Thanks to their strength, flexibility, and corrosion resistance, HDPE pipes are used in many sectors. With regard to these pipes, precise weight is crucial not only for engineers but also for project managers and procurement officers in order to guarantee that the pipes are handled, transported, and installed properly. This article explains the factors involved in using an HDPE pipe weight calculator and provides guidance with respect to measurement accuracy. This enables readers to have a better understanding of the attributes and the standards pertaining to the use of HDPE pipes, therefore improving the efficiency of their applications.

How Does a Pipe Weight Calculator Work?

Pipes which carry in them huge volumes of liquids or gases, tend to impart very heavy weight. This heavy load causes a lot of stress on joints, which causes leaks over time. Therefore, accurately estimating the weight of pipes is essential in order to ensure that the joints and casing supporting them are able to bear the load. It employs the parameters that are related to a pipe’s dimension and material properties as inputs. It usually asks for the outer diameter, wall thickness, length of the pipe, and density of the pipe’s material—HDPE in this case. This weight calculator incorporates the formula that determines the overall weight of the pipe mixer by incorporating the volume of the pipe and the density of the material used into a single equation after the necessary parameters have been fed. The automation of the process guarantees the accuracy of weight calculation and the reduction of errors that result from human handling, thereby conforming to the specifications of the industry, more so for the HDPE pipe.

What is the Formula for Calculating Pipe Weight?

it is evident that the equation for determining the weight of an HDPE pipe is based on the principles of geometry and materials science. This begins by determining first the volume of the pipe, and then the volumetric figure is multiplied by the density of the pipe material. In the case of a plastic pipe having the cross-sectional shape of a cylinder, the volume is found with the formula: ( V = pi times ( frac{D^2 – d^2}{4} ) times L ) where D and d are the diameters of the outer and inner surfaces respectively, and L is the length of the pipe. Since the material of the pipe is HDPE, the density of the material is considered to be 0.955 kg/m3. Hence, the pipe weight W can reasonably be evaluated as W = V×? This accuracy calculation helps to meet the requirements of the standards of the industry and ensures that the installation and handling operations are efficient.

How to Determine Pipe Size and Dimensions?

selecting the right size and other specifications of a pipe is one of the most preliminary tasks to undertake in any project involving these materials. It requires a grasp not only of the pipe’s structure elements’ arrangement but also of the conditions under which the pipe may be used. Here is a rough outline of the steps I have used:

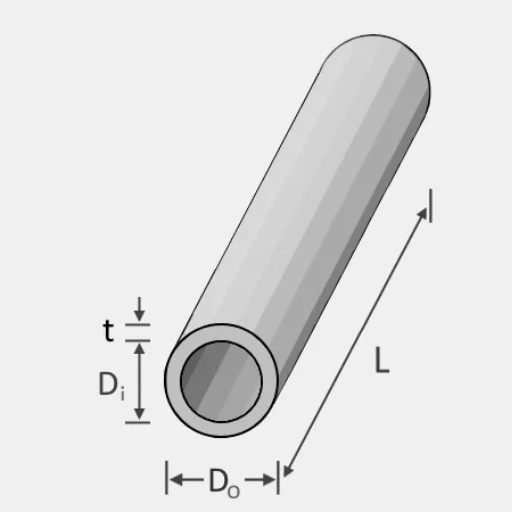

- Outer Diameter (D): This means the total breadth of the pipe that takes into consideration the wall as well. It is important for proper fittings so that the pipe can be accommodated within the space and other joints to be accommodated.

