High-density polyethylene (HDPE) has revolutionized the way we approach water infrastructure in modern engineering. With its unparalleled durability, flexibility, and resistance to both corrosion and chemical degradation, HDPE water main pipes provide an advanced solution for potable water systems. This article aims to explore the key advantages of HDPE piping, elucidating why it has become a preferred material for municipal and industrial water applications. From its long lifespan to its environmentally friendly properties, you’ll discover how HDPE pipes offer a sustainable, cost-effective, and highly reliable option for delivering clean, safe drinking water. Whether you’re a civil engineer, contractor, or decision-maker in municipal projects, this guide will provide valuable technical insights into why HDPE is the material of choice for potable water applications.

What is HDPE Pipe and Why is it Ideal for Water Supply?

Understanding High-Density Polyethylene in Pipeline Applications

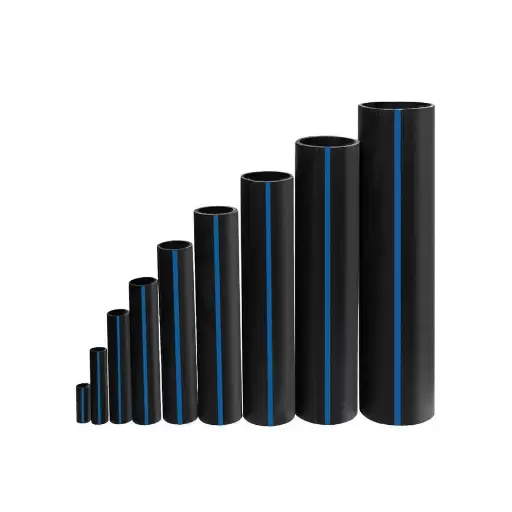

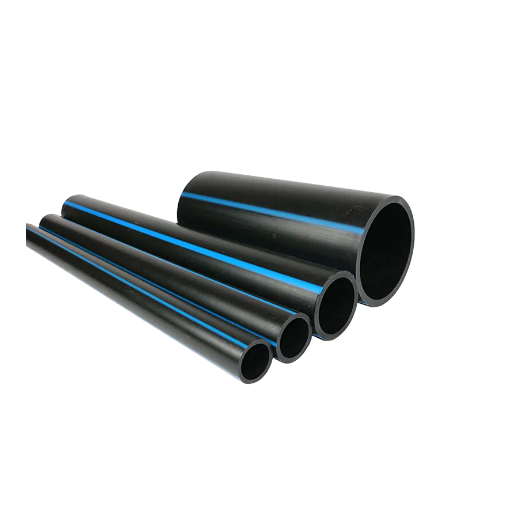

pipeline applications. One of its main advantages is its strength-to-weight ratio, boasting remarkable flexibility when compared to other materials. It is also chemically resistant, lightweight, and possesses strong, durable properties. HDPE: environmental stress cracking, which commonly occurs in metals or other piping. Furthermore, these properties enable HDPE to endure long-term functional reliability and significantly aid water supply systems, especially in demanding environments.

As for its application to water supply lines, supplied water pipelines benefit greatly from HDPE due to its fusion welding, flexibility, and inversely proportional surge weathering. Seamless and monolithic joints created through the fusion welding process eliminate any leakage potential, ensuring impeccable integrity within the water distribution system. Moreover, fusion welding capabilities coupled with innate resistance to surges and pressure fluctuations enable HDPE to excel in high-pressure municipal and smaller-scale potable water systems. Most importantly, the material’s lack of permeability to outside contaminants helps maintain the safety and quality of drinking water.

HDPE pipes are cheaper from an economic standpoint because of their lifecycle costing. The lightweight pipes facilitate easy transport and installation. They have a long service life of more than 50 years, which reduces the cost of replacements and maintenance, too. Their recyclability, low environmental impact, and sustainability prove that HDPE pipes are a modern solution for water supply infrastructures while balancing performance and environmental goals.

Key Advantages of Using HDPE Water Supply Pipe

- Durability and Longevity

Known to most as “the pipe that lasts the longest,” HDPE pipes last a lifetime, and the operational and environmental conditions do not seem to faze them. An additional reason as to why these materials are so useful is that there is no wear and tear, corrosion, or even physical damage. These smart pipes are designed in a way that ensures a utility life of over 50 years, which makes blunt water supply systems very efficient.

