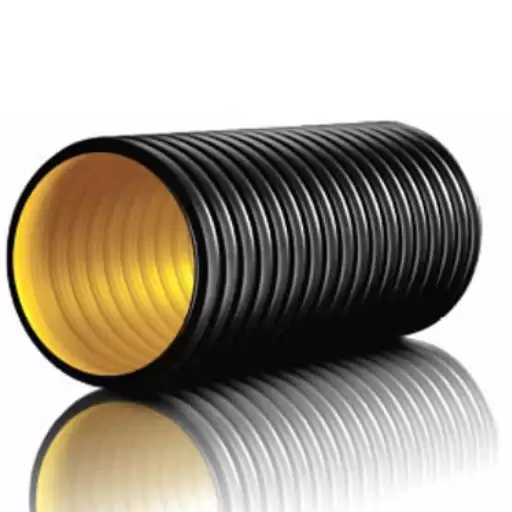

High-density polyethylene (HDPE) corrugated pipes have become an integral part of modern infrastructure projects, offering a versatile and highly durable solution for various drainage and water management applications. Whether you are working on large-scale civil engineering projects or smaller residential installations, understanding the sizes and dimensions of HDPE corrugated pipes is crucial to ensuring optimal performance and cost-efficiency. This article will guide you through the essential details surrounding HDPE pipe sizing, dimensional standards, and applications, empowering you to make informed decisions for your next project.

What Are the Common HDPE Pipe Sizes?

Standard Pipe Sizes and Dimensions

HDPE corrugated pipes have many sizes that can suit different needs. Common diameters of these pipes are between 4 inches and 60 inches, sometimes bigger depending on the manufacturer’s specifications. For residential purposes, pipes about 4 to 10 inches wide are common, while anything bigger is used for drainage, culverts, or industrial structures.

The dimensions of HDPE pipes, including wall thickness and internal diameter, are bound by certain standards, AASHTO M294 and ASTM F2306. This provides product consistency which streamlines project planning and execution. Pipes are categorized by their Stiffness NSK rating, leading to denotations such as SN4 or SN8, which quantify the structural capacity of a pipe and its utility for burial or other high-load installations.

While choosing the size of an HDPE pipe, factors such as flow capacity, installation conditions, and soil type need to be given special consideration. Bigger diameters are chosen for high volume water flow or storm drain management, while smaller ones are used for residential plumbing or lighter drainage tasks. Through regulatory and surveying standards, the appropriate pipe dimensions, ranging from installation to reliability, performance, and durability, can be identified.

How to Measure Pipe Diameter Effectively

Start measuring a pipe’s diameter by ascertaining whether you are measuring the outer (OD) or inner (ID) diameter. The outer side (OD) measures from the exterior wall’s edge to the edge of the exterior wall on the opposite side, while the inner side (ID) refers to measuring across the hollow part of the pipe. This distinction is critical as both ID and OD have their significance, where OD is employed in most pipe classification operations, while ID is critical for flow calculations.

Use a measuring tape or caliper to achieve greater accuracy. To measure OD, the tool needs to be placed across the pipe so that it straddles the widest cross-section of the pipe. If the pipe can be accessed from the inside, the inner diameter is measured by placing a caliper across the opening of the pipe. The position of the tool not being placed into the measuring caliper needs to be properly aligned to ensure measurement accuracy. For flexible pipes like HDPE, it is critical to make sure the pipe is not deformed during measurement, as these types of pipes can easily get deformed, which could lead to inaccurate readings.

Provided that the thickness of the pipe’s wall is known, the ID can be calculated by removing twice the wall thickness from the pipe’s OD. This strategy is used often when dealing with situations where direct observation isn’t possible. Standards and techniques put in place for accurate measurement are critical especially when dealing with growth, system dependability, and anticipating results.

Importance of Accurate Pipe Size Selection

Selecting the pipe size accurately for any piping scheme is central to its operational efficiency and its economic viability. Additionally, proper sizing optimally influences the flow rate, pressure, and system performance. Pipes that are too small will result in high pressure losses and excessive energy use, while pipes that are too large will require expensive materials and worsen system efficiency.

