Selecting the right type of pipe for underground drainage is a critical step in ensuring the long-term efficiency and sustainability of any drainage system. With various materials and designs available on the market, each option offers specific advantages and drawbacks depending on the intended application, soil conditions, water flow requirements, and project budget. This article provides a comprehensive analysis of the most commonly used options, including PVC and corrugated pipes, to help you make an informed decision based on both technical considerations and practical needs. Whether you are a contractor, property owner, or engineer, understanding the characteristics of these materials is essential for designing a reliable and durable drainage solution.

What Types of Pipe Are Used for Underground Drainage?

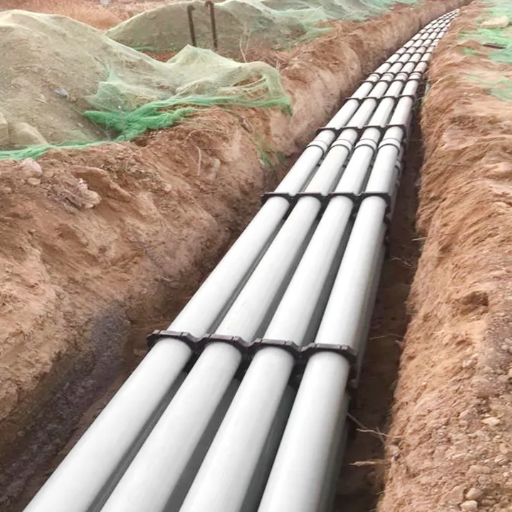

Understanding Different Types of Pipe

For underground drainage, some important types of pipes come to mind, each having its benefits based on its technical characteristics and area of usage.

- PVC Pipes: They are well known because of their strength and low price. Because PVC pipes have a smooth inner surface, they can allow for frictionless water flow. Furthermore, the pipes are corrosion-resistant, allowing them to be used successfully in various soils over a long period. Usually, the pipes come in a range of diameters of 4 inches to 12 inches, and have a tensile strength of about 7000 psi, which makes them strong enough for most residential and commercial light drainage systems. In addition, they are also resistant to many chemicals.

- Corrugated Pipes: These types of pipes are usually constructed from either polypropylene or polyethylene. They are skinny and flexible, which makes it easy to install where the layout is quite complex. The different design allows for improved structural support under pressure and adaption to uneven terrains. However, the ridged interior can sometimes inhibit water flow as compared to PVC. Depending on the application, standard versions have diameters from 4 inches to 36 inches and can carry load ratings of H-20 for traffic.

- Concrete Pipes: For more demanding tasks like city drainage systems, I suggest reinforced concrete pipes. These pipes are structurally robust enough to endure heavy external loads from machines or infrastructure projects. The compressive strength of such pipes typically exceeds 4,000 PSI and they are available in much greater diameters, up to 144 inches or more.

Selecting the right type of pipe ultimately depends on the specific requirements of the project, including soil type, load-bearing needs, flow rate requirements, and expected longevity.

When to Use PVC Pipe in Drainage Systems

PVC pipe is an excellent selection for drainage systems as long as particular conditions apply, especially, if its suitability is based on the requirements of the project’s particulars. My recommendation is PVC pipe when it comes to flexibility, chemical resistance, and ease of installment. As a lightweight material, the handling of pipes made out of PVC is simplified, thus saving on labor costs during installation. Additionally, it is corrosion-resistant, making it ideal for settings where the drainage systems may come in contact with acidic or alkaline solutions.

- Size Range: PVC pipes are available in post diameters from 1/2 inch to 36 inches built to fit small and mid-flow rate applications.

- Pressure Ratings: Depending on the wall thickness, typically rated for Schedule 40 pipes up to 160 PSI and for Schedule 80 up to 200 PSI.

- Temperature Tolerance: PVC is best effective from 0-60 degrees Celsius. Exceeding or dropping from that range may put the structure of the material at risk.

- Durability: In optimal conditions, PVC is said to have a life expectancy of 50 years, ensuring long-term efficiency.

Using PVC is particularly beneficial for residential construction or light commercial construction because of the low cost and the flexibility of the material enables the system’s operational requirements to be met without violating any regulatory codes.

How to Install Drainage Pipe Systems Correctly?

Common Mistakes to Avoid During Installation

While putting in place drainage pipes, the following mistakes should be avoided:

- Not Maintaining Proper Pipe Slope: Not using the correct slope can significantly affect the flow of water. The slope for different types of drainage systems may differ but is generally recommended to be between one-eighth to one-quarter inches for every foot. A low slope results in water getting stagnant while a high slope results in erosion.

- Using Incorrect Pipe Joining Methods: All joints need to be sealed without leaking. Failure to clean or sand the joints properly along with using the incorrect glue will severely hurt the overall system.