- Leak Resistance and Reliability

Each HDPE consists of pipes that are constructed together and can be later integrated into a single entity system. What this enhancement alters significantly are interconnect failures, leaks, and failures immensely, which integrates without a doubt a much more efficient water delivery system. Given that raw water doesn’t get wasted, fewer expenses are spent on refurbishing or restoring broken water supply pipes.

- Flexibility and Stress Resistance

The flexibility of HDPE is its biggest strength. Capable of bending and generating curves under pressure, this gives the pipes an additional edge over competing products. This condition permits the pipes to function properly in not only rural nonpopulated areas, but also in industrial surrounding zones, in addition to being stationed in earthquake-prone zones.

- Economic Use of Resources and Eco-Friendly

Due to the light structure of HDPE pipes, the expense incurred for transportation and installation is minimized. Moreover, its environmentally friendly composition makes it easy to recycle. In addition to these facts, the expenditure of energy while manufacturing HDPE pipes is low. All these features make HDPE pipes economically advantageous and help preserve nature’s resources, therefore making it ideal for modern construction.

With the integration of dependability and long-lasting performance, HDPE pipes become an unparalleled selection for water supply systems, solving modern requirements while preparing for future needs.

Comparing HDPE with Traditional Pipe Materials

Compared to traditional pipe materials such as concrete, steel, and PVC, HDPE pipes are far more durable, flexible, and efficient. Steel pipes, HDPE pipes, unlike steel ones, do not rust or corrode due to their high resistance to chemicals and environmental damage. This makes them ideal for use in water supply and wastewater management in tough settings that can cause other materials to fail prematurely.

Besides, HDPE pipes prove to have a significant advantage over concrete and steel in terms of weight, being much lighter. They can therefore be more easily transported and installed, which saves time, labor costs, and overall costs. Moreover, HDPE pipes are flexible enough to withstand ground movements such as earthquakes or settling soil compared to more rigid materials. This flexibility reduces the chances of cracks and leaks, increasing the reliability of infrastructure over time.

From an economic viewpoint, HDPE pipes lead to savings during installation and maintenance in the long run. Unlike traditional materials such as PVC, which have a low initial cost but high environmental maintenance costs due to degradation, HDPE has low manufacturing energy costs and a long service life. These factors combine to make HDPE an eco-friendly and affordable option. These combined advantages enhance HDPE’s position as a preferable material as opposed to traditional pipe materials used in modern construction and engineering projects.

How to Install HDPE Pipes for Efficient Water Supply?

Essential Steps for HDPE Pipe Installation

- Site Preparation and Planning

Before installation, conduct an entire evaluation of site conditions to confirm all requirements for HDPE pipe placement are met. This involves analyzing soil type, checking for utilities, and determining the pipeline alignment. Good planning of the site ensures no disruptions occur and compliance with engineering standards is met.

- Pipe Handling and Storage

Pipes should be stored in shaded and well-aerated aerated to avoid overheating. Contamination and surface damage must be avoided at all costs when dealing with HDPE pipes. The material is most likely to weaken over periods, thus, they should be placed on stable ground, which is flat, to avoid stress marks and deformation.

- Trenching and Bed Preparation

Make an excavation of the trench to ensure it meets depth and width specifications set by the project. Large rocks and debris should not be found at the bottom of the trench, which should be level. There should be a uniform support that helps in lessening the mechanical stress mounted on the pipes, therefore, some bedding material like fine sand or gravel should be used.

- Joining Strategies

Ensure that the joining method selected meets the application’s needs, such as butt fusion, electrofusion, or mechanical coupling. During butt fusion, the pipe ends are heated and pressured to make a joint that is both seamless and leak-proof. All fusion processes must comply with industry guidelines to maintain the structural integrity and hydraulic efficiency of the pipeline.

- Integrity Testing

Once the installation is complete, perform hydrostatic or pneumatic pressure testing to assess the pipeline’s operational performance. These tests determine if any leaks or vulnerabilities exist that could jeopardize system reliability. Ensure all safety measures are in place prior to conducting the test to reduce the risk of accidents.

- Compacting and Backfilling

Pipe movement can be avoided by using appropriate materials for backfilling the trench around the pipeline, hence achieving careful backfilling. Each layer of the backfill must be compacted to provide stability whilst preventing excessive deflection of the pipe. Sharp or heavy stones must be avoided as they could potentially harm the pipe.

- Commissioning the System

After backfilling, debris or contaminants trapped within the pipeline should be removed by flushing. Functionality and operational efficiency can be tested by slowly increasing the operating pressure. Monitoring during this phase ensures that the actual installation aligns with design parameters.

