High-density polyethylene (HDPE) storm drain pipes are transforming the way we approach drainage infrastructure. Among the various sizes available, 18-inch HDPE storm drain pipes stand out as a versatile and efficient solution for modern stormwater management needs. This article dives deep into the capabilities and advantages of 18-inch HDPE pipes, examining why they have become the ultimate choice for engineers, contractors, and municipal authorities. From their superior durability to their cost-effectiveness, we will explore how these pipes address the challenges of stormwater systems while meeting stringent environmental and performance standards. Whether you’re seeking to optimize a large-scale drainage project or simply want to understand the science behind innovative piping solutions, this guide will provide the insights you need. Stay tuned as we uncover the true power of 18 HDPE storm drain pipes and what makes them an industry-leading solution.

Why Choose an 18 HDPE Storm Drainage Pipe?

What Makes HDPE Pipes Stand Out?

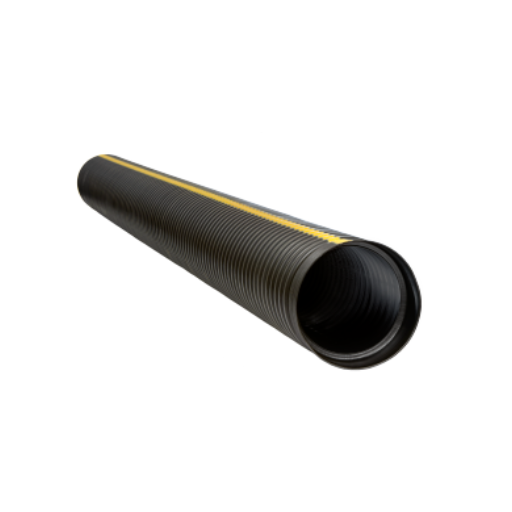

High-density polyethylene (HDPE) pipes offer incredible flexibility. They are resistant to environmental stress as well as being durable. These qualities make HDPE an ideal selection for storm drainage systems. Soils and waters that are aggressive to materials like concrete or metal do not cause corrosion on HDPE, making it have a longer life span.

Moreover, cracks or deformation on the surface of HDPE pipes do not occur due to extreme temperature and pressure changes. In regions that experience sudden climate shifts or experience heavy storms, those pipes can be relied upon to maintain structural integrity. In addition, ultra-light HDPE pipes further ease transportation, installation, and overall project costs by saving on both time and labor.

The interior surface of HDPE pipes has a smooth finish, which minimizes friction and water flow resistance. Efficient management and prevention of blockages of heavy stormwater loads is attributed to hydraulic efficiency. On top of these advantages, being fully recyclable and manufactured with lower resource consumption makes them an environmentally friendly choice. In conclusion, all these aspects make HDPE pipes a sustainable, cost-efficient, and high-performing drainage solution.

How Does HDPE Material Benefit Your Project?

The advantages of High-Density Polyethylene (HDPE) materials can significantly improve the efficiency and life of your project and including durability. The ability to resist corrosion, chemical exposure, and environmental stressors makes HDPE pipes a long-lasting solution for harsh conditions. Furthermore, this material endures harsh conditions such as prolonged exposure to UV rays and extreme temperatures, ensuring performance over time with minimal maintenance.

In addition, the lightweight nature of HDPE makes transportation, handling, and installation easier and more efficient. Compared to concrete and metal, HDPE’s reduced weight translates to lower installation costs, faster project completion, and improved flexibility. This allows the material to adjust to soil movements and ground shifts, minimizing the chances of pipe failure or damage under pressure.

Lastly, from an environmental perspective, HDPE is an eco-friendly choice. It is 100% recyclable and, therefore, aligns better with sustainable construction practices. Moreover, the manufacturing process of HDPE also requires fewer natural resources, which in turn lowers carbon emissions compared to other materials. These properties align with modern sustainability goals, making HDPE an optimal solution for projects that prioritize environmental responsibility without compromising on performance or cost efficiency.

Are HDPE Pipes the Right Solution for Your Drainage Needs?

HDPE pipes are usually a good option for drainage systems due to the unique combination of their durability, cost, and environmental advantages. The high-strength-to-density ratio of HDPE pipes ensures that they can handle both residential and industrial loads and challenging conditions. In addition, HDPE pipes are UV resistant and chemically inert, which makes them low maintenance and provides them with a much longer lifespan compared to traditional materials.

The ease of installation of HDPE pipes is one of their critical advantages. Their lightweight structure means enhanced ease of transport, reducing deployment time and associated expenses. They are highly flexible, which allows them to adapt to different terrains and reduces the chances of joint failure. During installation, heat-fusion methods are used to create leak-proof joints that guarantee optimal performance for the future.

