However, butt fusion flange fittings play an essential role in the world of high-density polyethylene (HDPE) piping systems. As a result, which is necessary for producing secure joints butt fusion process ensures that pipe connections remain free from leaks and enhances the durability of pipe networks. This article will delve into the critical aspects of butt fusion flange fittings, including their benefits, installation procedures, and applications. We aim to provide a complete overview that will enable readers to know why these fittings are essential in HDPE systems and identify how they can be used best through this paper. For both experienced professionals and newcomers in this field, this guide is a must-have resource for anyone who wants to know more about butt fusion technology.

What is the Butt Fusion Method?

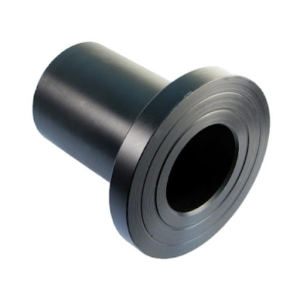

Image source: http://www.zjjunshan.com/

The butt fusion method is a technique employed in welding two pieces of HDPE pipe or fitting them together by heating their ends until they become soft and then pressing them against each other, creating permanent bonds. It involves using specialized equipment that can precisely control temperature and pressure during fusing, thus ensuring uniformity and strength of connection. Therefore, it results in smooth linkages that retain the integrity of the pipe system, making it advantageous for demanding service conditions. Leaks are easily prevented. Hence, its reputation as a practical measure against leaks results in long-lasting installations using HDPE systems.

Understanding the butt Fusion Process

Butt fusion is a process that requires following specific steps which will ensure successful jointing of HDPE components. For instance, the first step involves trimming the ends of pipes or fittings to make them flat and then cleaning such areas to ensure they are even. After that, specialized fusion machines align and hold the pieces into place. The ends are then heated with heating plates until they soften at the right temperature. The heating plate is removed once enough heat has been transferred and softened ends brought together under controlled pressure. This pressure is kept for a specific cooling period, which helps solidify the joint, creating a solid connection with no leaks. Operating personnel must closely regulate temperature and timing during this process since these parameters significantly influence the weld’s strength and quality. Butt fusion joints appropriately form an integral part of long-lasting as well as reliable HDPE pipe systems being applied for different purposes ranging from water distribution to industrial operations.

The Role of fusion machine in the Butt Fusion Method

The fusion machine serves as the equipment applying heat and pressure in connecting HDPE pipes and fittings through the butt fusion method. These devices are made with high-precision mechanisms enabling accurate control of temperatures alongside the alignment of pipe ends and their fusion. Usually, they incorporate hydraulic systems that help maintain consistent pressures necessary for good bonding uniformity. On the other hand, advanced models possess digital controls indicating heating and cooling cycles to guide operators in meeting specified standards required for a successful welding exercise. It is crucial because it prevents defects, thereby promoting the longevity of joints, which again means higher reliability on the overall performance of these HDPE piping systems serving various purposes like municipal water supply or industry applications.

Why Choose the butt fusion flange over Other Methods?

Among the alternative joining techniques, butt fusion flange selection has several advantages. First, when it comes to high-pressure applications, butt fusion results in a continuous joint that significantly minimizes the chance of possible leakages. Furthermore, this technique ensures an equivalent strength between the pipe and its joints, thus improving system integrity and durability. Also, it is perfect for connecting pipes made of the same material, unlike mechanical fittings, which may cause compatibility issues. Different from other methods, such as threaded or glued connections, butt fusion does not need much maintenance and reduces the chances of failure with time. Hence, experts in this field prefer using butt fusion due to its reliability and efficiency.

How to Select the Right Butt Fusion Flange Adapter?

Choosing a suitable butt fusion flange adapter involves many factors that must be considered for compatibility and functionality within your piping system. First, evaluate the pipe diameter and wall thickness while choosing an adapter for those measurements. Moreover, ensure that you confirm both the pipe’s material and that of the adaptor; they should be constructed using similar polymers to achieve optimal bonding. Another essential factor is pressure rating; select an adapter that satisfies your system pressure pressure-specified requirements. Finally, go through any industry regulations together with certifications available to ascertain compliance with these quality assurance measures on that particular fitting chosen. Thus, adhering to this approach fully ensures reliable connection in HDPE piping applications.

