Overview of HDPE Manufacturing

Raw Material Selection for HDPE

The manufacture of HDPE (High-Density Polyethylene) starts with polyethylene resin as its raw material. This resin is obtained from petroleum or natural gas through polymerization. The importance of quality resins can never be overstressed, as they affect the toughness, flexibility, and general functioning of the HDPE product.

Key Focus Areas for Manufacturers:

- Selecting resins within specific density and molecular weight ranges

- Introducing additives and stabilizers for enhanced UV resistance

- Improving thermal stability and processing ease

- Sourcing recycled polyethylene for sustainability

- Employing greener production methods to reduce the environmental footprint

The HDPE Manufacturing Process

The high-density polyethylene manufacturing process follows a systematic approach:

| Step | Process | Key Features |

|---|---|---|

| 1 | Polymerization of Ethylene | Ethylene gas is derived from petroleum/natural gas |

| 2 | Catalyst and High Pressure | Forms long chains of polyethylene molecules |

| 3 | Cooling and Pelletization | HDPE resin converted into pellets or granules |

| 4 | Additive Integration | UV resistance, strength, and flexibility enhancements |

| 5 | Final Processing | Molding or extrusion into final products |

Quality Standards and Specifications

HDPE production follows stringent quality standards to ensure consistency, safety, and performance:

- ISO 9001: Worldwide accepted certification for manufacturing excellence

- FDA Standards: Required for food-grade applications

- ASTM International: Industry tests for specific capabilities like pressure pipes

- Material Specifications: Density, tensile strength, chemical resistance, UV exposure

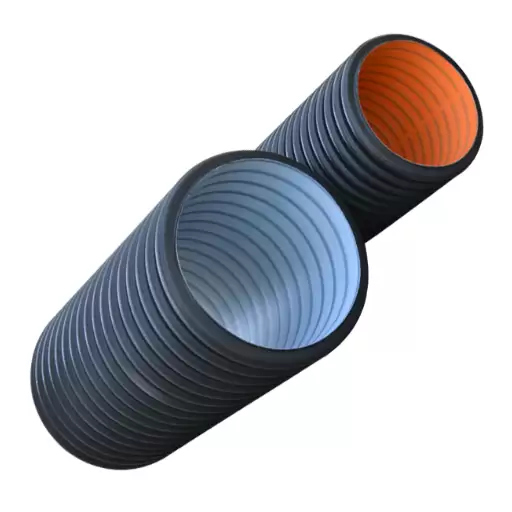

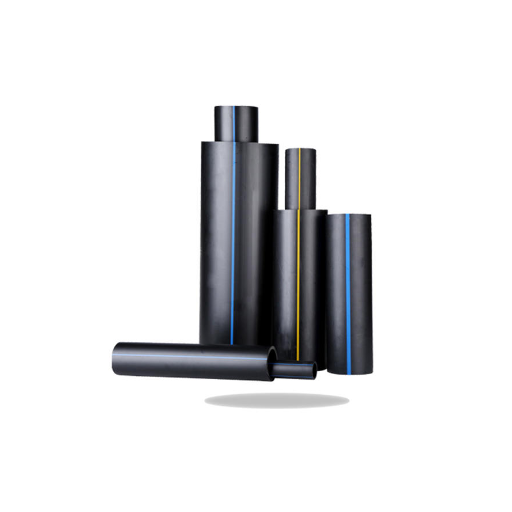

Applications of HDPE Pipes

HDPE in Packaging Solutions

HDPE presents a winning formula of strength, flexibility, and chemical resistance, making it ideal for packaging applications:

- Food and Beverage: Bottles, containers, and industrial drums

- Personal Care: Detergent and cosmetic packaging

- Industrial Applications: Large storage containers and transportation packaging

- Flexible Packaging: Shrink wrapping and protective films

Sustainability Advantage: HDPE is essentially recyclable, making it ideal for companies wanting to reduce their environmental footprint. Post-consumer HDPE can be recycled into containers, pipes, and garden furniture.

Utilization of HDPE in Construction

In the construction sector, HDPE serves multiple critical functions:

| Application | Function | Benefits |

|---|---|---|

| Geomembranes | Retaining walls and waterproofing | Impermeable to water, chemical resistance |

| Underground Pipes | Water systems, gas distribution, sewers | Pressure resistance, reduced failure rates |

| Drainage Systems | Irrigation channels, culverts, road drainage | Weather resistance, temperature tolerance |

HDPE Pipes in the Automotive Industry

HDPE pipes are extensively used in automotive applications due to their unique properties:

- Fuel Systems: Lightweight and corrosion-resistant

- Air Ducts: Flexible installation, cost-effective manufacturing

- Cooling Systems: High pressure and temperature resistance

- Electric Vehicles: Battery cooling systems and innovative applications

Agricultural Applications of HDPE

HDPE products serve numerous agricultural needs with their durability and versatility:

| Application | Purpose | Key Advantages |

|---|---|---|

| Irrigation Systems | Drip and sprinkler systems | Flexible, pressure-resistant, even water distribution |

| Water Storage Tanks | Water and liquid fertilizer storage | Corrosion-resistant, lightweight, long-term reliability |

| Mulch Films | Soil coverage for moisture retention | Temperature control, weed suppression |

| Greenhouse Covers | Plant protection and growth environment | UV-resistant, optimal light transmission |

| Pond Liners | Agricultural ponds and reservoirs | Waterproof, durable, resource conservation |

Benefits of High-Density Polyethylene

Durability and Longevity of HDPE Products

Performance Highlights:

- Excellent impact resistance, maintaining shape under demanding conditions

- Superior resistance to corrosion, chemicals, and weathering

- HDPE pipes can sustain strength for 50+ years under various conditions

- Less susceptible to cracking or warping compared to other plastics

- Reduced maintenance and replacement needs

Cost-Effectiveness of Using HDPE

HDPE offers significant economic advantages:

- Long-term Savings: Fewer replacements due to extended lifespan

- Reduced Transportation Costs: Lightweight material with full mechanical properties

- Lower Initial Investment: Generally cheaper than concrete, metals, or traditional plastics

- Recyclability Value: End-of-life material can be repurposed

- Project Cost Reduction: Up to 30% reduction in total project costs

Environmental Sustainability of HDPE

HDPE contributes significantly to environmental sustainability:

| Sustainability Factor | Benefit | Impact |

|---|---|---|

| Recyclability | Multiple reuse cycles without quality loss | Reduces demand for virgin materials |

| Lightweight Material | Lower transportation emissions | Reduced energy consumption during processing |

| Recycled HDPE (rHDPE) | 50% reduction in greenhouse gas emissions | Compared to virgin HDPE production |

| Extended Lifespan | Reduced frequent replacements | Less waste generation |

Choosing the Right HDPE Manufacturer

Evaluating Quality Standards and Certifications

When selecting an HDPE manufacturer, assess their compliance with recognized standards:

Essential Certifications to Look For:

- ISO 9001: Quality management systems

- ISO 14001: Environmental management systems

- FDA Approval: Food-grade HDPE applications

- ASTM Standards: Testing protocols for durability and performance

- Global Recycled Standard (GRS): Sustainable practices

Assessing Production Capacity and Efficiency

Critical factors to evaluate in potential manufacturers:

- Production Capacity: Ability to handle large or urgent orders

- Technology Integration: Automated systems and state-of-the-art machinery

- Quality Control: Real-time monitoring and control systems

- Energy Efficiency: Cost-saving and environmentally sustainable processes

- Supply Chain Management: Policies for handling disruptions

Trends and Innovations in the HDPE Industry

Advancements in HDPE Recycling Methods

The HDPE industry has made significant strides in recycling technologies:

| Technology | Method | Advantages |

|---|---|---|

| Mechanical Recycling | Physical processing and sorting | Higher purity levels, better quality recycled material |

| Near-Infrared Sorting | Advanced separation technology | Better separation from mixed plastic streams |

| Chemical Recycling | Pyrolysis and solvolysis | Virgin quality plastics from contaminated materials |

| AI-Powered Sorting | Artificial intelligence integration | Increased accuracy and operational efficiency |

Eco-Friendly Alternatives in HDPE Manufacturing

The industry is embracing sustainable manufacturing approaches:

- Bio-based HDPE: Made from renewable resources like sugarcane

- Advanced Chemical Recycling: Molecular-level processing for high-quality materials

- Energy-Efficient Systems: Renewable energy sources and recovery systems

- Lightweighting Technologies: Reduced material content without compromising strength

Frequently Asked Questions (FAQ)

What do HDPE manufacturers do?

HDPE manufacturers produce various HDPE products, including pipes, fittings, and packaging materials that serve different industries in residential and commercial sectors. They ensure products exceed industry standards to maintain market reputation.

How do HDPE products compare to copper in terms of durability?

HDPE products outperform copper in most conditions due to superior impact resistance and corrosion resistance. HDPE manufacturers produce resilient piping that requires minimal maintenance and can withstand adverse environmental conditions where copper might deteriorate over time.

What is the importance of NSF approval for HDPE products?

NSF approval ensures HDPE products follow public health and safety codes. Manufacturers with NSF-certified products guarantee that their plumbing tubing and fittings can be legally used for potable water systems.

How do HDPE manufacturers determine sizing for their products?

Sizing depends largely on the intended application. Diameter and length of tubing and fittings are adjusted according to specific project needs, ensuring products are correctly sized for their final application.

What role do partnerships play in HDPE manufacturer growth?

Partnerships are essential for HDPE manufacturers, allowing businesses to leverage each other’s strengths and resources. Collaborating with suppliers, distributors, and partners helps manufacturers expand their reach and improve product lines across various applications.

What is electrofusion in HDPE manufacturing?

Electrofusion is a process where HDPE manufacturers join pipes and fittings by using electricity to heat the material. This creates durable, strong, and leak-proof joints suitable for various piping systems, especially in high-pressure applications.

What products and services do HDPE manufacturers typically offer?

HDPE manufacturers typically provide:

- HDPE tubing and fittings

- Packaging products

- Customized solutions for specific market needs

- Installation guidance and technical support

- Quality assurance and testing services

How do HDPE manufacturers stay competitive?

Manufacturers remain competitive by continuously updating product lines, investing in modern manufacturing technology, conducting market research, diversifying offerings, and maintaining high-quality standards.

What factors should companies consider when choosing HDPE manufacturers?

Key considerations include:

- Manufacturer’s profile and experience

- Range of products and industries served

- Regulatory compliance and certifications

- Local market presence

- Customer testimonials and reliability record

- Quality of products and services

References

- Injection Molding Process Environmental Impact Analysis

- Manufacture and Characterization of Polypropylene and High-Density Polyethylene Blocks

- Strategic Hybrid Approach for Selecting Suppliers of High-Density Polyethylene

- Manufacture of HDPE Pipes: A Case Study in Seti Plastics, Nepal

- An Insightful Study of The Global Polyethylene Industry