With everything analyzed, additional problems such as system malfunction, declining effectiveness, and unanticipated equipment wear arise from false pipe size selection. Small pipes in the transport of fluids slow down fluid flow, but too small pipes can lead to overpressurization at the downstream, resulting in system failure. Conversely, large diameter pipes lower the fluid flow rates, leading to high chances of corrosion, sediment build-up, and stagnation within the pipes.

Choose to follow industry standards and assess a piping arrangement so the system features and properties encompassing flow rate, pressure, and nature of fluid is checked then the optimum diameter is selected. Efficiency, survivability, and reliability go up while costs go down.

How Does Corrugated HDPE Pipe Compare to Other Materials?

Advantages Over Corrugated Metal Pipe

Polyethylene, High-Density (HDPE) corrugated pipes offer a range of benefits when compared to other types of threaded metal pipes. These differences have resulted in HDPE pipes being widely adopted in engineering and industrial applications. Here are five key advantages of using HDPE pipes:

- Corrosion Resistance: HDPE pipes are from a durable thermoplastic material that is resistant to corrosion and HDPE withstands harsher chemicals and factors as compared to metal pipes. Unlike other types of corrugated metal pipes, HDPE does not corrode. As a result, the pipes are easier to maintain or replace, due to their extended lifespan.

- Lightweight and Easy Installation: As compared to other metal pipes, the ease in which tasks utilizing polyethylene pipes can be completed makes HDPE a go-to option. The lightweight nature of HDPE fabrics makes it abundantly easier to install and transport them without utilizing much manpower.

- Superior Longevity: The estimated lifespan of welded metal and other forms of bonded tend to outlast traditional means, nearing 100 years. During the duration where these pipes undergo the normal conditions of use, there is a lesser need for maintenance and frequent replacements.

- Hydraulic Efficiency: Unlike traditional welded threaded pipes, cycloidal pumps possess smoother replacements for the internal surface. This results in a greater under Bugs’ lower withstanding efficiency, which makes blockages less in comparison. HDPE also helps with water management.

- Cost-Effectiveness: Compared to other products, the cost of materials may differ, but the cost of installing, maintaining, and replacing HDPE pipe is much cheaper. With these factors, the overall cost of utilizing HDPE is significantly lower.

Such benefits highlight the increasing use of corrugated HDPE pipes across various applications.

Durability and Flexibility of Polyethylene

Polyethylene, particularly in its high-density form (HDPE), exhibits exceptional durability due to its intrinsic material properties. It is highly resistant to chemical corrosion, environmental stress cracking, and abrasion, making it an ideal choice for demanding applications. Furthermore, HDPE performs exceptionally well under extreme conditions, such as fluctuating temperatures and aggressive soil conditions, without compromising its structural integrity. These characteristics ensure long-term reliability in infrastructure systems like drainage, wastewater management, and industrial pipelines.

The flexibility of polyethylene is another critical advantage that enhances its utility in various contexts. Unlike rigid materials, HDPE pipes can flex to accommodate ground movements, vibrations, or external loads without sustaining damage or fracturing. This adaptability reduces the likelihood of system failure and minimizes the need for costly repairs. Additionally, its lightweight nature simplifies the transportation and installation process, allowing more efficient deployment, especially in complex or remote environments.

From my perspective, providing a concise response to the question involves emphasizing polyethylene’s dual advantages of durability and flexibility. These qualities, supported by extensive research and real-world applications, make it a preferred material for numerous industries. With its ability to combine strength, resilience, and adaptability, polyethylene continues to outperform traditional alternatives in modern engineering solutions.

Comparative Analysis with RCP (Reinforced Concrete Pipe)

RCP pipes are considered sustainable, and HDPE pipes are light, flexible, easy to maintain, and cost-efficient. On the other hand, RCP pipes are recognized for their strong structure and long-lasting durability.

| Aspect | HDPE | RCP |

|---|---|---|

|

Mass |

Lightweight |

Heavy |

|

Bendability |

High |

Low |

|

Rustproof |

Yes |

Yes |

|

Robustness |

Moderate |

High |

|

Setup |

Easy |

Complex |

|

Expense |

Lower |

Higher |

|

Longevity |

100 years |

50-100 years |

|

Eco-Friend |

Moderate impact |

Sustainable |

|

Sturdiness |

Moderate |

High |

|

Upkeep |

Low |

Moderate |

How to Select the Right HDPE Pipe Size for Your Drainage Needs?