- Not Having Enough Bedding Material: Using uneven and overly large rocks as bedding material is a fast way for the pipes to get damaged. Always use gravel or sand because of its ability to provide support and not add much stress to the pipeline, unlike already mentioned materials.

- Not Considering the Soil Type: Soil type in the surrounding area is extremely critical. For example, landscaping with a lot of soil clay can be beneficial but may hinder drainage efficiency. It is best to make planning with soil permeability and compaction in mind.

- Not Ventilating or Testing the System: Insufficient Ventilation or Initial Performance Testing often results in a low level of functionality or repeated obstructions. Vents and traps should be fitted where necessary, and the system must be tested for water excretion to verify placement and drainage performance.

While working through these problems and following the technical instructions, I can guarantee that the installed drainage pipe system will operate without error and will be compliant with legal regulations.

Importance of Proper Slope in Drainage Systems

Having the correct slope helps in the construction and functioning of the drainage systems since it affects the flow of water and the blockage of waste materials or pools of water. Generally, the required slope in drainage pipes is between 1/8 inch to 1/4 inch for every foot of pipe (which is around 1% to 2%) concerning the pipe’s length, adjusted by the pipe diameter and the system need. This range is also necessary so that the water does not flow so slowly as to allow blocks to be formed, but fast enough to ensure that debris is carried along and prevent erosion in the pipes.

- Pipe Diameter: Larger diameters generally require shallower slopes to maintain appropriate flow velocities.

- The velocity of Flow: To avoid any chance of sedimentation, at least 2 feet per second is the ideal aim, but the velocity should not go above 10 feet per second; failure would damage the pipe and fittings.

- Hydraulic Grade Line (HGL): The slope alignment must coincide with the HGL for proper drainage to take place.

- Avoidance of Adverse Slopes: Backpitched pipes adopt negative slopes and should be avoided to negate the chances of water pooling.

To ensure compliance, these should adhere to standards outlined in regulation codes such as the Uniform Plumbing Code (UPC) or local ordinances. Proper implementation prevents long-term maintenance issues and ensures a reliable and legally compliant drainage system.

Is PVC or Corrugated Pipe Better for Drainage?

Comparing PVC and Corrugated Pipe

- Durability: PVC pipes are inherently rigid and more resistant to cracking or warping over time which renders them suitable for long-term installations. In contrast, compartmentalized pipes are flexible and lightweight, however, they may perish under strain which makes them less durable for high-pressure situations.

- Flow Efficiency: Debris blockages are a common concern with hose pipes. PVC pipes tend to be more efficient as they have smooth surface interiors, which enhances water flow and minimizes obstacles. In comparison, corrugated pipes have internals that are ribbed, which can clamp down on the flow and are more susceptible to debris.

- Load-Bearing Capacity: PVC pipes tend to be more competent in scenarios where significant weight bearing is required as corrugated pipes suffer easily from deformation. PVC pipes can comfortably handle higher structural loads with proper bedding while compartmentalized pipes will require additional supportive measures which can also be detrimental if installed too deep.

- Cost: Most people prefer corrugated pipes over PVC pipes because the initial investment is much cheaper, but those pipes do need more maintenance which makes PVC more cost-effective in terms of the long-term value.

- Installation Flexibility: The lightweight and flexibility of corrugated pipes make them easy to transport and install in hard-to-reach spaces. PVC pipes do not offer the same degree of flexibility and are more demanding about joint alignments, but they are much more stable in structured systems.

Based on all these factors, the selection of PVC or corrugated pipes is made for a particular drainage project based on load limitations, budget restrictions, and the projected service life.

Factors Influencing Pipe Choice

While looking for the finest choice between PVC and corrugated pipes, I would consider factors like cost, load-bearing capacity, as well as installation conditions. The durability of both types of pipes PVC and corrugated is crucial as both structures tend to behave differently under static and dynamic loads. PVC pipes have a rigid structure and therefore, they are expected to last longer compared to corrugated pipes. At the same time, for larger projects where there is minimal structural stress, corrugated pipes tend to be more cost-effective. In high-performance applications, PVC pipes provide long-term savings.

- Load Bearing Capacity: Thanks to the structure stiffness, PVC pipes perform better under high-pressure systems, while the flexibility of corrugated pipes makes them more suitable in areas with soil movement.

- Chemical Resistance: Because of its exceptional resistance to chemical corrosion, PVC is an ideal choice for environments with high acidity or alkalinity.

- Installation Feasibility: The lightweight nature of corrugated pipes makes them easy to handle and install in uneven terrain, in contrast to PVC pipes that require careful alignment, especially in joint segments.

