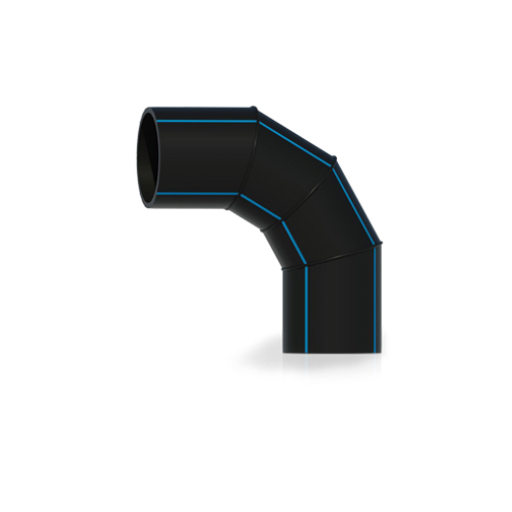

High-density polyethylene (HDPE) pipe bends are an indispensable component in modern piping systems, serving as critical elements in ensuring seamless fluid and gas transport across various industries. Whether used in water distribution, gas pipelines, or industrial applications, these pipe bends are engineered for durability, flexibility, and high-performance efficiency. This guide aims to equip you with a comprehensive understanding of HDPE pipe bends, covering essential aspects such as their design considerations, practical applications, and step-by-step installation methods. With the increasing demand for cost-effective and sustainable piping solutions, mastering the intricacies of HDPE pipe bends can help industry professionals optimize their systems and reduce operational challenges. Whether you’re a contractor, engineer, or facility manager, this article will provide the technical insights you need to make informed decisions about incorporating HDPE bends into your projects.

What are the Different Types of HDPE Pipe Bends?

Understanding Sweep Bend Design

Sweep bends are a crucial component in HDPE piping systems for the redirection of flows in such a manner that turbulence and pressure drops are minimized. This bend has a gradual curve whereby the fluid maintains velocity and creates neither friction nor resistance to the fluid flow, which otherwise hampers system performance. Such bends become preferred when flow characteristics signify applications where disruption is undesirable, such as irrigation, wastewater disposal, and industrial piping systems.

The design of a sweep bend embodies the compromise between hydraulic and mechanical requirements. Manufactured from high-density polyethylene, the bend inherits the principal characteristics of the material-flexibility, chemical resistance, and durability. These sweep bends are available in a few angles, including 11°, 22.5°, 45°, and 90°, allowing operators to select the most appropriate bend required for the specific layout of the pipeline. The appropriate angle choice should consider flow characteristics, space constraints, and system operating pressure.

For long-lasting service, the installation of sweep bends must ensure proper fusion of the joints by industry-accepted procedures, like butt-fusion and electrofusion, so that the connection is free from defects and leakage. Moreover, upon selection, check for specifications from ASTM or ISO relevant for sweep bends, as such specifications ensure that these components fulfill performance and quality requirements for high-end applications.

Exploring Seamless HDPE Pipe Bends

Continuous-process HDPE pipe bends are integral components that enable smooth fluid flow through pipes. Unlike their welded or segmented counterparts, the seamless HDPE bends are manufactured as a monolithic entity, minimizing occurrences of stress points or leakages through joints. This very characteristic imparts to them a requirement of ultimate reliability, most commonly found in water distribution, natural gas transport, and industrial piping applications.

The major advantage seamless HDPE pipe bends enjoy is maintaining a consistent wall thickness and mechanical integrity throughout the curve. The bend maintains consistent pressure handling, thereby reducing turbulence or flow disturbance caused by uneven surfaces. In addition, the design ensures that less drag and energy loss occur during operation, further benefiting the system. HDPE bends contribute to the longevity of the system as they are resistant to corrosion, chemicals, and environmental factors.

The selection of seamless HDPE pipe bends should fully comply with standards considered normal in the industry, such as ASTM F714 and ISO 4427. Such standards cater for critical material composition, dimensional tolerances, and pressure ratings, thus ensuring that in delivery, the bends shall perform consistently and predictably in a given application. Once installed with cognizance of proper alignments and fusion techniques, the structural and operational integrity of seamless HDPE bends stand ensured. Observance of these standards will guarantee the very safety and efficiency of any pipeline system utilizing these components.

