Have High-Density Polyethylene (HDPE) sewer pipes provided the modern redevelopment of infrastructure with great performance, versatility, and economy? Contractors, engineers, and municipal planners alike must truly know the benefits and applications for HDPE pipe for fine design work in the sewer system. This article delves into why HDPE has rapidly gained first preference in sewer installations because of its unparallelled strength, corrosion resistance, and ability to accommodate tough working conditions. Thereafter, we will look into some facets concerning its installation process to situate you well in the expertise required to work on HDPE installations with ease. So whenever you need to upgrade the legacy civil infrastructure or just want to parse why HDPE tends to set new trends in the industry, this guide offers value in return.

Understanding HDPE Pipes

What is HDPE?

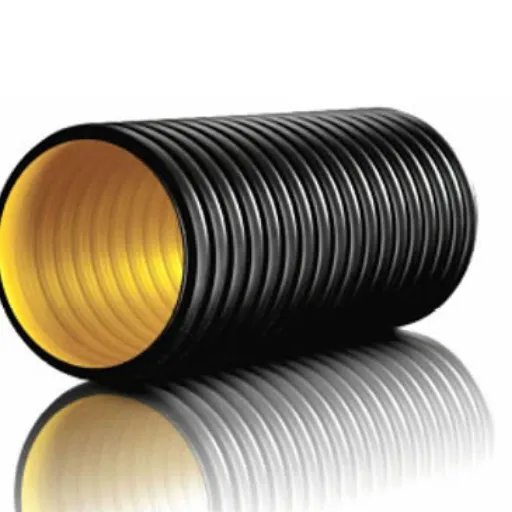

Being thermoplastic polymers, HDPEs are formed from oil. Known for their high strength-to-density ratio, they tend to be lightweight and yet durable. Due to its versatility and reliability, HDPE is used in industries to manufacture pipes, containers, and many other goods. The molecular arrangement of polymer chains imparts flexibility to HDPE to absorb impact, thereby allowing it to be useful in applications that require it to be rigid and in dynamic pressure.

An important property of HDPE is excellent resistance to chemical action, corrosion, and environmental stresses. Therefore, HDPE becomes especially suitable for transporting liquids and gases over long distances, while being exposed to pressure and harsh environments. Unlike any other material, HDPE pipes never rust; their service life is much longer, requiring little to no maintenance. So HDPE has become an ideal choice for development, agricultural projects, and industrial projects.

The material also promotes environmental benefits. Being recyclable, it fosters sustainability by lowering waste levels and providing a way for materials to be reused later. The greater strength of the material means long-term use; thus, it does not require replacement or repair in a short span of time, saving the consumption of raw materials. Putting it all together, HDPE is strong, versatile, and environmentally friendly, thereby opening opportunities in modern engineering and material science.

Key Features of HDPE Pipes

- High Durability and Flexibility: Looking at the benefits, HDPE pipes have high durability. They can resist severe mechanical stresses as well as hostile environmental conditions without cracking or breaking. The flexibility of HDPE pipes allows them to accommodate shifting soils and changes in topography, and, hence, they find applications in water supply systems and underground installations.

- Corrosion and Chemical Resistance: An important feature of HDPE pipes is corrosion and chemical resistance. HDPE pipes do not corrode if exposed to corrosive water, chemicals, or aggressive soil conditions, unlike metal pipes. In other words, this chemical inertness allows HDPE pipes to safely carry industrial fluids, potable water, and wastewater without the problem of contamination or degradation of the pipe materials from inside.

- Lightweight and Easy Installation: HDPE pipes are light in weight as compared to traditional materials such as steel or concrete, making them easy to transport and install. This property lowers labor expenses and installation time, and consequently lessens the need for heavy machinery in deployment. They are also easy to fuse with heat fusion techniques for leak-proof pipes, increasing reliability in both pressure and non-pressure applications.

- Longevity and Cost-Effectiveness: Most of the time, HDPE pipes last for more than 50 years, which means they help in saving costs over time for operators and project managers. Since they require hardly any maintenance and can endure very harsh conditions, over time, their repair costs or replacement costs remain very low, making HDPE pipes highly cost-effective as an option for long-term projects.

