The weight of HDPE (High-density polyethylene) pipes is of significant reliance during project planning and execution. Hence, their understanding is very useful and, at times, critical across various industries, from construction to plumbing. The purpose of this guide is to address in detail how the weight of HDPE pipes can be computed reasonably accurately so that the methods of handling, transportation, and installation are done effectively. Through the study of the graphs, the readers will learn how the weight of the pipes is affected by their dimensions and wall thickness, as well as their material density. The concept is useful not only in engineering but also in logistics and procurement. After reading this guide, readers will understand in detail how to calculate the dimensions and will also understand the design.

What is the Importance of an HDPE Pipe Weight Chart?

Importance of an HDPE Pipe Weight Chart

A weight chart of HDPE pipes is important as they play an important role in precise several aspects of industrial operations. Having this helps in arriving at the true measure of load that is to be supported by the structure and aid in the logistics planning, thereby eliminating mishaps that arise due to miscalculations. Furthermore, the heavy weight of HDPE pipes requires understanding when calculating estimates as well as controlling budgets within project execution. Their emphasis focuses on presenting accurate information regarding pipe dimensions together with corresponding weights so that engineers and project managers may be able to design in a manner that ensures the installation of safe building materials.

Understanding Pipe Weight and its Applications

The pipe weight determines the logistics of transporting the pipes because it details the vehicle and routes that can carry the load. Furthermore, proper knowledge of pipe weight is important in understanding load bearing in the course of the installation, enhancing their safety stability, and addressing the chances of structural failure. This knowledge also greatly assists in the management of costs since it helps estimate transport costs and the costs of handling materials. In my professional practice, when a detailed HDPE pipe weight chart is applied well, then there is sound planning and execution, which results in the successful completion of projects.

How Does Wall Thickness Affect Pipe Weight?

I am well-versed as to how wall thickness correlates with pipe weight in the simplest terms. To commence, let us grab one key parameter to explore: the density of the material the pipe is manufactured with. The HDPE welded cork density is constant. So this is how wall thickness alters weight:

- Material Volume: As the wall of a pipe increases in thickness, the volume of piping material needed also increases. Since they are weighty owing to the thicker material used, thicker walls signify heavier pipes, which is inversely proportional to the amount of material used.

- External Dimensions vs. Internal Diameter: There should always be an equilibrium between external dimensions and internal diameter. One could say that adjusting the proportions works as a remedy. When wall thickness increases and the external diameter remains the same, it logically explains that the internal diameter decreases; overall mass, however, will still increase since there is material that is proportional.

- Mechanical Strength: Mechanical strength and durability of thicker walls are important for some applications and improve the strength of the pipe. Most of the time, structural integrity gained outweighs the extra weight gained.

One can make prudent choices on material economy, transportational strategies, and appropriate applications with reasonable knowledge of these parameters. Appropriate wall thickness therefore helps in enhancing the weight limitations without failing to achieve the required performance specifications.

Utilizing the Weight Chart for Project Planning

As an expert in the industry, let’s take a closer look at the relevant issues concerning pipe weight, employing the weight chart for the purpose of effective project management:

- Material Selection: Due to its invariance, especially for HDPE pipes, it is pertinent to know the density of the material. The weight chart comes in handy by providing the different materials in a hierarchical order in relation to their mass, enabling you to select the one that best suits your project and budget.

- Wall Thickness Identification: Aider le tableau des poids, analyze the impact that wall thickness has on weight. By varying thicknesses, it becomes easier to appreciate the necessary trade-offs between weight and mechanical strength that may arise when the desired thickness is not available. This determination helps in deciding if it’s worthwhile increasing the wall’s thickness in the quest to fulfill what is specified in the work.

- Logistics and Transportation: Logistical and transportation cost will be affected more by the heavier pipes. With weight charts, planning and budgeting becomes easier because such charts enable one to know the requirements outlined for different pipe specifications as well as the costs that will be incurred.

- Performance and Application Suitability: Weight chart is surely of usage in attempts to correlate weight with performance. By examining a set of charts for thicknesses one can see how the amount of mechanical strength achieved owing to increased weight corresponds with the applications or purposes for which the project is intended.

With the weight charts applied, you figure out how the parameters in question influence your choice in a more systematic manner while planning a project. This eases resource allocation, cost control, and guarantees fit of the technologies used for the particular project requirements.

How to Use the HDPE Pipe Weight Chart?