Available Degree Options for Pipe Bends

Pipe bends come in various degree specifications to suit different pipeline layouts and directional changes. The common bends that are mostly available are 45°, 90°, and 180° angles, which stand as standard solutions for the majority of pipeline designs. These angles are preferred in general because they find wider applications in providing standard flow direction changes while minimally disturbing the performance of the pipeline.

In particular applications, 30°, 60° options, or other custom intermediate angles can be bent according to the project requirement. Such bends are usually required for meeting certain unique design challenges or spatial constraints peculiar to complicated piping networks. Having an intermediate angle custom-made offers further compatibility across varying industrial environments.

Depending upon the pipeline disposition and conditions for flow or structural constraints, the angle requirement is strictly diverse. Bends should also always maintain the highest industrial ratings of standards like ASTM or ISO with regard to reliability and durability. Any selection of a pipe bending degree can be guided with the assistance of a pipe bending specialist to the project design call-out, so as to lessen any chances of flow disruptions and to bring about operational efficiency.

How to Choose the Right HDPE Bend for Your Project?

Assessing Application and Installation Needs

The selection of an appropriate HDPE bend for a particular project starts with a thorough evaluation of the operational requirements and environmental setting. Pressure ratings, temperature ranges, corrosives, or abrasives should all be studied to ascertain that the bend can hold up against the peculiar soiling with which the application is imbued. Besides, the diameter and thickness of the bend should complement those of the rest of the piping to assure flow dynamics and structure. All things considered, the quality of installation must be considered with some attention to UV exposure, placing underground, or against the brutal trials of chemicals, as these can interfere with the life performance of HDPE.

One also needs to consider the bend radius because it affects flow efficiency and stress development on the pipe. In other words, tight bends, while a space saver, tend to increase losses, pressure drops, and flow disturbances; larger bend radii are better for fluid flow but require more space in layout. Proudly knowing your process requirements, therefore, can assist with such a decision.

Installation must be planned very carefully so as to ensure a smooth implementation of the HDPE bend into the system. This implies checking that the bend design will provide for thermal expansions and contractions, the HDPE being relatively flexible and responsive to temperature changes. Proper joining procedures during installation will ensure that a secure connection is made, which will further preclude leakage. In aligning the HDPE bend technical specifications with technical needs and following agreed best practices, not only would the engineers have the opportunity to optimize system performance, but it would also be the very beginning of echoing maintenance cost reduction in the years ahead.

Considering the Bending Radius and Wall Thickness

In their way, bending radius and wall thickness determine the structural integrity and operational capacity of HDPE pipes. The bending radius is commonly defined as the minimum radius of curvature that a pipe can achieve without failure; pipes should be installed taking into account the physical constraints so as not to over-stress the material. General acceptance in industry standards points toward 20-25 times the pipe’s outer diameter as the minimum bending radius, although this certainly may vary from one specification to another, depending on certain material grades and installation conditions.

Wall thickness, known in design as the Standard Dimension Ratio (SDR), is a controlling factor in the pressure rating of the pipe, and it relates to external load pressures. For example, an SDR of 11 has a higher pressure capacity than an SDR of 17. In addition to being able to withstand pressures and external forces, pipes must be selected for thickness sophistication to avoid deformation or failure upon service. Deviating from prescribed parameters may lead to sagging, increased collapse, or catastrophic failure.

The orientation of concepts around bending radius and wall thickness is conversely tied to the projection of piping systems as a whole and should allow engineers to arrive at designs that not just cater to application necessities but also comply with accepted safety standards and longevity. These factors, duly verified by FEA or field testing, emphasize the requirement of proper calculations and detailed specifications in the design of an HDPE component.

Evaluating Material and Environmental Requirements

When engineering HDPE equipment, it is perhaps most important to ensure that material capabilities correspond with operational environmental conditions. The chief considerations would include tensile strength, chemical resistance, temperature, and flexibility. HDPE, having a very high molecular density, remains resistant to a variety of chemicals, such as acids, bases, and hydrocarbons, and therefore is employed in an assortment of industries ranging from agriculture to wastewater treatment and industrial processing.