- Sustainability and Environmental Uniqueness: HDPE is fully recyclable and can be manufactured or reprocessed to form new pipes or other items, thereby supporting the concept of the circular economy and reducing waste in the environment. It is lightweight; thus, less energy is spent during transportation. Besides, its longevity promotes dwindling material consumption for decades of use. Such environmentally friendly features give HDPE the edge to be classified as a responsible and sustainable alternative in contemporary engineering works.

Comparison with Traditional Materials

Therefore, HDPE pipes get scored over traditional materials such as steel, concrete, and PVC in terms of durability, flexibility, cost-economy, corrosion resistance, and environmental sustainability.

| Aspect | HDPE Pipes | Steel | Concrete | PVC |

|---|---|---|---|---|

| Strength | High | Moderate | High | Moderate |

| Adaptability | High | Low | Low | Moderate |

| Affordability | High | Low | Moderate | High |

| Resistance | High | Low | High | High |

| Ease | High | Low | Low | High |

| Sustainability | High | Low | Low | Moderate |

| Longevity | 50+ years | 20-30 years | 50+ years | 20-30 years |

| Weight | Light | Heavy | Heavy | Light |

| Upkeep | Low | High | Moderate | Moderate |

| Usage | Broad | Limited | Limited | Broad |

Benefits of HDPE Sewer Pipes

Exceptional Durability and Flexibility

High-Density Polyethylene sewer pipes are designed to resist and overperform under demanding conditions. Through its high resistance to the attacks of corrosive agents, HDPE remains a better choice where exposure to chemicals or corrosive wastes would otherwise be anticipated. Basically, the pipe is flexible and can withstand ground movements caused by either vibration or mild seismic activity, thus preventing damage or failure to the pipe. HDPE pipes provide a resistant solution to impacts even at temperatures below zero, thus ensuring stable performance in all climatic conditions.

Availing an HDPE pipe mainly guarantees delivering an expected life of over 50 years with little or no maintenance. In addition to potentially scaling, sediment build-up, and root intrusion, anything that would hamper free flow or cause interruptions in the operations is resisted by the material. Much lighter and more flexible than metal or concrete pipes, HDPE piping is easy to transport and offers commercial handling advantages such as lower logistics costs and faster construction times.

Next, the seamless joints, heat fusion, or electrofusion welding create leak-proof systems, thus enhancing the overall operational efficiency. This will also reduce the risk of environmental pollution and thus embody the goal of sustainability. The combination of durability and flexibility makes HDPE one of the premier materials for sewer infrastructure in both urban and industrial applications in a reliable and cost-effective manner.

Resistance to Corrosion and Chemical Wear

HDPE possesses excellent resistance characteristics to corrosion and chemical wear, which places it among favored materials for use in aggressive conditions. Through exposure to various substances, including acids, alkalis, and saline solutions, HDPE is immune, unlike the usual materials like metals and concrete that are rusted, scaled off, or chemically degraded. This natural resistance aids in reduced efforts for extra surface treatment, such as chemical coating, leading ultimately to long-term reliability during operation and minimal maintenance requirements.

The steric structure of HDPE determines the degree to which it may resist chemical substances. High crystallinity and non-polar nature grant a protective sheath against many solvents in order to maintain its form when subjected to long-term exposure to corrosive substances. Industries that handle highly hazardous chemicals, such as mining, petrochemical, and waste management, require very corrosive environments for pipeline construction; HDPE pipes render such solutions due to their resistance. Also, being chemically inert, HDPE finds applications wherein potable water is stored or handled, or else the storage involves food-grade materials.

This data from recent research supports the extraordinary resilience of HDPE. Experiments designed with the ISO 4427 and ASTM D3350 standards indicate that HDPE pipelines can endure the pH range between 1 and 14 while sustaining mechanical properties, mainly tensile strength, and resistance to impact. Moreover, its ability to operate in an environment of fluctuating temperatures coupled with UV exposure, establishes another aspect of its versatility. Modern techniques, including stress-crack resistance improvements and multilayer technology, provide HDPE with anti-corrosion and chemical wear capabilities, making it an ideal choice for infrastructure solutions that sustain over time.