The first step in employing the HDPE Pipe Weight Chart is to find the relevant specifications and dimensions of the HDPE pipe of interest for the individual task. Then, find the requisite figures in the chart for the weight per unit length and take into account its wall thickness and diameter. These weight measures can be used to analyze logistics, costs, and structural engineering. Such an approach ensures a better understanding of the properties and practicality of the pipe in regard to the intended installation and resource and cost efficiency.

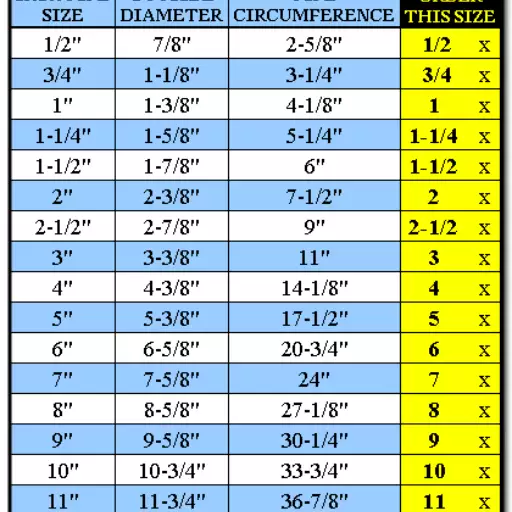

Decoding the Pipe Size and Dimension Table

It is important,to learn how to properly read a Pipe Size and Dimension Table. On first sight, it may look a bit complicated but it is very easy once you are guided on what to look for. For easier understanding, I will take it in a step by step approach.

- Nominal Pipe Size (NPS): The system for defining the pipe diameter standards. It is necessary to emphasize, however, that the NPS is not always equal to the actual diameter of the pipe. This discrepancy is common among pipes whose diameters are 14 inches or more.

- Outside Diameter (OD): This is the actual external diameter of the pipe. Also it is very important for assuring proper alignment of the pipes with the fittings and other couplings during installation.

- Wall Thickness (or Schedule): This variable designates the wall thickness of the pipe. It assists in evaluating the strength of the pipe as well as its ability to hold internal pressure. Variations in schedules represent varying levels of cylinder wall thickness.

- Weight Per Unit Length: This is a result of both shallow sea and deep sea and assists in estimating the overhead costs for transport duties and further assesses the ceiling strain that the pipe would be presenting.

Knowing and relating these parameters will help you read the Pipe Size and Dimension Table with ease, making sure that there is an appropriate selection of the pipes in your project. This not only enhances efficiency but also economical and practical applications of the pipes.

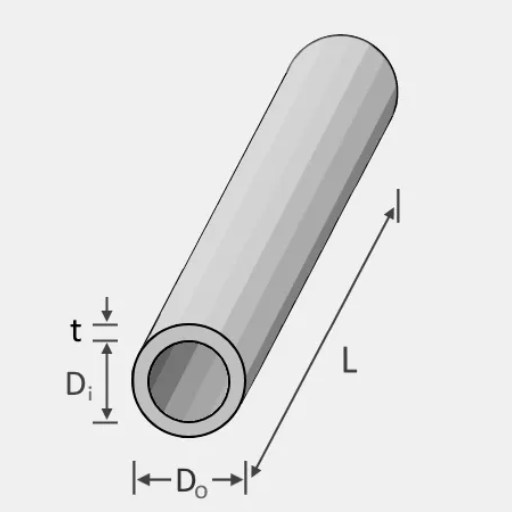

Calculating Pipe Weight Per Meter

In determining the weight of a pipe, its dimensions and material density, as discussed earlier, must be used. The first step is to calculate the volume of the pipe with the use of the following formula \( V = \pi \times (OD/2)^2 \times l \) Where \( OD \) is the outside diameter of the pipe and \( L \) is a constant metric length which should ideally be 1 meter. After this, I go further and look up the value of the hollow section as provided by the inside diameter (ID) and deduct it to find the material volume. I use such volume to calculate the weight of the material by multiplying it with the density of the material. With the application of such calculations, the weight of the pipe within the logistic planning and the project specifications can be attained.

Using Pipe Weight Information for PE100 and PE80

For the PE100 and PE80 pipes, it is important to know the weight per meter for distribution and material. In general, a step-by-step guide to this pipe weight information is outlined here:

- PE100 Pipes:

- Material Density: Polyethylene 100 possess a density between 0.950and 0.960 while PE80 density is in the range of 0.940 and 0.949.

- Weight Calculation: Knowing the dimensions of the pipe and applying the formula mentioned above calculates the weight per meter.

- Applications: due to its high strength and safeness features, Polyethylene 100 is widely used now a days in very high pressure water as well as gas pipe line systems.