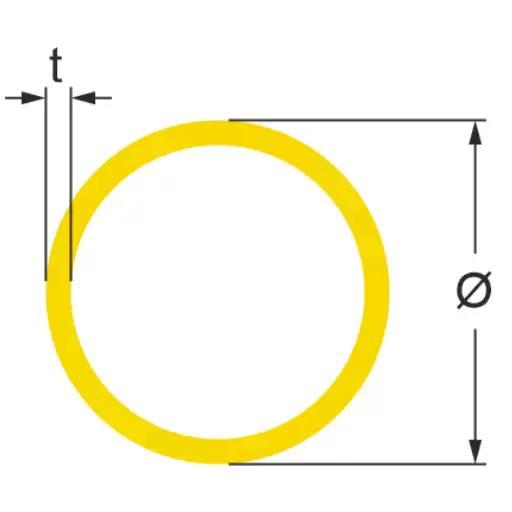

- Wall Thickness (t): this is the characteristic that embodies the strength of the pipe and how much pressure it can bear. A thicker wall means a stronger pipe which is essential for applications of high pressure.

- Inner Diameter (d): This refers to the volume of interiors of the pipe which is useful for placing materials inside. It is arrived at by deducting the double wall thickness from the outer diameter (d = D – 2t).

- Length (L): Overall length of the pipe that has been utilized in distinct areas of a certain work. This dimension is important for determining the volume and, therefore, the mass of the pipe.

- Material Density: Although this is not a volumetric character of the pipe, determining the density of the material HDPE, about 0.955 g/cm³ will be must in order to know the weight and thus the effectiveness of the pipe under various conditions.

Ensuring the appropriate calibration of these parameters is fundamental as it determines the performance and efficacy of the pipe when used. It is all about getting these details correct so as to meet the requirements of the project and ensuring that the pipes are well specified in line with best practices.

Understanding the Role of Density and Wall Thickness

allow me to explain in simple terms how the two features, that is, wall thickness and density, impact the strength and the correct functioning of HDPE pipes:

- Density: Density is defined as the amount of mass of a given volume of the pipe material. In the case of HDPE, the density value is between 0.955 grams per cubic centimeter. This data is important because it assists in estimating the pipe’s weight, which influences all features of the item, like strength and durability. To add on, higher-density connections suggest better properties, which is ideal for pipes expected to carry heavy loads, thereby allowing for more heavy-duty connections.

- Wall Thickness (t): A pipe’s thickness is a thin wall that has a direct role in both the strength and the pressures applied to the inside and outside of the pipe. Thus, the thicker the wall, the stronger and more endurable the pipe will be. For example, if a pipe is designed to transfer fluids under pressures about 20 bars and above a thicker wall, it is necessary to avoid ruptures or leakage. Moreover, wall thickness is also relevant in the determination of the inner diameter since it is deducted from the outer diameter as a measure of the volume in which the fluid would flow.

Your time was superb. It is my hope for those in your position that you will indeed meet the rigidity of the water, sanitation, or energy infrastructure. If I may, let us go through them systematically. And by doing this, let us look at HDPE pipes or polyethylene pipes as being used or doing certain tasks under certain or unique conditions. For many of us, the main characteristics of HDPE pipes or polyethylene pipes as assets seem to be their strength and rigidity, but these two characteristics must meet the pressures and stresses induced by any material- water, chemicals, sanitation, and the prospects will be contentious for that standpoint.

Why Use an HDPE Pipe Weight Calculator?

What is the density of HDPE? An HDPE pipe weight calculator is important in engineering and construction growth because it provides speed and accuracy in assessing the weight of the pipe. This helps to compute the cost of the material and transport and handle the business of setting it up. By entering certain parameters, such as the dimensions of the pipe and the density of the material, this calculator reduces human error and makes certain that the outcomes are within the acceptable criteria of the industry. Thus, it improves the management of a project by providing trustworthy information relevant to the making of decisions in all stages of the project management process.

Benefits of Using an HDPE Calculator in Industry

I can confidently say that employing an HDPE pipe weight calculator has its numerous significant advantages. Here’s why it enhances the game in our arena:

- Accuracy and Precision: A bead to be tied over the predetermined parameters of outer pipe diameter, wall thickness, length and density themselves enables a highly accurate calculation of the usable pipe weight even when all these parameters are predetermined. This accuracy becomes one of the crucial requirements for ensuring proper deposition, obsorption, and engineering discipline.

