Polyethylene pipe is quickly becoming the preferred choice for water supply systems due to its advantages over conventional pipe materials. This post will examine some of the significant benefits of using polyethylene pipes, such as their strength, flexibility, corrosion resistance, and chemical leaching. We shall also go through its affordability, ease of installation, and long life span, which make it a perfect solution for domestic and commercial water supply needs. By understanding polyethylene piping’s unique attributes, one can understand why it stands out regarding plumbing options and how it can effectively address contemporary water supply challenges.

What Makes Polyethylene Pipe Suitable for Water Supply?

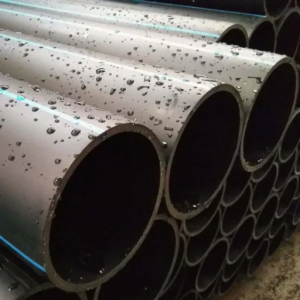

Image source: https://hby-c522.en.made-in-china.com/

The characteristics of polythene tubing make it ideal for water transport systems. The polyethylene tubes do not erode, making them last longer than traditional versions, reducing maintenance expenditure and frequent purchases. Polythene pipes are flexible enough to allow easy installation in rugged terrains without compromising their integrity under different pressures or temperatures. Moreover, the inner walls are designed to minimize flow restrictions resulting from friction losses, enhancing overall system performance and increasing flow rates. All these features and low-weight characteristics make this product advantageous in residential and commercial areas when transporting water.

Understanding Polyethylene and Its Benefits

Polyethylene is a highly versatile thermoplastic that is durable and suitable for different applications, especially water distribution systems. One of its most significant advantages is that it has good chemical and corrosion resistance, which expands the helpful life of pipelines. Additionally, PE pipes have low density, making them lightweight so that handling and installing them is very easy while transportation costs can be lowered.

In addition, polyethylene works perfectly wherever you install it regardless of geographical location, mainly when we have challenging terrain like interior surfaces that are not rough, improving fluid flow efficiency by minimizing frictional forces within this regard towards fluid movement. Generally speaking, polyethylene’s specific attributes, including being lightweight, long-lasting, and environmentally resistant, render it preferable for domestic and industrial water supply requirements.

Why HDPE is a Preferred Material for Water Pipes

I have seen that High-Density Polyethylene (HDPE) is generally considered the best choice for water piping systems because of its highly remarkable strength and durability. HDPE also has excellent resistance to impact and weathering and exhibits excellent chemical resistance, making it ideal for moving drinking water. Being flexible, HDPE can adapt to ground movements, reducing the possibility of leaks or breakages from which rigid materials often suffer. Additionally, installation is usually more accessible and cost-effective since HDPE can be welded seamlessly into a continuous pipeline without any leakage. These are reasons why HDPE remains my preferred material for water pipes found in residential and commercial areas.

Comparing Polyethylene Pipes to Other Pipe Materials

Comparing polyethylene pipes, particularly HDPE, with other pipe materials such as PVC, copper, or cast iron has several advantages. PVC is less flexible than HDPE, making it difficult to install in different types of terrains that are not leveled at all. Unlike copper, which erodes over time due to exposure to certain elements that cause rusting within water systems, HDPE is corrosion-resistant and resistant to chemicals, ensuring long-term use in water systems. Additionally, while cast iron pipes are rigid, they are heavy and thus more prone to rust and unsuitable for current uses. They will require further rust-proofing processes before correctly welding them together for joining purposes, among other issues related to their physical properties like weightiness. Besides being cost-effective regarding raw material costs, HDPE tends to be cheaper due to its lightweight nature, making it easier to handle during the installation process compared to other alternatives available today. These qualities make it appealing when installing domestic or commercial plumbing applications, improving its position as a dependable option adaptable to diverse requirements.

How to Install Polyethylene Pipes for Water Systems

Polyethylene pipes for water supply installation involve several essential steps to achieve a successful and efficient setup process. First, one needs to prepare a trench where the pipes will laid. This entails digging a trench deep enough for the pipe diameter but ensuring sufficient cover to protect from the outside.