Factors Influencing Pipe Size Selection

Choosing the right size of HDPE pipes for drainage requires adequate attention to several critical considerations. Each factor ensures optimal performance, cost effectiveness, and long-term reliability. Below is a detailed outline of the five most important factors to consider:

- Requirements of Hydraulic and Fluid Mechanics: Desired flow rate is a major influence in determining the pipe size. In order to ensure that the piping system can accommodate water discharge, engineers calculate volumetric flow rate in cubic feet per second (CFS) or gallons per minute (GPM). For example, in stormwater management systems in urban areas, larger pipe diameters are needed for high-flow applications.

- Slope and Gradient of Installation: As a percentage, the pipe’s slope will determine water velocity. Faster flow velocity enables smaller pipe sizes, but in case of flatter gradient slopes, larger diameters may be needed to prevent water pooling and make drainage as efficient as possible.

- Expected Load and Pressure: The majority of people do not consider internal hydraulic pressure or loads such as soil weight and vehicular traffic. However, these two are critical. The use of HDPE pipes in high pressure systems, or in locations prone to heavy load require specific diameters and wall thickness for the pipes in order to ensure structural integrity.

- Type and Composition of Drainage Material: The dominating set of criteria and parameters, like sediment or debris, determines the boundaries of size selection. For example, a pipe carrying waste of solid constituents has to be of a certain lower diameter or else no propulsion and free flowing of the waste is maintained, leading to plugging of the system.

- Local Regulatory Standards and Guidelines: This combines a set of laws, codes of practice, and policies relevant to the construction industry, environmental issues, and other applicable norms in the context. It stipulates that more often than not the minimum size of the pipes for different uses as set in drainage frameworks especially municipal ones are in fact greatly regulated.

With all the above guidelines provided, on the side of the engineer regarding the performance of the structure designed can be more reassuring knowing that the system will require lower intervention servicing, enduring high efficiency alongside ease of drainage at all times.

Calculating the Diameter for Various Applications

I always pay attention to the flow rate and the type of material being transported through the system when calculating the appropriate diameter for various uses. In case of a drainage system, the speed of the fluid and the slope of the pipe will always govern the diameter.

For basic calculations, I apply formulas based on fluid mechanics principles like the Hazen-Williams formula, which helps in pipe sizing water applications by pressure loss because of friction. Dealing with wastewater systems or mixed-use systems where solids will have to clog the system, disabling functionality, ensuring margins adds a safeguard. I painstakingly integrate these considerations into practically every piece of my design.

Proper assessment of all variables makes it possible to adequately estimate maximum conditions without failure which ensures that diameter is set to estimate upkeep and lifespan of the system. Incorporating safety factor enables sustainable performance during unexpected shifts in limit beyond standards. With these strategies, I can ensure that the design will still remain simple while advanced features make it robust.

How to Ensure Proper Installation of HDPE Pipes?

Guidelines for Trench Preparation

Proper pipe trench preparation is a crucial step for maintaining the long-term performance and structural integrity of an HDPE pipe installation. The trench design must incorporate the soil conditions to include the diameter of the pipe, the required depth, and the volume of the load that can be supported. Below are important tips:

- Excavation Dimensions: The width of the trench should be able to offer room for placement and jointing of the pipes. Generally, width of the trench should be 1.5 times the diameter of the outer part of the pipe. In addition, ensure widths are large enough for compaction of bedding and backfill materials.

- Bedding Material: A uniformly compacted base of granular material like crushed stone or sand should be used as fine aggregate for the pipe bedding. To ensure the uniform distribution of loads as well as minimization of stress concentration, add a standard layer thickness of 4 inches or 10% of the pipe’s outer diameter, whichever is greater.

- Trench Depth: In addition to frost lines and load conditions, ensure the operating environment is specific to the installation of the trapezoidal section of HDPE pipes. These pipes require adequate overburden cover which is usually from 18 to 36 inches for withstanding surface loads, for example, vehicular traffic.

- Trench Bottom Condition: At the bottom of the trench, there should not be any sharp objects, rocks, and other debris that can pierce or deform the pipe. Soft and unsuitable soil such as peat or clay must be removed and replaced with compacted granular fill to improve the support conditions of the trench.

- Compaction Requirements: The pipe should be placed and then backfilled with materials that are compacted in layers to prevent the formation of voids and improve stability. Sidefill and initial backfill compaction are critical since they have a direct impact on deflection of the pipe when under load.