With meticulous attention to HDPE pipe installation steps, optimal performance, longevity, and cost-efficiency are achieved, confirming its superiority to water distribution systems in diverse engineering projects.

Choosing the Right HDPE Pipe and Fittings

The selection of interface pipes with other types of pipes, components, and fittings impacts the integrity, efficiency, and durability of the pipeline system. When looking at HDPE piping, the pipe’s pressure rating is a foremost primary concern about the material’s density, thickness, and the application or use. Likewise, pipes with higher pressure ratings suit applications that require greater strength, such as industrial use or high-pressure water transmission systems.

Moreover, the operational environment needs further analysis. Depending on the intended use, any grade of HDPE pipes is relevant as long as it withstands some grade of extreme temperatures, chemical exposure, etc. Equally important is the selection of fittings that correspond to the pipe’s diameter, wall thickness, and application that is intended, so that risks of joint failure are minimized. Resistance to abrasion and flexibility to thermal expansion should aid in the decision-making process for long-term use of the joints.

The use of new technology in the manufacture of HDPE pipes has multilayer designs, and the compounds used for the materials themselves have offered improvements to increased performance. Latest industry report data suggests that failure rates up to 30% can be optimized with these tailor-designed changes to the selection of HDPE pipes corresponding with the precise needs of the project, without jeopardizing cost efficiency throughout the lifecycle.

Adding custom specifications and the most advanced HDPE pipe technologies helps engineers and planners correctly align the pipes and fittings for any application in water distribution or industry. Such an approach improves operational performance and meets contemporary standards for sustainability and cost efficiency.

Common Installation Methods and Techniques

To maintain long-lasting performance and structural integrity, high-density polyethylene (HDPE) piping systems must be installed following steps within industry standards. Several techniques are routinely applied during the installation procedure, the choices of which depend on site conditions and applications.

- Trenching and Burial: The traditional form of open trenching is one of the most popular techniques used for HDPE piping installation. This method consists of excavating an adequate trench, placing the pipe, backfilling the trench with appropriate materials, and then ensuring no deformation occurs. Backfill must be properly compacted to prevent stress concentration and settlement.

- Horizontal Directional Drilling (HDD): HDD is often used for underground pipe installation works in regions where conventional trenching is not possible. This technique employs a guidance system to drill a precise borepath, which is later used to pull HDPE pipes into position. HDD poses minimal problems for surface land alteration and is especially useful for under river, road, or other surface feature obstructions.

- Pipe Bursting: Pipe bursting is mainly used in rehabilitation projects, consisting of breaking apart an existing pipeline to replace it with an HDPE pipe of equal or larger diameter. The method is efficient for renewing aged systems while preserving the surrounding infrastructure.

- Sliplining: This method simplifies the rehabilitation of deteriorated pipelines by placing an HDPE pipe of smaller diameter into the existing pipe. To enhance stability and hydraulic retention, the space around the new pipe can be grouted.

- Fusion Techniques: Joining HDPE pipes using fusion techniques, including butt fusion and electrofusion, is essential. They produce an integrated system without any leaks by heating and melting the pipes rather than using mechanical joints, which decreases reliability.

- Above-Ground Installations: HDPE pipes can also be installed above ground for temporary or elevated use. The use of appropriate supports, anchorages, and taking into consideration expansion joints and UV heat to the environment is critical for the design.

Every technique needs specific planning, which includes adhering to the pertinent standards such as ASTM, ISO, and other external determinants like soil classification, soil bearing capacity, and other environmental factors. However, the performance and life span of piping systems made of HDPE can be improved through proper training, site assessments, and monitoring technologies during installation.

Are HDPE Pipes Suitable for Water Supply in Various Conditions?

Exploring the Durability of HDPE Piping Systems

Due to their exceptional HDPE pipe durability, their use for water supply is appropriate across a wide range of conditions. In my experience, these piping systems are highly reliable with regard to corrosion, scaling, and chemical degradation resistance. This ensures their performance longevity in challenging environments. They are highly reliable as well in different applications, owing to their ability to flex and absorb external stresses caused by soil shifting or seismic movement.

In addition to the above-mentioned points, I noticed that these pipes are engineered to withstand abnormally extreme low and high temperatures, making them further suitable for diverse climates. Moreover, I have observed that their strength, combined with their lightweight nature, results in easy transportation and installation without compromising structural integrity. Owing to the pipe’s requirements to carry and maintain water quality and reduce resources wasted over time, its risks include leak-free connections maintained through fusion welding methods.

