PEX (cross-linked polyethylene) pipe is a popular option in today’s plumbing applications due to its versatility, durability, and ease of installation. A comprehensive discussion on 1-inch PEX pipe is presented in this article, outlining its advantages, limitations, and possible uses in different plumbing situations. Whether planning a DIY project or considering PEX for professional plumbing installations, it’s essential to know the features and benefits of 1-inch PEX. This guide will provide you with all you need to know about its resistance to corrosion and scale and its ability to withstand extreme temperatures.

What is 1 Inch PEX Pipe, and How is it Used in Plumbing?

Image source: https://www.lowes.com/

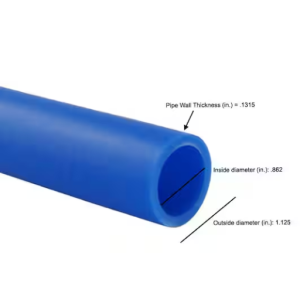

Commercially used cross-linked polyethylene tubing, which is flexible, is referred to as 1-inch PEX pipe. Being quite wide in diameter, this piping can be applied for numerous purposes, including radiant heating systems and water supply lines. The material makes it easier to install since it can be passed through walls, ceilings, and tight spaces without too many fittings, implying than those necessary for rigid pipes, among other things. Additionally, one-inch PEX does not corrode from scales or chlorine, thus reducing the occurrence of plumbing issues over time. The capability of expanding or contracting according to temperature changes further makes the tube ideal for the distribution of hot and cold water.

Understanding PEX Tubing: Types and Applications

The three main types of PEX tubing are PEX-A, PEX-B, and PEX-C. Each has different production processes and characteristics.

- PEX-A: This type is made by employing the Engel method for cross-linking and possesses maximum flexibility, which makes it an excellent option for applications that require tight bends or curves, like retrofit projects. It is also known for its kink resistance and ability to withstand extreme temperatures.

- PEX-B: The silane method is used to produce PEX-B, which is somewhat less flexible than PEX-A but is usually the cheapest. It is highly resilient to chlorine and can be employed in hot and cold water systems, hence making it a favorite among contractors and plumbers for contemporary plumbing duties.

- PEX-C: Irradiation is employed in this type of pipe to induce crosslinking, making it available in a narrower range of sizes. Though not as flexible as PEX-A, it may still be a more economical choice for different uses.

Regarding application, primarily water supply lines, radiant floor heating, and some fixtures have been considered for use in pex tubing. Its easy fitting and adaptability make it the preferred choice for new buildings and renovations. Understanding various types with their specific uses assists plumbers and DIY enthusiasts when carrying out plumbing projects that need their attention.

The Advantages of Using PEX Pipe in Plumbing

In terms of my own experience, PEX tubing has revolutionized plumbing projects. Firstly, it is flexible and, therefore, easier to install, meaning routes can be quicker and less complicated than rigid pipes. Additionally, the material resists corrosion and scaling, which prolongs its lifespan while requiring minimal repairs. It also holds well in freezing temperatures without breaking, which is an excellent advantage for colder areas. Moreover, few fittings are needed, reducing the chances of leaks that necessitate buying additional materials or employing plumbers. Thus, not only does PEX simplify installation, but it also supports long-lasting and effective plumbing systems.

Comparing 1-inch PEX to Other Plumbing Materials

Differences between 1-inch PEX pipe and similar materials like CPVC, copper, and PVC become apparent. In comparison with hard materials such as CPVC and copper, PEX is extremely flexible hence making it more convenient to fix in tight places and have fewer connections as well. Unlike PEX, copper corrodes while this material resists scales; thus, it lasts longer than them. As such 1” PEX pipe tends to be cheaper than copper so far its easy installation is concerned both in terms of material costs and reduced labor expenses. The latter however become brittle in cold temperatures unlike the freeze resistant property exhibited by PEX. Another type of plastic piping called PVC only handles cold water applications but cannot be used within drinking water systems thereby limiting its application when compared with PEX which can be employed for almost any plumbing need within a house. Thus, an alternative variant might include a broader sense of flexibility about diversity in plumbing services regarding these situations.