- Efficiency in Planning and Budgeting: Such accuracy allows estimating material and pipe weight which enhances budget estimates and helps to make hopes for expectations more reasonable. This efficiency is generalized to be as not just the purchasing procedure, but also reasonable estimates of costs to be made in relation to tenders.

- Logistics and Transportation: The process of carrying pipes around is complicated by the need to integrate the various weight, volume and distribution of pipes characteristics. An appropriate amount of weight does permit reasonable limits for the actual load to appreciate hence lower chances of accidents whilst also increasing delivery time management.

- Installation Optimization: With regard to weight, the value of the cubes assist the engineers in speculating what support and lifting devices will suffice. This alertness minimizes the chances of using too much unnecessary force during installation thus making unsafe handling less likely.

- Compliance with Standards: With such promised accurate outputs from the calculator, we do not anticipate any regulatory and operational performance inconsistency, which would attract negative queries from abusing issues.

- Decision Support: Databases managed by the calculator contain reliable information for decision-making at all stages of the project. From the design stage to the maintenance stage, knowledge of the pipe weight in state of design is vital in making the choices which will affect the success of the project as well as its durability or sustainability.

the HDPE pipe weight calculator can be seen as a tool, but rather it is a critical resource which improves performance, safety, and compliance of industrial applications.

How Accurate is the Pipe Volume Calculator?

Let me, as an industry expert, help you understand how reliable a pipe volume calculator can be. The determination of accuracy in such volumes depends on the degree of adherence to the parameters being computed. Here is a detailed explanation so as to appreciate some of the factors:

- Outer Diameter (OD): This parameter studies the width of the external face of the tube. This is important because it directly affects the total volume’s computation.

- Wall Thickness: The measurement of the wall thickness of the pipe accurately finds the value of the inner diameter, and hence, it is essential for the internal volume of the pipe.

- Length of the Pipe: Care should be taken in measuring this dimension since measuring too long or too short would significantly affect the volume calculated.

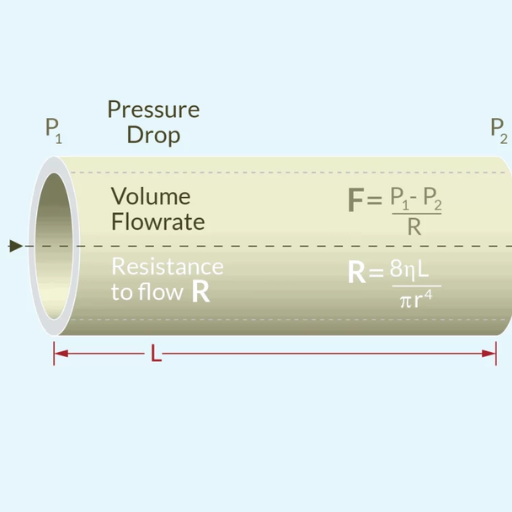

- Mathematical Formulas:When calculating the volume of an object, a set of specific instructions must be followed properly. This may include a significant aspect, such as a unit of measure that is consistent throughout. Normally, for cylinder pipes, the formula is:\[

Volume = \pi \left(\frac{d}{2}\right)^{2} L

\]

- User Input:The accuracy of the calculator depends greatly upon the entry of all the input values with the appropriate degree of correctness. Proper input leads to adequate functioning of the calculator and it provides correct measurements as output.

The provision of these parameters in the correct form ensures that the pipe volume calculator provides reasonably accurate results for engineering applications which, in turn, ensures that the planning and operations are efficient and reliable. If properly applied, the calculator is an important resource for estimating the amount of fluid that the given pipeline could contain, bearing relevance to design and application trends.