- Advantages: It provides better chemical as well as environmental stress cracking resistance which makes it ideal for harsh conditions.

- PE80 Pipes:

- Material Density: The density of polyethylene 80 is roughly 0.943 plus minus 0.02 g/cm3.

- Weight Calculation: in the same was as polyethylene 100, the weight is determined by the density of the pipe which is multiplied by its volume.

- Applications: polyethylene 80 is used for gas distribution of medium pressures and water supply systems.

- Advantages: provide a much cheaper option for a broad array of processes with cost effective measures while maintaining a fair amount of flexibility, strength and durability.

Through investigation of the pipe weight data for PE100 and PE80, project managers are able to control designs and organize resources, which enhances compliance and the success of pipeline projects.

What are the Factors Affecting HDPE Pipe Weight?

Quite a number of factors affect the weight of HDPE Pipes HDPE pipes. First, the density of the material itself is important. Different grades of High-Density Polyethylene, for example, PE100 and PE80, possess differing densities, which have an impact on weight calculations. Second, the pipe’s geometry in terms of length, diameter, and wall thickness also contributes to the volume, which, when added to the density, helps to give the weight of the pipe. Moreover, manufacturing conditions such as temperature and pressure can also affect the mass and composition of the pipes. Finally, if the pipe material contains some additives that increase some characteristics, like UV resistance or even flexibility, it should also affect the weight. All these factors are quite important in terms of accurate logistics and correct pipe usage in a given industry.

Influence of Material and Pressure Rating

I would say that it’s quite straightforward to understand the factors influencing the weight of HDPE pipes. The first point that one should keep in mind is the density of the material. HDPE is available in various grades such as PE100, PE80 grade etc., where each grade has different density values and thus determines the weight of the pipe. So density of the HDPE grade is therefore the first parameter to examine.

In the first place, however, it is the dimensions of the pipe that are of primary concern. Here also we have two basic parameters: diameter and wall thickness. These dimensions dictate the volume of the pipe and when multiplied with the material density we get the weight of the pipe. It is like baking a cake, that is, if you want a bigger and thicker cake you just need to make it bigger and thicker!

The next factor is the temperature and the pressure at which the pipe was produced. Thermoplastics such as HDPE have a degree of sensitivity to both temperature and pressure leading to fluctuation in the weight of the final product. In short, whether or not productive conditions can be maintained constant is of paramount importance.

Last but not least, any such additives or reinforcements which are recommended for use with the pipe can certainly affect the weight of the pipe. These additives for example, can be used for enhancing a particular property such as the UV protection or for flexibility, however it also increases the weight. These additives do not alter much but specific pipes, therefore they are worth mentioning.

With this regard, one can estimate and control HDPE pipe weight accurately, and make sure that everything complies with the requirements of the project beforehand.

The Role of SDR and PN in Weight Calculation

The next considerations that must be taken into account when determining the weight of HDPE pipes are the Standard Dimension Ratio (SDR) and the PN (Pressure Nominal). Allow me to explain them in depth:

- Standard Dimension Ratio (SDR): SDR, in its essence, is a ratio that shows the relationship between a pipe’s diameter and its wall thickness. The wall of a pipe with a low SDR number has a greater thickness, but the weight of the pipe is also, of course, influenced by this. In other words, if there were two pipes with the same diameter but of different SDRs, the pipe with a lower SDR would be heavier because its wall is thicker.

- Pressure Nominal (PN): PN is the measure of pressure load that a pipe can take. It shows the pressure ability of a pipe wall to make sure that it does not burst. Generally, if a pipe has been designed to handle a good amount of pressure, it will be heavier because its walls would have to be thick, right? Therefore, if you are planning to incorporate PN into your computations, understand it as a number that increases weight in relative terms since stronger materials will be needed.

Through these parameters—and SDR and PN—you can calculate the weight of HDPE pipes relative to their size, strength and durable needs. These factors make sure that the pipes not only fit adequately in your project but can also resist the environment and the operational pressure they will face.

How to Calculate and Determine Pipe Weight?

To work out and ascertain the weights of HDPE pipes, apply the following simple formula, taking into account the dimensions of the pipe as well as the density of the material:

- Determine the Pipe Dimensions:

- Outer Diameter (OD): Find the external circumference extending around the pipe.

- Wall Thickness: Take the wall thickness from SDR or the specification industry.

- Calculate the Pipe Volume:

- Inner Diameter (ID): Derive the ID from the formula ID=OD – (2 x Thickness of the wall).