Production of HDPE pipes has less environmental impact due to lower resource consumption and waste generation, making them sustainable by design. For clients seeking efficient, dependable, and environmentally responsible solutions, these piping systems are reliable and align with modern construction standards. In addition, HDPE pipes serve sustainable construction objectives as they are 100% recyclable.

Understanding the HDPE Pipe System

What is HDPE Pipe Construction?

The construction process of an HDPE pipe begins with designing and installing a piping system using High-Density Polyethylene materials. HDPE pipes are made from thermoplastic polymers (polymer resins) and have a great strength-to-density ratio. They also have marvelous chemical resistance. HDPE materials go through processes such as extrusion under specific conditions in order to ensure consistent wall thickness and durability.

As with any other computerized piping system, HDPE pipes also come equipped with unique features such as the welded joint system that forms monolithic connections through butt or electro fusion. Hybrid Mechanical joints are eliminated and replaced with sealed joints, increasing the longevity of the system. Alongside this, HDPE pipes are lauded for their flexibility. They can be installed in rough terrains such as places that experience major seismic shifts.

Multilayer and advanced formulations are added to the systems to increase the stress resistance. These advance the construction features of the piping systems. In comparison to other piping systems, HDPE pipes are way superior because extensive research claims that they lower the maintenance costs by 50 percent due to their resistance against corrosion, scaling, and growth of bacteria.

Due to the growing demand for infrastructure improvements and environmentally clean solutions, HDPE pipe systems are essential in today’s construction activities. Their flexibility enables use in water supply, wastewater treatment, gas piping, and even in various industrial activities while meeting legal and work requirements.

How Does the Dual Wall System Enhance Performance?

The dual wall design enhances performance by having a smooth interior and a corrugated exterior. This combination boosts structural strength and flow efficiency. The pipe’s smooth interior provides minimum friction, which improves hydraulic performance with higher flow rates and less chance of clogs. The dual wall system’s rigid and corrugated exterior offers added structural integrity as well as external pressure resistance, allowing the pipe to hold structural integrity under heavy loads and shifting soil conditions.

Modern advancements within dual wall systems enhance their sustainability against extreme temperatures and chemicals, as well as increasing their lifespan. Compared to steel and concrete, these pipes are lighter, lowering transportation and installation costs. Environmental wear and tear also has far less effect on dual wall systems because studies indicate that their enduring lifespan allows substantial savings in maintenance expenses, upwards of 60%!

Incorporating such technologies into essential systems like drainage, stormwater management, and sewers offers both efficiency and sustainability benefits. The dual wall design of modern piping solutions ensures water conveyance with a reduced environmental footprint.

What Are the Standards for HDPE Pipes?

I know that high-density polyethylene (HDPE) pipes must follow global and local regulations for quality, safety, and performance. These standards cover the most important aspects, such as the material of the pipe, its geometry, the rating of the pressure it can take, and how the pipe will perform under certain exposure conditions.

As an example, ASTM D3035 has specifications to be met for HDPE pipes and their applications. It ensures that there is a minimum required tensile strength and flexibility, as well as ISO 4427, which sets requirements for polyethylene piping systems used in water supply applications, ensuring chemical resistance and durability. For municipal and industrial water systems, AWWA C906 is the main document of reference as it contains an outline for pipe dimensions, installation procedures, and how to work with various fittings and joints.

I monitor specific compliance issues for certain industries or regions. Cumulatively, these requirements make sure that HDPE pipes are dependable and durable across various uses, which is why they are widely accepted in contemporary engineering and infrastructure projects.

Applications of 18 HDPE Stormwater Drain Pipes

Where Can You Use HDPE Drain Pipes?

The use of HDPE stormwater pipes in the management of storm and nonstormwater runoff has been adopted in a range of different construction projects because of the material’s resilience, lightweight, rot-resistant, and non-corrosive qualities. These pipes are often used in municipal systems for managing stormwater runoff and controlling flooding. Furthermore, HDPE pipes are also popular in agricultural drainage facilities to control water movement as well as soil erosion, promoting healthy crop growth.

The multifunctional nature of these materials also makes them ideal for highway and roadway drainage systems, where they help protect the road surfaces by controlling water collection, thus preventing structural damage and improving roadway longevity. Such storm and waste water drainage systems are often used in industrial buildings where the environment is hostile due to aggressive chemicals, therefore requiring protective HDPE drain pipes for the safe transport of waste water. Likewise, these pipes are used in residential buildings for landscaping purposes as subsurface drainage to control, collect, and disperse excess water sustainably.

The increasing importance of sustainability in engineering and construction design highlights the multitude of uses for HDPE stormwater drain pipes, reinforcing their position as a preferred modern engineering material.

How Does HDPE Drainage Pipe Perform in Different Conditions?