The cited works ISO 4427 and ASTM D3035 establish international standards for HDPE piping systems that offer frameworks for performance under pressure, further proving its durability. HDPE pipes have shown consistent performance, whether in the irrigation systems of rural areas or in urban potable water supply systems. Due to this reasoning, I am convinced that in most conditions, HDPE is not only suitable but also one of the most trustworthy materials for water supply infrastructures.

Performance in High-Pressure Water Scenarios

Due to remarkable material attributes, HDPE piping systems are capable of withstanding high water pressures. The tensile strength and flexibility of the high-strength polyethylene structure are so great that bends within the pipes can withstand moderate to extreme operational pressures. For instance, HDPE pipes have pressure classes (PN) rated between PN6 to PN25. Depending on the wall thickness, diameter configurations, and the pipe’s rating, it can withstand up to 25 bar.

Moreover, their resistance to surge pressure—for example, water hammer—is important for high-pressure piping. The reason is their high ductility and low modulus of elasticity, which allows the material to effectively absorb transient pressure spikes and reduce damage or failure. Other test data also indicates HDPE pipes can withstand repeated pressure cycling without loss of structural integrity, making them suitable for dynamic systems.

The aforementioned characteristics make HDPE an ideal resource for high municipal water distribution, firefighting, and industrial processes due to operational reliability and durability in harsh environments. Compliance with globally recognized standards, such as ISO 4427-2 or ANSI/AWWA C906-15, highlights the level of engineering design for such scenarios.

Resistance to Corrosion and Chemicals

The use of High-Density Polyethylene (HDPE) is advancing due to its unprecedented chemical resistance. Unlike traditional materials like steel and ductile iron, HDPE does not lose structural integrity when subjected to acidic, alkaline, saline, or marine environments. Such phenomena are most often brought about by non-polar chemical HDPE’s lack of interaction and oxidative deterioration due to its inert molecular identity.

There has been a variety of research done that shows that HDPE has almost no impact on the performance properties of industrial chemicals such as sulfuric acid, sodium hydroxide, and many hydrocarbon solvents. In addition, with chronic exposure to water or soil with stray currents, HDPE piping systems are immune to electrochemical corrosion – a trait most metals suffer from. Because of this, there is reduced need for maintenance while simultaneously increasing material lifespan.

HDPE pipes can withstand continuous aggressive service for 50 years under standard conditions. Using modern advancements that polymers provide, such as increased thermal resistance and UV stabilization, chemical processing industries, mining operations, and seawater desalination plants have a reliable funding source as well as sustainability, which makes it easy to justify the use of HDPE.

What are the Benefits and Limitations of Using HDPE Water Supply Pipes?

Benefits of Ease of Installation and Maintenance

- Lightweight Makes HDPE Pipes Easier to Handle

Because of its low density, HDPE pipes are much lighter than traditional piping materials such as concrete or steel. This lowers transportation expenses, makes handling easier on-site, and reduces the need for heavy lifting equipment during installation. A good example is HDPE has a density of about 0.94-0.96 g/cm³, while steel’s density is 7.85 g/cm³.

- Flexibility In Conformity To HDPE Pipes Adaptability For Complex Terrains

Pipes made from HDPE are best suited for installation in difficult terrains because the material’s inherent flexibility allows the pipe to be bent to fit curved pathways. This cuts down the need for frequent fittings and drastically reduces the installation time and material cost. Their adaptive nature stems from the fact that HDPE pipes usually have bending radii of 20-25 times their diameters.

- Leak-Free Joints Through Fusion-Welding Capabilities

The merge HDPE pipes through fusion-welding techniques guarantees seamless, monolithic joints that withstand external pressure and force without leaking. This enhances the reliability and overall durability of a piping system while also minimizing maintenance. Electrofusion and butt fusion techniques provide equal or superior joint strength to the pipes themselves.

- Corrosion Resistance Reducing Maintenance Efforts

Unlike its metallic counterparts, HDPE has a high resistance to corrosion, scaling, and aggressive chemicals. This makes it suitable for water transport in a wide range of environments, from potable water pipelines to industrial applications. As an example, HDPE is salt, acid, and alkali non-corrosive, which makes it unnecessary to have coatings or treatments over its lifespan.

