The demand for reliable, sustainable, and efficient infrastructure in potable water supply systems has never been more critical. High-Density Polyethylene (HDPE) pipes are increasingly becoming the preferred choice for such applications, offering unparalleled durability, flexibility, and environmental benefits. But what exactly makes HDPE pipes stand out as a material of choice for delivering clean and safe drinking water? This article will take an in-depth look at the unique properties, practical advantages, and diverse applications of HDPE piping systems in the realm of potable water supply. Whether you’re a civil engineer, contractor, or policymaker, understanding the role of HDPE pipes can provide valuable insights into building resilient and forward-looking water distribution systems.

What Makes HDPE Pipes Suitable for Water Supply?

Understanding the High-Density Polyethylene Material

While having a high strength-to-density ratio, High-Density Polyethylene (HDPE) is a thermoplastic polymer relevant to water supply systems. The molecular structure of HDPE offers extraordinary impact resistance and durability. As a result, HDPE pipes can sustain high internal and external pressures without cracking or breaking. These attributes guarantee longevity even when exposed to fluctuating temperatures, difficult installation sites, or strenuous environments.

HDPE is best known for its ability to resist erosion and corrosion. Unlike traditional metal pipes, HDPE does not rust or corrode when exposed to water, chemicals, or minerals and is therefore essential in maintaining the quality of potable water. Moreover, being non-toxic and food-grade compliant, HDPE pipes fulfill safety and health regulations concerning drinking water distribution and supply.

Another important characteristic of HDPE is its lightweight and flexible construct, which makes it easier to handle and install in comparison with other materials, such as concrete or steel. This type of flexibility minimizes the chances of pipes fracturing from ground movement, pressure surges, or even seismic activities. Furthermore, the smooth interior surface of the material also helps in reducing friction, thus enhancing hydraulic efficiency and lowering the energy required in pumping water through the system. These attributes, in unison, make HDPE the most suitable material to be used in contemporary sustainable water infrastructure projects.

Key Features of HDPE for Potable Water Systems

The unique characteristics of high-density polyethylene (HDPE) make it a perfect candidate for use in potable water systems. This is due to its resistance to chemicals, corrosion, durability, and increased lifespan when compared to traditional materials. Its ability to resist internal and external corrosion ensures that the HDPE will retain the integrity of the water quality over decades of use. Additionally, its capacity to maintain structural integrity under differing temperatures and pressures increases its reliability.

Another crucial aspect of HDPE is its jointing technology, which includes methods like heat fusion. These joints provide the additional benefits of creating seamless, monolithic systems that are free of leaks, which reduces water loss and maintenance costs associated with maintaining the system. Furthermore, these joints prevent contamination from external sources, making sure that the potable water being transported is safe for consumption.

Moreover, the low weight and flexibility of HDPE facilitate transport and installation, leading to lower costs for the entire project. Its capacity to be installed using trenchless methods like horizontal directional drilling is less destructive to the environment and convenient for use in difficult landscapes. All of these characteristics cumulatively place HDPE as a reliable and sustainable option for modern potable water systems.

Comparing HDPE to Other Pipe Materials

In comparison with other materials like PVC, ductile iron, and steel, High Density Polyethylene (HDPE) pipes offer a much better long-term value. One extremely advantageous factor is its corrosion and chemical resistance. Unlike ductile iron and steel, HDPE is immune to rust, erosion, and deterioration, even with exposure to aggressive chemicals or harsh soil conditions. This enables the use of HDPE pipes in extremely durable environments.

These demanding environments are made possible due to the flexibility and impact resistance of HDPE. Unlike rigid pipe materials like PVC and steel, HDPE is much more capable of enduring ground movement and high pressure without breaking or cracking. Hence, it is ideal for regions susceptible to seismic activity or areas with heavy soil loads. Moreover, HDPE is fused using heat, so the joints form a leak-free system that improves operational efficiency and longevity.