The construction of HDPE drainage pipes is done in such a way that they function properly in different environments and operational conditions. Due to their flexibility, these pipes can sustain soil changes and settlements, which makes them useful in areas with seismic activity or ground shifts. In addition, the material’s strong resistance to abrasion guarantees functionality for the long term even in a high-velocity flow of sediment or debris.

The performance of HDPE pipes is not significantly impacted by extreme temperatures because their thermal expansion and contraction are well documented and manageable with good design planning. They are freeze-resistant and remain flexible during extreme heat, which is ideal in regions with harsh seasonal shifts. In addition, HDPE pipes have remarkable resistance to chemicals and do well in environments where they are exposed to acids, bases, or salts, like industrial zones or wastewater management facilities. Their non-corrosive nature protects them from harsh corrosive soils and environments with high salinity.

These modern engineering marvels can be depended upon across varying infrastructural settings, as long as there is proper design, installation, and maintenance. This enables HDPE drainage pipes to maintain their reputation of being reliable and enduring.

Exploring the Range of HDPE Products

What Are the Available Sizes of HDPE Pipes?

To meet various applications and usage needs, HDPE pipes are produced in different sizes. For residential and low-capacity uses, an HDPE pipe’s diameter starts from 20 mm and goes all the way to over 1200 mm for industrial-scale and high-flow applications. These sizes are standardized and classified under various international and regional specifications such as ASTM, ISO, or DIN standards.

HDPE pipes are also stratified with Nominal Diameter (DN) and Standard Dimension Ratio (SDR), which is a measure of wall thickness to diameter of the pipe. As an example, specific pressure rating pipes can be selected, SDR 11 or SDR 17, providing operational conditions flexibility from low to high pressure. These size and SDR combinations provide adaptability and precision for small-scale municipal projects and large-scale industrial infrastructure needs.

These pipes efficiently address a wide range of applications, including, but not limited to, potable water supply, underground drainage systems, irrigation networks, and gas distribution systems. Maximum versatility is provided by tailored pipe sizes and configurations designed to suit custom requirements.

How Does HDPE Compare with Other Materials?

In terms of flexibility, impact resistance, chemical resistance, cost effectiveness, and even durability, HDPE stacks up well against PVC, polypropylene, LDPE, aluminum, fiberglass, acrylic, polycarbonate, and even ABS.

Below is a brief table that encapsulates the most important details:

|

Material |

Durability |

Flexibility |

Impact Res. |

Chem. Res. |

Cost |

|---|---|---|---|---|---|

|

HDPE |

High |

Moderate |

High |

High |

Low |

|

PVC |

Moderate |

Low |

Moderate |

High |

Low |

|

Polypropylene |

Moderate |

High |

Moderate |

High |

Low |

|

LDPE |

Low |

High |

High |

Moderate |

Low |

|

Aluminum |

High |

Low |

Low |

High |

High |

|

Fiberglass |

High |

Low |

Low |

High |

High |

|

Acrylic |

Low |

Low |

Low |

Low |

Moderate |

|

Polycarbonate |

High |

Low |

High |

Moderate |

High |

|

ABS |

High |

Low |

High |

Moderate |

Moderate |

Using important factors, this table summarizes compared other materials with HDPE.

What Fittings Are Compatible with HDPE Pipes?

HDPE or high-density polyethylene pipes are suitable for a wide variety of fittings that guarantee safe, leak-proof connections for different purposes. These fittings can be classified as mechanical, electrofusion, and butt fusion, with each catering to different needs and application environments.

- Mechanical Fittings: These fittings are the simplest of all and common in various uses, including quick installations or connections that may require future disassembly. These include compression fittings and couplings, as they allow seals to be achieved without the use of sophisticated equipment.

- Electrofusion Fittings: These fittings connect to HDPE pipes with seamless fusion using an integrated electrical coil to produce the necessary heat. As a result, each joint is robustly reinforced, making this method appropriate for high-pressure systems or any other situation that requires superior joint integrity.

- Butt Fusion Fittings: A specialized butt fusion welding technique is used to weld these directly to HDPE pipes. Consequently, the joint is as strong as the pipe, which makes it ideal for long-term installations that require durability and structural stability.

Moreover, project needs might require specialized fittings like flanged adapters, branch saddles, or even custom-fabricated fittings. HDPE fittings are made to the specific requirements of international standards, which makes them useful in important applications such as sewage systems, water distribution, and as pipelines as well. These factors, together with the stubborn strength, chemical resistance, and inflexibility of HDPE, increase its desirability as a modern piping system material.

Maintaining and Supplying HDPE Drainage Systems

How to Ensure the Durability of HDPE Drain Pipes?