How to Install 1 Inch PEX Pipe?

To install a 1-inch PEX pipe, you will have to follow these straightforward procedures. First, gather the necessary tools: a PEX cutter, crimp rings, a crimping tool, and appropriate connectors. To avoid water leaks, begin measuring and cutting the PEX pipe to the correct lengths; ensure the cuts are clean and straight. Then, put the crimp ring on the pipe and insert the fitting by pushing it in firmly. The crimping tool tightens the ring around the pipe, creating an airproof seal. Repeat this for each joint. All joints should be pressurized to check for leakage after fixing all fittings in their places. Finally, if needed (especially for colder areas), cover exposed pipes using insulation.

Necessary Tools and Materials for PEX Installation

Arguments Supporting 1-Inch Pex Pipe Installation

- Pex Pipe: Select your preferred length and size based on project specifications.

- Pex Cutter: A pointy device designed to cut pex plumbing materials neatly.

- Crimp Rings: These metallic bands hold pipes together with their fittings.

- Crimping Tool: This equipment helps compress crimp rings around PEX pipes, enhancing the tightness of the connection through a watertight seal.

- Fittings: Varied types of connectors, such as tees, elbows, or adapters, allow changes in direction and join existing plumbing fixtures.

- Measuring Tape: It gives better results when measurements are accurate enough for perfect alignment while cutting tubes into appropriate sizes.

- Deburring Tool: optional but helpful in smoothing out sharp edges of cut pipes before inserting them into fittings so that they fit well enough and make proper sealing.

- Insulation: Insulation is essential to protect any exposed PEX piping from freezing when temperatures drop below zero degrees Celsius or Fahrenheit, depending on where you live.

Once you have these tools and items at hand, installation becomes easy, which makes your plumbing project successful overall.

Step-by-Step Guide to Installing PEX Tubing

- Lay It Out: I start by sketching a layout of my plumbing system that indicates where the pipes and fittings will be placed. This gives me a mental picture of what I am doing and prepares me with all the necessary materials.

- Measure and Cut: With my tape measure, I measure the lengths of each segment of the PEX pipe and label them. Then, I use the PEX cutter, making sure that it leaves smooth ends through straight cutting.

- Deburr If Necessary: A deburring tool may help remove sharp edges from cut pipes to enable smoother connections.

- Insert Fittings: For safety, I make sure they are fully inserted into the ends of the cut PEX pipe.

- Attach Crimp Rings: The crimp ring must be positioned approximately an inch away from the pipe end and aligned correctly overfitting.

- Crimp the Connections: Using my crimping tool, I tightened crimp rings around both the PEX pipe and fitting; hence, there is no leakage. Enough pressure was applied to confirm complete tightness in this connection.

- Repeat for All Connections: Every joint must be secured by following a similar course throughout the plumbing arrangement without haste.

- Test for Leaks: After setting up all joints, I pressurize the system and check each one for leakage, which is very important before proceeding to step 10 as it confirms if everything has been done well.

- Insulate Exposed Pipes: Finally, to avoid freezing and increase energy efficiency in your home, you should cover any visible pipes with insulation.

Following these steps accurately ensures the successful installation of PEX tubing in my plumbing project.

Common Mistakes to Avoid During Installation

- Pipe Support is Inadequate: Not supplying appropriate support for PEX pipes may cause them to sag and cause damage. To maintain the alignment of the pipe, it must be bracketed or strapped every several feet to prevent it from wearing out.

- Expansion and Contraction Ignored: PEX pipes expand and contract when temperatures change. Fittings are stressed because they do not allow for this effect, causing leaks. Manufacturers’ spacing and supporting instructions should always be followed.

- Using Wrong Fittings: The integrity of the installation of non-compatible connectors with PEX can easily be compromised. Ensure the chosen fittings are compatible with PEX piping systems to guarantee leak-proof installation.

What are the Different Types of PEX and Their Applications?