Subsequently, HDPE pipes should be laid in the trench adequately aligned and connected. The pipes can be welded together employing either electrofusion or butt fusion techniques, thus creating a seamless joint that reduces the chances of leaks. When joints are secure, backfill soil into the excavation, taking care not to damage tubes during this process. Lastly, a pressure test must detect any leakages before commissioning. Always follow local legislation and regulations regarding installation to ensure compliance and safety procedures are correctly followed.

Step-by-Step Installation Guide

- Plan Your Installation: As a preliminary measure, I read through the local codes and regulations regarding polyethylene pipe installation. The piping layout must be planned to attain good water flow and prevent related problems.

- Prepare the trench: I dig a trench that is at least 12 inches more than the width of the tube on either side and deep enough to keep them below frost lines, which are common in most places, like 36 inches. This will protect pipes against freezing.

- Install the Pipe: I carefully installed HDPE pipes into my trench, ensuring they aligned well. Attention should be paid to bends and joints, especially so as not to disrupt smooth flow.

- Joining the Pipes: These pipes can be joined using either electrofusion or butt fusion techniques. I need to achieve strong seams without leaks when I follow welding instructions from manufacturers.

- Backfill: At this point, I gently fill the soil back into the trench not to damage the tubes. Soil compression should be done lightly to eliminate air pockets but should not exert extreme force on it.

- Testing: Leak checks by pressurizing ought to be done before doing anything else after installing PE pipe water systems.

- Documentation: Any information you have about the installation must be recorded, including all specifications of materials used and where they were located. This would help in future maintenance or modifications if necessary.

This way, I ensure the reliable and efficient installation of Polyethylene Pipes for Water Systems.

Common Installation Mistakes to Avoid

- Neglecting proper soil preparation: One common mistake associated with inadequate soil preparation before laying. Poorly compacted or rocky soils may cause pipe misalignment or damage over time.

- Overlooking manufacturer guidelines: Many installers fail to adhere strictly to the manufacturer’s requirements to join and handle pipes, leading to weak connections. These instructions must be adhered to for an installation process to be successful.

- Insufficient Leak Testing: However, pressure test omission or incomplete application may cause leakage, which will pose severe problems in the future. Always ensure the trench is tested after filling the backfill before such an installation is complete.

Tools and Equipment Needed for Installation

What I need during polyethylene pipe installation for it to succeed are as follows:

- Trenching Equipment: To have a trench ready for installing a pipe, I either use a trencher or dig out manually with a shovel as needed

- Pipe Cutting Tools: I require a saw or any other suitable tool to cut the required polyethylene pipe lengths accurately.

- Joining Tools: These can include clamps and fusion welding equipment, depending on whether they are used withered or not, respectively.

- Pressure Testing Equipment: Subsequent tests are carried out using a pressure gauge and fittings, after which appropriate leak tests can be done.

- Measuring Tools: Measuring tape and level help me get precise alignment and locations of pipes

- Safety Gear: It’s essential to take safety precautions by wearing personal protective clothing such as gloves, glasses (for eye protection), and boot shoes (steel-toe), among others,

With this availability, I can expedite installations while maintaining standards for safety and quality.

What Are the Specifications for HDPE Water Pipes?

High-density polyethylene (HDPE) water pipes are designed to meet particular industry standards and performance criteria. The main points of the specifications are as follows:

- Composition: These pipes are made of HDPE, which is very strong, flexible, and resistant to corrosion and chemicals.

- Diameter Sizes: This type of pipe is available in various diameters, ranging from ½ inches to 48 inches, to meet different needs and flows.

- Pressure Ratings: HDPE pipes have several pressure classes (i.e., SDR 11, SDR 17), indicating they can be used for high-pressure water systems.

- Temperature Resistance: These tubes usually have a temperature range of between -40°F and 140°F (-40°C to +60°C), making them adaptable to various weather conditions.

- Length: The standard HDPE pipe varies from 20 feet to about 40 feet, though other lengths are available upon request.