Best practices during installation, maintenance, and usage enhance the lifespan and durability of HDPE drain pipes. The bedding and backfilling materials used to cover the pipes need to meet engineering standards to avoid external compression or deformation. Also, for the joints to be secure and leak-proof, butt fusion or electrofusion welding methods must be used for HDPE pipe joints.

Routinely scheduled inspections along with maintenance greatly add to other aspects of durability. Keeping regularly scheduled maintenance to clean out debris ensures unobstructed flow, which minimizes the chances of internal damage or clogging. Furthermore, HDPE pipes should not be left unprotected from UV rays if placed above ground for long periods, as exposure to sunlight for prolonged periods is known to weaken polymers. When placed underground, it is advisable to use coatings that match the soil profile to guard against abrasives or corrosive materials often found in varying environments.

Pipes are HDPE nowadays for a reason. Along with modern changes in manufacturing, add-ons like stabilizers are included, which improve the resin’s ability to withstand environmental stress cracking and thermal expansion, enabling the pipes to function properly in harsh conditions. Using technical data from the manufacturers, along with industry standards such as ASTM D3350 or ISO 4427, guarantees that the selected HDPE pipe system will endure the designated mechanical and chemical factors over a long period.

What Are the Best Practices for HDPE Pipe Maintenance?

To guarantee that HDPE pipe systems will last and work effectively, they must be maintained properly. Conducting regular inspections to check for wear and damage, especially at the joints and fittings where stress is usually concentrated, is one of the main practices. Also, nondestructive ultrasonic testing can reveal possible weaknesses in the walls of the pipes without stopping service.

Ensuring cleanliness is another critical aspect. Periodic flushing of the pipes helps prevent the sediment, biofilm, or contaminants that could cause internal abrasion. Monitoring chemical compatibility is very important, too, because improper chemicals will ruin the pipe over time, especially in industrial or chemical uses.

Correct records and compliance with the instructions given by the manufacturer about the installation of the pipes and their operation limits aid in preservingthe reliability of the system. Correct soil stress limits are maintained, and proper backfill support around pipelines buried reduces external loads that might bring about deflection or buckling with time. Also, prompt leak detection systems enable immediate detection and repair of leaks, thereby conserving materials and protecting the environment from damage.

At last, operator training along with advanced monitoring technologies like pressure and flow meters improves the ability to predict problems and correct them before they cause problems. Advanced diagnostic tools used alongside routine maintenance further ensure that HDPE pipe systems are fully functional and decrease the chances of the systems failing unexpectedly.

References

Frequently Asked Questions (FAQ)

Q: What are 18 HDPE storm drain pipes?

A: 18 HDPE storm drain pipes are high-density polyethylene pipes commonly used for efficient drainage solutions. These pipes are known for their durability, flexibility, and resistance to corrosion, making them ideal for various stormwater management applications.

Q: Why are HDPE pipes considered the ultimate drainage solution?

A: HDPE pipes are considered the ultimate drainage solution due to their tough nature, long lifespan, and ability to withstand extreme weather conditions. Their flexibility and chemical resistance also make them preferable over traditional materials.

Q: How do HDPE pipes compare to traditional culverts?

A: HDPE pipes offer several advantages over traditional culverts, including lighter weight, easier installation, and greater resistance to environmental stressors. Unlike concrete or metal culverts, HDPE pipes are less prone to cracking and corrosion.

Q: What is a dual-wall pipe, and why is it beneficial?

A: A dual-wall pipe consists of a smooth interior wall and a corrugated exterior wall. This design provides high structural strength and efficient flow capacity, making it ideal for stormwater and drainage applications.

Q: How long are 18 HDPE storm drain pipes?

A: The typical length for 18 HDPE storm drain pipes is 20 feet, often referred to as “x 20,” which allows for fewer joints and quicker installation.

Q: Can HDPE pipes be used for downspouts?

A: Yes, HDPE pipes can be effectively used for downspouts due to their lightweight and versatile nature. They provide a reliable and long-lasting solution for directing rainwater away from structures.

Q: What is the end connection for HDPE storm drain pipes?

A: HDPE storm drain pipes often feature various end connections, such as bell and spigot or gasketed joints, to ensure a secure and leak-proof fit during installation.

Q: Are there different types of HDPE storm drain pipes available?

A: Yes, there is a wide range of products available in HDPE storm drain pipes, including different diameters, lengths, and wall types to suit various drainage needs and environmental conditions.

Q: What makes HDPE pipes an environmentally friendly option?

A: HDPE pipes are considered environmentally friendly due to their recyclability, reduced carbon footprint during manufacturing, and minimal maintenance requirements, which contribute to sustainable infrastructure development.

Q: How does the plastic nature of HDPE pipes benefit their application?

A: The plastic nature of HDPE pipes provides significant benefits, including flexibility, resistance to chemical attack, and ease of handling and installation, making them a popular choice for modern drainage solutions.