- Service Life: Considering both options can comfortably last for decades, the one that typically gives an edge is PVC due to its best performance under consistent pressure.

Taking into account all these factors helps in tailoring a solution but ultimately the decision remains based on the zone and operational conditions concerning the project.

Cost-Effectiveness and Durability of Each Option

Both pipes, PVC and corrugated, have their advantages in terms of applicability, cost-effectiveness, durability, and structural strength.

From the perspective of cost, PVC pipes prove to be more cost-effective in terms of strength construction required. Corrugated pipes have a lower production cost but they lack in strength. PVC can withstand higher degrees of internal corrosive pressure while showing greater structural integrity over a longer period. In comparison to plastic, PVC also offers added corrosion resistance in alkaline and acidic environments.

In terms of flexibility, corrugated pipes trump PVC, as PVC is more rigid under static conditions. However, in comparison, riveted pipes excel under static load scenarios, where their capability to withstand a certain amount of deformation over long periods gives them the edge. Conversely, for changing environments, corrugated pipes are more flexible and are exceptionally less likely to crack under dynamic loads.

In my opinion, old, flexible, and durable are the ideal considerations for a project that prioritizes low material cost. On the other hand, for systems that require maintenance of high pressure during operation such as hoses, fittings, valves, etc, Corrugated pipes are the best option.

How Does a French Drain Work in Underground Drainage Systems?

Components of a French Drain

A French drain is typically comprised of four principal components, each having a specific functional goal to facilitate the efficient redirection of water:

- Perforated Pipe: This pipe is responsible for capturing and conducting water via holes in the body that allow groundwater to flow into and through the pipe. Material’s choice is often placed on PVC or poorly shaped plastic which is durable and non-corrosive. Perforated pipes should usually measure from 4 to 6 inches in diameter depending on the volume of water being managed.

- Gravel or Aggregate: The gravel surrounding the pipe serves as a filter to prevent sediments from blocking the pipe. Aggregate typically ranges in size from 0.5 to 1.5 inches for optimum filtration and drainage efficiency.

- Geotextile Fabric: This is a fabric that is wrapped around the gravel and pipe which has very minimal water bone and soil permeable. For optimum performance, the fabric should have a high tensile strength and a porosity rating accommodating the projected drainage flow rate.

- Trench: The trench is excavated on the slope along the desired drainage of the area planning to be landscaped with an inclination of at least 1%( which is 1a –foot drop per 100 feet) for the drainage area. Proper trench dimensions ensure the accommodation of all components while maintaining structural integrity.

These system components are together to direct water flow, mitigate soil saturation, and eliminate concerns regarding structural damage from inadequate drainage.

Advantages of Using a French Drain

The deployment of a French drain system has multiple advantages when it comes to water management and boosting structural integrity:

- Surface Water and Ground Water have Diverted Properly: A French drain works superbly in directing surface and groundwater away from sweep areas like problem foundations or low areas of the property. The system has a minimal slope of 1% in the trench to guarantee gravity-driven water flow which avoids splatter and saturation.

- Reduction of Soil Erosion and Prevention of Structural Destruction: By preventing water splashing, French drains avoid the erosion of soil that could endanger nearby structures. In addition, it decreases the pressure that water exerts on walls and foundations, hence expanding the longevity of the building.

- Tailor-Made Solutions: The use of components such as perforated piping and geotextile fabrics enables the enhancement of specific site conditions. For example, a selectively strong fabric with good porosity can guarantee the passage of water whilst allowing the fabric to last long.

- Affordable and Eco-Friendly: French drains are cost-effective in installation and maintenance. French drains do not require pumps and other energy-driven devices because they depend on gravity and passive water flow.

- Multi-Purpose Features: These systems work effectively at homes, on farms, and in businesses, whether dealing with run-off from buildings, excess water around gardening sites, or controlling drainage on large sites.

I recommend assessing the soil type, estimated water flow rates, and the intended installation depth to fine-tune the trench dimensions and material specifications. These considerations ensure the French drain will operate reliably and meet your drainage requirements.

What Are the Benefits of Using HDPE Pipe in Drainage?

Durability and Flexibility of HDPE Pipe

High-density polyethylene (HDPE) pipes are lauded for their outstanding durability and versatility for a variety of drainage systems. Their durability stems from highly efficient chemical corrosion, abrasion, and environmental stress cracking resistance (ASTM D2837 tested). They have a service life of over 50 years under standard operating conditions, making them a go-to for long-term drainage solutions.

Another key feature of HDPE pipes is their flexibility, which allows them to withstand flexing loads and movements such as ground settling and expansion. With a minimum bending radius of 20-25 times the pipe’s outer diameter, SDPE pipes can adapt to difficult terrains and layouts without losing structural integrity. This flexibility significantly reduces risks of joint failure and also facilitates installation in areas with varying soil conditions.