There are three types of PEX tubing which cater for different applications:

- PEX-A: This type is manufactured through the Engel process, which makes it highly flexible and kink-resistant. It is an ideal choice when bends are involved, like those found in dwelling plumbing systems or radiant heating networks.

- PEX-B: This kind is made using the silane method, so it has good flexibility and resistance to chlorine. It is mainly used in general plumbing, particularly home systems, because of its capacity to handle high temperatures and pressures.

- PEX-C: The last category employs an irradiation technique during manufacturing, making it less flexible than others. Typically, straight runs demand this type of tubing since bending angles might be restricted by tight spaces common in commercial settings.

Every variation of PEX tube has benefits, so you can choose the one that is appropriate for your plumbing or heating needs.

Differences Between PEX-A, PEX-B, and PEX-C

The differences between PEX-A, PEX-B, and PEX-C are primarily in production methods, flexibility, and suitability for different applications.

- Flexibility: It is known for its excellent flexibility, which can be used in complex layouts and tight bends as well as in other situations, while PEX-B, on the other hand, has moderate flexibility that serves general plumbing purposes. Consequently, PEX-C is not as flexible as the others but would be great straight runs in commercial applications.

- Kink Resistance: Due to its manufacturing process (Engel), PEX-A has very high kink resistance which makes it bounce back from bends effectively. Although not as much as PEX-A, kink resistance is also good with PEX-B. On the other hand, Pex C, which has stiffness, may suffer more from this kinking problem than others.

- Chemical Resistance: In addition to being durable, there is also evidence that these materials do not stand up well against chlorine, such that Pex-a and pex-c are more likely to deteriorate when exposed to chlorinated water, while pex-b has better chlorine resistance.

- Applications: This one comes in handy for residential plumbing or radiant heating systems where durability and flexibility are considered key factors. Regarding home plumbing systems, you can use pex-b; however, space limitations do not allow pipe bends; hence, they mostly prefer using pex-c.

Depending on specific project requirements, these disparities help plumbers and builders select the appropriate pipes for their businesses.

When to Use Non-Barrier PEX Tubing?

For example, non-barrier pex tubing will go for installations where water quality does not matter about oxygen penetration. Non-barrier pex: I usually use it in applications like hot and cold water distribution systems because it doesn’t affect water quality, unlike simple plumbing installations. It is also suitable for non-heat-related purposes since no barrier layer against oxygen diffusion is required, allowing easy routing through any path. PEX without a barrier layer against oxygen diffusion is perfect for non-heating-related uses. Moreover, it is ideal for projects that do not require the enhanced performance characteristics of barrier pex; hence, it is also affordable for some residential plumbing jobs.

Applications for Non-Oxygen Barrier PEX

Non-barrier PEX tubing is suitable for several applications where oxygen diffusion is not particularly important. Some of its common uses include:

- Hot and Cold Water Distribution: It is widely used in residential plumbing systems for hot and cold water supply, thereby allowing smooth water transfer without any threats to its quality.

- Hydronic Heating Systems: Though lacking the oxygen barrier, it can still be used in some hydronic heating systems, provided the system design adequately addresses potential issues with oxygen leakage.

- Refrigeration Lines: In refrigeration systems, non-barrier PEX may be used due to its flexibility, ease of installation, and absence of risk from oxygen exposure.

- Residential Applications: Many homeowners prefer non-barrier PEX for general plumbing tasks as it is cheaper than other types and multifunctional, especially during home remodeling or construction.

This kind of pipe offers an economical solution for easy-to-execute plumbing projects, which do not require the advanced features provided by an oxygen barrier PEX.

Can PEX Pipe be Used for Hot and Cold Water Lines?

Yes, PEX pipes can be used as hot and cold water lines in residential plumbing systems. Their excellent flexibility and resistance to temperature swings make them good for many different uses. They withstand temperatures up to 200°F (93°C) and pressures up to 80 psi, thus making them perfect for hot water conveyance without fear of breakages or leakages. Corrosion-resistant properties are essential as they help maintain high-quality drinking water, hence making them a common choice for plumbers and homeowners alike.