Critical Factors in Choosing a butt fusion flange adapter

There are several factors to consider when selecting a flange adapter for butt fusion.

- Compatibility: Make sure the adapter is compatible with the specific type of pipe material, usually HDPE because compatible materials will form a stronger bond.

- Size and Specification: Match the adapter to the diameter and schedule of pipes. The wall thickness should also be considered to achieve a secure fusion.

- Pressure Rating: Ensure that the adapter’s pressure rating is equal to or exceeds the system’s pressure; otherwise, there may be failure or leakage in the future.

- Standards Compliance: Does the adaptor meet industry standards like ASTM and ISO? This guarantees quality control and dependability.

- Manufacturer Reputation: It is advisable to go for adapters from reputable manufacturers who have some sort of guarantee systems and customer services as it would give one confidence and better long-term performance

These considerations will help you make an informed decision leading to more reliable pipework.

Comparing high-quality HDPE Butt Fusion Flange Adapters

To evaluate butt fusion flange adapters with high resolution, we have to look at a few points that are typically outlined.

- Materials: Good adapters are usually made of virgin HDPE resin, which ensures that they are very durable and highly resistant to impact. This increases their life span as opposed to those made from recycled materials, which may have compromised structural strength.

- Fusion Techniques: Top suppliers focus on technologically advanced fusion processes that result in tight and dependable joints. Adapters designed to better distribute heat during the fusion process normally give stronger results.

- Testing and Performance: Reputable vendors subject their products to intensive tests such as hydrostatic and tensile testing; therefore, they can be used effectively under pressure as well as adhere to industrial specifications

- Warranty and Support: Fine-quality adapters often come with extended guarantees as a sign of the manufacturer’s confidence in the product. Furthermore, well-respected producers provide customers with excellent support services so that they can learn how to fix them in place or even maintain them.

By examining these considerations and comparing different products through trusted reviews from credible sites, customers can then make well-informed choices concerning their HDPE butt fusion flange adapters.

What Sizes Are Available for HDPE Butt Fusion Flanges?

HDPE flanges for butt fusion come in different sizes, corresponding to various pipe systems. They usually range between 1/2 inch and 24 inches in diameter, with some vendors having up to 63-inch sizes for massive applications. Generally, each size is designed per industry standards that ensure compatibility with other HDPE piping components. Therefore, when selecting the correct flange for a specific project, it is essential to consider the joint’s nominal size and pressure rating since these factors may significantly affect overall performance and system integrity. Also, always refer to manufacturer specifications for exact sizing and fitting requirements.

Step-by-Step Installation Guide for Butt Fusion Flange Fittings

- Preparation: Make sure that the working area is clean and that all necessary tools and materials, including the HDPE Flange, fusion machine, and safety equipment, are present.

- Cutting the Pipes: Use a pipe cutter to cut HDPE pipes cleanly and squarely without burrs.

- Aligning the Flange: Place it on each end of your prepared pipes, ensuring they are correctly aligned at the fusion angle.

- Heating the Joint: The fusion machine should be set at temperatures suitable for HDPE (about 500°F or 260°C). Put a heating plate between flanges, allowing surfaces to heat for the duration specified, such as 30-60 seconds.

- Fusing the Flanges: Remove the heating plate; quickly bring together the flanges, fusing them using controlled force and applying pressure over the recommended cooling time to allow the formation of the joint.

- Cooling: Allow undisturbed cooling for at least twenty minutes (or more, depending on the diameter) until a sound bond is formed.

- Inspection: After cooling down, check for any defects or gaps at the joint. Perform a pressure test to confirm if the installation has been done correctly.

- Documentation: Finally, record details about the process used during installation, including measurements taken, temperature points reached, and time frames allocated, among other things, for future reference or inspections.

Through these steps, you will have carried out a proper installation of HDPE butt fusion flange fittings which is in line with performance and safety codes.

Preparation: Tools and Raw Material Requirements

To successfully install HDPE butt fusion flange fittings, you will need the following tools and materials:

- Tools:

- Pipe Cutter: This tool is essential as it helps make clean and accurate cuts on HDPE pipes.