Cost-Effectiveness in Long-Term Projects

Being considered durable, low on maintenance, and long in service life, HDPE acts as an unequivocal proof of cost-effectiveness in long-term engineering works. HDPE performs better than the older generation materials in resisting corrosion, chemical degradation, or environmental stresses; thus, with time, these processes bring heavy charges for frequency in repair or replacement. In addition to being lightweight, it greatly helps lower the transportation and installation cost since more heavy equipment is required compared with heavier ones.

From the economic viewpoint, a longer HDPE life implies lower lifecycle costs–an important aspect in large-scale projects that may stretch across decades. Research revealed that HDPE pipes laid in water and sewage systems could operate perfectly for 50 years under treatment and perhaps up to 100 years under certain circumstances. The extended lifespan makes for better cost efficiency and supports sustainability objectives in terms of a reduction of materials and less adverse environmental impacts.

New and modernized manufacturing processes of HDPE, including multilayer technology and precision engineering, enhance the efficiency of materials with HDPE; hence, engineers could design more efficient infrastructure with fewer raw materials. On the whole, HDPE presents an interesting cost-benefit proposition for any contemporary infrastructure endeavor by giving ultimate functional goals, sustainability, and longevity emphasis.

Installation Methods for HDPE Pipes

Efficient Installation Techniques

While installing HDPE piping efficiently, factors such as time, labor, disruption to nature, cost, helplessness, and durability come into the picture. The trenchless method is perhaps the most popular nowadays, considering HDD and pipe bursting methods. These work best where the existing area is urban or environmentally sensitive since they vastly reduce open excavations and surface-level disturbances.

Butt fusion and electrofusion welding are two pertinent joining techniques for HDPE pipes to make a leak-proof and homogeneous system. These welds are at least as strong as the base material and, as such, enhance the lifespan and reliability of pipeline infrastructure. Now, with equipment automation advances, these methods are being performed under precision control systems, sharply lowering human error and a drop in weld quality.

In scenarios involving a vast installation, the drag-in method comes statistically as the most prominent method: Once the pre-fabricated pipe lengths have been assembled, they are pulled to their final setting. The treatment is thus extremely efficient for long pipelines, whereas in planning a method of installation, pipe damage must be carefully avoided. And the anchoring and bedding systems must provide structural support and load distribution, the latter being especially considered to maintain pipe integrity under varying soil conditions and thermal stress.

Using advanced GIS (Geographical Information Systems) and superior surveying techniques, engineers optimize pipe alignment and pipe gradients for maximum installation efficiency. These two aspects highlight the necessity to merge innovative practices with strict technical standards to create optimally better project outcomes for HDPE pipe installations.

Time and Labor Cost Savings

Another advantage that makes HDPE piping a big time saver in labor costs in infrastructure projects is that, being light and flexible, it is easy to install. Unlike traditional piping materials such as steel or concrete, an HDPE pipe is less manually handled and often needs to be hoisted using heavy-lifting equipment. Supply of continuous lengths through coiled rolls also eliminates numerous joints, and fewer installation interruptions translate to faster execution of the project.

Furthermore, with contemporary fusion welding methods such as butt fusion and electrofusion, pipe connections are made quicker and more reliably than with mechanical joints for other pipes. Hence, the installation time reduces, leading to fewer chances of joint failure and less maintenance cost as a whole.

Steel or concrete alternatives, based on industry case studies, are said to cost 20-30% extra to install when compared to HDPE piping. The difference increases in applications involving difficult terrains where the flexibility offered by HDPE smoothens the installation process, making it more adaptable. Such cost and time benefits due to which HDPE is slowly become the preferred option for modern utilities and infrastructure requirements.

Maintenance Considerations

In evaluating the maintenance requirements of HDPE piping systems, durability and corrosion resistance form the deciding factors. Unlike steel or concrete, HDPE pipes are very resistant to chemical reactions and environmental conditions such as UV light or extremes of temperature. The higher resistance to degradation over time makes incidental repairs and replacements not very common. Such is the flexural quality of this material that ground movements sustained either on seismic activity or on soil decrement, in any case, do not aggravate the HDPE pipe much for damage.