Common Applications for Plastic Pipe Calculations

In support of what I would say as an industry veteran, calculations of plastic pipes are essential in most areas. Firstly, in construction or other civil engineering works, these calculations are needed for the designing of water and wastewater supply and disposal systems in order to achieve an optimum flow and pressure. Considering chemical processing industries, properly made calculations help to optimally choose both the pipe diameters and their material to ensure the safe delivery of harmful fluids without getting detained. Also, these methods are used in agricultural activities in order to develop irrigation systems for crops where the amount of water used in applying the crops is greatly reduced. In addition, calculations such as these are used in the oil and gas industries to design pipelines that are able to sustain high pressure and environmental stresses for the safe movement of the fuel. Thus, these calculations are quite necessary for designing and implementing strategies for all kinds of activities in various technical areas.

How to Calculate the Weight of Different Pipe Materials?

In order to evaluate the weight of various pipe materials, the first step is determining the volume of the pipe, which is then multiplied by the density of the material. Here is a summary of the procedure:

- Determine the Pipe Volume:Find the Volume of the Pipe: First, find the volume by applying the cylindrical volume formula as stated below:\[

Volume = \pi \times \left (\frac{D_{Outer} – T}{2} \right )^2 \times L

\]And be certain that all units of measurement are equivalent.

- Identify Material Density:Get the pipe material density typically given in kg/m³ or lb/ft³.

- Calculate the Weight:To calculate the weight, use the formula below by performing the multiplication as shown:\[\text{Weight}= \text{Volume} \times \text{Density}\]

This way, the level of precision required for proper quantification and management of project materials and respective engineering logistics and requirements is provided.

Steps to Perform a PVC Weight Calculation

It requires extensive knowledge of the topic, but before I list the steps as a brief and detailed breakdown of how to calculate PVC pipe weight, let me elaborate on the calculation itself.

- Measure the Pipe Dimensions: Make sure to precisely record the outer diameter and wall thickness of the PVC pipe. Always use the same measurement units.

- Calculate the Pipe Volume: The volume of a pipe can be determined with the cylindrical volume formula as follows:[ \text{Volume} = \text{π} \times \left(\frac{OD-W}{2}\right)^{2} \times L ] Where the [L] is the length of the pipe. In this way, you ensure that the volume in the interior is correctly measured.

- Determine the Material Density:By using resources, find out the density of PVC which is approximately equal to [1.4] grams per cubic centimeter.

- Compute the Weight: Now, at the very end, you can find the weight of the pipe by simply multiplying the volume already computed by the density of the PVC:[\text{Weight} = \text{Volume} \times \text{Density} ]

The collection of data and creation of weight tables will allow the estimation of weight of a full range of PVC pipes thus assisting in better management of materials and controls of inventory.

Using Metric and Imperial Units in Calculations

I must say that in the process of breaking the system into smaller steps, it’s possible to simplify the calculation of pipe weights in both metric and imperial systems. In this regard, let us consider the relevant factors involved in both systems:

- Material Density:

- Metric: The metric system measures density as kilograms per cubic meter (kg/m³). Below are some density values for common construction materials, for instance steel has a density of about 7,8500 kg/m³ while PVC weighs at roughly 1,400 kg/m³.

- Imperial: About 490 lb/ft³ is the average measurement for a cubic foot of steel, while a cubic foot of PVC weighs in at around 87 lb/ft³.

- Pipe Volume:

- Metric:To calculate volume when provided dimensions of a cylinder (in meters), the question requires the use of the following formula:[\text{Volume} = \pi \times \left(\frac{\text{Outer Diameter} – \text{Wall Thickness}}{2}\right)^2 \times \text{Length} \quad \text{(in cubic meters)}]

- Imperial: If the above pipe measurement is given in inches, this formula will help figure out the volume of the same in cubic feet. Also, in this case, multiply by length in feet to put the volume in cubic feet:[\text{Volume} = \pi \times \left(\frac{\text{Outer Diameter} – \text{Wall Thickness}}{2}\right)^2 \times \text{Length} \quad \text{(in cubic feet)}]

- Measurement Units:

- Manage the accuracy within a system of units, either metric or imperial. First, translate all dimensions to meters or feet so that the final calculations remain precise.