- Fusion Machine: A device specializing in heating pipe ends, thus creating a solid joint by melting it.

- Heating Plates: They are used to provide heat during the fusion process.

- Pressure Gauge: This pressure gauge will enable you to test for pressure and establish whether there’s integrity in its joint.

- Raw Materials:

- HDPE Pipes: Ensure these have the correct diameter and length according to project specifications.

- HDPE Flanges: These items should be able to fit into the pipe system as well as serve their purpose well.

- Safety Equipment: Safety equipment includes personal protective clothing such as gloves, goggles, and heat-resistant garments for use with the fusion process.

Preparing these materials beforehand will smooth out the installation of these fittings and ensure the production of high-quality results.

Step-by-Step butt fusion fittings Installation Process

- Cut Pipe Ends: Use a pipe cutter to square off the ends of HDPE pipes that are being joined.

- Prepare Fusion Machine: Install the fusion machine, ensuring it is properly calibrated. Place heating plates inside and set the desired temperature (usually between 400°F and 450°F).

- Align the Fittings: Locate both the pipes and HDPE butt fusion fittings into the machine. Their ends must meet squarely before they are fastened together securely.

- Heat the Ends: Let your heating plates press down on top of both sides of your plastic plumbing until it gets too warm (usually takes minutes) enough so that they can become molten or liquefy properly as suggested in manufacturer’s guidelines or product instructions usually about five (5) times hotter than boiling water which means over 500 degrees Celsius!

- Joining Pipe Sections: After heating them up, simply remove your hotplate and gently squeeze together both edges with your hand or vices; this has to be done with care because if mishandled, any of them may slip apart, thereby causing damage.

- Excellent and Set: This pressure should be maintained for some time, during which the bond firmness is brought about by contraction as it cools off and hardens.

- Examine the Joint: Inspect the joint once it’s cool to ensure that there are no defects, such as gaps between materials or partial melting along its length.

- Conduct Testing: Before installation, a pressure test should be conducted to ascertain the integrity and performance of the fused joint.

- Record Keeping: Make sure you follow all steps involved to maintain records of what was done during the installation process.

By adhering to these measures, a safe and efficient installation can be guaranteed.

Post-installation Checks and Testing

Upon completion of the HDPE pipe fusion, it is essential to carry out comprehensive post-installation checks and tests to ascertain the integrity and dependability of the system. Initially, scrutinize all joints and connections visually for any evidence of leaks or deviations. Proceed to pressure test in line with industry standards, usually via a suitable medium such as water or air. Check for pressure drops that may mean leaks or loose connections. Additionally, make sure all fittings and supports are firm and properly aligned. Finally, written records of the findings, including any necessary repairs or adjustments made during testing, must be made to record installation conformity with health and safety regulations comprehensively.

Understanding the Product Description of Butt Fusion Flanges

Butt fusion flanges are integral parts used in joining high-density polyethylene (HDPE) pipes during the butt fusion process. These flanges ensure a robust and tight connection, which enables them to fit nicely into piping systems. The butt fusion flanges typically are prepared from a similar material to the pipes hence making them compatible and not compromising the system’s integrity. They can withstand high pressures and come in different sizes; thus, they can be able to accommodate various pipe diameters under consideration. In choosing butt fusion flanges, the particular applications must be considered, as well as a pound per square inch rating and how well they meet relevant industrial requirements so that performance becomes optimum, plus reliability is achieved.

Features of Quality HDPE Butt Fusion Flanges

Quality HDPE butt fusion flanges possess several essential attributes that guarantee long-lasting use and effective functioning in piping systems. Firstly, they must be fabricated from high-density polyethylene material (HDPE) corresponding to the pipe specifications to ensure optimum fusing and connecting strength. Moreover, these flanges are usually built strong enough to endure high pressures and temperature fluctuations for their long-term reliability in various applications. Equally important is their corrosion and chemical resistance, making them suitable for multiple environments, including industrial settings. Other than that, quality butt fusion flanges must also satisfy relevant industry standards/certifications, thus ensuring compliance/safety of infrastructure projects. Finally, ease of installation and being compatible with standard butt fusion equipment are some critical considerations when choosing them for such an integration into an existing system.