Cost-effectiveness is yet another area where HDPE excels. Even though raw HDPE material may cost more than PVC or other materials, the savings that can be made in the product’s lifecycle due to lower maintenance expenses, prolonged life, and minimal risk of failures compensate for the initial costs. Additionally, its suitability for use with trenchless installation techniques guarantees a lower impact on the environment, which strengthens an already preferential choice for modern eco-friendly infrastructure projects.

How Are HDPE Pipes Installed in Potable Water Systems?

Common Installation Methods for HDPE Water Pipes

Four major methods exist for installing HDPE pipes in potable water systems, with each selected due to a certain project’s needs, including, but not limited to, the surroundings, pipe size, and terrain features. These include:

- Open Trench Installation: This is the oldest technique used and is one that requires digging a trench where a pipeline will be placed. The HDPE pipes will be placed into the trench and will be fused using mechanical joints. After this, the pipes will be covered using sand or soil. Areas that have simple features, such as easy-to-access surfaces, are better for open trench installation, making it ideal for such areas.

- Horizontal Directional Drilling (HDD): HDD is a form of technique one can use when there is no available trench. This is mostly applied to urban or built-up areas that already have infrastructure. Using this method greatly reduces the impact on the environment, meaning it can also be utilized in high-traffic regions, removed water passages, or places where waterways are crossed.

- Slip Lining: This involves using an old pipeline and substituting the insides with a new HDPE pipe, while leaving the original structure intact. This modification helps improve the overall quality of the pipeline and expand its lifespan. This method decreases the amount of excavation that needs to be done on the pipelines while providing an effective method to improve worn-out systems.

- Pipe Bursting: This sophisticated trenchless technique is used when replacing a pipeline to replace it with a new HDPE pipe. An old pipe is fractured, and simultaneously, a new one is pulled into its place. If needed, this method allows for an increase in pipe size, which enhances the system’s capacity while removing structural defects in older materials.

Each of these methods uses HDPE material, which is flexible, lightweight, and durable, ensuring efficient installation while minimizing costs. A combination of methods can be applied; however, choosing the right one requires an evaluation of the site, environment, and regulatory requirements, all tailored to fit the hydraulic design of the system.

Ensuring Leak-Free Pipe Joints

Maintaining the integrity of pipeline systems and ensuring their efficiency depends on achieving leak-free pipe joints. Effective methods for HDPE piping include heat fusion techniques like butt fusion, electrofusion, and socket fusion. All of them make a joint that is at least as strong as the pipe itself. As a result, leak-free connections are created that can withstand high-pressure conditions.

With butt fusion, for instance, the pipe ends are heated until molten and then pressed under a controlled force. This creates a homogenous bond between the two pieces. Electro-fusion differs in that a specialized fitting containing an embedded electrical coil is used. Heat is then generated, which makes joint formation possible. Both methods clean, align, and properly scrub the bond clean filters.

These procedures give guidelines for monitoring the fusion pressure, temperature, and cooling time, which must be observed using sophisticated digital fusion controllers capable of real-time data tracking. Additional monitoring, post-installation pressure testing, and software checks further confirm the structural strength of the system while minimizing operational failure risks.

With these advanced methodologies, pipeline systems can sustain dependability while achieving optimal flow, meeting safety standards, and fulfilling environmental policies.

Role of Directional Drilling in HDPE Installation

Directional drilling is crucial for the implementation of High-Density Polyethylene (HDPE) pipes, especially in cases where trenching is not practical. This technique allows for the emplacement of pipelines with little disturbance to the ground surface, thus enhancing efficiency. Given below are five specific points that demonstrate the benefits and uses of directional drilling in the installation of HDPE:

- Minimized Surface Disruption: Directional drilling makes it possible to outfit areas with HDPE pipelines without the need for significant digging. This is especially useful in urban cities, under roads, or around sensitive ecological areas. Public disturbance and restoration costs are significantly diminished.