Understanding how to explicate individual weight values in both metric and imperial units permits professionals to use the adequate system depending on the particular region’s or project’s needs and requirements. Such a methodical regimen not only aids in precision but also promotes adherence to engineering specifications.

What are the Key Pipe Size and Volume Considerations?

In order to arrive at the key pipe size and volume considerations, a few facets come into play, most importantly the application and the fluid dynamics. To start with, it would be important to consider the internal diameter of the pipe, as this would enable the maintenance of the required flow rate against pressure losses. With the increase in the internal diameter, larger volumes are contained in the pipe with reduced friction, but at the same time, more costs are incurred due to the increased weight of the material. Apart from that, wall thickness is significant because it defines whether the pipe can bear a certain level of internal pressure and external forces without collapse. Also, the length of the pipe itself can affect the flow patterns along it and the hydrostatic pressure at the farthest point. By looking closely at these dimensions, designers can also specify a pipe that is effective and efficient within the budget, hence avoiding the wastage of resources. Such aspects are very useful not only in strategizing the development of the new system but also in the improvement of the current one.

How to Measure Inner Diameter and Outer Diameter?

Measuring the internal and external diameter of any pipe requires a series of important considerations and procedures which, in my opinion, as a professional in this field, should be followed. These dimensions are essential for proper clearance and effectiveness in any use case:

- Choosing the Right Tool:

- For precision measurements, calipers or micrometers should be employed. In some cases it is easy to measure the inner and outer diameters with the mics diameter setting.

- Measuring Outer Diameter (OD):

- Position the Caliper: Clamp the caliper around the pipe’s head from the radial measurement. It should be along the axis of the pipe and not on a slant so as not to give false readings.

- Read the Scale: The last step requires you to squeeze the two arms till the sides of the tube firmly but uncomfortably touch them. Now read the measurement from the scale. The priority however is to zero the caliper.

- Measuring Inner Diameter (ID):

- Insert the Caliper Arms: The inside jaws of the caliper should be placed at the mouth of the pipe for the inner diameter measurement.

- Ensure Contact: Circular transducers should be used to open the caliper till its jaws are in contact with the inner surface of the pipe but not so much that the pipe bends. Measurement readings should be made as soon as the jaw contacts the inner surface of the pipe.

- Temperature and Material Considerations:

- The integrity of the measurements taken may not be accurate especially if the two extremes of temperature and the material are large enough. As a rule of thumb these measurements should be taken in a controlled environment with a standard temperature that is around room temperature.

- In this case, whatever the diameter is, there would always be some coating that should be taken into consideration.

- Multiple Measurements:

- To obtain reliable outcomes, take additional measurements at other locations along the pipe, particularly since the pipe is not absolutely cylindrical.

In light of the activities outlined above, analyzing the already-presented information will also be of help in getting proper inner and outer diameters readings which are very basic in pipe selection and systems design.

How Length Affects the Weight Per Foot Calculation

While assessing a direct relationship between pipe weight per foot calculation and pipe length, some key parameters have to be considered in order to clearly understand this relationship.

- Material Density: Every material has its own density defined as absolute mass per unit volume which can be calculated as M/V. The density will have an impact to the weight of the pipe. Assuming that the thicker wall is 6 inches thicker than PVC pipe, the weight per foot will be higher if a dense material is used, say steel, which weighs more than a less dense material, PVC.

- Cross-Sectional Area: The affectation on the weight will be on the cross sectional area of the pipe, which is dependent on the inner and outer diameters. Since the cross sectional area gives width, this means that the diameter is wide which will give high weights per foot per cross sectioned area.

- Pipe Wall Thickness: The thickness added by the pipe walls also adds to the weight of the pipe. More walls formed means more weight per foot of the pipe due to more materials incorporated in the formation of the walls.

- Length of Pipe: This is true because as the number of slaves increases so does the total weight of slaves that comprise the entire weight of the pipe. However this suggests that if a pipe is made and then split into small bits, every other piece will probably be the same weight assuming the dimensions are exactly the same.