Environmental considerations must thus be studied in detail; UV exposure, thermal cycling, and mechanical loadings are examples of some environmental variables. Continuous and prolonged exposure to UV rays is considered to compromise material integrity; hence, UV stabilizers are usually added along with HDPE for use under outdoor applications. The temperature range of operations is of interest so that, during design, thermal expansion and contraction or brittleness of HDPE below the operating temperature can be allowed for.

With these tools at disposal, finite element analysis and computational modeling do great service in predicting HDPE system and component mechanical behavior under real-world conditions. Such simulations allow the designer to see areas of stress concentration and probable points of failure in order to develop good engineering designs focused on long life and compliance with industry standards. By making a thorough appraisal of material and environmental requirements, designers can create highly reliable and efficient systems suitable for the specific challenges at hand.

What are the Key Benefits of Using HDPE Sweep Bends?

Advantages of Water Distribution Systems

High-Density Polyethylene (HDPE) sweep bends form a range of technical advantages in water distribution, thereby making them a prime choice over conventional materials. These benefits essentially emanate from the superior material properties, design characteristics, and expected life of the product that manifest under different environmental conditions. The five major advantages include:

- Corrosion Resistance: HDPE sweep bends withstand corrosion caused by water, chemicals, or any environmental agent, whereas steel or cast iron may undergo some deterioration and rust in moisture presence. The corrosion resistance attributes of HDPE thus guarantee a longer service life. In most instances in water distribution, HDPE pipes and fittings show a service life of over 50 years.

- Flexibility and Resilience: Because of its intrinsic flexibility, the said HDPE sweep bend can absorb stresses resulting from ground movement or temperature differences. This would allow medium levels of cracking or leakage. Flexibility and resilience are thus important in areas where earthquakes and soil shifts occur.

- Improved Hydraulic Efficiency: The smooth interior surface of the HDPE sweep bends helps minimize friction losses and maximize flow rates. HDPE pipes having the Hazen-Williams C-factor of about 150 reduce the amount of energy needed for pumping water when compared to those made of concrete or ductile iron.

- Lightweight and Easy Installation: HDPE items, sweep bends included, are lightweight compared to conventional counterparts and hence possess ease of transportation and installation. This cuts down labor overheads while simultaneously speeding up the installation process, especially on mass-scale projects.

- Eco-Friendly: HDPE is recyclable and, therefore, can be considered green in water-distribution systems. Also, because it requires comparatively less energy in production, HDPE is better for the environment in contrast to its metallic or PVC counterparts.

Together, these advantages make HDPE sweep bends a very modern, efficient, and reliable solution to water distribution infrastructure problems, much more relevant to performance and sustainability.

Maintaining Integrity and Performance in Piping Systems

In the field of piping, anything that can in any way endanger life cannot be accepted. An inspection has to be carried out regularly on the piping system; it has to be installed properly, and the materials used have to be suitable for the application. A routine inspection will help in the early detection of wear, corrosion, or damage that may lead to piping failure. Accuracy in installation procedures, such as alignment of the piping system and good connection tightness, limits the possibility for stress points to damage the system.

To check on the materials depending on the environment of operation, this is another aspect I consider. For materials where strength coupled with environmental friendliness is necessary and resistance to chemical deterioration is desired, I go for HDPE pipes. Having decided on piping material, I then take into consideration all relevant factors- likely temperature, pressure requirement, and exposure to corrosive agents- to see that the system will function well for a long period.

Another aspect I consider is maintenance management. I prefer going proactive so that the minor repair issues will never balloon into much more serious and major maintenance problems. Other assessment methods for system performance include pressure testing and flow monitoring, as well as non-destructive evaluations (NDE). The combination of these activities has brought about an effective utility of piping systems that meet the technical performance criteria and maintain their integrity over time.