- Streamlined Installation in Complex Terrains: This technique is highly useful for natural features like rivers or hills, as well as more demanding terrains. Subsurface bores permit the installation of HDPE pipes without engineering changes to the distinctive landforms, enabling adherence to protected regions’ policies.

- Enhanced Precision with Bore Tracking Technology: Bore path accuracy in directional drilling is enhanced with the use of modern tracking systems. This reduces the likelihood of misplacement or damage to the pipes during installation, ensuring enhanced lifespan and structural integrity of HDPE pipelines.

- Improved Installation Speed and Safety: Directional drilling offers a better-optimized method of work when compared to traditional excavation techniques. As there is less surface disturbance needed, construction processes become safer for employees and communities around the site or construction area.

- Adaptability to Various Pipe Diameters and Lengths: From the perspective of project scope, directional drilling offers great adaptability concerning pipe sizes and distances. Service lines, hydronics, and even large diameter mainline pipelines can be installed with HDPE pipe, making the whole process streamlined and dependable.

The above reasoning explains the profound impact of modern installation techniques of HDPE pipelines with the use of directional drilling technology, which is more flexible and green than traditional techniques.

What Are the Advantages of HDPE Pipes?

Durability and Chemical Resistance

I know that HDPE pipes are believed to be one of the most durable types of pipes available. The reason behind this is their flexibility, which enables them to withstand shifts in soil, pressure, and external loads, making them less susceptible to cracking or failing. Unlike other piping materials, HDPE pipes are corrosion resistant and can be used in conditions such as underground and marine installations without any fear of damage.

HDPE pipes as a whole show remarkable chemical resistance characteristics. They do not break down due to a broad spectrum of chemicals like acids, bases, and salts. This quality enables them to be utilized even in processes that require the transport of corrosive fluids or those that undergo reactive chemical processes. Having such remarkable resilience not only prolongs the timeline of the infrastructure but also ensures structural safety and the undamaged state of fluids or gases contained within.

This fact, along with reduced long-term operational and maintenance expenses, is something I admire dearly. The inclined chemical and wear resistance of HDPE reduces the chances of repair work being needed to be done. This is especially crucial for the agricultural sector, wastewater treatment utilities, and chemical manufacturing industries that rely heavily on constant efficacy and optimal functionality.

Economic Benefits of Using HDPE Piping Systems

Sturdy, low-maintenance, and efficient, HDPE piping systems offer significant cost savings over their lifespan. Their maintenance-free durability is a strong asset. Economically speaking, savings start accruing at the very start due to considerable material cost savings linked to corrosion, scaling, and chemical degradation resistance. This greatly increases the longevity of the pipes as they do not require frequent repairs or replacements. To add to this, transport and installation expenses are lower due to HDPE pipes being lightweight compared to steel and concrete.

Efficiency-wise, an equally smooth surface internally allows lower friction, which increases efficiency by reducing energy costs for pumping and overall system use. The system then reaps savings on utility costs. Additionally, the lack of leakage created with HDPE prevents the costly loss of leaks or system downtime, further lowering expenses incurred with leaks.

Industries, too, gain from these factors since the lifespan of the files can extend upwards of fifty years when optimally used. When calculating the lifecycle cost—estimating the cost of the material, installation, maintenance, and replacement—HDPE consistently and effortlessly ranks as the best option against other piping materials. For the municipal water system, mining system, and even industrial process sectors, the cost benefits make HDPE a stellar option.

Environmental Impact and Sustainability

Reliable leakage leakage-free piping systems are built with HDPE (high-density polyethylene). It is known to have a low environmental impact and is sustainable in the long run, as it can be reused and is 100% recyclable. The process of making HDPE is less energy demanding compared to steel or concrete, further lowering the carbon footprint.

HDPE lowers emissions while transporting the pipes. At the same time, it reduces the burden on infrastructure like roads and bridges. The longevity and corrosion resistance of HDPE also mean less replacement and less waste, improving sustainability.