Generally speaking, HDPE pipes require minimal intervention to operate at peak efficiency. Inspection and occasional cleaning are enough to keep the system free from clogs, leaks, and imbibed damages. Advanced technologies such as robotic inspection systems can be easily attached to the HDPE pipelines, hence easing maintenance while providing detailed diagnoses to the system. This becomes more valuable to large-scale installations where early warnings can save from costly interruptions.

To summarize, I would point out to maintenance that HDPE piping systems require fewer and less-intensive maintenance activities in contrast with conventional materials. Their corrosion resistance, adaptability to environmental changes, and compatibility with modern monitoring techniques make them a perfect choice for any infrastructure project from an efficiency and cost perspective. Using HDPE means almost no maintenance, either from an operational or from a financial standpoint.

Applications of HDPE in Water Management

HDPE Drainage Pipes in Infrastructure

Drainage pipes made from high-density polyethylene provide a key component in modern infrastructure systems because of their particular performance capabilities. Engineered with durability in mind, HDPE pipes are known for their high strength-to-density ratio, flexibility, and resistance to chemical and environmental stressors. These characteristics make them well-suited for stormwater management, municipal sewage, and industrial drainage applications.

In terms of longevity, HDPE pipes perform best in standards with an estimated lifespan of more than 50 years under excellent conditions. Being lightweight, it becomes easy and quick to handle and install, thus less labor and cheaper transportation costs. Resistant to scaling, abrasion, and microbial growth, performance will remain uninterrupted even in harsh operational settings.

HDPE pipes have their efficacy further improved with the advanced jointing technology they utilize, most often heat fusion. The technique yields connections free from leaks. Hence, there is no infiltration or exfiltration as is common in traditional pipe systems. This particular ability would be most advantageous when preventing water contamination in an urban setting, a concern for public health.

There comes a boom in the growth rate of acceptance of HDPE drainage pipes in global infrastructure projects. There have been reports of municipalities and developers transitioning to HDPE systems in larger numbers to combat flooding and water conservation, and sustainability. Hence, therefore, by using the innovative design and material properties of these pipes, they give rise to the building of resilient and future-ready infrastructure systems.

Leak-Proof Water Distribution Systems

Leakages must be avoided in water distribution systems so that water is not lost to inefficiency and so the supply is reliable. Therefore, High-Density Polyethylene or HDPE pipes have become the most preferred choice. These pipes show better characteristics when compared to steel or concrete in terms of flexibility, chemical resistance, and ease of jointing. The installation of pipes by means of heat fusion ensures a totally continuous system with no leaks, thus greatly curtailing the possible contamination and wastage of water through leaks at joints and fittings.

One of the main factors behind the widespread use of HDPE pipes in contemporary water distribution networks is long-term cost savings and environmental advantages. Studies estimate that about 40% of water loss through distribution networks worldwide is leaky in nature, especially when inflicted upon by aging infrastructure. Moving to HDPE systems would however, check against this threat by affording pathways that would be durable and corrosion resistant, capable of withstanding variable pressure zones and shifting ground conditions. Furthermore, HDPE material tolerates temperature variations fairly well so that it can be laid in different kinds of climates and operational environments. The life of HDPE pipes is mostly beyond 50 years, which greatly increases value for money in the eyes of most municipalities and developers.

The pipe monitoring technology complements leak-proof systems, delivering real-time data to engineers about any pressure changes, flow rates, and potential leaks. Smart sensors installed in HDPE networks facilitate predictive maintenance, detecting weak points prior to turning into major disruptions. Joining innovations into modern materials epitomizes modern engineering responding to global challenges like water scarcity and infrastructural sustainability. Therefore, HDPE leak-proof systems are considered the basic foundation on which water management frameworks throughout the world will be built efficiently and ready for the future.

Role in Sustainable Development

The implementation of HDPE leak-proof systems plays an important role in progressing sustainable development by addressing environmental, social, and economic challenges. Below are five ways in detail how the leak-proof systems further sustainability:

- Water Conservation: Hello HDPE, because it is leak-proof, it does not allow water loss through pipeline failures. Studies show that, in conventional pipeline systems, leaks cause a 30% loss of water all over the world. HDPE networks thus minimize this loss and ensure the proper use of this precious resource.

- Energy Efficiency: HDPE pipes have an interior surface that is smooth and resistant to friction forces, requiring less energy to pump water through it. Thus, this energy-saving process results in a reduction of electricity by around 20%, thereby reducing greenhouse gas emissions related to the transportation of water.