Reducing Risk of Friction and Corrosion

Friction and corrosion present major challenges to the long-term functioning and reliability of any piping system as they can degrade the raw materials, cause losses of energy, and system failures. In order to safeguard the system from such dangers, a proper assortment of advanced materials, neat design adjustments, and preventative maintenance set forth needs to be applied. Material selection plays an equally important role; corrosion-resistant alloys like stainless steel or coatings such as epoxy or polyethylene are preferable to lessen the possibility of corrosion attack by environmental or chemical factors. In a similar vein, the provision of low-friction materials and lubricants at critical junctions can check abrasion and preclude damage due to surface interactions occurring with dynamic stress.

The other important aspect would be to utilize modern monitoring and diagnostic tools capable of identifying early symptoms of frictional resistance or corrosive activities. Ultrasound thickness measurement, electromagnetic testing, and continuous monitoring sensors are among many non-invasive techniques used to provide current data on the situation of the system. This will then allow the engineers to forecast areas that have the potential to wear or corrode and intervene accordingly before the occurrence of failure. Generally, cathodic protection methods—wherein an electrical current counteracts the chemical reaction causing corrosion—are installed for piping systems subjected to corrosive environments and have by far proven to greatly elongate system life timers.

Finally, a systematic maintenance schedule concentrating on regular inspections, cleaning, and chemical applications would cut down further on the risks posed by friction and corrosion. These include flushing to clear out particulate deposits, periodic anti-corrosion treatments, and adjustments to operating capacities to avert conditions that accelerate wear, such as high turbulence or non-uniform flow. By combining these with precision engineering practices, industries can thus further unlock enormous amounts of benefits in corrosion reduction while balancing system life, efficiency, safety, and management costs across time.

How to Properly Install HDPE Pipe Bends?

Guidelines for Fusion and Joint Techniques

HDPE pipe bends must be appropriately fused and jointed to ensure maximum service life and durability of the system. The two main fusion methods for HDPE pipes are butt fusion and electrofusion. These provide homogeneous joints with strength equal to that of the pipe, eliminating any weak points and thus reducing leakage in the future.

- Butt Fusion: The butt fusion process is one where the pipe ends are heated at a certain temperature and then pressed together under a specific pressure. Such a process requires calibrated machinery that will maintain proper and consistent heat and alignment. Another set includes heating time, pressure, and cooling time, all to be strictly adhered to as required by the pipe manufacturer and any other recognized industry standards. There must also be a comprehensive temperature measurement system to avoid instances of overheating or inadequate heating, either of which can create lousy joints.

- Electrofusion Welding: Such technique utilizes special fittings with embedded heating elements. An electrical current flows through the elements during the weld process, heating and melting the pipe surfaces to form a fusion bond. The installation will require the mating pipe and fittings to be correctly aligned and to ensure no displacement occurs during the welding process. Such critical factors as voltage, fusion time, and ambient temperature must be maintained strictly by the instructions provided by the fitting manufacturer to achieve satisfactory results. Verification instruments such as barcode scanners are frequently used to verify parameter consistency.

- Post-Installation Inspection and Quality Assurance: Each joint shall undergo non-destructive testing, including at least visual inspection and an ultrasonic evaluation after installation, to ensure that the fusion is of high quality, with no voids or inclusions that could weaken the joint. Where applicable, hydrostatic pressure tests should be carried out to prove the integrity of the system in its entirety.

Following these technically stringent guidelines will allow any operator to put together a robust, leak-proof HDPE pipe system, maximizing the life span and operational efficiency while minimizing potential operational disruption.

Ensuring Seamless Connections in Piping Systems

Provided materials need to be compatible with operational conditions such as pressure, temperature, and fluid type to ensure excellent, seamless connections in piping. HDPE materials are generally preferred for their flexibility, corrosion resistance, and durability, which in a way makes them ideal for both industrial and municipal purposes.

However, compatibility in terms of base materials is just one aspect-compatibility considerations for other pipeline accessories, such as fittings, couplings, and jointing methods, must be taken into account. Employing a suitable advanced thermal fusion process-the butt fusion process or electrofusion-will render joints uniform and reliable against mechanical failure. Thermal fusion joints, when done strictly according to manufacturer instructions, have attained success levels over 95% for pressure pipe systems.