These parameters combined and separately can provide a more detailed view as to how length of pipe affects its weight per foot and this would assist in effective planning and installation. Always take into account the individual characteristics of the material and the design features selected so that the final arrangement is consistent with the requirements of the project as well as the expected performance.

Importance of Correct Pipe Dimension Data

Grasping the significance of proper dimensional definitions of pipes is crucial in establishing the consistency and effectiveness of any piping system. Soaking up critical dimensioning principles in engineering practice does, in my case, not only concern introduction works but rather relates to operational works, including maintenance. Evaluation of correct dimensions allows for the evaluation of flow patterns critical in attaining desired fluid movement with minimal turbulence and maximum efficiency. Moreover, they ensure that the other system components can work without them being leaking or malfunctioning, as well as reducing the chances of those events happening. On the other hand, improper management of dimension data or incorrect interpretation thereof may have severe consequences, such as increased costs and delays in the completion of the project. As a result, all efforts in the achievement and confirmation of these parameters should be emphasized. Economically, this ensures that material and other resources are utilized efficiently, meet the required safety standards, and, in the end, save the project in question.

Where Can I Find Reliable Pipe Weight Calculator Tools?

Finding Reliable Pipe Weight Calculator Tools

I would suggest a few reliable sites where you can locate tools that calculate pipe weight. There are dozens of such calculators on the websites of the manufacturers and suppliers of piping materials. In addition, engineering companies and online engineering resources have more comprehensive kinds of pipe weight calculators. These tools sometimes consider the materials, dimensions, and even wall thicknesses to produce accurate results. In addition, engineering or construction software such as AutoCAD and SolidWorks has weight calculators as a module or as an add-on. Any tool that you apply has to be relevant to the industrial standards so that the accuracy of measurement is assured.

Top Online Calculator Tools for Accurate Measurements

so many of my colleagues and other people constantly ask me for a source with a pipe weight calculator, which is dependable, simple, and sleek. Allow me to recommend the following top-of-the-line online tools:

- Engineering ToolBox: This is a great platform which gives a wide range of online calculators related to pipe, material types as well as measurement units. It’s easy and effective as all the user has to do is enter the relevant dimensions and the material type and it does all the advanced calculations wire.

- MCS Pipe Weight Calculator: Online resource developed by McElroy Manufacturing this tool is designed specifically for pipe weight optimization. The weight output is arrived by considering pipe material density, dimensions and wall thickness.

- Calculators from Pipe Suppliers: Of the many such pipe suppliers and International American Piping Products, such websites offer some, especially in the steel tube institute, of their calculator’s weight of the products they supply. This is because they are adjusted to the specifications of the materials supplied or the supplier.

- Engineering Software Like AutoCAD and SolidWorks: These professional software packages come with good analytical tools or plug-in programs. Not only do the applications compute pipe weights but they also compute and design and measure within project contexts.

Every one of these systems takes into consideration specific parameters which are determined by them:

- Material Density: It is the mass of the material for every unit volume that will certainly affect the weight.

- Cross-Sectional Area: This involves the amounts of material taken into account in the weights since it encompasses the inner and outer diameters of the pipe.

- Wall Thickness: More weight is associated with thicker walls, and this results from the design that has been selected

- Length of Pipe: In calculating weight per foot which remains the same, the equipment must cater for the variance in how many feet there are for the total weight.

Such trusted devices function as the basis for ensuring that reliable project planning and budgeting is done. Remember to always check these calculators for up-to-date compliance with sector requirements.

Understanding Chart and Table References

I am periodically asked how the given charts and tables are supposed to be used. Here is what I can say about this in a simpler way. Charts and tables can be referred to as supportive tools that provide a graphical and systematic arrangement of data which makes comprehension and interpretation easier. Charts and tables are useful when conveying information about the piping systems, as they facilitate finding specific details, such as properties of materials, dimensions, or operational parameters.