LCA or life-cycle assessment shows that HDPE leads when compared to other materials in emissions of greenhouse gas and energy usage over a 50-year time frame. With water systems in municipalities, leaking is lessened due to the ‘leak-free’ joints. HDPE is advantageous for construction and meeting global sustainability goals.

Are There Disadvantages of HDPE Pipes?

Potential Health Effects of HDPE Pipes

We looked at the benefits of HDPE pipes, however, we must assess the potential health implications to ascertain whether they can be used safely. Below are some of the concerns that have been raised regarding HDPE pipes:

- Leaching of Chemicals into Water Supply: Research suggests that HDPE pipes can leach some chemical constituents, such as antioxidants that were incorporated during the manufacture of the pipes. Although these substances are usually found in minimal concentrations, the risk of chronic exposure, especially within drinking water systems, is concerning.

- Release of Volatile Organic Compounds (VOCs): VOCs and other gases, such as formaldehyde and aceton, have the propensity to be emitted from HDPE pipes. Chronic exposure to heightened levels of VOCs has been proven to have negative effects on a person’s health, for example, difficulty and headaches.

- Impact of Disinfection Byproducts: Where chlorine is used in the water system containing HDPE pipes, the pipe’s interaction with disinfectants can create byproducts. Some of them, such as certain forms of aldehyde, may become harmful after prolonged exposure.

- Microbial Growth in Pipe System: The smooth nature of HDPE piping can occasionally foster biofilm development in stagnant water, allowing underlying species to flourish. If water stagnates for a prolonged period, pathogenic microorganisms may be released unless adequate maintenance action is undertaken.

- Problemas Asociados al Uso de Material Reciclado: Los tubos de HDPE hechos de contenido reciclado pueden tener algunos contaminantes provenientes de usos anteriores. Si estos contaminantes no son adecuadamente tratados, hay la posibilidad que se filtren al suministro de agua, generando incertidumbre acerca de la seguridad y los estándares de agua potable.

Continuing research and observing strict industry standards greatly in easing these health risks and keeping HDPE pipes safe for multiple uses.

Challenges in Pipe Installations

Alignment of the pipes and the joint integrity of the installation are some of the most critical challenges during the installation of pipes. If the joints are misaligned, this may cause issues in the structure in the long run, as it would cause leaks or decrease the flow efficiency. In addition, compatibility of materials is also a major concern because using the wrong pipes with specific settings, like high pressure or corrosive systems, will increase the chances of a system degrading way before it is supposed to.

Figure out the soil conditions is another significant issue. With everything from soil movement to erosion, changes in pressure, and pipes experiencing outer stress that may risk deforming or cracking. Though High-Density Polyethylene pipes are flexible, if proper installation procedures are not adhered to, there are pose issues from stress.

Along with various other factors, the environment plays a role in installation issues. Ensuring minimum disruption caused by the excavation, along with abiding by the environmental laws, can delay projects and spike costs. Also, too much attention to temperature is needed during the installation process because pipe expansion due to heat needs to be avoided to avoid complications in the future.

These problems are being greatly solved by innovations in trenchless technologies and digital monitoring tools. Engineers are now able to anticipate and respond to the intricate challenges with great precision when installing pipes by using data-driven simulation tools, adapting techniques to ensure enduring safety.