Temperature Ratings and Limitations of PEX Tubing

While PEX tubing can be used continuously for hot water applications at temperatures up to 200°F (93°C), it is limited to a maximum temperature of 180°F (82°C) and pressure of 80 psi. It should, however, be noted that exposure to high temperatures over long periods tends to reduce the life of PEX tubing. Furthermore, though PEX has the advantage of freezing resistance, it is advisable not to install it in areas with extreme coldness as this may lead to bursting. Also, care must be taken not to expose PEX pipes directly to sunlight for a long time since ultraviolet rays will degrade them, thus leading to potential failure for outdoor use. Therefore, choosing the right pex based on its temperature requirement and environmental situation is highly important so one can have confidence in the plumbing system.

Ensuring Potable Water Safety with PEX

When selecting PEX for drinking water safety, I ensure that I use Premium-Quality pex tubes that meet or exceed the required standards for potable water. Drinking safe water necessitates using pex pipes certified by organizations like NSF (National Sanitation Foundation). Additionally, proper installation methods are insisted upon me to avoid possible contamination cases, thereby being against direct contact with chemicals or abrasive materials during piping because they tend into tube walls, which would, in turn, pollute water quality. Check leaks regularly and maintain cleanliness and dryness in an installation area, which also helps guarantee a secure plumbing system. These practices ensure my family’s health and welfare through the unending support of durable pex plumbing systems within our premises.

Using PEX for Radiant Heat Systems

Due to its flexibility, durability, and ability to withstand thermal expansion, PEX is considered an ideal choice for radiant heat systems. Moreover, PEX ensures efficient energy usage in radiant heating while providing even heat distribution, enhancing overall comfort. When discussing corners and other obstructions, it’s important to mention that this material can easily bend around them without using fittings and causing minimal temperature loss. Also, resistance to scale and chlorine extends the service time and supports sanitary water conditions in a system made of PEX. This necessitates choosing the right PEX to withstand the operating temperatures commonly encountered with radiant heat systems to ensure optimal performance over its lifetime.

What Fittings and Accessories Are Needed for 1-inch PEX?

Working on 1-inch PEX tubing requires several fittings and accessories for a secure and efficient plumbing system. Some of these key parts include:

- PEX Couplings: These are needed to connect two pieces of PEX tubing.

- Elbows: These are used when pipes need to go around corners or change direction at a 45° or 90° angle.

- Tees: Tees allow branching off from main lines into more pipe sections

- Shut-off Valves: Water flow is vital for easy maintenance and repair.

- PEX Crimp Rings or Sleeves: To tighten joints, you will need these rings, which encircle both tube ends and fit.

- Expansion Fittings: They are needed when expanding PEX through an expansion method since only special fittings designed for expanding pex will do.

- End Caps and Plugs: For sealing off ends of pex tubing

Once you use quality fittings and accessories that fit well with one-inch PEX, you can get a reliable plumbing system tailored to your requirements.

Types of PEX Fittings: Crimp, Clamp, and Push-Fit

For PEX tubing, the three most common fittings are crimp, clamp, and push-fit.

- Crimp Fittings: These are the most traditional option and require a unique tool to crimp a metal ring around the PEX tubing and the fitting. This type of fitting is called “crimp” because it requires a unique tool to press a metal ring over its part to seal it tightly. However, they must be installed correctly, or poor crimping will cause leaks.

- Clamp (or Cinch) Fittings: Like crimp fittings, clamp connections use stainless steel clamps to hold them together. Moreover, these locks can be adjusted easily and do not require certain tools for their performance, which makes them demanded by those who prefer self-preservation.

- Push-Fit Fittings: These fittings require no tools and offer quick installations. The best thing about push fittings is that once you fit your tube into it, they make an automatically watertight seal, which is good for quick fixes and tight installations. However, they might cost higher compared to crimps and clamps.

Thus, each type has benefits and serves different purposes depending on your plumbing requirements; therefore, choose wisely.