If these guidelines are followed, deformation and failure over time due to a lack of consistent support on HDPE pipes will be avoided. Proper preparation of trench improves system efficiency and durability while increasing lifespan.

Steps for Joint and Connection Integrity

To maintain the integrity of joints and connections, high-density polyethylene (HDPE) piping systems require proper maintenance and longevity. Best practices include, but are not limited to, the following steps:

- Aligning the Pipe Properly: Before the joining stage begins, check the alignment of the ends of the pipes. Make sure that the parts do not contact one another resulting in excessive stress on the joint and potential leaks or operational weaknesses.

- End Preparation: Ensure that the ends of the pipe are free from contaminants such as dirt, grease, or other forms of interference. In the case of fusion joints, be certain that the surfaces are clean and do not contain materials that would hinder bonding.

- Damage Inspection: Check for pipe ends and connecting portions for harm such as deformations, cracks, or signs of scoring. Compromised areas must be documented and replaced, or if possible, sufficiently fixed with proper sealing compound and materials that would not hinder the integrity of the joints.

- Heat and Pressure Application: In the case of butt fusion or electrofusion methods, ensure that the recommended guideline provided by the manufacturer for the heating and cooling cycle is closely monitored and maintained. Make sure that the guide specification on heating plates, temperature, and pressure fusion are complied with.

- Check the Torque and Tension on Mechanical Links: With bolt and screw type mechanical connections, it is best to pre-set the torque level to the recommended settings so that when loosened, component over-tightening is avoided. Too much pressure can break the pipe, while too little can result in leaking.

- Test and Inspection: Joint strength, along with any existing defects, can be verified by performing pressure testing, non-destructive testing (NDT), or ultrasonic testing. A specific percentage of the operating pressure, usually above, is used for pressure testing to guarantee the field reliability of the joint.

- Process Documentation: Document the entire joining process along with the surrounding conditions, values for equipment settings, and test outcomes. That record can be useful for cross-checking during maintenance and quality checks.

These systematic approaches to joining HDPE pipes ensure dependable performance and function while greatly decreasing the chances of failure during operations. It also ensures that all set engineering, operational, and safety standards are satisfactorily met.

Common Installation Mistakes to Avoid

Improper Surface Preparation: One of the most common oversights during HDPE pipe installation is the lack of surface cleaning and pre-treatment before joining. The joint will most likely fail either through leakage or joint failure due to pressure when a joint is contaminated with dirt, oil, or moisture. All surfaces must be cleaned, and drying done prior to proceeding with the operation. Use only approved cleaning agents.

- Incorrect Fusion: As is the case with just about everything, there is a set of steps to be followed when fusing HDPE pipes. Common issues arise during the trimming phase where heat, pressure, or rest extremes deviate from the set guidelines. Material degradation will occur with overheating, and insufficient heat will create weak bonds. A set of guidelines is provided by the manufacturer, thus equipment check-ups, calibration, and temperature measuring devices should always be set to mentioned specifications in order.

- Using Substandard or Damaged Equipment: Employing poorly maintained equipment or equipment not designated for use with HDPE pipes greatly increases the chance of defects occurring in the joining process. Routine equipment check-ups, setting attending schedules, and timely calibration aid greatly in avoiding these issues.

- Ignoring Environmental Factors: Ignoring temperature extremes, wind conditions, and humidity level can drastically alter the fusion procedure. Severe cold prolongs heating times, while high wind speed cools the heated area too fast. Implement work area shelters in order to prevent extreme wind interference.

- Skipping Post-Installation Testing: Inadequate or no pressure or integrity testing after installation may lead to concealed weaknesses in the system. Validate the reliability of the system using industry-standard testing, like hydrostatic or pneumatic pressure tests, before operational deployment.

System durability as well as performance are greatly enhanced through compliance with identified imperatives. HDPE Pipe mistakes that enable professionals to succeed and achieve enduring regulatory compliance.

What Are the Typical Applications of Dual-Wall Pipe?