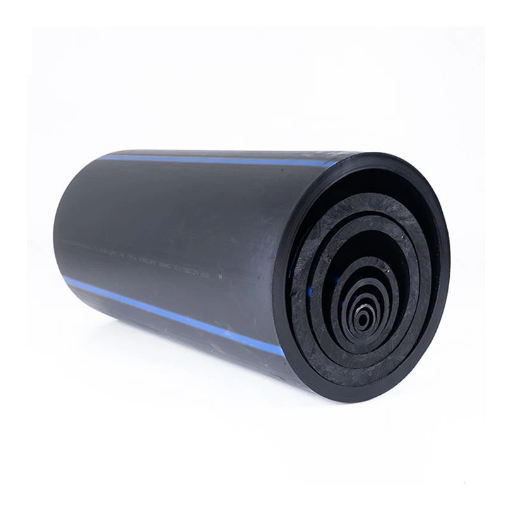

Limitations in Pressure Rating and Pipe Diameter

Pressure rating and pipe diameter are critical factors that significantly influence the performance and application of pipeline systems. One of the major drawbacks comes from the mechanical strength of the pipeline, the material that comprises it. For example, thermoplastic pipes like polyethylene (PE) or polyvinyl chloride (PVC) have upper pressure limits that reduce with increasing diameter due to material stress distribution. Thus, it is common practice to incur a lower Maximum Allowable Operating Pressure (MAOP) for large-diameter pipes to ensure structural strength. When it comes to steel pipes, their material strength normally permits higher pressure ratings, but wall thickness, corrosion resistance, joint integrity, and several other factors may deteriorate the pipe’s efficiency in the long term.

Another issue includes the balancing act of achieving the desired shape for the pipe with the flow rate. Larger diameters allow achieving lower flow velocity and frictional pressure loss, but sharply increase the weight required to maintain pressure resistance. This leads to increasing installation costs. Smaller diameter pipes are cheaper to install, but their long-distance installation requires the use of booster stations or higher initial pressure generation due to exacerbated pressure drop issues.

New engineering tools overcome these limitations with predictive analysis done in real-time. For example, computational fluid dynamics (CFD) models help engineers gauge the stress-strain behavior over various diameters, accounting for pressure and thermal changes. Further, newer composite materials for pipes, like fiber-reinforced polymers, are lightweight, enabling higher pressure resistance and wider diameter applicability without performance loss.

Where Can HDPE Pipes Be Used in Potable Water Applications?

Residential and Commercial Water Supply

Both for homes and businesses, HDPE pipes are some of the most popular potable water systems due to their durability in high-pressure environments, low maintenance needs, and overall life cycle cost. Their flexibility allows them to be installed almost everywhere – even in cities with tight spaces that would otherwise require a lot of excavation. The biological and chemical resistance that HDPE pipes have protects the water systems for a good period of time, safeguarding the constituents of the plumbing systems.

In practical use, their performance is exceptional as HDPE pipes outperform most historically popular choices like PVC or ductile iron. This is due to their high-pressure resistance and low wear rate. With the innovation in heat-fusion, there is no longer a need for gaskets, which means no black flow and good conservation of water. In residential buildings, these pipes can be found in plumbing grids. In office buildings, factories, and mountain-high skyscrapers, you will find these pipes distributing water at a high volume.

Additionally, in comparison to metal piping systems that corrode and have leaks, HDPE piping outperforms them all, with research showing up to 50% less water loss. With all of the praises being said, and for a good reason, HDPE is a vital material to the new age water distribution networks due to the trust and the high capacity of water they are able to deliver easily.

Municipal and Industrial Water Systems

As with any other service, modern municipal and industrial water systems have adapted over the years with the introduction of new standards and materials aimed at increasing dependability, efficiency, and sustainability. The use of new materials such as high-density polyethylene (HDPE) pipes is continually changing the water distribution infrastructure. Industry studies state that HDPE pipes not only resist environmental stress cracking but also have a greater lifespan, lower maintenance costs, and less deterioration than galvanized steel or concrete.

Also, new developments in sensor technology and data technology have improved the monitoring and management of water networks, which contributes to operational efficiency. Smart sensors can now monitor real-time changes in pressure, flow rate, and leakage, enabling timely action to be taken to reduce water wastage. For the industrial systems, the use of automated control valves coupled with digitally integrated pumping stations across the expansive networks helps sustain optimal water usage, thus further reducing the amount of water used.