- Cross-Sectional Area: Area is found using A=∏x((OD/2)^2-(ID/2)^2).

- Pipe Length: Consider the length of the pipe to be evaluated.

- Estimate the Material Density:

- Use the average density of HDPE, which is approximately equal to 0.955g/cm³ or 955 kg/m³.

- Calculate the Pipe Weight:

- Use the equation Pipe weight = Cross-sectional area x Length of pipe x Density of material

- Ensure unit measurement uniformity (for example, all measurements in this case should be in meters and measured in kilograms).

These calculations will allow the correct calculations of the pipe’s weight, aiding in the logistical processes and validating that the project meets its specifications and requirements.

Step-by-Step Guide to Calculation

As I began calculating the weight of the HDPE pipes for my project, I adhered to a precise methodology, ensuring each step was thoroughly executed. Here’s how I approached the process:

- Step 1: Measurement of Dimensions

I am not very different from my colleagues who begin estimating the weights of manufactured products like HDPE pipes of my projects. However in my case, I am systematic about the process and my focus is on performing each phase to the fullest . So such was the way I approached it.

- Step 2: Volume Calculation

After getting the outer diameter and wall thickness, I went ahead to find the inner diameter (ID) as follows: ID = OD – (2 X Wall Thickness). After that, I worked out the area of a cross-section, which required me to put these dimensions into A = π x ((OD/2)^2 – (ID/2)^2). This enabled me to establish the area of a cross-section of the pipe.

- Step 3: Material Density Estimation

Ahora bien, para la densidad del material, consulté algunos valores estándar sobre el HDPE que son del orden de 0.955 g/cm³. Estando la unidad en el sistema métrico, la medida de todos los elementos se vio restringida a metros y kilogramos a fin de facilitar la realización de mis cálculo.

- Step 4: Weight Calculation

In the end, in order to calculate the pipe weight I used the formula: Pipe Weight = (Cross-Sectional Area x Pipe Length x Material Density). I took care to record the length of all the particular segments of pipes which I was estimating in order to avoid random errors in the calculations.

By adhering to these steps properly, I was able to determine the pipe weight with absolute precision which was significant for logistics management of my project as well as the satisfaction of all the stated requirements.

Tools and Formulas for Accurate Weight Measurement

I rely heavily on precision tools and established formulas to ensure accurate weight measurement of piping materials. For this purpose, I first take the measurements of the outer diameter and wall thickness using a tape measure and calipers, which are very precise. In fact, these tools are able to give a round of acceptable measurement. Regarding formulas, as long as all dimensions are consistently expressed in the same metric system, the inner diameter and cross-sectional area, as well as the length of a pipe, are the units governing the formula for weighing pipes. Having them together with material density value, in the case of HDPE 0,955 g/cm³, helps me make precise calculations. Such corporate policy of approach is in accordance with the requirements of the industry, which secures the efficiency of operations with relevant controlling requirements of the project.

Where to Find and Share HDPE Pipe Weight Chart Information?

Allied with the above characteristic, any HDPE pipe weight chart information can be sourced from manufacturer catalogs or technical datasheets issued by reputable industry organizations or the web pages affiliated with such organizations. These charts enable the determination of the weight of pipes of various dimensions and material density. In order to make this information circulate, industry experts may use email, industry forums, or project management and communication software. However, it is necessary to ensure that the supplied information is relevant and well-sourced so that the data is accurate for planning and carrying out the projects.

Accessing the Document Online

To access HDPE pipe weight chart information online, you can start by visiting the websites of major pipe manufacturers. They often have downloadable versions of their catalogs or technical datasheets, which include detailed weight charts. Another reliable source is professional organizations in the industry, such as the Plastics Pipe Institute, which often have resources available directly on their websites. When looking for this information, it’s beneficial to check the following parameters to ensure accuracy:

- Outer Diameter (OD): The distance covering the pipes, measured from one outer edge to the other.

- Inner Diameter (ID): This is important particularly for mass calculations and should be positioned taking into consideration the thickness of the wall.

- Wall Thickness: This affects the ID and overall weight, and it should be taken into account, along with other dimensions.

- Material Density: In the case of HDPE, an average density of 0.955 g/cm3 is applied, although it should conform to the properties of the particular product.

- Length of the Pipe: Modifies the overall weight based on the other dimensional measures.

You can easily email this information, integrate it into project management systems, or discuss it in relevant industry discussions. However, ensure that the information which is used or shared is verified and up to date so as to not compromise the quality of your work.