Benefits in Agricultural Settings

The innovative design and agricultural plumbing materials make dual-wall pipes extremely useful when dealing with drainage systems in agricultural plumbing. Benefits include the following five points:

- Effective draining: Because of its ultra smooth interior, dual wall pipes are used in subsurface drainage systems which aid in managing excessive field water. Thus multi dual pipe structures are waterlog friendly and make relocation of water possible. This aids in crop yield efficiency by up to 30% said researchers.

- Resistance to Chemicals and Corrosion: Fertilizers, soil acidity, and pesticides are deemed super corrosive to plumbing agriculture appliances, but with dual wall pipes having high-density polyethylene (HDPE) construction, their overall lifespan increases by 50+ years.

- Maintaining Inner Integrity Due to Under Load: The use of dual wall pipes is widely accepted for heavy-duty farm machinery and anywhere deeply buried. Rigid construction with dual pipes makes them withstand highly compressive loads of 150 psi without deformation.

- Ease of Installation: The lightweight plastic dual wall pipes come in different sizes which increases ease of handling and installation. The use of quick coupling systems can also reduce labor time by up to 25% when compared to traditional materials like concrete or steel due to lower installation times.

- Cost-Effectiveness Over Time: Although the upfront cost of dual wall pipes is greater, their maintenance costs and needed durability dramatically improves long-term expenses. On average, dual wall pipe systems lower operational costs by 20-40% when compared to alternative solutions.

These advantages emphasize the importance of dual-wall pipes in modern agricultural systems, which are crucial for responsive and eco-friendly farming methods.

Usage in Drainage Systems and Water Management

The performance characteristics and versatility of dual wall pipes makes them vital for managing water and drainage systems. These pipes have a smooth inner wall while their outer wall is corrugated which allows for adequate flow and preservation of the internal structure when exposed to different loads. This makes them ideal for use in agricultural drainage, municipal stormwater systems, and flood mitigation efforts.

The advancements in the engineering of materials increased the performance of dual wall pipes. The primary material, High-Density Polyethylene (HDPE), shields the pipes from sulfuric acid, UV light, and abrasion which makes them withstand severe environmental conditions. In addition, their light weight enables easy transport which decreases the time needed for installation during infrastructure developments.

Field studies suggest that dual-walled pipe systems can increase the flow of water by up to 30% when compared to smooth-walled alternatives. Their performance under extreme sediment conditions with precise hydraulic control proves dual-wall pipes to be invaluable for dependable water management. By providing sustainable water channeling solutions, dual wall pipes effectively reduce the environmental impact as well as operational costs in critical applications.

References

Frequently Asked Questions (FAQ)

Q: What is HDPE corrugated pipe, and how is it used in drainage systems?

A: HDPE corrugated pipe, commonly used as a drainage pipe, is made from high-density polyethylene. It features a corrugated exterior for strength and a smooth interior wall to facilitate the flow of water. It’s a popular alternative to reinforced concrete due to its corrosion and abrasion resistance.

Q: How does the specification of HDPE corrugated pipe affect its performance?

A: The specification, including diameter of a pipe, the wall thickness, and material grade, directly affects its performance. Proper product specifications ensure the pipe can withstand environmental stresses and offer exceptional hydraulics in drainage applications.

Q: What are the benefits of using N-12 dual-wall HDPE pipes?

A: N-12 dual-wall HDPE pipes offer a smooth interior wall for enhanced flow capacity and a corrugated exterior for structural strength.

Q: How do I determine the correct size and dimensions for an HDPE corrugated pipe?

A: Determining the correct size involves considering the outside diameter, wall thickness, and fitting requirements. Pages of detailed information and product details are available in documentation and drainage handbooks to guide your selection.

Q: What factors contribute to the pipe quality of HDPE corrugated pipes?

A: Pipe quality is influenced by the manufacturing process, material grade, and adherence to standards. These pipes must be produced according to recognized specifications to ensure durability and effectiveness in their application.

Q: How does HDPE corrugated pipe compare to CMP and other alternatives?

A: HDPE corrugated pipes are an alternative to CMP (corrugated metal pipe) and reinforced concrete, offering benefits like corrosion resistance, lightweight design, and ease of installation. They also provide detailed information about our products’ long-term performance and cost-effectiveness.

Q: How do I connect HDPE corrugated pipes in a drainage system?

A: Connecting HDPE corrugated pipes typically involves using appropriate fittings and connectors designed for plastic pipes. Proper installation ensures a secure and leak-free connection, crucial for effective drainage systems.