- Minimized Downtime with Rapid Repairs

Repairs and changes to HDPE piping systems are simple, owing to the ease of cutting and reconnection. HDPE piping utilizes Fusion-welding equipment, which allows for repairs to be done quickly on-site, thus reducing downtime in critical applications and disrupting operations. This is useful in mining and desalination industries where system reliability is crucial.

Limitations in Specific Piping System Applications

Although the implementation of piping systems made of HDPE comes with substantial advantages, some drawbacks also exist relative to its application. The first drawback would be the tolerance of temperature extremes. HDPE pipes are known to weaken mechanically with increasing temperature, above 140°F (60°C), limiting their utilization in high-temperature industrial processes or areas requiring thermal resistance.

Another limitation deals with the ultraviolet (UV) oxidative ageing exposure. While most modern HDPE pipes are treated with UV inhibitors, direct sunlight for extended periods results in material fatigue, particularly in above-ground installations in tropical and arid areas, thereby impacting longevity and correctly defined integrity.

Moreover, the relatively lower strength of HDPE pipes in comparison to ductile iron and steel renders these pipes less efficient for high-pressure applications due to the increased chance of deformation due to heavy external loads. These strategies must be addressed during the design phase, considering the possibility of deformation under high loads or certain high-pressure situations.

Finally, the availability of butt or electrofusion welding instruments and the needed precise skill has the possibility to restrict effectiveness in certain remote locations. Having these dependencies on skilled control can, therefore, create unforeseen delays that would impact deployment scenarios.

Comparative Analysis: HDPE Pipe’s Fused Joints vs. Alternatives

The comparison of fused joints of HDPE pipe with joints made of welding, threaded joints, flange joints, and mechanical coupling joints is outlined.

| Aspect | HDPE Fusion | Welding | Threaded | Flange | Mechanical |

|---|---|---|---|---|---|

|

Joint Quality |

Excellent |

Good |

Poor |

Good |

Good |

|

Leak Prevention |

Superior |

Average |

Weak |

Average |

Average |

|

Rust Resistance |

Complete |

Partial |

None |

Partial |

Partial |

|

Installation |

Moderate |

Difficult |

Easy |

Difficult |

Easy |

|

Pressure Tolerance |

High |

High |

Low |

High |

Low |

|

Cost |

Moderate |

High |

Low |

High |

Low |

|

Longevity |

High |

Medium |

Low |

Medium |

Medium |

Why Choose Polyethylene Over Other Pipe Materials?

Environmental Impact of Polyethylene Pipe Usage

When compared to steel, concrete, or PVC, the environmental impacts of using polyethylene (PE) pipes are much more favorable. These benefits stem from the material’s lower environmental burden during its entire lifecycle: from construction to disposal. The following are five critical environmental impacts of polyethylene pipe usage:

- Lower Carbon Footprint During Production: Traditional materials such as steel or concrete have a much greater upfront cost in terms of energy. PE pipes, on the other hand, use significantly less energy to produce. A life cycle assessment (LCA) notes that the production of PE pipes emits up to 35% less CO₂ compared to steel pipes, making them the more sustainable selection.

- Reduced Energy for Transportation: Transportation of polyethylene pipes is more economical due to their lower weight, which reduces fuel consumption compared to concrete or metal pipes. Consequently, there are reduced emissions of greenhouse gases during the logistics stage.

- Minimized Leakage and Water Loss: Water leakage from polyethylene piping systems is virtually non-existent due to the fused joints. Avoiding water wastage goes a long way in the conservation of natural resources, especially in water-scarce regions.

- Extended Service Life: The lifespan of 50-100 years for polyethylene pipes means their replacement is infrequent, which lowers the environmental impact tied to production, transport, and the installation of substitute materials. This prolongs lifespan also helps lessen the amount of waste in dumps.

- Recyclability Post-Use: At the end of its life, polyethylene is recyclable. In contrast to some materials that disintegrate or emit harmful substances during disposal, PE can be reformed and remade into new products, which encourages reduced pollution through recycling.

These attributes together define polyethylene pipes as an eco-responsible system suitable for industrial and civic use.

Long-Term Service Life and Pressure Rating

The optimal use conditions of these pipes, under field studies performed, show that operational efficiency over the years ranges from 50-100 years without any additional support. This is achieved through abrasion, chemical corrosion, environmental stress, and other factors that resist, along with enabling environmental cracking, extending their life span by multiple years. Additionally, the ability to retain structure and performance while exposing these pipes to various temperatures, both hot and cold, makes these pipes highly efficient.