Furthermore, HDPE pipes can endure extreme climates as low as -40 °C due to their high-impact resistance, ensuring reliable operations. The material also has smooth tubing with a Manning’s roughness coefficient of 0.009 that improves the flow by achieving lesser friction which propels effective drainage even at higher flow.

These certain characteristic features enable HDPE pipes to be effective, strong, and economical. There is a need to determine the proper pipe size along with the wall thickness, which is based on SDR ratings as well as the installation depth so that the application demands will be able to meet system efficiency.

Applications for HDPE Pipe in Drainage Systems

HDPE Pipes are commonly used in agriculture, civil engineering, and construction activities due to their ability to withstand high-impact flexural forces. This includes a plethora of systems such as Agricultural drainage, Sanitary sewer systems, Industrial sewage disposal, and Stormwater management systems. More specifically, HDPE pipes are used in applications where long-term efficient flow capacity is required while also needing resistance against corrosion, abrasives, and chemicals.

As an illustration, HDPE pipes are also prominently used in stormwater management systems due to their high-impact resistance flexural zones. Moreover, having a smooth internal surface combined with a Mannings roughness coefficient of 0.009 enables HDPE pipes to retain high throughput. Agricultural drainage also benefits through enhanced service life from the flexibility of the material to access soil chemicals without degradation.

When dealing with the appropriate wall thickness and pipe size, depth of installation and SDR (standard dimension ratio) govern it best. The justification can be calculated as follows:

- SDR rating: Determines the ratio of a pipe’s diameter to the wall’s width. Lower SDR ratings such as 11, are more favorable in pressurized drainage systems. Pipes tend to increase in width for higher SDR ratings, meaning they are more suitable for low-pressure environments.

- Installation Depth: If the pipe is placed deeper into the ground, it has to endure more stress from soil weight and possible surface vehicles. This means deeper installations require stronger pipes to avoid bulging or collapsing. Thicker walls and increased compression strength are also necessary.

The use of HDPE pipes that meet these specific standards guarantees dependable and efficient sustained use for a wide variety of drainage systems.

Reference sources

Frequently Asked Questions (FAQs)

Q: What factors should be considered when choosing a pipe for underground drainage?

A: When selecting a pipe for underground drainage, consider the type of project, the amount of water the pipe needs to carry, the durability of the material, and corrosion resistance. It’s also important to consider whether the pipe needs to be perforated for leach fields or solid for direct runoff management.

Q: Is PVC drainage pipe the best choice for underground drainage systems?

A: PVC drainage pipe is often considered one of the most common options due to its durability, resistance to corrosion, and availability in various sizes.

Q: How does corrugated pipe compare to PVC for yard drainage?

A: Corrugated pipe is less expensive and flexible, making it a good choice for winding around obstacles. However, it may not be as durable or resistant to clogging as PVC, making it better suited for temporary or less critical applications.

Q: What role do downspouts play in underground drainage systems?

A: Downspouts are crucial in directing roof runoff into underground drainage systems. Properly installing downspouts ensures that water is efficiently moved away from the house foundation, minimizing erosion and water damage.

Q: What size pipe is most commonly used for underground drainage projects?

A: A 4″ pipe is one of the most common sizes used for underground drainage due to its ability to handle a substantial amount of water, making it suitable for most residential applications.

Q: Why might a homeowner choose a solid pipe over a perforated pipe?

A: A solid pipe is best for applications where the goal is to carry water away from the source quickly, such as from a sump pump or downspout, without allowing it to leach into the surrounding soil.

Q: Can underground drainage pipes impact water quality?

A: Yes, underground drainage pipes can affect water quality. Using high-quality materials like polyvinyl chloride (PVC) that are resistant to corrosion helps maintain clean water by preventing contaminants from entering the system.

Q: How does pipe installation affect the performance of an underground drainage system?

A: Proper pipe installation is critical for the effective performance of an underground drainage system. Ensuring correct slope, secure connections, and adequate coverage with soil or gravel will help prevent clogging and enhance the system’s longevity.

Q: What are some common types of underground drainage pipes available?

A: Common types of underground drainage pipes include PVC, corrugated, and concrete pipes. Each offers different benefits, such as PVC’s durability, corrugated flexibility, and concrete strength, depending on the specific needs of the project.

Q: How can yard drainage solutions be optimized for homeowners in the north?

A: Homeowners in the north should consider using durable materials like schedule 40 PVC to withstand freeze-thaw cycles, and ensure proper slope and insulation to maintain effective underground drainage during harsh weather conditions.