- Joining Methods: Typical examples include electrofusion, butt fusion, and mechanical fittings that enable tight non-leaking connections.

These specifications make HDPE water pipes an attractive option for many applications involving distribution systems for water supply.

Understanding 200 PSI Rating

Regarding HDPE water pipes, the rating of 200 PSI is specifically referred to as the amount of pressure a pipe can withstand under given circumstances. This rating is crucially important, especially with high-pressure water systems, since it guarantees that the conduit will not fail when subjected to such demands. Ordinarily, a pipe with a 200 PSI rating can resist pressures reaching 200 pounds per square inch without breaking down. Consequently, it is suitable for diverse municipal or industrial piping systems where keeping steady pressure levels becomes highly desirable. On top of this, one also has to consider aspects like temperature and what type of fluid is in question; all these could impact performance over time, too.

Different Sizes and Dimensions of HDPE Pipes

For different purposes, HDPE pipes are available in various sizes and dimensions. These can typically run from ½” to 63″ in diameter, with standard sizes such as 2 inch, 4 inch, and 6″ extensively used in residential and commercial projects. These dimensions usually adhere to the standards specified by organizations like ASTM or AWWA that define outer diameters and wall thicknesses based on pressure ratings. For instance, pipes rated at about 200 psi tend to have thicker walls than those rated for lower pressures. This wide selection of sizes permits engineers to design water distribution systems flexibly to identify the correct size pipe based on system pressure or flow requirements.

Standards and Certifications for Drinking Water Pipes

Safety and reliability are vital considerations when discussing drinking water pipes; therefore, strict compliance with standards and certifications is necessary. I will, hence, focus on those plumbing items meant for drinking purposes that should have complied with the Environmental Protection Agency (EPA), among other bodies that set out rules on potable water quality. I also rely on NSF/ANSI 61 certification, specifically for evaluating the health effects of materials employed in drinking water systems. The chosen pipes should, therefore, not only comply with these guidelines but also be tested for impurities to maintain the cleanliness of the water for human consumption. This thorough vetting process gives peace of mind and consistency with good practices adopted in water management.

How Does Polyethylene Pipe Affect Water Quality?

Distilled DJ booths equipped with reflection filters and trapdoors doubling as loudspeakers: If you want a band that brings something extra to their shows – opt for Polyethylene (PE) pipes. The latter ensures low reactivity and corrosion resistance, making them preferred options. Doing so prevents harmful substances from entering the water, which happens more commonly when dealing with metals or other tubes that transport liquids under pressure. Besides these reasons, biological growth is inhibited in PE pipes, reducing contamination chances. If properly installed and made according to the set standards, these tubes will not affect the water’s taste or smell, making them suitable for human consumption. All in all, this means that if they are correctly employed, they help uphold the integrity and safety of potable drinking water.

Ensuring Safe Drinking Water with HDPE Pipes

HDPE pipes are perfect for drinking water systems. This is because they do not rust easily, minimizing the chance of leaks and contamination. Lime or other minerals do not affect HDPE pipes, maintaining clean water quality. Moreover, HDPE is highly resistant to temperature variations; thus, it remains intact during harsh temperatures. Significantly, smooth interior surfaces discourage biofilm and sediment build-up that essentially increases water flow rate and standards. HDPE pipes help maintain uncontaminated drinking water by ensuring strict manufacturing requirements and certificates, thus enhancing public health.

Corrosion Resistance and Its Benefits

The durability of any water supply system is determined by its anti-corrosion properties. Numerous advantages are associated with using such materials as HDPE on the piping system. I discovered that using HDPE pipes is beneficial in terms of corrosion resistance and helps prevent pipe breakages and contamination, and I am familiar with traditional metallic piping systems. Being an inert substance, it does not react with minerals or chemicals in the water, keeping its quality over time. Ultimately, this means lesser repair costs and fewer chances of diseases caused by impure water, boosting my confidence in using High-Density Polyethylene (HDPE) in safe drinking water systems.