Choosing the Right Crimp Rings and Clamps

When I choose PEX fitting rings with crimps or clamps, I think about quality before anything else. After researching online forums, I have discovered that rings made from top-grade materials like copper or stainless steel tend to last longer without rusting. To guarantee that my connection will not break down easily due to wear or size of the tube needed I learn how to select correct size of crimp rings that match the diameter of my piping system. Also, when installing them, I must have the right tools. For instance, if I’m working on specific diameters, then using a specialized crimper tool for such sizes would help prevent any potential leakage issues at the end stage of installation. Finally, I would check reviews or anything that could assist me in gauging whether these products are dependable since other clients’ opinions may help me make accurate choices.

Compatibility with Other Plumbing Systems

This compatibility PEX fittings have with other plumbing systems must be known: PEX can link smoothly to copper, CPVC, and PVC pipes using appropriate transition fittings. These connections are allowed under most plumbing codes, but one must confirm that the connector is meant for transitioning between these materials. Moreover, using high-quality fittings when combining PEX with existing plumbing is advised to avoid leaks and get a tight seal instead. Specific adaptors may be required for certain instances, such as when dealing with old metal pipes; therefore, referring to local codes and manufacturer’s instructions is recommended in every case. Prioritizing compatibility can make your overall plumbing system more reliable and efficient in delivering its services.

Reference sources

- 1″ Non-Barrier PEX B Tubing 1000′ coil – BLUE Certified – Badger Pipe

- SharkBite 1-in x 100-ft White PEX-B Pipe – Lowe’s

- 1″ x 300 Feet PEX for Potable Water (Blue) – PEX Superstore

Frequently Asked Questions (FAQs)

Q: What is a 1-inch PEX pipe, and where is it commonly used?

A: A one-inch PEX pipe is a flexible plumbing tube typically used for water supply lines. It is popular in residential and commercial plumbing applications due to its ease of installation and durability.

Q: What does “nonoxygen barrier” mean with PEX tubing?

A: “Non-oxygen barrier” refers to PEX tubing that does not have a special layer to prevent oxygen from permeating through the pipe. This type of PEX is typically used for potable water systems, not radiant floor heating systems, where oxygen can cause corrosion.

Q: How flexible is the 1-inch x 500 ft PEX pipe?

A: The 1-inch x 500 ft PEX pipe is highly flexible, making maneuvering around corners and through tight spaces easy. This flexibility makes it an excellent choice for long runs in plumbing applications.

Q: What specifications should I look for for potable water in PEX-B tubing?

A: When selecting PEX-B tubing for potable water, ensure it is NSF-certified and meets ASTM standards. Additionally, it should be labeled as a “nonoxygen barrier” to confirm its suitability for drinking water.

Q: How does PEX-B compare to traditional copper pipe?

A: PEX-B pipe is generally more flexible, easier to install, and less expensive than traditional copper pipe. It is also resistant to scaling and corrosion, making it a durable choice for water supply lines.

Q: Can I use VEVOR PEX pipe for hot and cold water plumbing?

A: The VEVOR PEX pipe is designed to handle hot and cold water plumbing applications. It is rated for temperatures up to 200°F and pressures up to 160 psi.

Q: What is the maximum pressure rating for 1-inch PEX tubing?

A: Most 1-inch PEX tubing, including VEVOR ones, can handle pressures up to 160 psi. Always check the manufacturer’s specifications to ensure compliance with your plumbing requirements.

Q: Is it possible to use PEX tubing for radiant floor heating?

A: Yes, PEX tubing can be used for radiant floor heating. However, to prevent oxygen from entering the system and causing corrosion, oxygen barrier PEX tubing is essential for this application.

Q: How long is a typical coil of 1-inch PEX pipe?

A: A typical coil of 1-inch PEX pipe can come in lengths such as 300 feet or 500 feet. Depending on your project needs, you can find options like 1 inch x 300 feet PEX or 1 inch x 500 ft PEX.

Q: What are the advantages of using white PEX-B pipe for cold water plumbing?

A: White PEX-B pipe is highly resistant to freezing and bursting, making it ideal for cold water plumbing. Its flexibility and ease of installation also reduce labor costs and time, making it a cost-effective solution.