- Durability and Longevity: With a lifespan of 50-plus years under most conditions, HDPE pipes lessen the waste disposition of being replaced regularly. Such durability requires minimal extraction of resources and manufacturing processes. Therefore, the pipeline installation aligns with sustainable infrastructure.

- Lower Costs of Operations: With HDPE systems being low-maintenance and operating in a reliable manner, there must be cost savings involved. The comparative studies showed HDPE systems could help reduce maintenance costs by 40% compared to conventional materials such as cast iron or PVC.

- Waste Reduction: HDPE materials are recyclable, meaning that at the end of their lifecycle, these pipes can be recycled rather than discarded into landfills. Such circular use of resources supports the global target of waste reduction and promotes the sustainable materials economy.

Combining all these characteristics, the HDPE-based systems stand for a pragmatic approach to concrete data in order to make infrastructure development compatible with sustainable development goals.

HDPE Pipe Fittings and Sizes

Overview of HDPE Pipe Fittings

HDPE pipe fittings are quality-assured components that make the proper connections and allow efficient transitions within high-density polyethylene piping systems. These fittings are designed to withstand rigor, such as very high pressure and temperature variations, without jeopardizing the reliability or structural integrity. HDPE pipe fittings come in the forms of tees, elbows, reducers, flanges, and couplers for various installation needs. Each type aims to lessen pressure losses in the system, keep leakage at a minimum, and maintain flow efficiency at its maximum.

HDPE fittings are long-lasting due to corrosion resistance, chemical interference, and resistance to abrasion. It is, therefore, installed in particular use cases in water distribution, gas transmission, and industrial process systems where such characteristics are needed. Many of these HDPE fittings are thermally welded, creating a uniform joint; hence, the joint will never become a weak spot that will shorten the life of a pipe system. This fusion technique forbids infiltration, exfiltration, and joint separations due to any heavy mechanical stress.

HDPE pipe fittings are engineered as per standards, thus ensuring compatibility and reliability for most piping systems. HDPE fittings are widely sized, normally ½ inch and upward through 63 inches in diameter, thereby serving small residential installations as well as large-scale industrial projects. The versatility of HDPE fittings is just another proof of their utilization in modern infrastructure and utility networks.

Selecting the Right Pipe Size

When choosing the pipe size for a system, the flow rate, pressure requirements, and application have to be studied. Calculating the flow rate becomes necessary as it is usually given in GPM or L/s, something that directly affects the diameter of the pipe to be fitted. Then comes the necessity to look at system pressure, whether it is given in PSI or bar, as the pipe has to stand the operational pressures and those of surges with a margin of safety without a chance of failure.

Pipe sizes under 2 inches in diameter normally work for domestic water distribution, drainage, or irrigation applications. In contrast, industrial and municipal projects may require larger pipe diameters exceeding 63 inches to carry greater volumes under higher pressure for services like sewage, gas distribution, or large-scale water transportation.

Pens and pencils in our arsenal are the hydraulics design calculators and the flow simulation software. These tools enable our engineers in pipe sizing optimization, thus ensuring standard codes such as ISO 4427 for HDPE pipes will not be violated. Consequently, the wastage of materials due to excessively large pipe sizes is somehow avoided, but the efficiency of the system is maintained. But one must pay special attention to thermal expansion and contraction, especially for a system under high-temperature variation. These factors, otherwise, would somehow impede the operational integrity of the pipe over time.

Innovations in HDPE Fittings

Recent developments in HDPE fitting technology have enhanced the efficiency, durability, and versatility of piping systems. The major improvement has been in the invention of electrofusion and butt fusion style fittings that provide seamless, leakproof joints capable of withstanding high pressures and high rates of temperature change. Fusion techniques cost far less installation time and labor compared to mechanical techniques, thus making fusion the preferred alternative.

Further material developments have also enriched the evolution of HDPE fittings. With UV stabilizers in the modern HDPE fittings, it is best to expose them for a long time to sunlight and end environmental assaults. Biofilm formation is minimized through the incorporation of an antimicrobial coating in the fittings, thereby maintaining water quality in potable water applications.