Predictive analytics and real-time monitoring tools can further elevate diagnostic capabilities for modern piping networks. These technologies can detect joint degradation, pressure variances, or leak possibilities even before they occur, supporting a maintenance strategy that prioritizes prevention. Data trends will also assist operators in monitoring system performance to ensure it affords an optimal flow dynamic with the least amount of energy consumption and maximizes the longevity of the infrastructure.

It is these best practices that give consideration to not only the efficient transport of fluids but also assure compliance with industry standards. When combined with sound engineering principles, it is through real-time data-driven insights that a great synergy is ensured for excellence in performance and reliability.

Common Installation Mistakes to Avoid

Before the commissioning phase, there is a need to establish installation as per good practice so that the system functions optimally and can remain risk-free from failure. Some of the most common installation errors that should be avoided are explained as follows:

- Improper Joint Preparation: Do not, under any circumstances, weld or join the pipe without first ensuring that the ends are thoroughly and completely cleaned. Anything that might remain on the surface, even impurities or contaminants, weakens the joint and sets it up for leakage or failure. In joining, the use of cleaning agents as prescribed by applicable standards and alignment tools, preferably automatic, will ensure perfect alignment during assembly.

- Wrong Fusion: Deviation from specified fusion temperatures, pressure, or cooling times can produce poor-quality joints. Fusion operators have to follow requirements as strictly as possible, especially as defined by standards such as ASTM F2620 for consistent and durable fusion. Prevention can be achieved through continuous training of the operators and calibration of fusion machines.

- Inadequate Trench Preparation: Uneven trench bases or those inadequately supported set the pipe out of alignment during backfilling. This breeds potential stress concentration zones that increase pipe fatigue with time and eventual premature failure. Make sure trenches are flat, free of debris, and well compacted before installation to allow for an even load distribution.

- Forgetting Expansion and Contraction Issues: Not considering thermal expansion and contraction of piping systems can lead to the buildup of excessive stresses, particularly in areas with wide temperature variations. Installation of expansion loops or joints and proper set-apart spacing to allow pipe movement from the thermal expansion will save the system from needless stresses.

- Not Testing Installed Systems: Avoid not testing the system against pressure and leakage. One may end up with faults that will incapacitate the system during operation. Hydrostatic or pneumatic testing after installation will guarantee system reliability and allow for detecting potential weaknesses before full operation.

Avoiding common installation pitfalls on the basis of good planning and standards will ensure better results. Using modern monitoring technology coupled with data analytics to provide real-time verification during construction furthers the accuracy and reliability of the setup.

Why is HDPE Preferred for Industrial and Environmental Applications?

Understanding Resistance to Corrosion and Chemicals

HDPE is considered the best for corrosion resistance against an array of corrosive substances and chemicals, and thus finds preference for various industrial and environmental applications. HDPE’s molecular architecture poses an exceptional barrier against punishing chemicals such as acids, alkalis, and salts. For example, HDPE performs well in prolonged exposure situations involving highly corrosive atmospheres, i.e., within wastewater treatment installations and chemical processing plants.

With the greatest resistance to degradation, HDPE features very low moisture absorption and a typical non-reactive character to chemical agents. HDPE pipes maintain performance with minimal degradation upon testing in extreme pH environments: acidic with pH 1, and alkaline with pH 14, providing further assurances on their reliability in varying applications.

Moreover, resistance is also granted to environmental factors: UV radiation, oxidation, and temperature fluctuations, thus ensuring that HDPE structures stay intact over long times. The ASTM D3350, among others, approves these performance limits of HDPE in chemically harsh environments, making it a system that is dependable where infrastructure is critically required.

Exploring Flexibility and Durability in Harsh Conditions

HDPE has now proved its flexibility and strength in harsher conditions requiring it. Since its strange molecular composition, an HDPE pipe could be strained greatly while still being able to withstand severe mechanical stress without compromise. For example, HDPE pipelines are capable of accommodating ground movement and thermal expansion without cracking or rupturing, such factors being of great importance in seismic zones or areas of fluctuating temperature.

