- Risk Assessment: Comprehensive evaluation before work begins

- Equipment Safety: Follow the manufacturer’s instructions for fusion welding equipment

- Work Area Management: Keep clean and organized to prevent tripping hazards

- Proper Lifting: Use mechanical equipment to avoid strain injuries

- Pressure Testing Safety: Implement pressure-relief and monitoring systems

Common Fitting Techniques

| Fitting Type | Application | Key Features | Best Use Cases |

|---|---|---|---|

| Compression Fittings | Leak-proof connections without welding | Nut, ferrule, and body assembly | Hydraulic and pneumatic systems |

| Butt Weld Fittings | High pressure and temperature | Beveled edge welding | Critical pressure applications |

| Threaded Fittings | Low-pressure systems | Male and female threads | Easy maintenance access |

| Flange Fittings | Repeated assembly/disassembly | Bolting connection with a gasket | Maintenance and inspection points |

| Push-Fit Fittings | Tool-free installation | Integrated O-ring seal | Potable water and small pressure systems |

Durability and Environmental Benefits

Durability and Lifespan of HDPE Pipes

HDPE pipes enjoy a reputation for high durability and long operational life due to their resistance against multiple stress factors.

Durability Factors:

- Chemical Resistance: Withstands acids, alkalis, and solvents

- Environmental Tolerance: UV radiation and extreme temperature resistance

- Flexibility: Handles soil displacement and seismic activity

- Smooth Surface: Reduces frictional losses and deposits

- Non-reactive Nature: Compatible with various transported media

Recyclability and Environmental Impact

HDPE is widely regarded for its recyclability, contributing to a significant reduction in environmental footprint.

Environmental Advantages:

- Circular Economy Compatibility: Can be melted and remolded multiple times

- Recycled Applications: Manufacturing pipes, plastic lumber, and non-pressure products

- Carbon Footprint Reduction: Lower manufacturing emissions compared to alternatives

- Transportation Efficiency: Lightweight reduces shipping emissions

- Energy Conservation: Minimizes frictional resistance and maximizes insulation properties

Minimizing Ecosystem Disruption

DR11 HDPE pipes contribute to environmental protection through sustainable installation practices and minimal ecosystem interference.

Ecosystem Protection Strategies:

- Precision Installation: Mapping technology identifies sensitive ecological areas

- Closed-Loop Systems: Waste materials reused in production cycles

- Trenchless Technology: Minimizes surface disruption during installation

- Long-Term Performance: Reduces need for replacement and re-excavation

- Chemical Inertness: No leaching of harmful substances into soil or water