Smart fittings integrated with IoT (Internet of Things) sensors are another breakthrough. These sensors perform real-time monitoring of the pipeline’s performance variations in pressure, temperature, and flow anomalies so that operators can be alerted and avert potential failures. In addition to that, 3-D printing has become a method to make custom HDPE fittings with greater accuracy, saving on lead time for special projects, plus less waste of material.

Such breakthroughs, along with conformity to international manufacturing standards, have widened applications of HDPE fittings across various industries, such as municipal utilities, mining, agriculture, and industrial applications, for reliability and efficiency under rigorous environments.

Frequently Asked Questions (FAQ)

Q: What is an HDPE sewer pipe?

A: An HDPE sewer pipe is a pipe made from high-density polyethylene, which is considered a highly durable material with resistance to a variety of environmental factors. Since HDPE pipes never leak and are flexible in nature, they are generally considered good for use in sewerage and drainage systems with both residential and industrial applications.

Q: How does HDPE compare to PVC pipe?

A: HDPE sewer pipe has become more and more preferable to the PVC pipe due to its ability to resist impact and also to flex more easily in the system. It does not corrode with time as does PVC, and can withstand pressure surges for a better reliability of drainage systems.

Q: What are the pressure ratings of HDPE pipes?

A: Various pressure ratings for HDPE sewer pipes exist, which make them suitable for diverse applications. The pressure rating depends on parameters such as wall thickness and outside diameter, making sure that the pipes can withstand suitable pressure for sewerage and drainage systems.

Q: Can directional drilling be used for the installation of HDPE pipes?

A: Horizontal directional drilling techniques can indeed have HDPE pipes installed therein. This method reduces disturbance of the surrounding area and facilitates installation in places where it is difficult to go, thus a very useful technique in urban drainage.

Q: What are some merits of heat-fused joints in HDPE pipe systems?

A: From the point of view of the materials and methods, heat-fused joints in HDPE pipe systems form strong joints with no potential leak points. This ensures superior durability of the sewer system against pressure surges to achieve long-term performance and reliability.

Q: Can you describe the impact of the physical properties of HDPE on its application?

A: The physical properties of HDPE, including flexibility and impact resistance, ensure that HDPE sewer pipes are fit for all manner of applications. Its properties that resist scale build-up and corrosion ensure that HDPE sewer pipes remain fully functional in conventional drainage and modern irrigation systems.

Q: What is the cost of HDPE sewer pipes in comparison with those of other materials?

A: Depending on the pipe dimensions and installation methods, the cost of HDPE sewer pipes varies. However, significant savings can be realized with time due to their low maintenance requirements, while HDPE pipe is much more durable than traditional materials, such as ductile iron pipes.

Q: Are HDPE pipes good for dynamic soils?

A: Because of their flexibility and accommodation for ground movement, HDPE pipes are suitable for dynamic soils. This makes the pipe a reliable alternative in areas susceptible to shifting soil conditions that maintain the functioning of their sewerage and drainage systems.

Q: What sizes are available for HDPE sewer pipes?

A: Various sizes of HDPE sewer pipes are provided to match differing circumstances. From small-scale residential systems to large-scale industrial ones, the pipes are altered to satisfy the particular pipe dimension requirements of the project.

Q: How would fittings and reduced installation costs benefit HDPE sewer systems?

A: Offering fittings for HDPE sewer systems might thus reduce the installation cost by having simpler connections that may need fewer materials than others. This saves time and material cost, which is a big saving, particularly for the bigger projects.

References

- Field Performance Analysis of Steel-Reinforced HDPE Pipes

The study from KU ScholarWorks evaluates the performance of steel-reinforced HDPE pipes under different conditions. - Quality Evaluation of High-Density Polyethylene Pipe

This study in Academia.edu analyzes the quality of HDPE pipes for water supply and sewerage systems. - Experimental Study on Steel-Reinforced HDPE Pipes

This experimental study at the University of Texas at Arlington investigates the behavior of steel-reinforced HDPE pipes in contrast to other materials.

Ready to Upgrade Your Infrastructure?

HDPE sewer pipes offer unmatched durability, cost-effectiveness, and environmental sustainability for modern infrastructure projects. Contact your engineering team today to explore how HDPE solutions can benefit your next project.