Follow these instructions to get the most out of these resources:

- Material Specifications: Pipe has been classified in tables by material of construction such as steel, copper or PVC. Knowing these materials is very important because the safety level of a pipe depends on its strength, flexibility, and temperature resistance.

- Dimension Details: Detailed dimension in terms of diameter, wall thickness and length is provided in charts and tables. The accurate dimensioning data is important during assembly of the pipes and fittings into the system so that the system is leak free and use the pipes without failing.

- Performance Factors: Many tables consist of piping performance details which include maximum allowable pressure and temperature range for the piping system. This information assists in guiding what type of pipe to acquire for use in the application.

- Flow Characteristics:Flow rates and head losses are sometimes included in charts creating a good basis for planning and design of the system for good flow.

- Compliance and Standards: The tables referred to in conformity with the industry standards form a basis that guarantees that the materials and specifications done meet the requirements in safety and regulations thus aiding in conformance to requirements and risk management.

By understanding these parameters, you can make informed decisions that ensure safety, efficiency, and cost-effectiveness in your piping projects. Always verify that the charts and tables you rely on are current and reflect the latest standards and data.

Reference

- Pittsburgh Pipe – Pipe Weight Calculator: This resource provides a formula for calculating pipe weight based on diameter and thickness.

- Calculator Academy – HDPE Weight Calculator: Offers a tool to calculate the weight of HDPE based on shape and other variables.

- JM Eagle – HDPE Specification Sheet: Provides detailed specifications for HDPE pipes, including lengths and bending radius.

Frequently Asked Questions (FAQs)

Q: What is the purpose of using an HDPE Pipe Weight Calculator?

A: An HDPE Pipe Weight Calculator is used to accurately determine the weight of pipes based on their specifications. This helps in ensuring the right size and type of pipe is chosen for specific applications and services.

Q: How does the outside diameter affect the weight calculation of HDPE pipes?

A: The outside diameter is crucial for calculating the weight of HDPE pipes. It is used in the equation to determine the volume of the hollow cylinder, which in turn helps figure out the total weight when combined with the pipe’s density.

Q: Can I learn to use the HDPE Pipe Weight Calculator without prior math knowledge?

A: Yes, the HDPE Pipe Weight Calculator is designed for ease of use. It provides a straightforward way to input data, such as the outside diameter and length, to get accurate weight measurements without needing extensive math skills.

Q: Where can I access a reliable HDPE Pipe Weight Calculator?

A: You can access a reliable HDPE Pipe Weight Calculator online on various websites dedicated to plumbing and construction services. These calculators are often provided by manufacturers or industry experts.

Q: Why is it important to know the weight of an HDPE pipe?

A: Knowing the weight of an HDPE pipe is important for transportation and installation, as well as ensuring the pipe can withstand certain loads and pressures without failure. It is also essential to calculate the ideal pipe size for specific service requirements.

Q: What information do I need to input into the HDPE Pipe Weight Calculator?

A: To use the HDPE Pipe Weight Calculator, you need to input information such as the outside diameter, wall thickness, and length of the pipe. This data helps the calculator provide an accurate weight measurement.

Q: How does knowing the cylinder volume of the pipe help in its application?

A: Knowing the cylinder volume of the pipe helps determine the capacity it can handle, which is essential for applications involving fluid flow. This ensures the pipe is suitable for the pump and the pressure requirements of the system.

Q: Is there any special advice for using HDPE pipes in high-temperature environments?

A: Yes, when using HDPE pipes in high-temperature environments, it’s important to account for the heat resistance properties of HDPE material. The calculations may need adjustments to ensure the pipe remains functional under heat stress.

Q: Can the HDPE Pipe Weight Calculator help in selecting the right pipe size for a specific project?

A: Absolutely; the HDPE Pipe Weight Calculator assists in determining the ideal pipe size by providing accurate weight estimates, which are essential for ensuring the pipe meets the project’s load and service requirements.