Based on the class of the material and overall thickness of the walls, polyethylene pipes are subdivided into multiple categories. Various industry standards are followed by the manufacturers, ensuring sustained performance under peak and continuous pressures. Reach high-density rated PE100 pipes, for example, support upwards of 16 bar pressure in water distribution systems. It is imperative to know that this number can change based on design, temperature, or the pipeline itself. Any alteration has design consequences which need careful examination, displaying the peculiarity of engineering problem solving.

Even with the phenomenon of multi-compartmental designs, voltages, these pipes eclipse all metals in continuum infrastructures for industrial processes, water, gas, and many other services, providing end-users with support solutions.

Cost-Effectiveness and Pipeline Performance

Cost savings related to pipeline systems depend heavily on the material selection, operational efficiency, and lifecycle performance metrics. Newer pipelines, specifically those made of advanced alloys or reinforced thermoplastic materials, require infrequent maintenance owing to their exceptional resistance against corrosion and wear. For example, thermoplastic composite pipes (TCPs) are highly durable under extreme conditions, which reduces the downtime of the system as well as the operational cost.

Further empirical studies have shown that optimizing pipeline performance involves not only material strength but also precision-optimizing flow patterns to reduce pressure drops and energy loss. Computational fluid dynamics (CFD) simulations are now an integral part of pipeline design as they allow engineers to predict and improve flow and efficiency economically. The introduction of automation and remote monitoring has revolutionized the management of performance metrics by providing the ability to measure and monitor real-time data like flow rate, temperature, and pressure.

Moreover, the implementation of energy-efficient pumping systems greatly aids in decreasing the operational costs for liquid and gas transport. Modern pumps with tire VFDs (Variable Frequency Drives) allow for a greater dynamic reduction in energy input to be delivered by the system according to the system’s demands. All these advances improve the feasibility and effectiveness of pipelines in industrial, municipal, and commercial services.

References

Frequently Asked Questions (FAQ)

Q: What are the main benefits of using HDPE water main pipes for potable water applications?

A: HDPE (High Density Polyethylene) pipes offer several benefits for potable water applications, including resistance to many chemicals, easier installation, and durability. They are an excellent choice for water supply systems and are particularly suited for dynamic soils due to their flexibility and ability to handle water flow efficiently.

Q: How does HDPE compare to PVC and ductile iron pipes in terms of installation?

A: HDPE pipes are generally easier to handle and install compared to PVC and ductile iron pipes. The lightweight nature of polyethylene material and its flexibility allow for alternate installation methods, making it a preferred choice in the pipe industry.

Q: Why are HDPE pipes considered an excellent choice for water supply systems?

A: HDPE pipes are an excellent choice for water supply systems because they are durable, resistant to many chemicals, and have joints that do not leak. This makes them reliable for carrying potable water without concerns about allowable water leakage or contamination from chemicals in the water.

Q: Can HDPE pipes be used in areas with dynamic soils?

A: Yes, HDPE pipes are particularly suitable for areas with dynamic soils. Their flexibility allows them to adjust to soil movements without cracking or breaking, unlike more rigid materials such as ductile iron pipes.

Q: What makes HDPE an easier installation option compared to other materials?

A: HDPE pipes are easier to install due to their lightweight nature and the ability to be supplied in long coils, reducing the number of joints needed. This results in quicker installation times and lower labor costs.

Q: Are there any limitations to using HDPE pipes for potable water applications?

A: While HDPE pipes are highly advantageous, they may not be suitable in situations where extremely high temperatures or pressures are involved, as these conditions can affect the integrity of polyethylene material. It’s essential to specify HDPE pipe according to the specific requirements of the project.

Q: How do HDPE pipe fused joints contribute to the overall reliability of a water supply system?

A: HDPE pipe fused joints provide a seamless and leak-proof connection, which ensures that joints do not leak. This is crucial for maintaining the integrity of a water supply system, preventing water loss, and reducing replacement costs over time.

Q: In terms of longevity, how do HDPE pipes compare to other drainage pipes?

A: HDPE pipes are known for their long lifespan and durability. They are resistant to corrosion and chemical degradation, unlike traditional drainage pipes such as iron pipes, making them a cost-effective option for long-term water supply and drainage solutions.

Q: What role does the polyethylene pipe industry play in advancing potable water applications?

A: The polyethylene pipe industry is continually innovating to improve the performance and versatility of HDPE products. By developing new technologies and materials, the industry supports the growing demand for reliable and sustainable potable water applications.