Countries around the world are trying to improve water systems while keeping sustainability in mind. The use of renewable resources such as solar and hydropower, along with energy-efficient pumping solutions, is lessening the carbon footprint of water supply facilities. This approach not only helps the environment but also lowers operational expenses, resulting in long-term economic advantages.

Innovative Uses in Non-Traditional Settings

From new growing methods to automation, new technologies are being embraced to save water as a resource. For example, the Implementation of constructed wetlands along with green roofs enables rainfall capture and natural filtration in urbanized areas. These systems help reduce outflows towards wastewater drainage systems at the same time as improving urban microclimates and mitigating the heat island effect. Persian civilizations built wind catchers, which are towers that capture air. Today, in drier regions, these form the basis of modern water-generating technologies that extract moisture from the air.

Undoubtedly, one of the most powerful methods to enhance water management, recycling wastewater or using it multiple times in industrial processes such as for cooling, cleaning, or even manufacturing, greatly reduces the need for freshwater resources.

Untapped modern technologies coupled with ancient methods of building enable a greener future with environmental sustainability and resilience without the need for complex changes to existing integrated systems like urban planning or engineering design.

References

Frequently Asked Questions (FAQ)

Q: What are the key features of HDPE pipes for potable water supply?

A: HDPE pipes are known for their high resistance to corrosion, flexibility, and durability. They have a long service life and can withstand high water pressure, making them ideal for potable water supply applications. HDPE pipes are also lightweight, easy to transport and install, and their fused joints eliminate potential leak points, ensuring safe potable water delivery.

Q: How do HDPE pipes compare to PVC pipes for potable water supply?

A: HDPE pipes offer greater flexibility and are more resistant to cracking under stress compared to PVC pipes. While both materials are used in the pipe industry, HDPE pipes have fused joints that reduce potential leak points, which is a significant advantage over PVC pipes. Additionally, HDPE pipes can handle a wider range of temperatures and pressures.

Q: What are the common applications of HDPE pipes in water supply systems?

A: HDPE pipes are commonly used in a variety of water supply applications, including potable water systems, sewer pipes, and reclaimed water systems. They are also used for hot drinking water and other drinkable water needs due to their NSF certification for safe potable water.

Q: Why are HDPE pipe fittings important in water supply systems?

A: HDPE pipe fittings are crucial for connecting sections of pipe and directing the flow of water in a system. They ensure a secure and leak-proof connection, which is essential for maintaining clean drinking water standards. The fittings required for HDPE pipes are designed to complement the pipe’s flexibility and durability.

Q: Can HDPE pipes be used in conjunction with other types of pipes?

A: Yes, HDPE pipes can be used alongside other types of pipes, such as PVC and ductile iron pipes. However, it is important to use appropriate fittings to ensure a secure and leak-free connection. This compatibility allows for the integration of HDPE pipes into existing systems.

Q: What makes HDPE pipes ideal for potable water supply applications?

A: HDPE pipes are ideal for potable water supply due to their high-density polyethylene composition, which provides excellent resistance to chemicals and environmental stressors. Their ability to handle high water pressure and their long service life make them suitable for delivering clean drinking water.

Q: Are there any special considerations for installing HDPE pipes for potable water?

A: When installing HDPE pipes for potable water, it is important to ensure that the pipes and fittings are certified for potable water use, such as having an NSF certification. Proper installation techniques, such as ensuring fused joints are correctly executed, are also crucial to prevent potential leak points and maintain water quality.

Q: How do HDPE pipes help in reducing water loss in potable water systems?

A: HDPE pipes help reduce water loss in potable water systems due to their leak-proof fused joints, which eliminate potential leak points often found in traditional pipes like iron pipes or concrete pipes. This results in a more efficient and reliable water distribution system.

Q: What types of fittings are required for HDPE pipes in potable water systems?

A: The fittings required for HDPE pipes in potable water systems include couplings, elbows, tees, and reducers. These fittings are designed to match the pipe’s flexibility and strength, providing secure connections that help maintain the integrity of the water supply system.