Additionally, HDPE resists chemical degradation and destruction. The material remains stable when exposed to acid or alkaline materials, profiting from a long life in environments that are chemically aggressive, such as industrial waste disposal or chemical works. Standards such as ISO 4427 and ASTM F714 independently test and verify the reliability of HDPE under such conditions.

Through evolution in technology relating to HDPE fabrication, the newest formulations are designed to further enhance performance metrics with features such as superior resistance against slow crack growth and greater flexibility at lower temperatures. Given such advancements, HDPE components are now assured for dependence even in challenging environmental situations in critical infrastructure works like potable water distribution and gas transportation.

Long-term Performance and Cost-effectiveness

With molecular construction and processing improvements added to the HDPE, this polymer enjoys exceptional long-term performance. Expected to be in service for 50 or more years, HDPE is made to withstand extended environmental exposure to UV radiation, chemical exposures, and mechanical stresses. Longevity over a time period is attained through improved stabilization of the polymer, along with cutting-edge additives that limit degradation.

For infrastructure projects, HDPE is a very cost-efficient product. Since conventional products such as steel or concrete would require maintenance, which is needed far less for HDPE due to its superior durability, it can save on lifecycle costs. For instance, corrosion resistance avoids the need for frequent protective coatings or replacements, thus decreasing material and labor costs. Improving this further are state-of-the-art HDPE jointing systems employing heat fusion to create practically leak-proof connections, thereby preventing water or gas leakage and maintaining a high level of operational efficiency.

So, as materials science continues to develop and testing standards evolve, these preferred characteristics of HDPE will be applied towards green infrastructure.

References

Frequently Asked Questions (FAQ)

Q: What is an HDPE pipe, and why is it preferred for bends in piping systems?

A: HDPE (High-Density Polyethylene) pipe is preferred for pipe bends due to its flexibility, durability, and resistance to corrosion. It is particularly beneficial for creating bends without the need for sharp bends, ensuring efficient fluid or gas flow.

Q: How are HDPE pipe bends beneficial in irrigation systems?

A: HDPE pipe bends are ideal for irrigation systems because they can accommodate a wide range of movement and terrain changes. This flexibility allows for easy navigation around obstacles, ensuring efficient water distribution with minimal maintenance.

Q: What considerations should be taken into account when designing HDPE pipe bends?

A: Key considerations include the size of the pipe, the angle of the bend, and the specific application requirements, such as the type of fluid or gas being transported. International standards may also dictate specific design criteria to ensure optimal performance.

Q: How does the size of an HDPE pipe affect its bending capabilities?

A: The size of an HDPE pipe, including its bore, directly impacts its bending capabilities. Larger pipes may require specific bending techniques or additional support to maintain the desired bend without compromising the pipe’s integrity.

Q: Can HDPE pipe bends be used in stormwater management systems?

A: Yes, HDPE pipe bends are well-suited for stormwater management systems due to their ability to handle large volumes of water efficiently. Their flexibility and durability make them ideal for managing stormwater runoff and reducing flood risks.

Q: What is the process of installing HDPE pipe bends in agricultural settings?

A: Installing HDPE pipe bends in agricultural settings involves carefully planning the layout to avoid obstacles, using appropriate joining techniques such as heat fusion, and ensuring the system meets the specific needs of the agricultural operation for efficient water or gas flow.

Q: How do HDPE pipe bends improve gas flow in piping systems?

A: HDPE pipe bends facilitate smooth gas flow by minimizing turbulence and pressure drops that can occur with sharp bends. This ensures efficient gas transmission, which is crucial in industrial and commercial applications.

Q: Are there any international standards for HDPE pipe bends?

A: Yes, there are international standards that govern the design and application of HDPE pipe bends. These standards ensure that the pipes meet safety, quality, and performance criteria, which are essential for reliable operation across various applications.

Q: What maintenance is required for HDPE pipe bends?

A: HDPE pipe bends require minimal maintenance due to their resistance to corrosion and environmental stress. Regular inspections can help ensure that the system remains efficient and free from leaks or blockages.