Impact on Water Taste and Odor

The choice of piping material significantly influences the taste and odor of drinking water. For instance, HDPE pipes do not react with other materials present in them, thereby preventing any unpleasant tastes or smells associated with them. To be specific, influential experts say that this chemical inactive nature consequently maintains a natural flavoring preference for the liquid being drunk all through till it reaches a consumer’s mouth at home or office premises without changing even minor constituents like mineral ions found inside it if only one consider what goes into his/her glass otherwise day after day week upon week year after year till s/he changes location either completely forever just temporarily yet Fasihuddin et al. (2019), found out that HDPE materials were less likely to contribute such metallic flavors or smells due metal plus water reactions brought about by either oxidation processes accompanying oxidation-reduction reactions, which sometimes occur between metals like copper as well stainless steel both have been shown earlier within this article. Additionally, HDPE is characterized by smooth inner walls that limit sedimentation or biological film formation and thus enhance the taste of water. As a result, employing HDPE in water supply systems helps to retain desirable qualities of drinking water, such as its crispness and purity, which are free from impurities and stenches.

What Are the Advantages of Using HDPE Pipe Over Other Plastic Pipes?

Unlike other plastics, HDPE pipes have several advantages that make them suitable for use in different areas. It is recognized due to its high strength, durability, and capacity to withstand high pressure and impact resistance, reducing failures. This property makes it more flexible than PVC or CPVC, and it is easily installed in rugged terrains or during adverse weather. In addition, the material has excellent chemical resistance, enabling good service life even when exposed to very aggressive fluids. On the other hand, a lower coefficient of thermal expansion than other plastics maintains structural integrity under temperature changes. Lastly, HDPE is a recyclable plastic pipe made from renewable resources, giving it an edge over traditional piping materials.

Durability and Longevity

On many occasions, HDPE pipes have been known for their remarkable ability to last long, even if they are subjected to unfavorable conditions where they can go up to 50 years. They are ideal for use in aggressive soil environments and soils with high acid contents since they are not affected by these factors that generally cause metals like iron and copper to corrode. Unlike metals and most other plastics, UV light does not affect HDPE pipes; hence, they do not get spoilt by UV radiations, resulting in a long-lasting performance over their expected functional periods without any need for maintenance purposes throughout. They also have minimal maintenance costs, thus reducing lifecycle expenses and having strong resistance against cracking.

Flexibility and Ease of Handling

From my perspective, I find HDPE a highly flexible product line that simplifies installation processes, especially when dealing with rugged terrain. Its comparatively lightweight quality means that less time is taken during transportation and handling, hence reducing labor needs during fixing at some point. Being able to bend without snapping leads to fewer joints needed to minimize the potentiality of leaking, while setting up becomes simpler, too. Therefore, innovators should exploit the inherent flexibility of this material because such qualities would offer significant benefits in terms of quick but safe fixing activities required by complex projects within a limited time. Thus, the flexibility and ease of handling make HDPE well-suited for various applications.

Cost-Effectiveness and Economic Benefits

HDPE pipe is widely used in various industries because it is cost-effective compared to conventional pipes. This is because initial installation costs are lower since HDPE pipe is light and flexible, thus requiring less labor and fewer fittings. The material’s longevity also minimizes replacement and maintenance costs, contributing to overall economic efficiency. The resistance to corrosion and chemicals also means less downtime and fewer repairs, making HDPE a financially sound investment for water and gas distribution systems. These factors combine to make HDPE an economically advantageous choice compared to traditional piping materials.

How to Maintain and Repair Polyethylene Water Pipes?

Ensuring that polyethylene (PE) water pipes have a long life span while functioning well will entail several processes. Firstly, regular check-ups should be done to identify any signs of wear or damage, including cracks or leakage. Cleaning the external part of pipes can prevent substances from building up that may destroy the pipes. An area with a leak must be separated, drained, and repaired using an appropriate method, like mechanical joints or fusion welding. Ensure this conforms to all local rules on safety when performing such repairs at any given time. By being proactive about maintenance issues and dealing with them promptly, one can vastly enhance the service duration of polyethylene water pipes.