Differentiating Between SDR 11 and Other Ratings

SDR, or Standard Dimension Ratio, is an important figure that relates a pipe’s diameter to its wall thickness. For example, SDR 11 means a particular ratio of 11:1, implying that the pipe’s diameter is 11 times its wall thickness only. This value becomes significant, mainly when pressure ratings matter since it influences the pipe’s ability to withstand internal forces.

On the contrary, other SDRs like SDR 17 or SDR 9 represent different wall thicknesses on pipes with the same outer diameters, leading to variations in their pressure capacity and structural integrity, respectively. For illustration purposes, thinner walls in SDR 17 are applicable for low-pressure applications, while thicker walls are featured in SDR 9 pipes, enabling higher pressure ratings. Therefore, understanding these distinctions will help identify specific piping requirements so that any system chosen for these purposes can meet safety and performance standards.

How polyethylene Properties Affect Fusion Fittings

The performance and reliability of fusion fittings highly depend on the properties of polyethylene. Durable joints that can withstand stress and movement without cracking can be formed using polyethylene’s excellent flexibility and impact resistance. For instance, due to its low density and high chemical resistance, it is a suitable material for piping in various industries, increasing lifespan and reducing maintenance costs. Furthermore, this plastic allows for efficient heat fusion during installation, resulting in joint seams free from leakage. Similarly, continuity in the quality of materials supplied by credible manufacturers enhances the performance of fusion fittings, ensuring their compliance with industry specifications and safety.

Issues with Shipping and Delivery of Butt Fusion Flange Adapters

Many challenges may hinder the timely arrival of butt fusion flange adapters leading to high costs. Shipping problems can also arise because of natural disasters, transport strikes, or increased demand. Moreover, if errors are made in order fulfillment where one receives smaller sizes or wrong types of adapters, projects will be delayed, leading to additional expenses when ordering them afresh. Again, packaging inadequacy might necessitate replacements while further impeding project progress after causing damage during transit. To handle such issues well, it is essential to deal with trustworthy suppliers who can communicate clearly with their clients, along with other benefits like accurate inventory management and robust logistics assistance.

Handling shipment Delays and Issues

When shipment delays or issues with butt fusion flange adapters come up, a proactive approach can go a long way in reducing its impact. First and foremost, fast contact with the supplier is crucial because it helps us understand the order status and find other solutions that could apply. Secondly, creating a contingency plan with alternative suppliers or holding stock backup would ensure that projects do not stop. Moreover, using tracking tools and asking for regular updates will help us monitor the shipment’s progress and identify any potential problems beforehand. Finally, having comprehensive records for orders and communications can be helpful should there be any complaints. These strategies assist firms in dealing with shipping delays and complexities while still having project momentum.

Additional Products to Consider When Buying Butt Fusion Fittings

The purchase of butt fusion fittings also means taking into consideration several other complementary products which can enhance the overall quality and efficiency of your projects. The first step involves purchasing high-quality polyethylene pipe to ensure compatibility and durability with your fittings. Secondarily, fusion machines or tools are necessary for proper connections; these must meet specifications regarding fittings to create strong joints. Eventually, one may need accessories like valves, gaskets, and other connectors to comprise an entire system setup. Ensuring you have these extra materials around will make pipe installation easier while protecting its integrity.

Reference sources

-

HDPE Butt Fusion Flange Fittings – HDPE Supply

This source provides detailed information on HDPE butt fusion flange fittings, including their specifications, applications, and fusion process. It offers technical insights and practical details for using these fittings in various piping systems.

Read more -

HDPE Butt Fusion Flange Fittings – ISCO Industries

ISCO Industries’ page covers the standards, testing procedures, and quality assurance for HDPE butt fusion flange fittings. The content explores the benefits and applications of these fittings in different industries, offering a comprehensive guide.

Read more -

HDPE Butt Fusion Flange Fitting – SUNPLAST

SUNPLAST offers in-depth information on HDPE butt fusion flange fittings, highlighting their features, advantages, and uses. The site also covers the manufacturing process and quality standards followed during production.

Read more

Related Articles: Applications of Butt Fusion Flange