How to Share and Upload the Chart

Upload or share the HDPE pipe weight chart does not comprise complex processes and therefore makes the information to be readily available. The following steps are what you can try:

- Email Distribution:

- It is recommended that the chart be exported as a PDF or Excel document to maintain its original format when emailing.

-

Upload the document to the email and give a short description of the information contained in the data sets provided.

- Project Management Software:

- Lend your file to popular software such as Asana, Trello, and/or Microsoft Project.

- Connect or embed the chart within the appropriate project sections where it is needed.

- Cloud Storage Services:

- Utilize Google Drive, Dropbox, or OneDrive to save or upload the graph.

- Share the document by generating a secure link, which can be distributed to stakeholders.

- Internal Company Intranet:

- Upload the chart to your organization’s intranet for team access.

- Generate a secure link to the document so it can be shared with the relevant stakeholders.

- Industry Forums or Websites:

- As appropriate, distribute the chart on other relevant industry forums or forums for collaboration.

- Utilize these virtual spaces to request critique and communicate viewpoints with other professionals.

It is essential to check that the material is still valid and falls within the correct jurisdiction, as this will help protect the integrity of the project. Anytime ranging of permissions is feasible, the security of data confidentiality is assured.

Benefits of Sharing Options and Uploading

I consider the sharing and uploading of the HDPE pipe weight chart through these different means to be beneficial in several aspects. Therefore, first of all, it allows everyone involved to have all the necessary information at hand, which improves communication and decision-making in projects. Members of the team will have different preferences and levels of technology, and such tools as email newsletters, project management tools, file-sharing services, or the company’s internal network can efficiently address these requirements. Furthermore, publishing these charts on the Internet enables an industry-wide forum for comments and professional opinions regarding the charts, fostering a cyclical self-improvement process. Further, there are methods of sharing that are safe and controlled; hence, sensitive information is not compromised, and the project is not put in any form of jeopardy. All in all, the combination of these different sorts of methods for sharing and uploading is very useful in enhancing the operational capabilities of the company and the coherence of the teams.

Reference

- BIM Modeller – HDPE Pipe Weight: This site provides a step-by-step guide to calculating HDPE pipe weight using dimensions and ratios.

- Edoburg – How to Calculate the Weight of HDPE Pipe: Offers a comprehensive guide with formulas, technical insights, and practical examples.

- Puhui Industry – How to Calculate HDPE Pipe Weight: Provides a formula-based approach to calculating HDPE pipe weight using outer diameter, wall thickness, and density.

Frequently Asked Questions (FAQs)

Q: What is HDPE, and how is pipe weight calculated?

A: HDPE, or High-Density Polyethylene, is a type of plastic commonly used for pipes. To calculate the weight of an HDPE pipe, you need to know the pipe’s dimensions, including diameter and wall thickness. The document provides formulas and a chart to determine the weight based on these measurements.

Q: How can I use the HDPE pipe weight chart effectively?

A: The weight chart in the document provides a quick reference to determine the weight of a specific pipe size. Locate the diameter and wall thickness on the chart to find the corresponding weight. This method is efficient and precise for planning and logistics.

Q: What is the significance of PE 100 in HDPE pipes?

A: PE 100 is a grade of HDPE that offers higher strength and pressure resistance. It is often used in pipes requiring high durability and performance. The document information includes details about PE 100 specifications.

Q: Can I calculate HDPE pipe weight for different wall thicknesses?

A: Yes, the document provides data for minimum and maximum wall thicknesses, allowing you to calculate the weight for various pipe specifications. This flexibility helps in accurate planning and resource allocation.

Q: Is there a standard size range for HDPE pipes in the weight chart?

A: The chart typically includes sizes ranging from small diameters like 20mm to larger ones. Ensure you have the correct measurements for precise calculations.

Q: How do I prepare the document to share with others?

A: You can share this document in various formats, such as a text file or PDF. Make sure to include all relevant pages and charts for comprehensive sharing.

Q: Where can I find more detailed information in the document?

A: For additional details, contact the document provider or consult supplementary materials that accompany the main document. This ensures you have all necessary information at your disposal.

Q: What should I know about PN 20 in relation to HDPE pipes?

A: PN 20 indicates the pressure rating of a pipe, meaning it can withstand 20 bar of pressure. This is essential for applications requiring specific pressure capabilities. Check the document for more context on pressure ratings.

Q: How does the document reward your curiosity about HDPE pipes?

A: The document is designed to provide comprehensive answers and insights into HDPE pipe specifications, calculations, and applications, satisfying your curiosity with detailed and accurate information.