Regular Maintenance Tips

Efficient maintenance of my polyethylene water pipes calls for a few essential steps. First, I check them regularly every few months to catch any potential leaks or cracks before they become real problems. Furthermore, I always try not to forget that my tubes need cleaning since I do not want them to accumulate much dirt, which could interfere with their effectiveness. I ensure no unnecessary plants near my lines, hence fittingly limiting access by roots into its interior parts. Any time i come across such leakages however, i take immediate action by isolating the affected section swiftly then use fusion welding as per industry standards for repair work resulting in strong fix there after. Lastly, I will keep up with current regulations in my work area and ensure that all repairs are conducted within the proper standards. Using these suggestions as part of my maintenance routine will help me prolong the life of my polyethylene water pipes.

Identifying and Fixing Leaks

To find water leakages in pipes made of polyethylene, you need to be observant and perform routine checks. Some common signs are if there is an unusual moisture content in the surrounding area, a sudden decrease in water pressure, or even visible cracks along the surface pipe. When a leakage is suspected, it is essential to isolate the affected section first to minimize water loss and potential damage. Fusion welding works very well to fix leaks like this because it forms strong bonds that restore pipe integrity. Quick repairs can also be done using mechanical fittings, among others. After repairs have been completed, another inspection must be carried out to ascertain the success of fixing and the absence of further leakage to keep their durability and prevent future problems. Regular monitoring should be done, and timely maintenance should be maintained for PEX water pipes.

Reference sources

- HDPE Pipe for Potable Water – WL Plastics

- Polyethylene Pipe | Poly Pipe for Sale – PlumbersStock

- Black HDPE Polyethylene Pipe – HDPE Supply

Frequently Asked Questions (FAQs)

Q: What is a polyethylene (PE) pipe?

A: Polyethylene (PE) pipe, also known as poly pipe or black poly pipe, is a type of plastic tubing made from PE. Due to its durability and flexibility, it is commonly used in water supply lines, irrigation, and natural gas transportation.

Q: Why is PE pipe preferred for water supply lines?

A: PE pipe is preferred for water supply lines because it is lightweight and easy to install, has a long service life, and is suitable for potable water applications. Its ability to be installed without extensive pipe fittings makes it ideal for various projects.

Q: Can PE pipe be used for potable water supply?

A: Yes, PE pipe is suitable for potable water supply systems. It is safe for transporting drinking water and meets all relevant safety and health standards.

Q: How does the coil format of PE pipe benefit installation?

A: PE pipe’s coil format allows for more accessible transportation and installation. Coils reduce the number of joints needed, which minimizes potential leak points and speeds up the installation process.

Q: What applications are PE pipes used in?

A: PE pipes are used in many applications, including water supply lines, irrigation systems, natural gas transportation, sewer systems, and more. They are versatile and reliable for both residential and commercial projects.

Q: Are PE pipes durable and flexible?

A: Yes, PE pipes are known for their durability and flexibility. They can withstand various environmental conditions and pressures, making them ideal for long-term use in different piping solutions.

Q: How do I connect PE pipes?

A: PE pipes can be connected using various pipe fittings explicitly designed for polyethylene tubing. These fittings ensure a secure and leak-proof connection. Contact us today for detailed instructions on connecting PE pipes.

Q: What are the advantages of using PE pipes for irrigation?

A: PE pipes are lightweight and easy to handle, making them perfect for irrigation systems. Their flexibility allows for easy directional changes without the need for additional fittings, and they can be used to connect various irrigation components seamlessly.

Q: Is there any maintenance required for PE pipes?

A: PE pipes require minimal maintenance due to their long service life and resistance to corrosion and scaling. Regular inspections are recommended to ensure no leaks or damages, but overall, they offer a low-maintenance piping solution.

Q: Where can I purchase PE pipe products?

A: PE pipe products can be purchased from various suppliers and retailers. Contact us today to find the right pipe products for your next project and the best deals and options, including free shipping on bulk orders.